Greenhouse Ventilation

Greenhouse ventilation involves removing air from inside the greenhouse and replacing it with outside air. The ventilation may be natural (caused by wind and temperature forces) or mechanical (accomplished by using fans). The purposes of ventilation are to control high temperatures during the summer caused by the influx of solar radiation, to maintain relative humidity at acceptable levels during winter, to provide uniform airflow throughout the greenhouse, and to maintain acceptable levels of gas concentration in the greenhouse. Ventilation systems for greenhouses must be considered for three climatic conditions that typically occur during the year—winter, summer, and spring–fall.

Winter Ventilation

A heating system with adequate capacity is needed in the winter to maintain conditions conducive to plant growth and development inside the greenhouse. Even during the coldest part of winter when the heating system is running at full capacity, some ventilation is required in the greenhouse. Fresh, outside air must be ventilated into the greenhouse to remove the warm, moisture-laden air from within. If moist air within the greenhouse is not removed, high humidities and excessive condensation will occur. Studies have shown that humidities over 90% foster rapid development of fungal diseases (Grange and Hand 1987; Jovicich, Cantliffe, Sargent, and Osborne 2004; Körner and Challa 2003). For example, problems with infection of tomatoes with leaf mold start occurring when humidities exceed 80%, but below 70%, problems with infection are slight. In addition, economic problems associated with condensation in greenhouses make it difficult to maintain a clean production environment due to more rapid deterioration of structural components as well as damp, uncomfortable conditions for workers.

Condensation occurs when warm, humid air in the greenhouse comes into contact with a cold surface, such as glass, fiberglass, plastic, or structural components. The air in contact with the cold surface cools to the temperature of the surface. If the surface temperature is below the dew point temperature of the air, then water vapor in the air will condense onto the surface. For example, condensation occurs if air in a greenhouse at 70°F and 70% relative humidity comes in contact with a surface that is 60°F or colder.

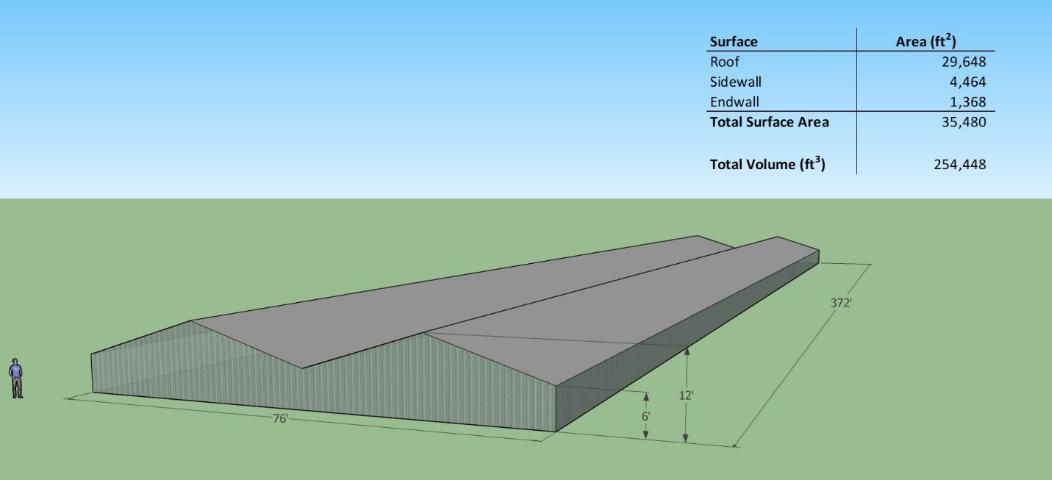

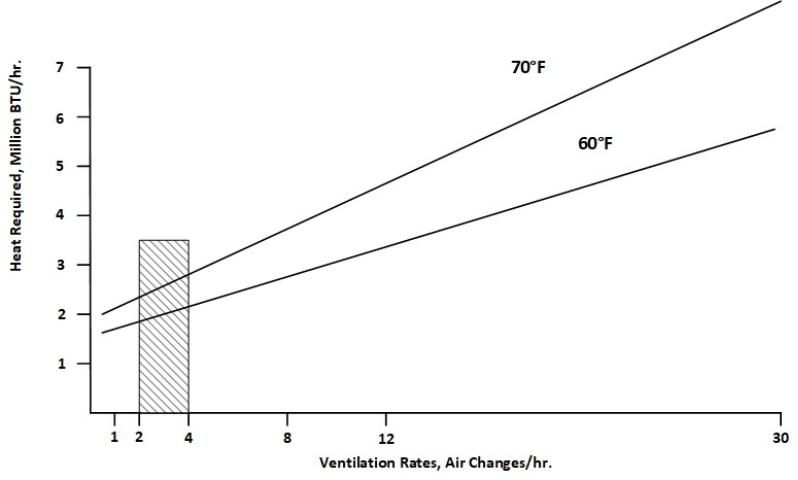

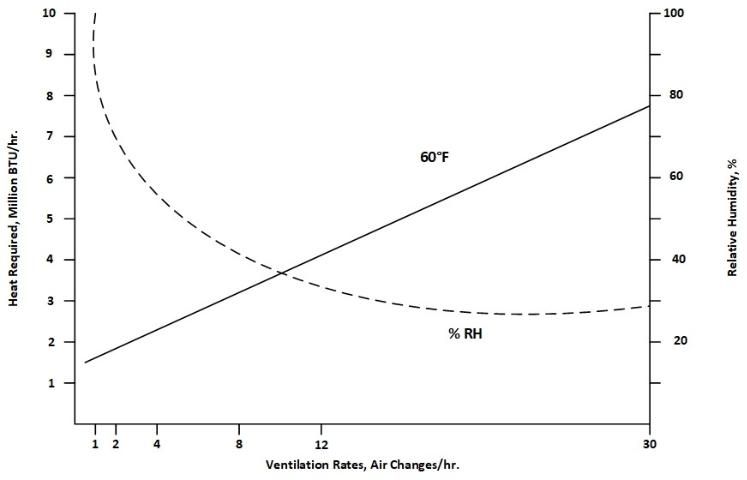

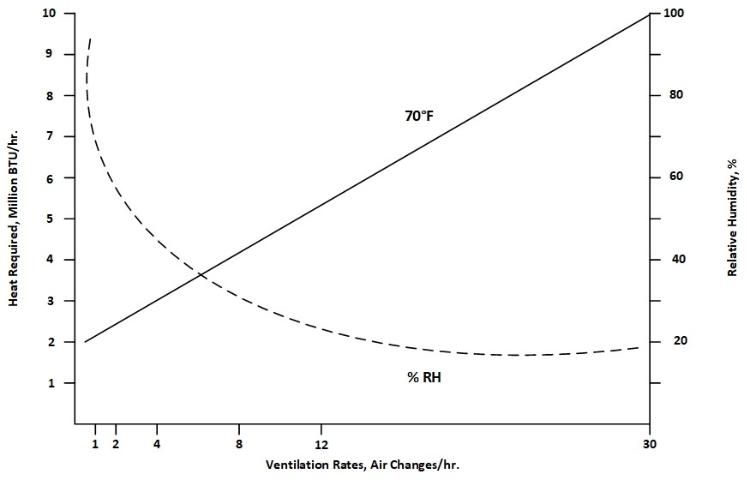

Exhausting moist air and replacing it with dryer air drawn from outside and then heated is effective in eliminating condensation and other problems resulting from high humidities. However, when ventilation rates are increased in the winter, the heating requirements also increase. Consequently, it is necessary to determine a ventilation rate that will maintain humidities below the damaging level and at the same time keep the heating requirements as low as possible. Ventilation requirements of greenhouses in winter are generally on the order of two to three air changes per hour. The higher the inside temperature in the greenhouse, the lower the air exchange rate that is required to maintain humidities below the damaging level. However, ventilation rates of at least two air changes per hour should be used. In addition to controlling humidity, this minimum ventilation rate will remove gases of combustion that may be present due to leakages around the heater and ducting when a direct-fired heating system is used. Figure 2 presents the heating requirements of a polycarbonate greenhouse shown in Figure 1 for two different inside air temperatures when the outside conditions are 30°F and 80% RH. The heating requirement when the greenhouse is maintained at 60°F is about 20% less than the heating required to keep it at 70°F. At 60°F, the ventilation rate necessary to maintain humidities at ideal levels is three air changes per hour. Figure 3 and Figure 4 show the inside relative humidities that would result as a function of the different winter ventilation rates for 60°F and 70°F. Note that there is no benefit in ventilating above four air changes per hour in the winter, as this would result in excessive heating requirements. The low relative humidity may also affect plant growth and developments.

Credit: J. A. Watson, UF/IFAS

Credit: J. A. Watson, UF/IFAS

Credit: J. A. Watson, UF/IFAS

Credit: J. A. Watson, UF/IFAS

Summer Ventilation

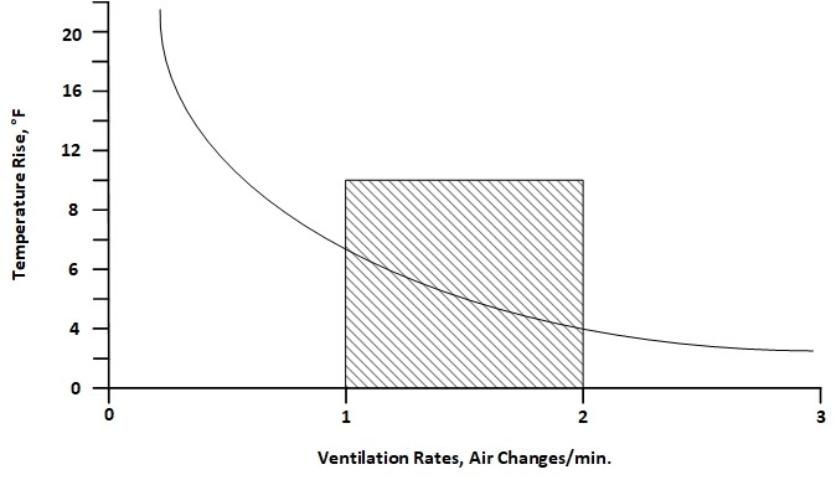

The main purpose of greenhouse ventilation during the summer is to prevent the inside air temperature from rising too high above the outside air temperature. This would occur due to the large influx of solar radiation through the greenhouse glazing material. The ventilation system must effectively move air directly through the crop and over the soil to prevent excessive temperature buildups around the plants. A generally accepted minimum ventilation rate for temperature control in the summer is one air change per minute. The resulting temperature increases (inside temperature minus outside temperature) on a clear summer day for the greenhouse shown in Figure 1 are presented in Figure 5. The ventilation rates range from one air change every three minutes to three air changes per minute. As ventilation rates increase, the temperature difference between the inside and outside air decreases. Potential disadvantages of increased ventilation rate are the increased cost for fans and equipment as well as increased operating costs. Regardless of the ventilation rate used during summer, the inside air temperature during the day will never be as low as the outside air temperature by relying on ventilation alone. If one is interested in maintaining an inside air temperature below outside air temperature, then evaporative cooling or some other means of conditioning the air must be used.

Credit: J. A. Watson, UF/IFAS

Filtering out a portion of the incident solar radiation is very effective in reducing the inside air temperature of a greenhouse. Filtering can be accomplished by using shade curtains within the greenhouse, painting the exterior surfaces of the glazing materials with whitewash, or selecting glazing materials with a low transmission coefficient. Shade curtains can separate the hot air that accumulates in the top of the greenhouse from the air below in the production area where crops are grown. Thus, the air below will be cooler and the overall efficiency of the ventilation system will be increased. Filtering solar radiation to decrease heat load on a greenhouse should only be done in operations where plants can be economically grown under lower light intensities, because shade curtains will block some of the sunlight from reaching the crops.

Spring–Fall Ventilation

The recommended ventilation rates for the spring–fall seasonal periods will fall between rates required for summer temperature control and those required for winter humidity control. The spring–fall periods are characterized by days that are relatively cool and cloudy and other days that are warm and sunny. No special provisions are necessary for maintaining ventilation rates during this period except for the temperature and humidity controls that will determine the amount of ventilation necessary.

Determining Ventilation Volume Rates

In the preceding discussion, ventilation rates were expressed as a minimum ventilation rate of two air changes per hour in winter and a minimum summer ventilation rate of one air change per minute. To select fans as part of a ventilation system, one must know the total volume of air to be moved. Volume of air to be moved is calculated from air changes per hour or minute. One air change is equivalent to the volume of the greenhouse. For example, the greenhouse indicated in Figure 1 has a volume of 254,448 cubic feet. Therefore, one air change per minute would correspond to a ventilation flow rate of 254,448 cubic feet per minute. In winter when the minimum ventilation rate is stated as two air changes per hour, the volume flow rate of air would then be 508,896 cubic feet per hour (254,448 cubic feet per air change x 2 air changes per hour). Dividing the previous answer by 60 minutes per hour yields an airflow rate of 8,482 cubic feet per minute.

The volume of a specific greenhouse is the product of the area of one end wall times the length of the greenhouse. In the example in Figure 1, one end-wall area of the greenhouse is 684 square feet. The length is 372 feet. The product of 684 square feet times 372 feet is 254,448 cubic feet. In calculating the area of an end wall of a greenhouse, the following relationships may be helpful:

- Area of a rectangle is base times height.

- Area of a triangle is base times height, divided by 2.

Only choose fans that are rated in accordance with AMCA (Air Moving and Conditioning Association) Standards. This rating specifies the volume capacity of a fan versus static pressure resistance to airflow measured in inches of water pressure. For ventilation in most greenhouses, the fans should move the desired air volume rate against a static pressure of 1/8-inch water. When evaporative cooling pads are used, information on the expected static resistance must be obtained from the supplier or manufacturer.

For more information on fan theory, selection, testing, noise, inspection and care, and fan motor selection, consult EDIS document AE12, Fans for Greenhouses (https://edis.ifas.ufl.edu/ae020).

Air Distribution within Greenhouses

Many greenhouses depend on natural passive ventilation for air movement. In greenhouses employing natural passive ventilation, sidewall and ridge vents along the length of the greenhouse can be opened to allow outside air to move through the greenhouse. If a greenhouse only has sidewall vents, it can only be ventilated during periods of sufficiently strong wind movement from outside. Using both sidewall and ridge vents allows the greenhouse to be ventilated by both wind pressure and thermal gradients. Thermal gradients are generally created within the greenhouse by solar energy heating the materials inside, which in turn heat the air. As air is heated, it becomes lighter and rises through the ridge vents, with the makeup air coming from outside through the sidewall vents. If sidewall and ridge vents are properly sized, satisfactory ventilation rates can be achieved with some degree of temperature control.

A natural ventilation system will not be as dependable or satisfactory as a mechanical ventilation system in terms of providing continuous, uniform greenhouse ventilation. However, some newly designed greenhouses with natural passive ventilation systems can achieve a high degree of environmental control. The main advantages of a natural ventilation system are: (1) no expenses for ventilation equipment, electrical operation, and maintenance; and (2) no problems created by brownouts or blackouts, caused by storms or insufficient energy generation capabilities. As the cost of energy and the likelihood of power failures increase, the natural ventilation systems become more desirable. One major disadvantage of natural ventilation is that pests may enter the greenhouse. When using natural ventilation, insect screens are recommended. While insect screens prevent pests from entering the greenhouse, they also reduce airflow. In addition, dust and other particles accumulate on insect screens over time; therefore, screens will need to be cleaned regularly.

References

Grange, R. I., and D. W. Hand. 1987. "A review of the effects of atmospheric humidity on the growth of horticultural crops." Journal of Horticultural Science 62(2): 125–134. https://doi.org/10.1080/14620316.1987.11515760

Jovicich, E., D. J. Cantliffe, S. A. Sargent, and L. S. Osborne. 2004. Production of Greenhouse-Grown Peppers in Florida. HS979. Gainesville: University of Florida Institute of Food and Agricultural Sciences.

Körner, O., and H. Challa. 2003. "Process-based humidity control regime for greenhouse crops." Computers and Electronics in Agriculture 39(3): 173–192. https://doi.org/10.1016/S0168-1699(03)00079-6