Florida is the major domestic producer of fresh-market tomatoes during fall, winter, and spring seasons (October through June). The main commercial growing counties are Gadsden, Manatee, Hillsborough, Collier, Miami-Dade, Hendry, and Palm Beach. Besides round-type tomatoes, Florida also produces a significant amount of roma, grape, and cherry tomato types and a small quantity of heirloom tomatoes. Open field production is the dominant practice for tomato production in Florida due to favorable weather, but a small amount of tomatoes is produced in greenhouses. US tomato imports are primarily vine-ripe types from Mexico and Canada and are typically grown under protected culture.

Upon completion of growth on the plant, tomato fruit can be harvested green and ripened off the plant. The majority of Florida-grown tomatoes are harvested at this mature-green stage to extend the marketing period. After packing, the green tomatoes are placed in specially constructed ripening rooms and exposed to the natural ripening hormone ethylene to uniformly initiate fruit ripening. If picked at the proper mature-green stage and handled properly, tomatoes will ripen to excellent eating quality. Proper postharvest handling of Florida tomatoes is critical to ensure the continued competitiveness of Florida growers.

To promote safe production and handling practices, implementation of Tomato Good Agricultural Practices

(T-GAP) and Tomato Best Management Practices (T-BMP) is mandatory in the state of Florida. Food safety is a critical concern in tomato production. Growers must follow the Produce Safety Alliance (PSA) through cultivation, harvest, packing, processing and handling to guarantee the safe food for consumers. Tomato growers and handlers, regardless of variety and production system, must follow these guidelines for cultivation, field management, harvest, transportation, packing, and handling operations. Further information is included below.

This publication focuses on handling recommendations for green-harvested round and roma (plum) tomatoes since these types are most commonly grown and are handled similarly under commercial conditions. Recommendations are similar for these tomatoes harvested at vine-ripe stage.

Obtaining Quality

Nutritional Value

One medium-sized tomato provides 40 percent of the Recommended Daily Allowance (RDA) of vitamin C (ascorbic acid); 20 percent of the RDA of vitamin A; substantial amounts of potassium, dietary fiber, and calcium, and lesser amounts of iron, magnesium, thiamine, riboflavin, and niacin; yet contains only about 35 calories (USDA 2014). Tomatoes are particularly rich in lycopene (the red pigment in tomato fruit), vitamin C, and a variety of other natural antioxidants, which have been associated with decreased risk of chronic diseases such as cancer and cardiovascular disease. Based on nutrient content and the quantity of tomatoes consumed, they are major contributors to our health.

Cultivar Selection

Cultivar selection is one of the most important management decisions in successful tomato production. Due to its geographic location, Florida has numerous microclimates with various growing seasons. Suitable cultivars should have the following characteristics: economic yield, resistance to pests, and adaptability to local soil and climatic conditions. Horticultural quality of fruit and acceptance by markets are other important cultivar qualities. There are a number of cultivars available that are suitable for Florida. Those cultivars have various characteristics for growers to consider, such as plant size; firmness, color, and flavor of fruit; and resistance to pests.

The latest recommendations for round and roma tomato cultivars are published annually in the Vegetable Production Handbook of Florida (https://edis.ifas.ufl.edu/publication/CV292)

Cultural Practices

Cultural practices necessary for production of quality marketable yields include field preparation, such as multiple disking, laser leveling, and preparing irrigation or drainage ditches in some production areas; raised bed preparation, including bed shaping; basal dressing of fertilizers; selecting soil fumigants, such as Telone (except Miami-Dade County), K-PAM, or V-PAM; application by following the guideline on the label; laying of drip lines with flat tapes and plastic mulch; setting tomato transplants in the field; making a plan for irrigation and nutrient management; pruning, staking and tying tomato plants; implementing Integrated Pest Management (IPM) including scouting and application of pesticides; harvesting; grading; and destruction of the crop debris after the last harvest. Suitable windbreaks are needed in some production areas to protect young plants and reduce sand scratching on tomato fruit.

Optimization of irrigation and nutrient management is a key practice for achieving optimum plant growth and high yields and quality, and for preventing ground water pollution. Actual practices vary depending upon the scale, location, and management systems. For details regarding specific cultural practices, refer to the Vegetable Production Handbook of Florida https://edis.ifas.ufl.edu/publication/CV292.

Harvest and Transport Operations

Fresh market tomatoes are hand-harvested in Florida (Figure 1). The harvest crew needs to be trained and supervised so that immature, over mature, defective, and decayed tomatoes are left in the field. This reduces the need for subsequent grading and minimizes the chances of spreading decay to sound tomatoes during handling and shipping. Plants should be dry prior to harvest to reduce spread of decay pathogens in the field.

Credit: J. K. Brecht

For green-harvest operations, harvest maturity is critical to ensure proper ripening and flavor. External indicators of tomato maturity are position on the plant (fruit set occurs from the bottom up), size, shape, surface appearance (waxy gloss or sheen), and the presence of brown corky tissue on the stem scar. External indicators are not completely reliable; therefore, prior to harvest, tomato samples should be taken from throughout the field, sliced, and rated for internal indicators. Internal indicators are rated on a scale of M1 to M4 based on locule gel and seed development (Table 2 and Figure 2). These maturity ratings apply to both round and roma types.

Credit: J. K. Brecht

Tomato fruit ripening begins internally as described by the M1 through M4 maturity ratings and continues as red color progresses to the surface of the fruit. Green tomatoes picked at M3 and M4 stages will ripen to the best eating quality; those picked at M2 will ripen with quality suitable for food service, and those picked at M1 will never ripen properly. It is not uncommon to find 20 percent or more of a harvested lot of green tomatoes to be at M1 stage.

The first appearance of red color on the fruit surface is called the “breaker” stage, and color development continues through “turning,” “pink,” “light red,” and “red” stages (Table 3). Tomatoes harvested at any color stage from breaker on are collectively referred to as “vine ripe.” The advantage to harvesting at breaker stage is that ripening is already underway, so no immature fruit will be included, and ethylene treatment is unnecessary. However, harvest constraints such as labor availability and price may limit the ability of growers to make the frequent harvests required to harvest at breaker stage.

Green-harvested tomatoes are picked into plastic buckets, which are emptied into field (pallet) bins on flat-bed trucks or into gondolas (Figure 3). A pallet bin holds about 1,000 pounds of fruit and a gondola from 8 to 12 tons. The bins or gondolas should be positioned in the field near the harvest crew to minimize the walking distance. Tomatoes are sensitive to mechanical damage during harvest and handling. Therefore, the harvest crew must be trained and supervised to ensure gentle handling at harvest and when transferring fruit into the bins and gondolas.

Drop heights should be kept to a minimum to reduce bruising. To avoid fruit crushing, field bins should not be over- filled. Round and roma tomatoes picked at breaker stage or later may be picked directly into lugs and stacked on pallets in the field. Dirty buckets, bins and gondolas should be cleaned after each use to reduce decay cross-contamination, and those with rough contact surfaces, which can scuff the fruit, should be replaced. It is recommended that all harvest containers and bins be constructed from plastic to facilitate cleaning and sanitizing.

Credit: S. A. Sargent

Harvest aids show promise to make the tomato harvest operation more cost-effective by utilizing labor more efficiently. These systems are composed of one or two mobile conveyors that extend across several rows to facilitate harvest. In this system the harvest crew still pick into buckets, but they walk closely behind the conveyor. Once filled, buckets are emptied directly onto the conveyor, eliminating the need for the picker to walk to a distant truck or gondola to empty the bucket. The conveyor moves the tomatoes to one side of the unit for loading into an accompanying truck with field bins or a gondola. Harvest aids can be tractor-mounted or self-propelled. The latter, larger, system can carry a small packing line, permitting removal of undersized tomatoes and presorting (Figure 4). Our timing studies with an over-the-row system showed that harvest time was reduced up to 30 percent compared to conventional harvest. Also, a significant amount of cull tomatoes were removed in the field, reducing costs for sorting and cull disposal later in the packinghouse. These efficiencies may make this harvest operation sufficiently cost-effective to permit harvesting of mature-green and breaker-stage fruit. Costs for conventional tomato harvest are available at https://edis.ifas.ufl.edu/publication/FE1026.

The availability of mechanical harvesters for fresh-market tomatoes would significantly reduce labor costs for growers. For mechanical harvest to be feasible, several requirements are fundamental. The harvester must have a pick-up head that is capable of gently removing the tomato from the plant. Since commercial tomato cultivars do not have a concentrated fruit set, the fruit grow and develop at different rates, requiring the harvester to have the capability to discriminate by size and color for desired harvest maturity. Plant size and spacing and production methods may have to be adapted for mechanical harvesting.

Some continuous canopy shakers designed for blueberry harvest have been trialed on staked grape and cherry tomatoes. Since these crops are harvested multiple times, mechanical harvest would best serve for the final harvest, when fewer partially ripe or immature fruit are present. At this time, no harvesters are available for staked round or roma tomatoes. Mechanical harvest could become feasible with continuing advances in sensor design and development of new tomato germplasm with compact growth habit and concentrated fruit set that would promote once-over harvest.

Credit: S. A. Sargent

Maintaining Quality

Unloading Operations

Upon arrival at the packinghouse, field bins and gondolas should be unloaded under shade until packing; tomatoes left in the sun for an hour may become as much as 25°F hotter than those held in the shade, significantly reducing postharvest life. Tomatoes ripen with poor color and flavor when fruit temperatures remain above 85°F for extended periods.

Tomatoes typically are transferred from field bins or gondolas into a water flume system (dump tank) for gentle transfer to the packing line. Tomatoes handled in field bins are automatically dumped into the dump tank (Figure 5), while tomatoes in gondolas are flumed out using the dump-tank water (Figure 6). Plant pathogens present on the fruit surfaces wash off and accumulate in dump-tank water since the water is recirculated throughout the packing day.

Credit: J. K. Brecht

Credit: S. A. Sargent, UF/IFAS

Therefore, dump-tank water must be constantly sanitized to minimize the possibility of cross-contamination via infiltration of water and pathogenic microorganisms through the stem scar, the blossom-end scar, or cuts and punctures https://edis.ifas.ufl.edu/publication/CH160. T-BMP requirements for dump-tank management include maintaining water 10oF warmer than incoming pulp temperature, the use of an approved sanitizer, and not exceeding 2 minutes residence time in the water. See specific requirements at https://www.fdacs.gov/Agriculture-Industry/Fruit-and-Vegetables/Tomato-Good-Agricultural-Practices-T-GAP.

The rate of bin or gondola unloading determines the flow of tomatoes through the packing line. The dump rate needs to be adjustable to accommodate the degree of sorting and grading that each lot of tomatoes requires so that the packing line workers can most effectively accomplish their tasks. Studies have shown that if the packing line volume is too high, workers cannot remove all off-grade product, while if the volume is too low, they tend to remove in-grade product to keep busy. However, maintaining full coverage of the packing line helps to minimize physical injuries that can occur when loose tomatoes roll freely and accelerate before encountering drops and turns (Sargent et al. 1991).

After the tomatoes are elevated from the dump tank, they may be rinsed with fresh water prior to being brushed, rinsed, sorted, graded, and dried (Figure 7); they may or may not be waxed. The fruit are then sized and packed into shipping cartons. Tomatoes at breaker stage or riper (“pinks”) are sorted out prior to sizing and sent to a separate packing line that operates at a lower speed for gentler handling. During all operations from harvesting through packing, all tomatoes must be handled carefully to avoid bruising, cuts, and punctures. These injuries interfere with normal ripening and promote postharvest decay during ethylene treatment and later during handling and shipping operations.

Credit: S. A. Sargent

Grade and Size

In Florida, green tomatoes packed in the areas regulated by the Florida Tomato Committee are graded as “U.S. No. 1,” “85 percent U.S. No. 1,” “U.S. Combination,” and “U.S. No. 2” according to the U.S. Standards for Grades of Fresh Tomatoes https://www.ams.usda.gov/grades-standards/tomato-grades-and-standards. The Florida Tomato Committee, under authority of the Federal Marketing Order, annually publishes regulatory bulletins https://www.floridatomatoes.org/regulations/.

Size classifications are also established by the Florida Tomato Committee and are slightly different than those specified in the U.S. Grade Standards (Florida Tomato Committee 2023): Tomatoes are mechanically sized by dimensional sizers. Graded fruit pass over a series of perforated belts with openings that correspond to the maximum allowable diameter for the particular size. The undersize tomatoes drop through the first sizing belt, followed by the 6×7, 6×6, and 5×6 sizing belts. Electronic sizers are also available that dimensionally size individual fruit via video cameras or by weight; these systems are more often used in tomato repack or vine-ripe operations.

Packing

Sized and graded green tomatoes must be packed into new, unwaxed, fiberboard cartons (2-piece) to a net weight of 10, 20, or 25 pounds (Figure 8). Vine-ripe (breaker-turning and pink-light red stages) tomatoes can be packed into the same cartons or into smaller, 2-layer or single-layer cartons. Filled cartons are automatically lidded and stamped with size and grower designation. In areas regulated by the Federal Marketing Order tomatoes are next inspected for conformity to grade standards by federal/state inspectors (Figure 9). Special provisions are made by the marketing order regarding hydroponically grown, specialty, and heirloom tomatoes.

Credit: J. K. Brecht

Table 1.

Credit: J. K. Brecht

Tomato shipping cartons should be designed to completely cover a standard-size pallet (40 inches × 48 inches); shipment as a unitized load reduces the risk of mechanical injuries. During stacking a few drops of glue can be placed on each lid to stabilize the stacked containers; strapping material can be used in place of glue. Each pallet typically contains 80, 25-lb cartons of tomatoes (10 cartons per layer and 8 layers per pallet).

Ripening

Normal ripening of tomatoes is adversely affected by exposure to temperature extremes. Tomatoes ripen best at temperatures between 55°F and 77°F. Optimum development of characteristic red color occurs at 68 to 72°F. Ripening at temperatures above 77°F results in more orange-colored fruit and can cause premature softening; temperatures below 55°F retard color and flavor development.

Ethylene is a gaseous ripening hormone that is naturally produced by many ripening fruit, including tomatoes. It is commercially applied postharvest to green-harvested round and roma tomatoes to promote faster and more uniform ripening. Major tomato packers and repackers have specially equipped ripening rooms to maintain optimal conditions of 68 to 72°F, 85 to 95 percent relative humidity, and 150 ppm ethylene. Mature-green round tomatoes typically require 1 to 5 days of exposure to ethylene, depending on harvest maturity, to reach the breaker stage. Studies have shown that tomatoes that required more than 5 days of ethylene treatment to reach breaker stage were immature when harvested; they will never ripen to normal color and flavor, even with continued ethylene exposure. Once ripening is initiated, the tomatoes are shipped either to retailers or to repackers who complete ripening and perform color sorting and specialty packing according to specifications from their customers.

Some packers will run roma tomatoes over the packing line twice—first, to sort and clean the fruit, then to return them to bins for ethylene treatment. Other packers place the bins directly into the ripening room and then run them once over the packing line after ripening is initiated. This latter procedure has the risk of the unsorted tomatoes developing significant decay during the several days of ripening in warm, humid conditions.

There are two sizes of ripening rooms. Small rooms have a capacity of 40 pallets (equivalent to two trailer loads); large packers may have 50 or more ripening rooms. Large ripening rooms have capacities over 100 pallets. Ripening rooms must have sufficient refrigeration capacity and adequate air circulation (20 to 40 cfm [cubic feet per minute] per ton of product) for timely removal of field heat and even distribution of ethylene. It is critical that the ripening room air be exchanged or ventilated on a regular basis to prevent accumulation of carbon dioxide (CO2) that is given off by the respiring tomatoes. If CO2 concentration accumulates in the room above 1 percent, ripening can be retarded or inhibited. Continuous ethylene application is the most common method employed, and one air change should be made each 6 hours. If ethylene gas is applied in shots, the ripening room should be opened and ventilated for about one half-hour every 12 hours. It is very important to note that ethylene is a combustible gas above 2.7 percent concentration (27,000 ppm); therefore, it is recommended to use systems that generate proper ethylene mixture onsite to assure that in-room concentrations remain in the safe range. There are systems that monitor ethylene and CO2 concentrations in ripening rooms. These systems automatically dose ethylene to maintain a desired set point and vent with fresh air as necessary to avoid excessive CO2 buildup.

Temperature Management During Handling and Shipping

For maximum shelf life and highest quality, ripening should be initiated as soon as possible after harvest; the tomatoes then can be cooled to 55-68°F for continued ripening during shipping. However, tomatoes are sensitive to temperatures below 55°F and ripen abnormally due to chilling injury.

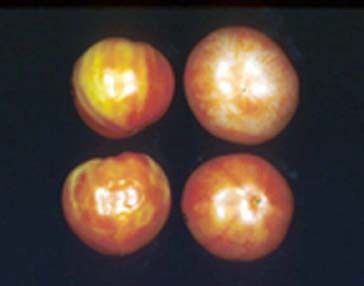

Chilling injury symptoms are time/temperature-dependent: the lower the temperature to which tomatoes are exposed, the faster and more severe is the chilling injury development. Symptoms of chilling injury include reduced flavor development at temperatures below 68°F and, in order of appearance at temperatures below 55°F, impaired or abnormal color development (Figure 10), water-soaked spots, pitting, tissue collapse, and decay. Green and ripening tomatoes are more susceptible to chilling injury than are ripe tomatoes. Storage at lower temperatures, especially below 50°F, both during handling and in the home, is a major contributor to poor tomato flavor.

Tomatoes are susceptible to water loss, mainly through the stem scar. Shrivel symptoms can become apparent with as little as 3 percent weight loss; for this reason, relative humidity should be kept at 85 to 95 percent to minimize weight loss. Applying wax to tomatoes reduces water loss. A thin coating also provides some surface lubrication, which reduces chafing during handling and transit. Care should be taken to prevent heavy waxing of the stem scar, because the wax can block gas exchange and interfere with normal ripening.

Credit: J. K. Brecht

Mixed Load/Storage Compatibility

Tomatoes have storage requirements similar to those of several other climacteric (i.e., ethylene-producing) fruits, such as banana, avocado, mango, and papaya. They also are compatible with winter squash and pumpkin. Therefore, these products can be transported and stored together without deleterious effects. A number of ethylene-sensitive commodities, including cucumber, eggplant, watermelon, okra, early (new) potato, summer squash, and sweet- potato, have temperature requirements similar to those of tomatoes, but because of their sensitivity to ethylene, these commodities should never be shipped or stored with tomatoes. Ice should never be placed in contact with these commodities. Specific shipping information is available in: Protecting Perishable Foods During Transport by Truck and Rail. https://edis.ifas.ufl.edu/publication/HS1328

Postharvest Decay and Disorders

Tomatoes are subject to several market diseases and disorders. Proper handling, grading, and temperature management will minimize the occurrence of these potentially devastating problems. Listed below are some that may occur.

- Alternaria rot—This disease may follow blossom-end rot (see below), physical injuries, chilling injury, and other decays. Large greenish-brown to black lesions covered with grayish-brown mold are produced. The larger lesions may show alternating light-brown and dark-brown/black concentric zones.

- Bacterial soft rot—Decay may occur at injuries anywhere over the surface of the fruit. The causal organism can also be taken up through the stem scar or blossom scar of tomatoes in unheated dump tanks. Bacterial soft rot is easily recognized by the soft, mushy consistency of the affected tissues and is generally associated with a bad odor.

- Bacterial spot and speck—Spots are small, brown-to- black, scab-like lesions that constitute blemishes of serious consequence only when they are present in large numbers on the fruit. Tomato cultivars show variation in susceptibility. Care should be exercised to grade out all tomatoes showing spots that would reduce their marketability.

- Blossom-end rot—This disorder frequently occurs under conditions of calcium deficiency. It disfigures the fruit and opens the way for secondary bacterial and fungal invaders that cause extensive decay. A small, water-soaked spot on the lower half of the fruit near the blossom end is the first symptom of this disorder. As the spot enlarges, it becomes light brown to brownish black and dry, so that the affected tissues are more or less leathery in texture.

- Sour or watery rot—On green fruit, watery rot lesions have a dull, greasy, and water-soaked to bleached appearance. Although the decay may originate at cracks, cuts, or skin punctures, it frequently is found starting at the edge of the stem scar. The affected tissues remain fairly firm until the decay is quite advanced and have a pickled appearance and a definite sour odor. Bacterial soft rot often follows sour rot.

- Rhizopus rot—This is another soft rot disease that is distinguished from bacterial soft rot by the presence of coarse mold that can be seen by gently pulling apart the diseased tissue. Under humid conditions the mold may grow out over the lesions.

- Virus mottling—Stunting, distortion, yellow and green mottling, and definite rings or loops on the fruit are the usual characteristics of this disease.

- Irregular ripening—This disorder differs from blotchy ripening, which typically is a symptom of chilling injury, by its streaky appearance. Irregular areas on the fruit fail to ripen and generally the affected tissue appears to be more leathery or tough. This disorder is avoided by maintaining adequate control of sweet potato whitefly during production.

Descriptions and color images of tomato postharvest diseases, disorders, and control strategies are available in https://edis.ifas.ufl.edu/publication/HS131.

Food Safety Issues

Florida law requires tomato grower, packers, and handlers to establish T-GAP/T-BMP programs according to specific requirements. “The purpose of these practices therefore will be to: 1) enhance the safety of tomatoes to the consuming public by the implementation of safer handling, production and packing practices; 2) prevent or minimize contamination of tomatoes either in the natural environment in which they are grown or in the handling, packing, repacking, or selling of tomatoes once harvested, since once contaminated, removing or killing pathogens is difficult; and 3) provide the necessary education and training on food safety practices to workers at all levels.” (FDACS 2012)

Transmission occurs by numerous means, including direct contact with infected employees or animals or through contaminated water or soil. Once a microorganism becomes internalized in tomato tissue, it is difficult or impossible to remove. Only thorough cooking (or other similar thermal treatment, such as pasteurization) will reliably neutralize human pathogens in tomatoes. Therefore, in order to minimize the likelihood of contamination of fresh-market tomatoes by human pathogens, a series of precautions are necessary, including excluding animals from tomato handling areas, requiring employees to practice approved personal hygiene techniques, and regularly cleaning and sanitizing handling areas and equipment.

An added benefit of good T-BMP programs to growers and shippers is that sanitation also reduces infection by plant pathogens and reduces decay during shipping and storage. Keeping records of good sanitation practices is important to document adherence to a food safety plan and to help identify potential problem areas. For more information on food safety guidelines for packing operations, see https://edis.ifas.ufl.edu/publication/FS189.

Table 2. Maturity ratings for green tomatoes sliced by a sharp knife through the equator (USDA 1991).

Table 3. Color stage descriptions for ripening tomatoes (USDA 1991).*