Nothing works like a solar wax extractor, or "melter", when it comes to rendering beeswax. It can be made from almost any materials found around the beekeeper's establishment and adapted to any size apiary.

Credit: David Reed, used with permission

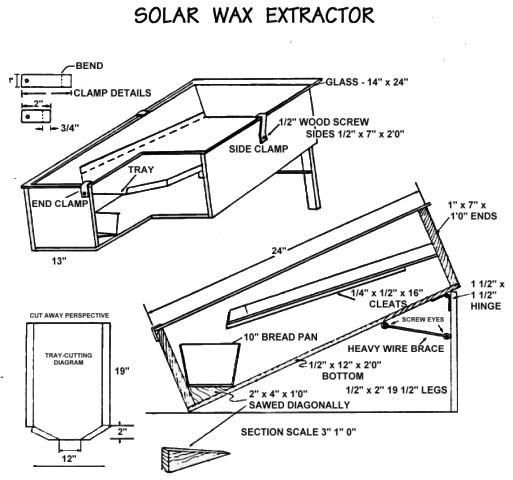

The principles of wax extractor design are always the same, although the details of each specific apparatus may differ. Bits of wax, old comb and other scrapings from the hive are placed on a slanted (usually metal) tray inside a box. The box is then covered tightly with a glass top and oriented toward the sun. As the temperature rises inside the box, the wax melts and drips off the tray into a collector pan. This pan usually has slanted sides, facilitating removal of the wax block once it hardens. A suggested plan for building an extractor is shown in Figure 2 .

The inside of the box can be painted black to absorb as much radiation as possible, facilitating heat buildup inside the melter. The melter should always be bee tight; honey bees are usually attracted to the odor of melting wax.

Wax rendered using a solar extractor can be entered in honey shows where it is judged on several criteria including color, cleanliness and freedom from honey, propolis and other adulterants; uniformity of appearance; and freedom from cracking and shrinking. The cleanest beeswax is usually rendered from honey cappings, which tend to be the newest comb in the hive.Wax from other comb tends to be older and is often darker due to the accumulation of debris. Bleaching in the sun can also lighten the color of rendered wax.

Credit: Shelly Jacob, D&J Apiary, used with permission

Wax from a melter can be purified by keeping the liquid wax warm so foreign materials settle to the bottom. This can be accomplished in the wax extractor or in a warm, turned-off oven. Once a cake of wax has hardened, detritus can be scraped off the bottom and if necessary, the cleaning process repeated.

Crack formation in the final wax block due to shrinkage can be minimized by allowing it to cool very slowly. The preferred mold is a bread pan with slanted sides. Once a cake is ready for submitting to a judge, do not touch it (fingerprints will cause points to be subtracted), but wrap it in plastic. Good luck!