Bermudagrasses (Cynodon dactylon L.) and Cynodon crosses (Cynodon spp.) are among the most important forage and turf species in the southeastern US. With biomass production of up to 7 tons of dry matter per acre and relatively high nutritive value, bermudagrasses are one of the best forages for grazing and hay production in Florida. The growing season for bermudagrass generally ranges from early spring to mid-fall, depending on weather conditions, but is more concentrated during the summer months. Cattle performance when grazing bermudagrass also tends to be greater than it is with other traditional warm-season forages, such as bahiagrass and limpograss. This document is primarily for Extension agents and farmers looking for detailed information about bermudagrass production in Florida, including cultivar characteristics, fertilization, and pest and disease management.

General Characteristics and Adaptation

Botanical characteristics of bermudagrass are quite variable among cultivars (Taliferro et al. 2004). In general, bermudagrass leaf blades are gray-green in color, generally 1/16–1/8 in wide and 1.2–3.2 in long, with a hairy ligule (ciliate membrane) at the base. The plants produce both rhizomes and stolons. Stem diameter is variable, ranging from slender to stout, and from short (common bermudagrass) to relatively long (Tifton 85) internodes. Certain varieties are preferred over others for hay production because of ease of drying. Seedheads form a digitally arranged cluster of 3 to 5 thin spikelets (1–2.5 in long). Only a few of the available cultivars produce seed (e.g., common, Coastal). Hybrids (e.g., Tifton 85), however, do not produce viable seeds. Plants are normally short, ranging from 12 to 25 in. Bermudagrass is normally not tolerant to waterlogged soils or soils with very low pH. Significant growth starts after temperature rises above 59°F, but the optimum temperature for growth is between 75 and 99°F.

Credit: Marcelo Wallau, UF/IFAS

Bermudagrass Varieties

There are several commercial bermudagrass cultivars used in Florida. The most cultivated cultivars are Coastal, Suwannee, Coastcross-1, Callie, Alicia, Tifton 44, Tifton 85, Florakirk, and Jiggs.

Common bermudagrass was first introduced to the US over 150 years ago from Africa. It has very aggressive growth characteristics and is often a major weed in cultivated crops of the Southeast due to viable seed production. It has relatively low nutritive value and productivity, forms a dense sod, and barely grows over 3 to 4 in tall. It is a very common weed in many pastures that is hard to eradicate selectively. However, it is still used as a pasture crop, especially in soils with low fertility and management levels.

Coastal was the first improved forage bermudagrass. It is well-adapted in north Florida and has performed well for many years, becoming an industry standard.

Suwannee was released in 1953 and is similar to Coastal. However, it will produce higher yields than Coastal when grown on very drought-susceptible deep sands.

Coastcross-1 was released in 1967. It is much more digestible than Coastal, but has less cold tolerance. It may be subject to winterkilling in severe winters. It spreads rapidly by aboveground stolons and develops few, if any, rhizomes. Coastcross-1 fields are difficult to find due to lack of persistence under adverse climatic and management conditions.

Callie is more digestible and higher-yielding than Coastal but is also susceptible to rust disease, which may become severe if the grass is not harvested on a 4- to 5-week schedule. Callie produces few rhizomes. It is therefore best established by planting the green tops instead of sprigs.

Alicia was introduced to producers by a private individual from Texas. Its ease of establishment and yield is similar to those of Coastal; however, it may be the least digestible of the bermudagrasses. It is generally not recommended.

Tifton 44 is more digestible than Coastal and is more cold tolerant than any of the other bermudagrasses. Because of that, it grows earlier in the spring and later into the fall compared to Coastal or Alicia. It is more difficult to establish than other bermudagrasses and should be planted using sprigs.

Tifton 85 (or T85) is a hybrid between a bermudagrass and a stargrass developed and released by Dr. Glenn Burton's breeding program at the Coastal Plain Station in Tifton, Georgia. It is more digestible and has produced greater hay yield and animal weight gain than Coastal across the Southeast. It has performed well in north Florida and has been widely accepted by producers. It has the same adaptation area as Coastal, but is not recommended for seasonally flooded flatwood soils. Tifton 85 has larger stems than Coastal, which may increase hay-drying time compared to the finer-stemmed bermudagrasses. Tifton 85 usually has the best digestibility among other bermudagrass cultivars (Vendramini et al. 2010) and better tolerance to stem maggot than fine-stemmed varieties (Baxter et al. 2017).

Florakirk is a release by the University of Florida Institute of Food and Agricultural Sciences. Similarly to Callie, Florakirk is susceptible to rust disease on the leaves, which may become severe with greater herbage accumulation during the summer. It is a fine-stemmed bermudagrass recommended primarily for hay production in the Panhandle and north peninsular Florida.

Jiggs is a private release from Texas that is widely used in south Florida because it performs better than the other bermudagrass hybrids in poorly drained soils. However, it may have less total digestible nutrients than Tifton 85. Jiggs has greater spring and fall production than other bermudagrass cultivars and has been used for hay, haylage, and grazing.

Mislevy 2000 is a recent release from the University of Florida Institute of Food and Agricultural Sciences. It has greater early spring forage production than most bermudagrass cultivars with similar nutritive value and persistence (Vendramini et al., 2022). Current planted area is limited, and plant material for nursery establishment is available upon request through forages@ifas.ufl.edu.

Newell is a hybrid bermudagrass recently released by the University of Florida Institute of Food and Agricultural Sciences. Newell’s selection was based on total productivity and length of the growing season. Compared to Tifton 85, Newell has faster establishment, about 15% greater biomass production and similar bermudagrass stem maggot tolerance (Rios et al., 2023). Current planted area is limited, plant material for nursery establishment is available upon request through forages@ifas.ufl.edu.

Forage Production and Nutritive Value

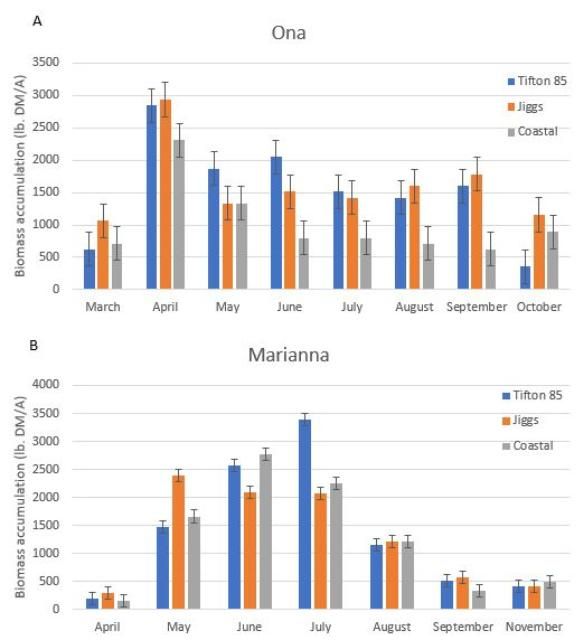

In general, bermudagrass production in Florida ranges from 4 to 7 tons of dry matter per acre, with 47–60% in vitro digestibility and 12–19% crude protein. The main factors responsible for the variation in production and nutritive value are cultivar, fertilization management, and harvesting/grazing intervals. Figure 2 shows forage production of 3 cultivars of bermudagrass in Ona and Marianna, FL (J. Vendramini and J. C. Dubeux, Jr., unpublished data), and Table 1 presents total annual forage production. Bermudagrasses are very responsive to N fertilization; the increase in forage production and nutritive value due to different N fertilization levels is shown in Table 1.

Credit: J. Vendramini and J. Dubeux, Jr., UF/IFAS

A common practice to increase total forage production is to overseed bermudagrass fields with cool-season forages. Those can be drilled or broadcast (annual ryegrass) after the last cut of hay in October, if weather conditions are favorable. In the spring, prior to the onset of growth of bermudagrass, it is important to remove the excessive biomass of the winter annuals (via grazing or cutting) to reduce competition for the bermudagrass during green-up. Interseeding alfalfa in bermudagrass fields has also been proposed as a way to increase productivity and nutritive value of the pasture (Beck et al. 2017). In Florida, this practice is limited to the north and Panhandle region. Alfalfa can be drilled after the first frost in the fall or following a chemical mowing using a reduced rate of herbicide (e.g., 20 oz/A of glyphosate or 12 oz/A of paraquat). Alfalfa should be drilled in 14-in rows at a rate of 15 lb/A. Denser plantings (i.e., 7-in rows at 25 lb/A) can result in heavy competition of the alfalfa on the bermudagrass and reduce overall production. Pastures can be grazed or used for hay or haylage. When grazed, the best management option is rotational stocking with a 28-day grazing interval and residual stubble of 4–5 in to avoid reduction of alfalfa persistence.

Hay and Baleage Management

In general, bermudagrass should be harvested for hay or baleage with approximately 4–5 weeks regrowth, to a 3- to 4-in stubble, for better compromise between quantity and quality. Long regrowth periods (intervals between harvest over 6 weeks) can offer more biomass accumulation, but with limited nutritive value. On the other hand, harvesting bermudagrass repeatedly at 2- to 3-week intervals to a stubble height less than 4 in may result in stand decline. Some bermudagrass cultivars are susceptible to insects and diseases, and long regrowth intervals may result in increased incidence of pests. A balanced fertilization with N, P, and K is recommended for bermudagrass fields that are harvested as hay or haylage. Fertilization in late fall is not recommended because it can result in in slower regrowth in the spring and reduce persistence.

In Florida, frequent summer rains hinder a regular hay-cutting schedule, often resulting in overgrown and rank fields. Grazing the hayfield can be another way to utilize the forage before it further declines in nutritive value. Another option is to bale wet hay and wrap it (baleage; Figure 3). However, baling requires specialized equipment and plastic, which increase production costs. The recommended procedures for hay and haylage production in Florida can be found in EDIS document SS-AGR-70, Hay Production in Florida (https://edis.ifas.ufl.edu/pdffiles/AA/AA25100.pdf). Additional information is available in EDIS document SS-AGR-178, Methods of Forage Moisture Testing (https://edis.ifas.ufl.edu/ag181), and EDIS document AN266, Comparison of Hay or Round Bale Silage as a Means to Conserve Forage (https://edis.ifas.ufl.edu/an266).

Credit: Marcelo Wallau, UF/IFAS

Grazing Management and Animal Performance

The same rationale of quantity vs. quality applies for grazing management. Long regrowth intervals or understocking will result in mature forage with low nutritive value and decreases in average daily gain (Bransby 1983). On the other hand, heavy grazing can reduce forage production, increase weed pressure, and reduce animal performance. As a rule of thumb, the more intensive the grazing event is, the greater the regrowth interval for complete recovery.

Cultivars respond differently to grazing management. In general, it is ideal to maintain a 4- to 5-in stubble height during the growing season to avoid overgrazing, especially on more upright-growing cultivars. Overgrazing can result in slow regrowth, weed encroachment, and loss of stand. A 3-year study on Tifton 85 showed that a short grazing height (~3 in) with a long regrowth period (28 days) and a tall grazing height (~8 in) with a short regrowth period (14 days) produced similar biomass. However, increasing the regrowth period lowered crude protein from 15% to 13% when bermudagrass was grazed to 3 in, and from 13% to 11% when bermudagrass was grazed to 8 in (Liu et al. 2011). Peak bermudagrass production occurs during the summer, and that can present a challenge for determining the required stocking rate to maintain a proper grazing pressure throughout the year. Early fertilization will help increase production in the spring. As forage growth increases in the summer, a section of the pasture can be closed off while animals are concentrated in the remaining area to improve forage utilization. That will help maintain proper grazing pressure in the grazed area. Excess growth can be stockpiled for later use in the fall or harvested for hay.

Well-managed bermudagrass can result in animal gains of around 1.5 lb/d and stocking rates of over 1 animal unit/A (1 animal unit = 1,100 lb of live weight) during the growing season (~150–180 days). A three-year grazing study conducted at the Georgia Coastal Plain Experiment Station with yearling beef steers to compare Tifton 85 to Tifton 78 showed similar average daily gain, but Tifton 85 produced 46% greater liveweight gain per acre because of increased productivity (Table 4) (Hill et al. 1993). A similar trial under continuous stocking in Gainesville, FL, showed that Tifton 85 supported 2.6 head/A vs. 1.4 head/A for Florakirk over an average of 159 grazing days, resulting in 568 lb/A vs. 319 lb/A of liveweight gain, respectively (Pedreira et al. 2016). Tifton 85 also had greater digestibility (56% vs. 52%), but average daily gain was similar for both grasses (1.3 lb/day).

Stockpiling bermudagrass for fall/early-winter use is another important practice in the Southeast. Pastures should be closed (grazing-excluded) 6–8 weeks prior to the first expected frost and fertilized with 40–60 lb N/A. It is possible to accumulate from 1,500 to 2,500 lb DM/A, or even up to 3,000 lb DM/A with improved hybrids like Tifton 85. This roughly represents between 30 and 50 cow-days/acre grazing. Although nutritive value will not be excellent, CP and total digestible nutrients (TDN) should remain above 10% and 50%, respectively, which should be sufficient for dry cows.

Establishment

Successful establishment of a bermudagrass variety requires adherence to a few important steps. Start ahead of time, so that proper weed control, soil pH, and soil fertility are accounted for before planting. For more detailed information, see EDIS document SS-AGR-161, Forage Planting and Establishment Methods on Prepared Seedbed (https://edis.ifas.ufl.edu/ag107).

- Site Selection and Land Preparation: Choose a reasonably well-drained soil. Destroy existing vegetation by spraying a broad-spectrum herbicide (e.g., glyphosate) and cultivating the soil. Depending on the weed pressure, a more aggressive herbicide protocol may be needed. If reestablishing bermudagrass over an existing field (i.e., planting an improved variety), it might be a good practice to plant a cycle of annual crops to make sure the old variety is completely killed and will not contaminate the new planting.

- Lime and Fertilization: The ideal soil pH for bermudagrass and stargrass is between 5.5 and 6.0, or up to 6.5 if the pasture will be overseeded with legumes (e.g., alfalfa or clovers) in the future. For sandy soils, apply soil test-recommended rates of phosphorus (P) and potassium (K), along with 30 pounds of nitrogen per acre as soon as the bermudagrass plants start to grow. Apply an additional 70 pounds of nitrogen per acre and one-half of the recommended potassium when stolons (runners) begin to develop.

- Time of Planting: The improved hybrid bermudagrasses do not produce viable seeds and must be established from vegetative plant parts, either tops (stems) or sprigs (rhizomes). The best time to plant when using sprigs is in late winter when bermudagrass is dormant, but before spring green-up. This will ensure maximum carbohydrate reserves in the planting material. Sprigs dug in early spring after the plants have broken dormancy will have lower levels of energy reserves. Tops can be planted mid-summer, around mid-June until August, depending on the location. It is important to use well-fertilized and mature stems (at least eight weeks of regrowth) to ensure maximum concentration of reserves. Try to plant during a cloudy, rainy period to have sufficient moisture and prevent the planting material from drying out or "scalding." Some varieties have greater chances of success when establishing using sprigs (e.g., Tifton 85), while others can be planted both ways.

If possible, all plantings should be completed no later than mid-August. Fall plantings have been successful in some years in peninsular Florida, but as a general rule, fall planting is not recommended because of the possibility of damage from drought or an early freeze in the fall. Young plants should be allowed plenty of time (three months) to develop a strong root system before the onset of cold weather.

4. Planting Material: Obtain planting material (sprigs or tops) from nurseries that have a pure stand of the variety desired and are free from common bermudagrass or other weeds. Plant fresh, pure, live sprigs or freshly cut tops that are eight weeks old or older. If using tops, planting material should receive 35–50 pounds of N fertilizer per acre two weeks before harvesting to induce a flush of new tillers.

5. Planting Rate: Plant 30–40 bushels (37–50 cubic ft) of dug sprigs or approximately 1,500 – 1,800 pounds of tops per acre. Higher planting rates can be used to ensure rapid establishment and low weed encroachment if planting material is readily available or low in cost (Bassegio et al., 2015a,b).

6. Planting Method: Dug sprigs can be planted with commercial sprig planters that place the sprigs two to three inches deep. Both dug sprigs and tops can be broadcasted on the surface with a spinner-type grass planter (slinger). Other planting devices, such as hay busters, can also be used to broadcast large roll bales of green tops. If using a hay buster, remove the knives to avoid chopping the planting material. The planting material should be immediately covered with a disk harrow to a depth of 2–4 inches for sprigs, and 1-3 inches for tops. Long tops (stems) can also be pushed into the soil with a "fairway"-type roller crimper, where part of the stem is still above the soil surface. Pack the soil with a heavy roller so that soil capillarity can be established, which will keep the soil moist around the planting material. If a roller is not available, driving over the soil with a tractor will help compact soil as well.

7. Establishment Weed Control: Spray 2 pt/acre of 2,4-D + dicamba 7 days after planting for controlling broadleaf weeds. Another application in 30–40 days may be needed for control of any broadleaf weeds that escaped the initial herbicide treatment. Diuron (0.2–2.4 lb/A) is another alternative with greater residual for the control of summer annual grasses (e.g., crabgrass and goosegrass) when planting sprigs. Diuron must be applied immediately after planting, before any green-up, and sprigs have to be planted 2 inches deep to avoid injury. Do not use diuron when planting tops. Nutsedge can be controlled with 1 oz of Outrider or Sandea per acre. Contact your county's UF/IFAS Extension agricultural agent for updates on herbicide recommendations. More information can be found in EDIS document SS-AGR-287, Weed Management during Pasture Establishment (https://edis.ifas.ufl.edu/ag290).

Failures in establishment are generally caused by:

- Poorly prepared or weedy seedbeds

- Lack of moisture at planting

- Inviable planting material due to desiccation or heat damage

- Lack of or poor planting material

- Failure to firm the soil (roll) to ensure soil contact with planting material

- Excessive or inadequate depth of planting material

With sustained soil moisture, good weed control, and adequate fertility, bermudagrass can be established in three to four months and ready for the first hay harvest or light grazing. Late plantings should not be harvested, but allowed to go through the winter with plenty of top growth. To establish a large acreage, it may be wise to start a nursery area to supply planting material for the following years. This can reduce the cost of planting and spread the risk of establishment failure over more than one season.

Fertilization for Hay and Grazing

Bermudagrasses, especially the newer, improved varieties, have high nutrient requirements and are very responsive to nitrogen fertilization. A complete fertilization (N, P, K, S, and Mg) is essential not only to enhance productivity, but also to sustain persistence, especially in poor, sandy soils. Low rates of N (< 50 lb/A annually) are generally insufficient to maintain a good stand and will results in weed encroachment (Burton 1954). Potassium is commonly overlooked in fertilization protocols for perennial forages. However, it is an essential nutrient for stand persistence and disease resistance, and it is associated with increased uptake of P and N. After three years of clipping treatments, pastures that did not receive K fertilization had only 34% bermudagrass cover (Silveira et al. 2017). In a literature review of fertilization protocols for bermudagrass, Taliaferro et al. (2004) suggested maintaining a ratio of 4-1-3 to 4-1-4 of N-P2O5-K2O.

For hay production, apply 80 lb of N per acre and soil test-recommended amounts of P and K in early spring. After each cutting, except the last in the fall, apply an additional 80 lb N and 40 lb K2O/acre, along with 20 lb P2O5/acre if the soil tested low or medium in P. For grazing, apply 80 lb of N per acre and soil test-recommended amounts of P and K. An additional 80 pounds of N can be applied mid-season if needed. Sulfur is recommended, especially for hay production, at a rate of 10 lb/A along with the N application (early-spring and top dressing). This can be achieved using elemental sulfur or ammonium sulfate in the fertilizer mix. Studies show that K fertilization along with N increase herbage production and tissue K levels (Silveira et al. 2017; Kohmann et al. 2017). The need for frequent application of micronutrients has not been demonstrated. For more details on bermudagrass fertilization, see EDIS document SL129, UF/IFAS Standardized Fertilization Recommendations for Agronomic Crops (https://edis.ifas.ufl.edu/ss163).

Weed Control

The first step for weed management is maintaining a vigorous, healthy stand via proper fertilization and grazing/hay management. On established bermudagrass, many broadleaf weeds can be controlled with timely applications of 2,4-D, dicamba (e.g., Banvel), metsulfuron (e.g., Escort), triclopyr (e.g., Remedy), or premixed products such as Chaparral (aminopyralid + metsulfuron), Weedmaster (Banvel + 2,4-D), Pastureguard HL (triclopyr + fluroxypyr), or GrazonNext HL (aminopyralid + 2,4-D). Annual or perennial sedges can be effectively controlled with sulfosulfuron (e.g., Outrider). Pensacola bahiagrass can be controlled with metsulfuron, and annual grasses (e.g., crabgrass) can be controlled with imazapic (e.g., Impose; Figure 4) or low application rates of glyphosate. To lessen injury from imazapic and glyphosate, apply these herbicides within 7 to 10 days after cutting. Hexazinone (e.g., Velpar) can be used for smutgrass control, but certain varieties are more sensitive than others to this herbicide. Glyphosate can be used during the winter (dormancy) to control cool-season weeds that might delay onset of growth in the spring, and 7 to 10 days after cutting to help control annual and perennial grasses. Prowl H2O can be applied as pre-emergent in the winter to control a range of small-seeded weeds in the spring and summer. However, rainfall is necessary for incorporation of this herbicide, which often prevents its use during the dormant period. Spot treatment of common bermudagrass with glyphosate in a hybrid bermudagrass nursery is effective; however, the hybrid bermudagrass will be injured or killed in the treated area.

Credit: Marcelo Wallau, UF/IFAS

Check grazing and haying restrictions before application of any product. The label will provide information on the period that must elapse between application of herbicide and resumption of grazing or removal as hay. For more information, see EDIS document SS-AGR-08, Weed Management in Pastures and Rangeland (https://edis.ifas.ufl.edu/wg006). Annual updates of this information can be obtained from your local UF/IFAS Extension office.

Insects

As in any crop, insect management should use an integrated approach (i.e., IPM). The first barrier against insects and diseases is the grass variety; some cultivars are more tolerant than others to certain pests. Proper fertility can reduce susceptibility to pests and damage. Additionally, cultural practices such as timely grazing or cutting can reduce yield losses from insects and diseases. Monitoring for insects (e.g., walking the fields, using sticky traps and sweeping nets) is essential because insects are easier to control in early stages of development and during the initial infestation.

Bermudagrass stem maggot (Atherigona reversura, Figure 5) has been one of the major insect pests in bermudagrass. It feeds on the tip of the stems where new leaves are emerging, causing "bronzing" of the field. The tip of the plant dies and is easily pulled from the stem. This will cease growth on that tiller, and the standing dead material shades bottom stems, further limiting growth of new tillers. If pastures are infested near harvesting time, yield losses are minimal (less than 10%) and cutting will remove the maggots from the pasture; however, if infestation occurs early during the regrowth period, up to 80% yield loss may occur. In this case, two applications of a pyrethroid insecticide, one 7–10 days after cutting, and a second 7–10 days after are recommended for controlling the fly. Since the maggot lives inside the pseudostem, it will not be affected by contact insecticides, and insecticide application must target the fly. There are no systemic insecticide is labeled for bermudagrass stem maggot. There are currently no tolerant varieties, but thin-stemmed, common, and seeded bermudagrass types are more susceptible (Baxter et al. 2023). More information on bermudagrass stem maggot can be found in the Ask IFAS document SS-AGR-106, Management of Spittlebugs in Pasture (https://edis.ifas.ufl.edu/ag242). A detailed management guide is available through UGA Extension, Bulletin 1484 (Baxter et al. 2017).

Credit: Tim Wilson, UF/IFAS

Armyworms (Spodoptera frugiperda; Figure 6A), grass loopers (Mocis spp.; Figure 6B and C), and grasshoppers may occasionally be a problem. These pests are usually common in the summer and fall, especially on recently fertilized bermudagrass fields. These insects can completely strip a bermudagrass field of leaves if not detected in time. Fall armyworm is very common mid- to late-summer into the fall and is considered a problem if there are 3 or more worms per square foot of pasture. When scouting, avoid the margins of the field and sample in early mornings or late afternoons when larvae are more active. Grazing or mowing can suppress infestations, but if an infestation occurs in the early stages of pasture or hay regrowth, an insecticide (e.g., carbaryl, malathion, cyhalothrin) can be used. Follow label instructions for rates and observe withdrawal periods, which vary depending on the product and use (hay or grazing). More information on fall armyworm can be found in EDIS publication ENY-098, Fall Armyworm, Spodoptera frugiperda (https://edis.ifas.ufl.edu/in255).

Credit: (A and C) Robert Meagher, USDA. (B) Marcelo Wallau, UF/IFAS

Spittlebug (Prosapia bicincta) is another insect that can damage bermudagrass in wet weather. The presence of the insect is indicated by a white froth or spittle-like material at the base of the plant, which contains the young insect. Adults emerge from the froth as dark brown or black flying insects that are about 3/8 inch long with two orange-red lines across the wings. Spittlebugs appear in June and late August. When feeding, the adults and immature insects inject a toxin into the plant that causes the leaves to turn brown and look frosted. The affected areas enlarge as the adults spread and feed. Mowing or grazing to keep the grass from growing tall, lodging, and becoming densely matted will prevent most spittlebug problems. Burning of the bermudagrass in February or just prior to green-up will help to control spittlebug by killing the overwintering eggs and early immature stages of the insect. There is a small risk involved when this practice is used on a less cold-tolerant variety such as Coastcross-1. Burning will stimulate the grass to start growing earlier and faster. If a late hard freeze in March occurs during this early growth stage, the plant could be killed. Use of insecticides is often not feasible. The young insects are protected by the spittle mass and the insecticide must be timed to contact the adults in either June or September to be effective, meaning the grass must be grazed short or mechanically harvested.

Mole crickets (Neoscapteriscus spp. and Neocurtilla hexadactyla) are a pest more commonly seen in bahiagrass pastures, but they can also be found in bermudagrass. Mole crickets tunnel under the ground, causing detrimental separation between soil and roots. On bare ground, the tunnels are easily detected. They also feed on the roots and shoots of grasses. Presence of mole crickets can be determined with a simple "soap flush" test. Mix 1.5 oz of liquid dishwashing soap with 2 gallons of water. Pour the soap mixture over 4 ft2 (2 ft x 2 ft) of pasture. If mole crickets are in the area, they will crawl to the surface for air in approximately 3 minutes. If two or more appear, treatment might be beneficial. For more information on mole cricket identification and management alternatives, see EDIS document IPM-206, Mole Cricket IPM Guide for Florida (https://edis.ifas.ufl.edu/in1021).

Chinch bugs (Blissus spp.) infest bermudagrass pastures in dry years and prefer thin grass stands. The adult chinch bug has white wing covers, each with a black triangle in the middle of the outer margin. The nymphs are reddish with a white band across the back, whereas older nymphs are reddish brown with a white band (see EDIS document ENY-325, Managing Southern Chinch Bug in Warm Season Turfgrasses, at https://edis.ifas.ufl.edu/lh036). The mixture of nymphs and adults gives the appearance of red-black-white ants emerging on grass thatch during a soap flush. The chinch bug remains in the thatch of infested fields over the winter as adults and large nymphs, resuming activity once temperatures reach 60°F in the spring. Heavily infested areas turn yellow and then brown. After depletion of green tissue in one area, the chinch bugs migrate to new areas, causing an expansion of the damaged section. When appropriate insecticide is used for control, it is recommended that the damaged area be sprayed (along with 20 ft of green border around it). Contact your county UF/IFAS Extension agricultural agent for the latest update on recommended insecticides.

Diseases

Diseases are usually not a serious problem as long as the grass is fertilized and harvested on a four- to five-week schedule. However, when present, they can reduce yield and quality of the forage crop. Helminthosporium (Bipolaris), or leaf blight, is the most common disease found on bermudagrass, in which large areas of what appears to be frosted grass may develop in the field. It forms reddish-brown to purplish-black spots on the foliage (Figure 7A). Puccinia, or leaf rust (Figure 7B), forms pustules that, when disrupted, release an orange-red powdery mass of spores similar to rust. Both diseases typically appear in late summer, when temperature is above 75°F and humidity is high. There are no effective, economic, or legal fungicides to control those diseases in bermudagrass. The best practice is to prevent the disease through variety selection, maintenance of fertility, thatch removal (especially by burning in winter) and timely harvest of forage. Maintaining the appropriate potassium levels, burning the fields just before green-up, and harvesting or grazing on a regular schedule will help prevent the occurrence of this disease. More information can be found in UGA Extension Circular 887 (Andrae and Martinez 2012). Rhizoctonia is a soil fungus that causes "brown patch" disease. In hot, wet weather, the fungus infects plants, forming brown, circular patches. No fungicide application is recommended. The best control is to avoid excessive rates of N and remove hay from the field as soon as possible (Hancock et al. 2017).

Credit: (A) Clemson University—USDA Cooperative Extension Slide Series, Bugwood.org. (B) Gerald Holmes, California Polytechnic State University at San Luis Obispo, Bugwood.org

References

Andrae, J., A. Martinez, and R. Morgan. 2012. "Leaf Spot Diagnosis and Management in Bermudagrass Forages." University of Georgia Extension Circular 887.

Baseggio, M., Newman, Y. C., Sollenberger, L. E., Fraisse, C., & Obreza, T. (2015a). Stolon planting rate effects on Tifton 85 bermudagrass establishment. Agronomy Journal, 107(4), 1287–1294.

Baseggio, M., Newman, Y., Sollenberger, L. E., Fraisse, C., & Obreza, T. (2015b). Planting rate and depth effects on Tifton 85 bermudagrass establishment using rhizomes. Crop Science, 55(3), 1338–1345.

Baxter, L. L., W. G. Hudson, and J. J. Tucker. 2023. "Managing Bermudagrass Stem Maggots." University of Georgia Extension Bulletin 1484. https://extension.uga.edu/publications/detail.html?number=B1484&title=managing-bermudagrass-stem-maggots

Bransby, D. 1983. "Herbage Availability as a Stress Factor on Grazed Coastcross-1 Bermudagrass." S. Afr. J. Anim. Sci. 13: 3–5.

Burton, G. W. 1954. "Coastal Bermuda Grass." Bull. N. S. 2. Athens: Georgia Agricultural Experiment Station.

Hill, G. M., R. N. Gates, and G. W. Burton. 1993. "Forage Quality and Grazing Steer Performance from Tifton 85 and Tifton 78 Bermudagrass Pastures." J. Anim. Sci. 71(12): 3219–3225. https://doi.org/10.2527/1993.71123219x

Kohmann, M. M., L. E. Sollenberger, J. M. B. Vendramini, M. L. Silveira, and L. S. B. Moreno. 2017. "Harvest Stubble Height and K Fertilization Affect Performance of Jiggs and 'Tifton 85' Bermudagrasses." Crop Sci. 57: 3352–3359. https://doi.org/10.2135/cropsci2017.05.0308

Lee, R. D., G. Harris, T. R. Murphy, D. W. Hancock, and P. McCullough. 2017. "Bermudagrasses in Georgia." University of Georgia Extension Bulletin 911.

Liu, K., L. E. Sollenberger, Y. C. Newman, J. M. B. Vendramini, S. M. Interrante, and R. White-Leech. 2011. "Grazing Management Effects on Productivity, Nutritive Value, and Persistence." Crop Sci. 51: 353–360.

McCullough, M. E., and G. W. Burton. 1962. "Quality in Coastal Bermudagrass Hay." Georgia Agric. Res. 4: 4–5.

Overman, A. R., F. M. Rhoads, R. L. Stanley, and C. G. Chambliss. 2000. Estimation of Bermudagrass Production in Florida. CIR938. Gainesville: University of Florida Institute of Food and Agricultural Sciences.

Pedreira, C. G. S., V. J. Silva, Y. C. Newman, and L. E. Sollenberger. 2016. "Yearling Cattle Performance on Continuously Stocked 'Tifton 85' and 'Florakirk' Bermudagrass Pastures." Crop Sci. 56: 3354–3360. https://doi.org/10.2135/cropsci2016.06.0522

Rios, E. F., Lopez, Y., Munoz, P., Dubeux Jr, J. C. B., Vendramini, J. M. B., Wallau, M., ... & Kenworthy, K. (2023). ‘Newell’ bermudagrass: A public release from the USDA Cynodon collection. Journal of Plant Registrations, 17(3), 605–615.

Scarbrough, D. A., W. K. Coblentz, K. P. Coffey, K. F. Harrison, T. F. Smith, D. S. Hubbell, J. B. Humphry, Z. B. Johnson, and J. E. Turner. 2004. "Effects of Nitrogen Fertilization Rate, Stockpiling Initiation Date, and Harvest Date on Canopy Height and Dry Matter Yield of Autumn-Stockpiled Bermudagrass." Agron. J. 96: 538–546.

Scarbrough, D. A., W. K. Coblentz, J. B. Humphry, K. P. Coffey, T. C. Daniel, T. J. Sauer, J. A. Jennings, J. E. Turner, and D. W. Kellogg. 2005. "Evaluation of Dry Matter Loss, Nutritive Value, and In Situ Dry Matter Disappearance for Wilting Orchardgrass and Bermudagrass Forages Damaged by Simulated Rainfall." Agron. J. 97: 604. https://doi.org/10.2134/agronj2005.0604

Silveira, M. L., J. M. B. Vendramini, H. M. S. da Silva, B. M. M. N. Borges, V. S. Ribeirinho, J. J. J. Lacerda, M. V. Azenha, P. R. A. Viegas, and A. D. Aguiar. 2017. "Potassium and Phosphorus Fertilization Impacts on Bermudagrass and Limpograss Herbage Accumulation, Nutritive Value, and Persistence." Crop Sci. 57: 2881–2890. https://doi.org/10.2135/cropsci2017.03.0147

Taliaferro, C. M., F. M. Rouquette, and P. Mislevy. 2013. "Bermudagrass and Stargrass." In Warm-Season (C4) Grasses, edited by L. E. Moser, B. L. Burson, and L. E. Sollenberger. 417–475. Agronomy Monograph No. 45. American Society of Agronomy, Crop Science Society of America, Soil Science Society of America. https://doi.org/10.2134/agronmonogr45.c12

Vendramini, J. M. B., Rios, E., Dubeux Jr, J. C. B., Quesenberry, K., & Munoz, P. (2021). Registration of ‘Mislevy’ bermudagrass. Journal of Plant Registrations, 15(1), 7–15.

Response of Coastal bermudagrass crude protein, herbage accumulation, and nitrogen removal to increasing levels of nitrogen fertilization, harvested every six weeks.1

Effect of cutting intervals on digestibility, dry matter intake, and daily gain per animal of Coastal bermudagrass hay (Georgia).1