Cotton production and management requires much planning and timely action throughout the season. Preparation for planting cotton can be done by strip-tilling rows 4–6 weeks before planting into a cover crop or old crop residue to warm the soil. Strip-till planting can also be made a one-pass operation by running rows and planting in the same operation. Bedding in the fall and knocking off beds to plant into moist soils in the spring is another way to use conservation tillage. Tilling and bedding rows 4–6 weeks ahead of planting, followed by knocking off tops of beds to plant into moist and warmer soils, is a widely accepted practice on non-irrigated fields. Bedding with early planting may be the best way of ensuring stands in non-irrigated fields. Where irrigation is available, neither bedding nor subsoiling is as critical; however, ripping rows ahead of strip tillage or bedding usually results in warmer soils, which may be critical to reduce stand loss due to seedling disease in early planted cotton. Most soils in Florida have a natural compaction layer 6–14 inches deep and must be subsoiled that leave root channels through the compaction layer to allow cotton roots to grow through. Cotton is planted from late April to early June. It is important to bear in mind that soil moisture is usually adequate for planting in late March to early April as compared to late April and May if irrigation is not available.

Stands and Plant Population

The desired cotton plant population is 2–3 plants per foot of row in 36-40 inch-wide rows. To get this population, plant 3–4 seeds per foot of row. Because of high seed costs, many growers are on the low end of seeding rates. If environmental stress factors are high (e.g., drought, wet, cold, or nematodes), seeding rate should be increased. For quick emergence, high-quality cotton seed should be planted into moist seedbeds, using depth bands or down pressure springs to control seeding depth. Seed depth should be from 1/2 to 1 inch deep, but not over 1 inch because of increased chance of seedling disease and poor stand establishment from crusting. Plant when there is good soil moisture and when the overnight lows are expected to be 62°F or higher for 5 days following planting. When planted at this time, seedlings should emerge in 5–7 days and a stand established in 8–11 days. Growers can decide whether a stand is adequate within 2 weeks after planting. The first step to successful germination is adequate water uptake. Cotton seed is notorious for being slow to absorb water and getting dehydrated. Sandy soils do not hold water well, conduct water poorly, and dry out more rapidly than other soils. These factors contribute to poor cotton stands in Florida's sandy soils. However, data shows that plant densities from 1 to 5 plants/ft of row make little difference in yield (Table 1), and if stands are as low as 1 plant/ft, good yields can still be expected.

Temperature is also critical to successful seed germination. Once a cotton seed begins to absorb water, temperature is very important to survival and development of the plant. Specifically, soil temperature less than 50°F causes chilling injury. A plant may be killed if exposed to temperatures of 50°F or lower after absorbing water, or it may result in weak plants, delayed maturity, and reduced yields. Because of this susceptibility, planting should be delayed until soil temperatures are at least 65°F or higher at the 4-inch depth at 8:00 a.m. The optimum soil temperature for seed germination is near 85°F.

Generally cotton is planted in 36- to 38-inch wide rows on the majority of farms, which fits current planting and harvesting equipment. Seed costs with technology fee has resulted in a cost of $80–$100+/acre for the planting operation. Skip-row planting has been used, which is plant two rows and skip one, which resulted in yields of near 90%–95% of solid stands. However, weed control is more of a challenge. Herbicides and irrigation will still be needed on the entire land area. Florida data has shown a slight economic advantage to skip-row cotton with the 2:1 skip being the most economical and other skip patterns not much different from the full plant system. Skip-row requires more management, since planters, sprayers, and other equipment have to be modified to adapt to skip-row patterns. The advantages of 30"–36" cotton over 40" row widths have been examined over the past 25 years in numerous studies from California to the Southeast. Extensive trials have shown that 30"–36" rows are comparable in cost to a 40" row system. Other studies have shown that with appropriate modifications of production practices, 30"–36" cotton out-yields cotton planted in wider rows. Most of the producers in the Southeast and Florida plant in 36" rows to accommodate other crops being grown simultaneously so that equipment does not have to be changed back and forth during the growing season.

Narrow row cotton (7"–10") produces smaller plants, which intercepts more sunlight, water, and nutrients. Narrow row cotton has to be harvested with a stripper, and cotton has more trash in the lint which lowers the quality. Narrow rows also require adjustments to seeding rate, fertilization, and the use of growth regulators such as Pix. Cotton can be double-cropped successfully behind wheat for grain. However, if there is a problem with stands (e.g., dry weather, packing rains, insects) and planting is done in late May or early June, it is often mid- to late-June before poor stands are recognized; by then, it may be too late to replant without sacrificing yields. Under irrigated conditions, cotton stands are usually not a problem and very good yields have been obtained with late May to mid-June plantings.

Fertilization

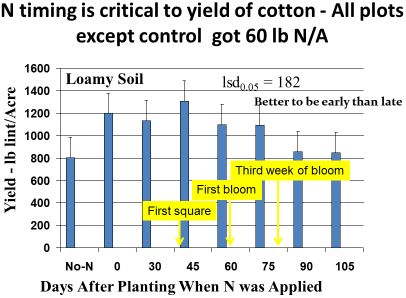

Of the row crops grown in Florida, cotton has the slowest early growth and the lowest nutrient uptake for the first 40–60 days of growth, but this increases rapidly at squaring. Therefore, fertilization should be timed to provide adequate nutrition to the young cotton plants at the rapid development stage. As with other crops requiring N fertilization, N management is critical to ensure adequate vegetative growth without causing rank growth due to excessive fertilizer. If fertilizer application after the third week of bloom results in poorer yield. Boll rot and hard lock causing pathogens increase with shading, high humidity and temperature, and poor insect control, which are associated with high N applications.

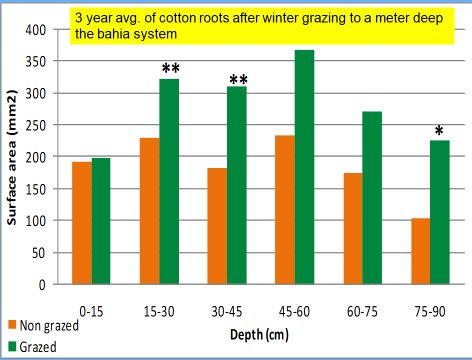

Nitrogen needs for cotton under different soil types and crop rotations are shown in Table 2 and may vary with soil type and cropping history. Our data (Figure 1) show that N applications made after the third week of bloom result in lower yields than when N is applied earlier. When N is applied after the third week it has little or no effect. Therefore, late applications are detrimental to yield and costly to apply. This suggests that even if the plant has an N deficiency late in the season and the plant has a good fruit load, no additional N should be applied. Four years of Florida data show that the optimum time to apply N is at first square followed closely by at planting applications on heavier soils. It is probably not necessary to make more than one sidedress application of N on heavy soils, while two or more split applications may be made on sandy soils (at squaring and at first bloom). A total of 90 lb/A of N is adequate with split applications on sands as well as heavy soils. Research from Florida has shown that planting cotton after winter grazing can result in almost doubling of the root system as compared to no grazing (Figure 2). This usually results in reducing N applications to 60 lb/A since cattle recycle N and enhance rooting. Grazed systems usually result in 200–300 lbs/A more lint in most years compared to systems without cattle.

Petiole testing for adequate N and K levels in plant tissue can be done through private laboratories. This can help determine how and when N and K should be applied on these fields in another year.

If cotton is planted on sandy soils, K applications may be split between at-plant (1/3 or less) and squaring to early bloom (2/3). Where petiole K levels have been followed using this practice, no K deficiencies have been noted. Table 3 shows why sidedress applications of nutrients may be beneficial during high rainfall years on sandy soils. Less than 10% of the N, P, and K are taken up during the first 60 days, while more than 80% of the nutrients are taken up during the next 60-day period.

High rates of P in the starter fertilizer are not necessary unless soil tests show lowlevels. If P is called for, all of it may be applied at planting since it moves very little through the soil profile.

Some fields of cotton have leaf diseases and defoliate early under high rainfall conditions. Research shows that low K results in disease incidence and also inadequate amounts of K in the leaves which is critical for boll filling. Sidedressing K near the row and applying amounts recommended from soil tests are crucial on sandy soils that are low in K.

Starter or Row-Applied Fertilizer

Fertilizers are most efficiently used when applied near the row where most of the roots occur. Liquid or complete dry granular fertilizer may be applied at planting near the row, and some data suggest that rates may be reduced 25%–30% when row-applied as compared with broadcast applications. Starter or row-applied fertilizer may be more critical on infertile, cold, and droughty soils. Starter N on sandy soils has resulted in increased yields, while no yield increase was noted for starter N on heavy soils. Many producers apply a mixture of 28-0-0-5 and 10-34-0 in a dribble beside the row or in a 2" × 2" placement. These mixtures may be composed of 3 or 4 parts of 28-0-0-5 to 1 part 10-34-0, up to 1:1 mixtures on soils needing more P. If liquid N is dribbled to the side of the row, distance away from the seed should be 1" for every 10 lb N/A. Complete dry granular fertilizers such as 3-9-18 or 5-10-15 have been applied over the row at planting or immediately after planting at 500 lb/A with good results but high salt fertilizers can reduce stands. Micronutrients can also be applied at planting if granular fertilizers are applied in-row. Sulfur is generally required on soils where the clay layer is 12" or deeper. The S needs may be met partially in the starter fertilizer (1/3 or less) followed by a sidedress application along with N at the square-early bloom period. Applying S at 30 lb/A has resulted in as much as one bale increase in lint on sandy soils.

Strip-Till Cotton

Management practices for strip-till cotton are essentially the same as for conventional plantings. Rows can be stripped off several weeks prior to planting to warm up the soil in the strip for early planting. Cover crops can be terminated with materials such as glyphosate or paraquat along with a low rate of residual material to inhibit new weed seedling development. If 2,4-D or residual cotton herbicides are used to help kill weeds and reduce regrowth, at least 4 weeks is necessary between killing the cover crop and planting (refer to the label for each chemical); otherwise seedling injury can occur. This can be avoided if the cotton variety has herbicide resistant trait. If moisture and soil temperature are adequate, a single pass of a strip-till rig with planters results in good stands and yield. Volunteer peanuts and other hard-to-control weeds can be removed by a second pass with the strip-till rig if more than 3 weeks have passed between the initial pass and planting, making the seedbed smoother.

Killing cover crops or weeds several weeks ahead of planting reduces cutworm and other insect problems and allows soil moisture to remain available to the new cotton seedlings. Other production practices are much the same as conventional farming, except that hooded or shielded sprayers are used instead of cultivation. If no cultivation is done, there are usually fewer weeds and fewer "flushes" of weeds.

Where nematodes are a problem in strip-tilled fields, it may be advisable to plant in row middles the following year if cotton follows cotton, because nematode numbers may remain many times higher in-row compared with row middles. This is more of a problem if there has not been a killing frost and cotton roots survive the winter. However, three years of research has shown a 33% higher yield by planting in row middles of reniform nematode-infested cotton as compared to planting in-row the next year.

Strip till cotton yields are as high or higher as compared to conventional plantings. Strip-tillage also has the advantage of preventing sand-blasting on young plants, as well as moisture conservation and erosion benefits. Herbicide tolerance traits in cotton has made the transition to conservation tillage easier. However, with weed resistance, it is important to use residual herbicides for adequate weed control.

Tables

Effect of cotton plant density on plant growth characteristics and yield (Information from D&PL).