Introduction

Sous vide is a French method of cooking food in airtight, vacuum-sealed plastic bags in a temperature-controlled water bath at low temperatures for an extended period of time. Sous vide cooking ensures a properly cooked inside without overcooking the outside.

Advantages

Meat with a lot of connective tissue will be more tender if it is cooked at a low temperature for a long time.

Sous vide cooking yields a product with a consistent, reproducible degree of doneness from end to end. Specifically for foodservice, it can reduce the time from order to plate or it can provide more flexibility to time of service by maintaining a consistent temperature.

Cooking food in a vacuum-sealed bag allows for more efficient transfer of heat from water to the food by convection. Cooking as well as storing food in a vacuum-sealed environment thermally kills aerobic bacteria and removes the oxygen supply, reducing risk of recontamination and extending shelf life.

Necessary Equipment

You will need the following:

-

a vacuum packaging machine which can handle a 7×20-inch bag or larger;

-

an immersion thermal circulator (or water bath with aquarium aerator);

-

a water container with sealable lid to contain heat/vapors.

Some home cooks use slow cookers and thermostat temperature controllers if they can evenly maintain temperature.

Safe and Effective Sous Vide Cooking

The inside of a muscle that has not been injected with solutions or tenderized by breaking the surface of the meat is naïve to any pathogens that can cause foodborne illness (Gill 1979). However, pathogens can be on the muscle's exterior. Cooking is an effective way to terminate most pathogens.

Fully submerge products in the water bath, but do not overlap them.

Never cook below 55°C/131°F because the temperature is not high enough to:

-

Kill pathogens quickly.

-

Solubilize collagen effectively and increase tenderness.

The surface of a large vacuum-sealed boneless roast will reach the temperature of a water bath at 58°C/136°F within 2 hours.

After 2 additional hours, an inoculated surface will have a 5-log reduction of pathogenic E. coli, a 6-log reduction of Listeria species, and a 7-log reduction of Salmonella species (Baldwin 2012).

Cooking Large Cuts

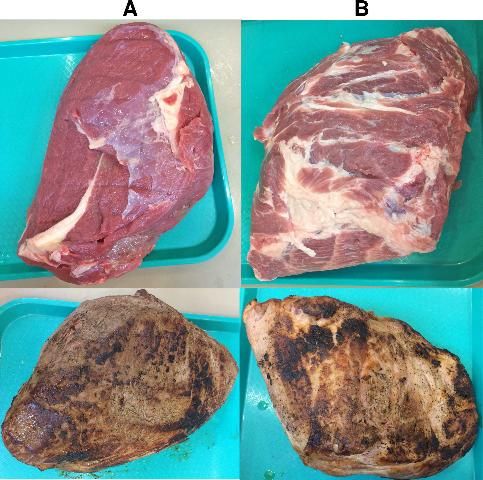

Moisture loss is the most significant palatability challenge with sous vide. Searing before sous vide cooking reduces cooking loss and increases sensory tenderness.

Results from our lab have shown pork serratus ventralis from cellar trimmed (CT) butts browned prior to 10 hours of sous vide cooking at 57.2°C/135°F had a 20 percent decrease in cooking loss than the same cuts browned after sous vide cooking (Table 1). Browning prior to sous vide cooking improved trained panelists' juiciness values of beef clod hearts and pork serratus ventralis and also tended to improve objective tenderness measurements (Table 1).

Cylinder-shaped muscles with 4.5 inches of maximum thickness reach the same internal temperature as the temperature of the water bath within 6 hours. Insert a temperature probe into the thickest portion of the largest roast through closed cell foam tape.

Sous vide cooking to 57.2°C/135°F for 10 hours for large cuts, such as chuck eye rolls, whole briskets, split inside rounds, clod hearts, or pork cellar trimmed butts, results in effective tenderness improvement (Christensen et al. 2013; Suriaatmaja and Lanier 2014).

Chilling and Refrigerated Storage of Large Cuts

Keeping the food sealed prevents recontamination after cooking, but spores of C. botulinum, C. perfringens, and B. cereus can all survive the mild heat treatment.

Large cylinder-shaped muscles with approximately 5 inches of maximum thickness will take almost 5 hours to reduce from 60°C/140°F to 4.4°C/40°F in an ice bath (Baldwin 2012).

After chilling in an ice bath, the food must either be frozen or held at or below 2.5°C/36°F for up to 90 days to prevent spores of nonproteolytic C. botulinum from outgrowing and producing deadly neurotoxin (Peck 1997; Gould 1999).

If tight refrigeration control and first-in, first-out standard operating procedures are followed, sous vide meat cookery can help improve tenderness and reduce food safety risk of meat in foodservice.

Reheating Large Cuts

The key to reheating is to warm the product without cooking it any further. Place the chilled, vacuum-sealed sous vide product into approximately 82.2°C/180°F water for approximately 2 minutes per pound.

Conclusions

Sous vide cookery provides precise temperature control and tenderness improvement with minimal supervision throughout cooking as well as consistent, almost perfect reproducibility.

Close monitoring of chilling and refrigeration temperatures during storage will facilitate the production of safe, high-quality products with extended refrigerated shelf life.

References

Baldwin, D. E. 2012. "Sous vide cooking: a review." International Journal of Gastronomy and Food Sci. 1: 15–30.

Christensen, L., P. Ertbjerg, H. Loje, J. Risbo, F. W. J. Van Den Berg, and M. Christensen. 2013. "Relationship between meat toughness and properties of connective tissue from cows and young bulls treated at low temperatures for prolonged times." Meat Science 93: 787–95.

Gill, C. O. 1979. "Intrinsic bacteria in meat." Journal of Applied Bacteriology 47: 367–78.

Gould, G. W. 1999. "Sous vide food: conclusions of an ECFF botulinum working party." Food Control 10: 47–51.

Peck, M. W. 1997. "C. botulinum and the safety of refrigerated processed foods of extended durability." Trends in Food Sci. & Tech. 8: 186–92.

Suriaatmaja, D., and T. C. Lanier. 2014. "Mechanism of meat tenderization by long-time low-temperature heating." Masters Thesis, North Carolina State University, Raleigh, NC.