Introduction

Shrink in beef cattle is weight loss that occurs between an animal's departure from one location and weigh-in at another. The shrink occurs as a result of gut fill or tissue loss from the animal. Shrink in beef calves constitutes a potential economic loss to both the seller and the buyer if it is not fully considered. A number of factors can cause shrink, but feed and water deprivation, lack of consumption, and exposure to stress have the greatest impact.

How Shrink Occurs

Shrink occurs from the pasture to the working facilities, the pasture to the sale barn, or the ranch to the feedlot. These examples demonstrate the effects that stress, travel, time, and food/water deprivation can have on shrink. In general, animals that are taken off feed and water for 12 hours or fewer only experience excretory shrink. However, the amount of shrink grows with an increasing number of stressors and extended duration of exposure to them.

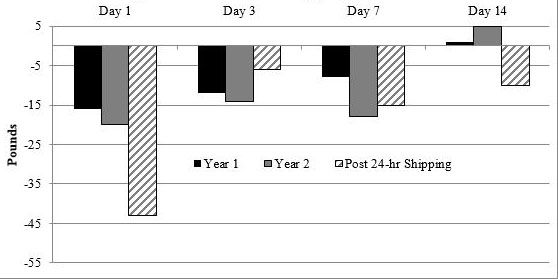

Table 1 demonstrates how different handling and time affect the percent shrink in feeder calves. Shrink increases with time and severity of the stress. Figure 1 shows the amount of body weight lost from calves at weaning in two separate years (Hersom et al. 2015). Additionally, in year 2, cattle were preconditioned for 50 days and transported for 1,000 miles over a 24-hour shipping event. These calves were born and weaned in Florida. After weaning, the amount of shrink in a day was between 3.5 and 3.9%, similar to the amount of shrink after 8 hours of standing in a drylot. In years 1 and 2, calves did not regain their off-pasture weaning weight until day 14, even though these calves were offered high-quality large round bale hay and a pelleted supplement at 0.5% of their weaning weight. Shrink was associated not only with a dietary change, but with handling, change in environment, and tissue loss from stress. After a shipping event in year 2, these calves were unable to regain the lost body weight within 14 days, despite adequate access to hay, supplement, and water. The amount of shrink increased because feed and water removal was coupled with the stress of transit. The severity of shrink varies within a group of calves, but shrink management has implications for the group's health and profit potential.

Credit: Adapted from Hersom et al. 2015

Factors Affecting Shrink

Transportation Time

The amount of time a calf spends in transit on a trailer is one of the largest factors affecting the amount of shrink. Most of the shrink generally occurs early in the shipping event. Studies have demonstrated that calves will shrink about 1% per hour for the first 3 to 4 hours, then 0.25% for the next 8 to 10 hours (Tippets et al. 1957). Table 1 indicates that 8 hours in transit can result in over 5% shrink, increasing up to 8% at 16 hours and almost 9% at 24 hours in transit. Many calves leaving Florida and the Gulf Coast region can experience a 24-hour shipping event to reach their next destination in the Southern Plains.

Amount of Fill

Cattle diet can affect the amount of gut fill and subsequent shrink experienced. Diets low in dry matter and high in moisture result in a greater amount of shrink, and drier diets create less shrink. Cattle that are exceptionally full can shrink a great deal. Cattle buyers are aware of this and will reduce the price offered for overly full cattle. Cattle that shrink 10 to 12% undergo a greater amount of stress which makes them more susceptible to sickness and poor performance.

Condition/Weight

Fatter cattle tend to shrink less than cattle that have less body fat. Fat contains less water than lean muscle tissue does, so less metabolic tissue water is lost to shrink. There is a relationship between body weight and fat content, but it is not always strong. Cattle with similar body weights but different body compositions will have different shrink responses.

Season

Higher temperatures induce a greater stress response in cattle, leading to a greater shrink response. When temperatures are high, cattle lose more metabolic water through heavy breathing and higher maintenance energy expenditure than they do in cool conditions. Seasons also affect diet composition and fill associated with diet.

Handling Procedures

Cattle shrink less when they are handled in a quiet manner using good Beef Quality Assurance handling practices. The amount of shrink is also minimized when cattle are shipped directly from the ranch of origin to their final destination. Congregation, comingling of cattle for sorting, overcrowding, and re-shipping add heightened stress and increase shrink in cattle.

Calf Price and Shrink

The outward appearance of the calves at market can affect the final price received for them. Arkansas data indicates that gaunt and shrunken cattle received sale prices that were $3 to $8 higher compared to average fill calves (Barham and Troxel 2007). This happens when the buyer intends to capitalize on the lost weight by providing feed and water to regain body weight in an inexpensive manner. In contrast, calves that were full or very full were discounted $3 to $24 from the base selling price received for average fill calves (Barham and Troxel 2007). Table 2 considers the relationship between the bid prices offered on cattle, the shrink allowed in the negotiation by the buyer, and the actual purchase price of the cattle. Instead of purchasing the cattle on a delivered basis, the buyer may offer a price with a declared pencil shrink percent (a predetermined percent shrink applied to all animals regardless of the actual percent shrink). For example, a buyer may offer an owner $200/cwt with a 4% pencil shrink. According to Table 2, the actual purchase price is $192/cwt for the cattle. Alternatively, cattle owners can decide to market the animals at a sale, then consider the relationship between their asking price for the cattle, the amount of actual shrink that occurs, and the resulting price of the cattle based on the decreased amount of weight that actually sells. In this example, a cattle owner may have wanted $225/cwt; if the cattle actually experienced an 8% shrink while in transit and standing at the sale barn, then the real price actually needs to be $243/cwt to account for the reduction of pounds for sale. Shrink happens. What needs to be determined is who pays for it.

Summary

Shrink in cattle occurs often and has detrimental economic impacts. The cattle owner can mitigate some causes for shrink at the ranch of origin through timing of marketing and animal handling techniques. Failure to consider shrink and the potential outcomes during the marketing process jeopardizes the optimum price point for both the buyer and seller.

References

Barham, B. L., and T. R. Troxel. 2007. "Factors affecting the selling price of feeder cattle sold at Arkansas livestock auctions in 2005." J. Anim. Sci. 85: 3434–3441.

Hersom, M., A. Imler, T. Thrift, J. Yelich, and J. Arthington. 2015. "Comparison of feed additive technologies for preconditioning of weaned beef calves." J. Anim. Sci. 93: 3169–3178.

Tippets, N., I. M. Stevens, C. B. Brotherton, and H. Abel. 1957. "In transit shrinkages of cattle." Wyoming Agri. Exp. St. Mimeograph Circular 75.