The goal of most fish farmers is to maximize production and profits while holding labor and management efforts to the minimum. Risk of fish kills, disease outbreaks, poor water quality, and reduced feed conversion often result when efforts to increase production are unsupported by improved management strategies.

In most pond culture operations, aeration offers the most immediate and practical solution to water quality problems encountered at higher stocking and feeding rates. Aeration may be broadly classified into two different applications, emergency aeration and maintenance aeration.

Emergency Aeration

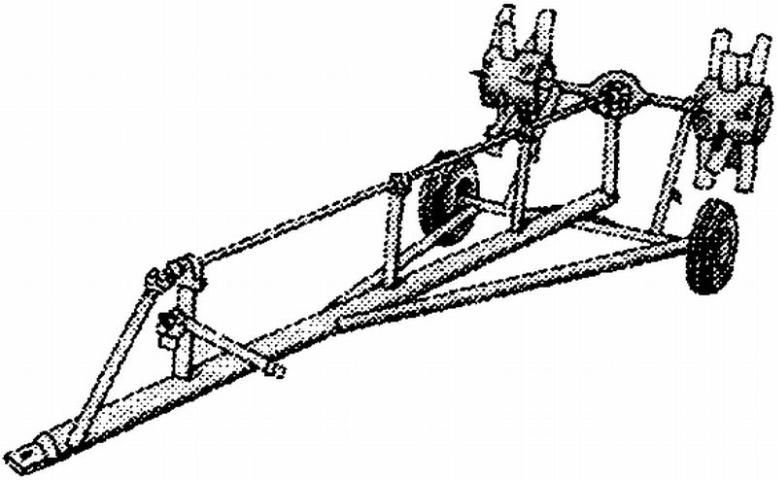

Emergency aeration is commonly practiced in larger ponds of 3 to 20 acres and involves the use of splash or spray type aerators typically powered by tractors, or electric or fuel driven motors. This aeration is used only when dissolved oxygen drops to levels stressful to fish. Inherent in this approach is the need to frequently monitor oxygen in the pond to anticipate when crises may arise. To maximize the efficient use of emergency aeration equipment, it is desirable to only aerate during periods of low oxygen and to be able to move the aerators from pond to pond as needed. The more powerful the aerator the more rapidly the oxygen may be raised to safe levels. Tractor driven paddle wheels are very portable and powerful, hence they are the most widely used type of emergency aerators in large ponds on commercial fish farms (Figure 1).

Stationary emergency aerators, or those which cannot be rapidly moved are often sized to about 1 hp per surface acre of water. Emergency aerators provide a point source of oxygenation and water movement which carries oxygenated water throughout the pond. Fish congregate near aerators during periods of low oxygen until oxygen in the ponds returns to safe levels.

Maintenance Aeration

Maintenance aeration systems are intended to prevent critical low oxygen levels from occurring. Aeration systems of this type typically include a low-pressure high-volume blower, PVC and/or polyethylene distribution pipe, and air releasers. Often small bubble diffusers are used to maximize oxygen transfer from the air stream. Air is released near the pond bottom, aerating and mixing water as it rises to the surface. These systems are relatively energy efficient and, when operated continuously, create and sustain an improved environment for fish production. Total operating costs may be higher for the maintenance systems, but labor cost of oxygen monitoring are reduced, risk due to low oxygen kills minimized, and higher production per acre is often realized. Oxygen maintenance systems usually entail higher purchase and installation costs, but again the benefits realized can offset the initial expense over a relatively short period of time.