This document discusses the meaning of the terms “defoliant” and “desiccant,” their uses, and factors that impact their performance, and also provides a list of registered products for use in Florida. This information is intended for researchers, Extension agents, growers, crop consultants, policy makers, and agricultural professionals to guide decision-making when applying these products. Always check product labels for specific recommendations and precautions prior to using harvest aids.

What are defoliants and desiccants?

Defoliants and desiccants are harvest aid chemicals used to homogenize crop maturity and remove green foliage that may interfere with harvest. Harvest aids can provide greater flexibility of harvest date and/or improve harvest quality by reducing leaf trash. Harvest aids will not generally increase crop yield. They assist the grower to harvest as much of the crop as possible, thereby increasing harvest efficiency, and maintain high quality of harvest.

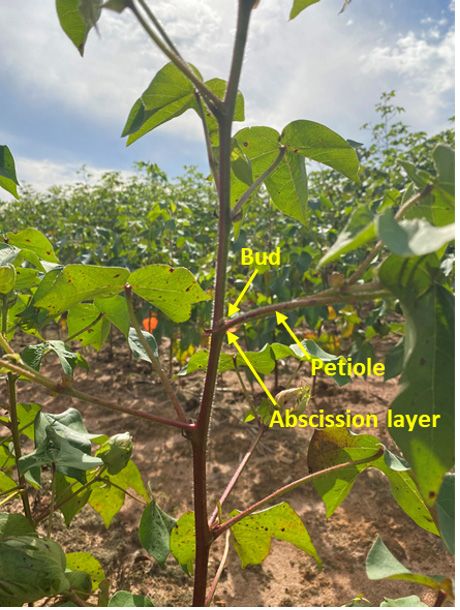

Defoliants and desiccants are regulated as pesticides under the Florida Department of Agriculture and Consumer Services (FDACS). The terms “defoliant” and “desiccant” are often used interchangeably. For purposes of this article, a defoliant is any substance that acts on the abscission layer between the leaf and petiole to assist with leaf drop. Desiccants are defined as chemistries that cause drying of green tissue, and are also used as herbicides for this reason. Both desiccants and defoliants typically result in leaf necrosis, defoliation, or leaf shedding.

Defoliants

Defoliation is the abscission, or shedding, of leaves that occurs naturally after annual plants reach physiological maturity, but may also be induced by frost, disease, insect damage, drought, or mineral deficiency. Defoliation can be induced using chemical defoliants. Defoliants promote the formation of the abscission layer by increasing plant hormonal activity (e.g., ethylene). The abscission layer is the zone where the leaf petiole meets the stem (Figure 1); once formed, leaves drop from the plant.

Credit: J. E. Iboyi, UF/IFAS

What are the benefits of defoliation?

Defoliants are used on grain crops (e.g., soybean) and horticultural crops (e.g., potato), but in Florida, they are commonly used during cotton production for several reasons:

- Fewer leaves result in better lint quality grades because of less leaf staining.

- Leaf removal facilitates air flow and therefore drying of the harvestable portion of the crop.

- Leaf removal reduces insect harborage sites, which can reduce the quality of the crop.

- Decreased lodging of the crop by reducing leaf area during windstorms.

- Reduced moisture content of the crop. In cotton, for instance, moisture content of the seed cotton prior to harvesting needs to be 12% or less to reduce fiber damage and to avoid heating in modules and trailers.

- Faster, more efficient harvest operation.

Limitations

- Increased cost of production.

- Multiple applications may be required.

- Crop quality may be reduced under certain circumstances (for instance, fiber staining from regrowth if harvest is delayed).

- Improper application may result in yield loss.

Desiccants

Desiccants cause green foliage to lose moisture and hasten the drying process that results in leaf removal without the formation of an abscission layer (they generally work more quickly than defoliants). In grain crop production (soybean, canola, or carinata), for example, contaminating plant matter such as weeds and other green plant material at harvest can reduce seed quality (Ellis et al. 1998), ultimately affecting net returns to the grower. Leaving these crops in the field past maturity (for natural drying) and awaiting harvest exposes seed to adverse weather conditions that can reduce seed yield and quality (Boudreaux and Griffin 2008). The use of desiccants can ameliorate these problems. Desiccants are used to improve crop uniformity, desiccate weeds and green tissue, and increase harvest efficiency.

Numerous materials that are applied for weed control are also registered for use as harvest aids. For example, paraquat and diquat dibromide are fast-acting and labeled for control of a wide spectrum of weeds, and have been used as effective harvest aids for many years. These are essentially contact herbicides that are also labeled as harvest aids. Glyphosate products are also commonly used as desiccants or harvest aids for oilseed crops (safflower, sunflower, etc.) and small grain crops (wheat and feed barley).

What are the benefits of desiccation?

Desiccants are commonly used during grain (soybean, canola, or carinata) and tuber (potato) crop production and have several benefits:

- Facilitation of timely harvest and increased harvest efficiency. The potential yield advantage with early-planted grain or tuber crops has been documented (Hu and Wiatrak 2012). However, earlier planting can also lead to increased incidence of green stem and delayed leaf senescence in some varieties after seeds or tubers have reached physiological maturity. Desiccating grain or tuber crops helps resolve these issues.

- Facilitation of late-season weed management in grain or tuber crop production systems. Late-season rains and late or poor canopy closure can result in weedy fields, which can lead to difficulties with harvest if stems and leaves are still green. Although frost may help desiccate weeds, if crops are ready for harvest before weeds have dried down, desiccation can facilitate an efficient harvest.

- Protection of crop quality. For example, in potato production, the presence of green vine material can interfere with harvest operations. Such interference can result in skinning and bruising of tubers. Skinned and bruised tubers will readily discolor and are more predisposed to soft rot. Low-quality tubers lower fresh market value; in some cases, such tubers may be rejected.

Limitations

- Consistency of seed drying may vary depending on environmental conditions, current seed moisture content, adequate spray coverage, etc.

- Increased production cost should be offset by increased harvest quality and speed.

- Crop yield and quality may be reduced if applied improperly.

Application Timing and Crop Maturity

For maximum yield and crop quality, defoliants and desiccants should not be applied until after the crop has reached physiological maturity. It is advantageous to allow the crop as much time as possible to mature because harvest aid products do not speed up the maturity of plants or directly lower seed moisture content.

In grain crops (e.g., soybean, canola, or carinata), monitoring pod and seed development is key to making desiccation decisions. If a desiccant is applied too early before these crops have sufficiently matured, seed weight and yield can be reduced. Applying desiccants too late may cause a delay of harvest, resulting in increased seed shattering prior to or during harvest. Depending on the product used, treat crops 3 to 15 days prior to the anticipated harvest date, according to the label instructions.

In cotton, the proper timing of harvest aid applications is a balance between allowing immature green bolls to mature and preserving the lint quality of mature bolls (Leon et al. 2020). Applying harvest aids too early may halt the development of green bolls that could contribute to yield, and may negatively impact fiber and seed quality. Product labels generally recommend defoliating when 60% to 70% of the bolls are open. However, in some situations, defoliation at this stage may be premature and terminate the development of bolls in the upper canopy, thereby reducing yield. To accurately determine the percent of bolls that are open, measure 5 ft of row in representative areas of the field, count the number of open and closed bolls, and calculate the percent that are open (Mulvaney et al. 2021). Defoliants should be applied 10 to 14 days prior to anticipated harvest dates. If a defoliant is applied properly and under optimal weather conditions, leaf drop should start approximately three to four days after application and be complete within 10 days.

Weather Conditions during and after Application

The efficacy of harvest aid products is greatly affected by weather conditions. Defoliants and desiccants are most active under warm, sunny conditions. An extended period of absorption generally increases plant response to harvest aids. Sunlight intensity, temperature, relative humidity, and wind speed influence the amount of time spray droplets remain on the plant, and ultimately, plant response to harvest aids. When night temperatures rise above 60°F, the rate of leaf drop roughly doubles for each 10°F rise in temperature. Cooler conditions and cloud cover reduce the activity of most defoliants and desiccants, especially when night temperatures fall below 60°F. If desiccants must be applied under cool conditions, higher application rates may be needed, although regrowth is reduced compared to warmer conditions. Temperatures above 80°F reduce the amount of time spray droplets remain on the plant. Relative humidity above 70% allows a droplet twice as much time on the plant as relative humidity below 30%. Although mild wind may improve the distribution of harvest aids throughout the plant canopy, high wind speeds increase evaporation, thereby reducing droplet contact time with the leaf. For best results, at least one full day of clear weather after application is recommended. Avoid spraying harvest aids on windy days to reduce drift to nontarget vegetation.

Regrowth following application of harvest aids should be considered. As a rule of thumb, do not treat more acreage than can be harvested within a reasonable length of time. Rain, equipment breakdowns, and other unexpected circumstances that delay harvest will often result in regrowth. A few harvest aids also provide control or suppression of regrowth.

Crop Condition at Time of Application

Plants may thicken cuticles and develop leathery leaves in response to drought stress. This can inhibit uptake of many harvest aids. In such scenarios, higher rates of harvest aids may be needed.

In cotton, the potential for regrowth can be high due to residual nitrogen remaining after cutout (Reynolds et al. 2016). Rank cotton may present a problem for adequate spray coverage, making defoliation of cotton challenging. In this scenario, do not increase rates in an effort to achieve better defoliation, because increased rates are likely to cause leaf desiccation at the top of the plant where most of the spray is intercepted. Consider making two applications at normal rates. The first application is intended to remove as much foliage as possible to expose unopened bolls. The second application (with boll opener added) is used to remove lower canopy leaves, and more importantly, to stimulate boll opening.

Application or Spray Coverage

This is particularly important because most harvest aid chemicals are not readily translocated within the plant. Each leaf that is to be removed or desiccated must receive some spray. Choose a fine droplet-producing nozzle to provide uniform coverage. Nozzle types, tank pressure, spray volume, and ground speed should be matched appropriately to achieve the desired spray volume as recommended on the product label. Likewise, make sure to calibrate the sprayer properly to deliver the desired spray output for uniform coverage.

Table 1 lists commonly used defoliant/desiccant materials registered for use in Florida along with some example trade names.

Table 1. Materials registered for use as defoliants/desiccants in Florida with example trade names.

Summary

The application of the chemicals in Table 1 can be used to desiccate and/or defoliate aboveground plant tissues to improve harvest efficiency. Likewise, some of these products, which are herbicides, can be helpful to manage late-season weeds that could interfere with harvest efficiency. Application timing, crop maturity, weather conditions, crop condition, and application coverage are factors that can impact their performance and harvest efficiency. Always check product labels prior to use for specific recommendations and precautions.

References

Boudreaux, J. M., and J. L. Griffin. 2008. “Harvest Aids in Indeterminate and Determinate Soybeans – Application Timing and Value.” Louisiana Agriculture 51:26–27.

Ellis, J. M., D. R. Shaw, and W. L. Barrentine. 1998. “Soybean (Glycine max) Seed Quality and Harvesting Efficiency as Affected by Low Weed Densities.” Weed Technology 12:166–173.

Hu, M., and P. Wiatrak. 2012. “Effect of Planting Date on Soybean Growth, Yield, and Grain Quality: Review.” Agronomy Journal 104:785–790.

Leon, R. G., D. L. Wright, and B. J. Brecke. 2020. 2020 Cotton Defoliation and Harvest Aid Guide. SS-AGR-181. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/publication/ag188

Mulvaney, M. J., E. Brooks, P. Devkota, E. Carter, D. Broughton, M. Mauldin, J. E. Iboyi, M. Bashyal, D. Wright, and I. Small. 2021. Estimating Cotton Yield. SS-AGR-450. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/publication/ag450

Reynolds, D. B., L. T. Barber, and T. B. Raper. 2016. “2016 Mid-South Cotton Defoliation Guide.” https://news.utcrops.com/wp-content/uploads/2016/09/2016-MidSouth-Cotton-Defoliation-Guide.pdf