Introduction

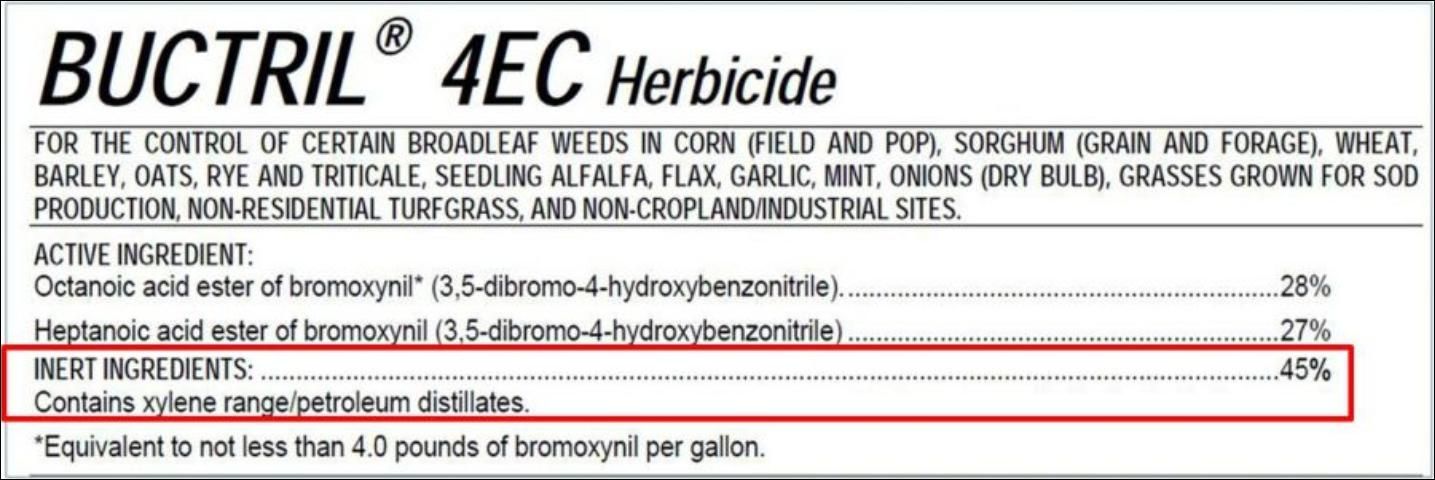

Pesticide chemicals in their "raw" or unformulated state are not usually suitable for pest control. These concentrated chemicals and active ingredients may not mix well with water, may be chemically unstable, and may be difficult to handle and transport. For these reasons, manufacturers add inert substances, such as clays and solvents, to improve application effectiveness, safety, handling, and storage. Inert ingredients do not possess pesticidal activity and are added to serve as a carrier for the active ingredient. Manufacturers will list the percentage of inert ingredients in the formulation or designate them as "other ingredients" on their labels. There are several inert substances, such as petroleum distillates and xylene, which will have a specific statement identifying their presence in the formulation (Figure 1). The mixture of active and inert ingredients is called a pesticide formulation. This formulation may consist of:

- The pesticide active ingredient that controls the target pest

- The carrier, such as an organic solvent or mineral clay

- Adjuvants, such as stickers and spreaders

- Other ingredients, such as stabilizers, safeners, dyes, and chemicals that improve or enhance pesticidal activity

Credit: CDMS.

Usually you need to mix a formulated product with water or oil for final application. Most baits, granules, gels, and dusts, however, are ready for use without additional dilution. Manufacturers package many specialized pesticides, such as products for households, in ready-to-use formulations (Figure 2).

Credit: UF/IFAS Pesticide Information Office.

A single active ingredient often is sold in several kinds of formulations. Abbreviations are frequently used to describe the formulation (e.g., WP for wettable powders); how the pesticide is used (e.g., TC for termiticide concentrate); or the characteristics of the formulation (e.g., ULV for an ultra-low-volume formulation). Common abbreviations and their interpretations are listed in Table 1. The amount of active ingredient (a.i.) and the kind of formulation are listed on the product label. For example, an 80% SP contains 80 percent by weight of active ingredient and is a "soluble powder." If it is in a 10-pound bag, it contains 8 pounds of a.i. and 2 pounds of inert ingredient. Liquid formulations indicate the amount of a.i. in pounds per gallon. For example, 1E means 1 pound, and 4E means 4 pounds of the a.i. per gallon in an emulsifiable concentrate formulation (Figure 3).

Credit: UF/IFAS Pesticide Information Office.

If you find that more than one formulation is available for your pest control situation, you should choose the best one for the job. Before you make the choice, ask several questions about each formulation. For example:

- Do I have the necessary application equipment?

- Can the formulation be applied appropriately under the conditions in the application area?

- Will the formulation reach the target and stay in place long enough to control the pest?

- Is the formulation likely to damage the surface to which you will apply it?

- Could I choose a less hazardous formulation that would still be as effective?

To answer these kinds of questions, you need to know something about the characteristics of different types of formulations and the general advantages and disadvantages of each type.

Liquid Formulations

Liquid formulations are generally mixed with water, but in some instances labels may permit the use of crop oil, diesel fuel, kerosene, or some other light oil as a carrier. This section will present more detailed information about the common liquid pesticide formulations.

Emulsifiable Concentrates (EC or E)

An emulsifiable concentrate formulation usually contains a liquid active ingredient, one or more petroleum-based solvents (which give EC formulations their strong odor), and an agent—known as an emulsifier—that allows the formulation to be mixed with water to form an emulsion. Upon mixing with water, they take on a "milky" appearance (Figure 4).

Credit: IFAS Communication Services.

Most ECs contain between 25% and 75% (2–8 pounds) active ingredient per gallon. ECs are among the most versatile formulations. They are used against agricultural, ornamental and turf, forestry, structural, food processing, livestock, and public health pests. They are adaptable to many types of application equipment including portable sprayers, hydraulic sprayers, low-volume ground sprayers, mist blowers, and low-volume aircraft sprayers. Advantages of emulsifiable concentrates include:

- Relatively easy to handle, transport, and store

- Little agitation required; will not settle out or separate when equipment is running

- Not abrasive

- Will not plug screens or nozzles

- Little visible residue on treated surfaces

Their disadvantages:

- High a.i. concentration makes it easy to overdose or underdose through mixing or calibration errors

- Easily absorbed through skin of humans or animals

- Solvents may cause rubber or plastic hoses, gaskets, and pump parts and surfaces to deteriorate

- May cause pitting or discoloration of painted finishes

- Flammable—should be used and stored away from heat or open flame

- May be corrosive

Solutions (S)

Some pesticide active ingredients dissolve readily in a liquid carrier, such as water or a petroleum-based solvent. When mixed with the carrier, they form a solution that does not settle out or separate (Figure 5). Formulations of these pesticides usually contain the active ingredient, the carrier, and one or more other ingredients.

Credit: IFAS Communication Services.

Ready-to-Use Low Concentration Solutions (RTU)

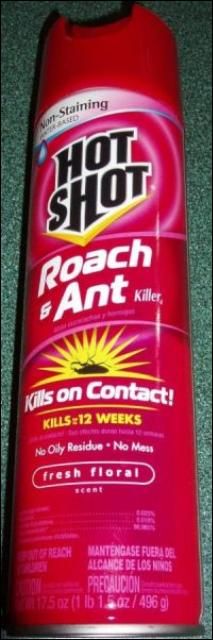

Low-concentrate RTU formulations are ready to use and require no further dilution before application (Figure 6). They consist of a small amount of active ingredient (often 1% or less per unit volume) dissolved in an organic solvent. They usually do not stain fabrics nor have unpleasant odors. They are especially useful for structural and institutional pests and for household use. Major disadvantages of low-concentrate formulations include limited availability and high cost per unit of active ingredient.

Credit: UF/IFAS Pesticide Information Office.

Ultra-Low Volume (ULV)

These concentrates may approach 100% active ingredient. They are designed to be used "as is" or to be diluted with only small quantities of a specified carrier. They are used at rates of no more than 1/2 gallon per acre. These special purpose formulations are used mostly in outdoor applications, such as in agricultural, forestry, ornamental, and mosquito control programs. Advantages of ultra-low-volume formulations include:

- Relatively easy to transport and store

- Remain in solution; little agitation required

- Not abrasive to equipment

- Will not plug screens and nozzles

- Leave little visible residue on treated surfaces

Their disadvantages:

- Difficult to keep pesticide on target—high drift hazard

- Specialized equipment required

- Easily absorbed through skin of humans or animals

- Solvents may cause rubber or plastic hoses, gaskets, and pump parts and surfaces to deteriorate

- Calibration and application must be done very carefully because of the high concentration of active ingredient

Invert Emulsions

An invert emulsion contains a water-soluble pesticide dispersed in an oil carrier. Invert emulsions require a special kind of emulsifier that allows the pesticide to be mixed with a large volume of petroleum-based carrier, usually fuel oil. Invert emulsions aid in reducing drift. With other formulations, some spray drift results when water droplets begin to evaporate before reaching target surfaces; as a result, the droplets become very small and light. Because oil evaporates more slowly than water, invert emulsion droplets shrink less; therefore, more pesticide reaches the target. The oil helps to reduce runoff and improves rain resistance. It also serves as a sticker-spreader by improving surface coverage and absorption. Because droplets are relatively large and heavy, it is difficult to get thorough coverage on the undersides of foliage. Invert emulsions are most commonly used along rights-of-way where drift to susceptible nontarget plants or sensitive areas can be a problem (Figure 7).

Credit: UF/IFAS Agronomy Dept.

Flowables (F)/Liquids (L)

A flowable or liquid formulation combines many of the characteristics of emulsifiable concentrates and wettable powders. Manufacturers use these formulations when the active ingredient is a solid that does not dissolve in either water or oil. The active ingredient, impregnated on a substance such as clay, is ground to a very fine powder. The powder is then suspended in a small amount of liquid. The resulting liquid product is quite thick (Figure 8). Flowables and liquids share many of the features of emulsifiable concentrates, and they have similar disadvantages. They require moderate agitation to keep them in suspension and leave visible residues similar to those of wettable powders. Flowables/liquids are easy to handle and apply. Because they are liquids, they are subject to spilling and splashing. They contain solid particles, so they contribute to abrasive wear of nozzles and pumps. Flowable and liquid suspensions settle out in their containers. Always shake them thoroughly before pouring and mixing. Because flowable and liquid formulations tend to settle, manufacturers package them in containers of 5 gallons or less to make remixing easier.

Credit: UF/IFAS Communication Services.

Aerosols (A)

These formulations contain one or more active ingredients and a solvent. Most aerosols contain a low percentage of active ingredients. There are two types of aerosol formulations: the ready-to-use type commonly available in pressurized, sealed containers and those products used in electric- or gasoline-powered aerosol generators that release the formulation as a "smoke" or "fog."

Ready-to-use aerosols are usually small, self-contained units that release the pesticide when the nozzle valve is triggered (Figure 9). The pesticide is driven through a fine opening by an inert gas under pressure, creating fine droplets. These products are used in greenhouses, in small areas inside buildings, or in localized outdoor areas. Commercial models, which hold 5–10 pounds of pesticide, are usually refillable. Their advantages include:

- Ready to use

- Portable

- Easily stored

- Convenient way to buy a small amount of a pesticide

- Retain potency over fairly long time

Their disadvantages:

- Practical for only very limited uses

- Risk of inhalation injury

- Hazardous if punctured, overheated, or used near an open flame

- Difficult to confine to target site or pest

Credit: UF/IFAS Pesticide Information Office.

Formulations for smoke or fog generators are aerosol formulations but not under pressure. They are used in machines that break the liquid formulation into a fine mist or fog (aerosol) using a rapidly whirling disk or heated surface. These formulations are used mainly for insect control in structures such as greenhouses and warehouses and for mosquito and biting fly control outdoors. Their advantages include:

- Easy way to fill entire enclosed space with pesticide

Their disadvantages:

- Highly specialized use and associated equipment

- Difficult to confine to target site or pest

- May require respiratory protection to prevent risk of inhalation injury

Liquid Baits

An increasing number of insecticides and rodenticides are being formulated as liquid baits. Liquid rodenticides are mixed with water and placed in bait stations designed for these products. They have two major benefits. Liquid rodenticides are effective in controlling rodents, especially rats, in areas where they cannot find water. They are also effective in areas of poor sanitation where readily available food renders traditional baits ineffective.

Liquid insecticide baits are used primarily by the structural pest control industry for controlling ants and, to a lesser extent, cockroaches. They are packaged as ready-to-use, sugar-based liquids placed inside bait stations. Liquid insecticide ant baits have a number of advantages. They are very effective against certain species of sugar-feeding ants. These ants typically accept and transfer liquid baits into the ant colonies. However, some ants will not feed on liquid baits. Liquid baits also must be replaced often.

Dry or Solid Formulations

Dry formulations can be divided into two types: ready-to-use and concentrates that must be mixed with water to be applied as a spray. This section will present more detailed information about the common dry or solid pesticide formulations.

Dusts (D)

Most dust formulations are ready to use and contain a low percentage of active ingredients (usually 10% or less by weight), plus a very fine, dry inert carrier made from talc, chalk, clay, nut hulls, or volcanic ash. The size of individual dust particles varies.

A few dust formulations are concentrates and contain a high percentage of active ingredients. These concentrates are mixed with dry inert carriers before applying.

Dusts are always used dry and can easily drift to nontarget sites. They are widely used as seed treatments and sometimes for agricultural applications. In structures, dust formulations are used in cracks and crevices and for spot treatments to control insects such as cockroaches. Insects ingest poisonous dusts during grooming or absorb the dusts through their outer body covering. Dusts also are used to control lice, fleas, and other parasites on pets and livestock. Advantages of dust formulations include:

- Most are ready to use, with no mixing

- Effective where moisture from a spray might cause damage

- Require simple equipment

- Effective in hard-to-reach indoor areas

Their disadvantages:

- Easily drift off target during application

- Residue easily moved off target by air movement or water

- May irritate eyes, nose, throat, and skin

- Will not stick to surfaces as well as liquids

- Dampness can cause clogging and lumping

- Difficult to get an even distribution of particles on surfaces

Special dusts, known as tracking powders, are used for monitoring and controlling rodents and insects. For rodent control, the tracking powder consists of finely ground dust combined with a stomach poison. Rodents walk through the dust, pick it up on their feet and fur, and ingest it when they clean themselves. Tracking powders are useful when bait acceptance is poor because of an abundant, readily available food supply. Nontoxic powders, such as talc or flour, often are used to monitor and track the activity of rodents in buildings.

Baits (B)

A bait formulation is an active ingredient mixed with food or another attractive substance. The bait either attracts the pests or is placed where the pests will find it. Federal regulations require that certain rodenticide baits must be contained in tamper-resistant bait stations (Figure 10). Pests are killed by eating the bait that contains the pesticide. The amount of active ingredient in most bait formulations is quite low, usually less than 5%.

Credit: UF/IFAS Pesticide Information Office.

Baits are used inside buildings to control ants, roaches, flies, other insects, and rodents. Outdoors they sometimes are used to control snails, slugs, and insects such as ants and termites. Their main use is for control of vertebrate pests such as rodents, other mammals, and birds. Advantages of baits include:

- Ready to use

- Entire area need not be covered because pest goes to bait

- Control pests that move in and out of an area

Their disadvantages:

- Can be attractive to children and pets

- May kill domestic animals and nontarget wildlife outdoors

- Pest may prefer the crop or other food to the bait

- Dead vertebrate pests may cause odor problem

- Other animals may be poisoned as a result of feeding on the poisoned pests

- If baits are not removed when the pesticide becomes ineffective, they may serve as a food supply for the target pest or other pests

- Laws require that outdoor, above-ground placement of certain rodenticide bait products be contained in tamper-resistant bait stations

Pastes and gels are mainly used in the pest control industry for ants and cockroaches. Insecticides formulated as pastes and gels are now the primary formulations used in cockroach control. They are designed to be injected or placed as either a bead or dot inside small cracks and crevices of building elements where insects tend to hide or travel. Two basic types of tools are used to apply pastes and gels: syringes and bait guns. The applicator forces the bait out of the tip of the device by applying pressure to a plunger or trigger.

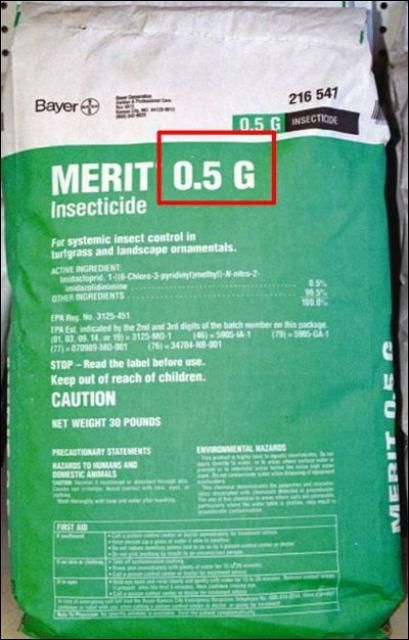

Granules (G)

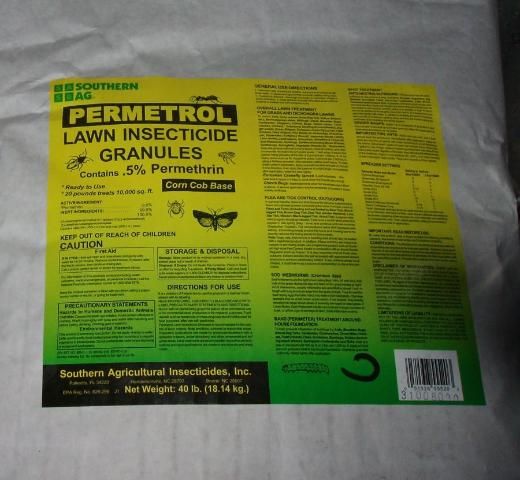

Granular formulations are similar to dust formulations except granular particles are larger and heavier (Figure 11). The coarse particles are made from materials such as clay, corncobs, or walnut shells. The active ingredient either coats the outside of the granules or is absorbed into them. The amount of active ingredient is relatively low, usually ranging from less than 1 to 15 percent by weight (Figure 12).

Credit: UF/IFAS Communication Services.

Credit: UF/IFAS Pesticide Information Office.

Granular pesticides are most often used to apply chemicals to the soil to control weeds, fire ants, nematodes, and insects living in the soil or for absorption into plants through the roots (Figure 13). Granular formulations are sometimes applied by airplane or helicopter to minimize drift or to penetrate dense vegetation. Once applied, granules release the active ingredient slowly. Some granules require soil moisture to release the active ingredient. Granular formulations also are used to control larval mosquitoes and other aquatic pests. Granules are used in agricultural, structural, ornamental, turf, aquatic, right-of-way, and public health (biting insect) pest control operations.

Credit: UF/IFAS Pesticide Information Office.

Advantages of granular formulations include:

- Ready to use, no mixing

- Drift hazard is low, and particles settle quickly

- Little hazard to applicator; no spray, little dust

- Weight carries the formulation through foliage to soil or water target

- Simple application equipment needed, such as seeders or fertilizer spreaders

- May break down more slowly than WPs or ECs because of a slow-release coating

Their disadvantages:

- Often difficult to calibrate equipment and apply uniformly

- Will not stick to foliage or other uneven surfaces

- May need to be incorporated into soil or planting medium

- May need moisture to activate pesticide

- May be hazardous to nontarget species, especially waterfowl and other birds that mistakenly feed on the seed-like granules

- May not be effective under drought conditions because the active ingredient is not released in sufficient quantity to control the pest

Pellets (P or PS)

Most pellet formulations are very similar to granular formulations; the terms often are used interchangeably. In a pellet formulation, however, all the particles are the same weight and shape (Figure 14). The uniformity of the particles allows use with precision application equipment. A few fumigants are formulated as pellets; some may be referred to as tablets (Figure 15). However, these are clearly labeled as fumigants. Do not confuse them with nonfumigant pellets.

Credit: UF/IFAS Pesticide Information Office.

Wettable Powders (WP or W)

Wettable powders are dry, finely ground formulations that look like dusts (Figure 16). They usually must be mixed with water for application as a spray. A few products, however, may be applied either as a dust or as a wettable powder; the choice is left to the applicator. Wettable powders contain 5%–95% active ingredient by weight, usually 50% or more. The particles do not dissolve in water. They settle out quickly unless constantly agitated to keep them suspended. Wettable powders are one of the most widely used pesticide formulations. They can be used for most pest problems and in most types of spray equipment where agitation is possible. Wettable powders have excellent residual activity. Because of their physical properties, most of the pesticide remains on the surface of treated porous materials such as concrete, plaster, and untreated wood. In such cases, only the water penetrates the material.

Credit: UF/IFAS Communication Services.

Advantages of wettable powders include:

- Easy to store, transport, and handle

- Less likely than ECs and other petroleum-based pesticides to cause unwanted harm to treated plants, animals, and surfaces

- Easily measured and mixed

- Less skin and eye absorption than ECs and other liquid formulations

Their disadvantages:

- Inhalation hazard to applicator while measuring and mixing the concentrated powder

- Require good and constant agitation (usually mechanical) in the spray tank or will quickly settle out if the agitator is turned off

- Abrasive to many pumps and nozzles, causing them to wear out quickly

- Difficult to mix in very hard, alkaline water

- Often clog nozzles and screens

- Residues may be visible on treated surfaces

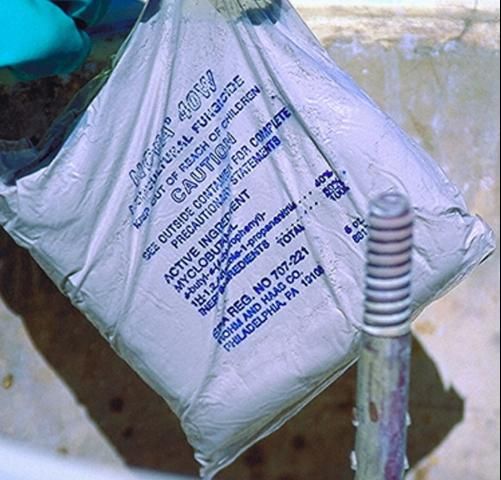

Soluble Powders (SP or WSP)

Soluble powder formulations look like wettable powders. However, when mixed with water, soluble powders dissolve readily and form a true solution. After they are mixed thoroughly, no additional agitation is necessary. The amount of active ingredient in soluble powders ranges from 15% to 95% by weight; it usually is more than 50%. Soluble powders have all the advantages of wettable powders and none of the disadvantages except the inhalation hazard during mixing. Few pesticides are available in this formulation because few active ingredients are readily soluble in water.

Water-Dispersible Granules (WDG) or Dry Flowables (DF)

Water-dispersible granules, also known as dry flowables, are like wettable powders except instead of being dustlike, they are formulated as small, easily measured granules (Figure 17). Water-dispersible granules must be mixed with water to be applied. Once in water, the granules break apart into fine particles similar to wettable powders. The formulation requires constant agitation to keep them suspended in water. The percentage of active ingredient is high, often as much as 90 percent by weight. Water-dispersible granules share many of the same advantages and disadvantages of wettable powders except:

- They are more easily measured and mixed

- Because of low dust, they cause less inhalation hazard to the applicator during handling

Credit: UF/IFAS Communication Services.

Other Formulations

Other formulations include chemicals that cannot be clearly classified as liquid or as dry/solid pesticide formulations.

Microencapsulated Materials (M or ME)

Manufacturers cover liquid or dry pesticide particles in a plastic coating to produce a microencapsulated formulation. Microencapsulated pesticides are mixed with water and sprayed in the same manner as other sprayable formulations. After spraying, the plastic coating breaks down and slowly releases the active ingredient. Microencapsulated materials have several advantages:

- Highly toxic materials are safer for applicators to mix and apply

- Delayed or slow release of the active ingredient prolongs its effectiveness, allowing for fewer and less precisely timed applications

- The pesticide volatilizes more slowly; less is lost from the application site

In residential, industrial, and institutional applications, microencapsulated formulations offer several advantages. These include reduced odor, the release of small quantities of pesticide over a long time, and greater safety. Microencapsulated materials offer fewer hazards to the skin than ordinary formulations. Microencapsulated materials, however, pose a special hazard to bees. Foraging bees may carry microencapsulated materials back to their hives because they are about the same size as pollen grains. As the capsules break down, they release the pesticide, poisoning the adults and brood.

Breakdown of the microencapsulated materials to release the pesticide sometimes depends on weather conditions. Under certain conditions, the microencapsulated materials may break down more slowly than expected. This could leave higher residues of pesticide active ingredient in treated areas beyond normal restricted-entry or harvest intervals with the potential to injure fieldworkers. For this reason, regulations require long restricted-entry intervals for some microencapsulated formulations.

Water-Soluble Packets (WSB or WSP)

Water-soluble packets reduce the mixing and handling hazards of some highly toxic pesticides (Figure 18). Manufacturers package precise amounts of wettable powder or soluble powder formulations in a special type of plastic bag. When you drop these bags into a filled spray tank, they dissolve and release their contents to mix with the water. There are no risks of inhaling or contacting the undiluted pesticide as long as you do not open the packets. Once mixed with water, however, pesticides packaged in water-soluble packets are no safer than other diluted pesticides.

Credit: Virginia Tech Pesticide Programs.

Attractants

Attractants include pheromones, sugar and protein syrups, yeasts, and rotting meat. Pest managers use these attractants in various types of traps (Figure 19). Attractants also can be combined with pesticides and sprayed onto foliage or other items in the treatment area.

Credit: UF/IFAS Pesticide Information Office.

Impregnated Products

Manufacturers impregnate (saturate) pet collars, livestock ear tags, adhesive tapes, plastic pest strips, and other products with pesticides (Figure 20). These pesticides evaporate over time, and the vapors provide control of nearby pests. Some paints and wood finishes have pesticides incorporated into them to kill insects or retard fungal growth. Fertilizers also may be impregnated with pesticides.

Credit: UF/IFAS Pesticide Information Office.

Repellents

Various types of insect repellents are available in aerosol and lotion formulations. People apply these to their skin or clothing or to plant foliage to repel biting and nuisance insects. You can mix other types of repellents with water and spray them onto ornamental plants and agricultural crops to prevent damage from deer, dogs, and other animals.

Animal Systemics

Systemic pesticides protect animals against fleas and other external blood-feeding insects as well as against worms and other internal parasites. A systemic animal pesticide is one that is absorbed and moves within the animal. These pesticides enter the animal's tissues after being applied orally or externally. Oral applications include food additives and premeasured capsules and liquids. External applications involve pour-on liquids, liquid sprays, and dusts. Most animal systemics are used under the supervision of veterinarians.

Pesticide/Fertilizer Combinations

Pest managers frequently use insecticides, fungicides, and herbicides in combination with fertilizers. This provides a convenient way of controlling pests while fertilizing crops or lawns. Homeowners commonly use these combinations, although the unit cost of pesticide in these formulations is usually high. Dealers or growers often custom-mix pesticides with fertilizers to meet specific crop requirements.

Fumigants

Fumigants are pesticides that form gases or vapors toxic to plants, animals, and microorganisms. Some active ingredients are formulated, packaged, and released as gases (Figure 21); others are liquids when packaged under high pressure and change to gases when they are released. Other active ingredients are volatile liquids when enclosed in an ordinary container and, therefore, are not formulated under pressure. Others are solids that release gases when applied under conditions of high humidity or in the presence of water vapor. Fumigants are used for structural pest control, in food and grain storage facilities, and in regulatory pest control at ports of entry and at state and national borders (Figure 22). In agricultural pest control, fumigants are used in soil, greenhouses, granaries, and grain bins (Figure 23).

Credit: UF/IFAS Pesticide Information Office.

Credit: UF/IFAS Pesticide Information Office.

Credit: UF/IFAS Pesticide Information Office.

Advantages of fumigants:

- Toxic to a wide range of pests

- Can penetrate cracks, crevices, wood, and tightly packed areas such as soil or stored grains

- Single treatment usually kills most pests in treated area

Disadvantages of fumigants:

- The target site must be enclosed or covered to prevent the gas from escaping

- Nonspecific in that they are highly toxic to humans and all other living organisms

- Require the use of specialized protective equipment, including respirators specifically approved for use with fumigants

- Require the use of specialized application equipment

Adjuvants

Adjuvants are substances used with a pesticide to enhance performance. By themselves, they do not possess pesticidal activity. Adjuvants may be added to the product at the time of formulation or by the applicator to the spray mix just prior to treatment. Adjuvants include surfactants, compatibility agents, antifoaming agents and spray colorants (dyes), and drift control agents.

Much of the confusion surrounding adjuvants can be attributed to the lack of understanding of adjuvant terminology. For example, many people use the terms adjuvant and surfactant interchangeably. These terms can refer to the same product because all surfactants are adjuvants. However, not all adjuvants are surfactants.

Care should be taken when selecting an adjuvant. Pesticide performance can differ depending on what type of adjuvant is used. The pesticide label will state if specific surfactants are required and the amount (%) of active ingredient it must contain.

Conclusion

In summary, the pesticide user must consider several factors when selecting a pesticide formulation, such as the risks associated with the formulation type, the practicality of using the formulation on the target site or pest, and whether it will provide effective control. Having a basic understanding of formulation types before using pesticides helps the user avoid mistakes and accidents in choosing, mixing, loading, and applying the product.

Glossary

Abrasive: Capable of wearing away or grinding down another object.

Active ingredient (a.i.): The substance in a pesticide product that is intended to kill, repel, or otherwise control a target pest.

Adjuvant: Chemical that is either premixed in the pesticide formulation or added to the spray tank to improve mixing, application or to enhance pesticidal activity.

Carrier: The primary material used to allow a pesticide to be dispersed effectively. For example, talc in a dust formulation.

Diluent: Anything used to dilute a pesticide.

Emulsifier: Agent that helps to prevent an emulsion from separating.

Emulsion: A mixture of two or more liquids that is not soluble in one another. For example, oil droplets dispersed in water.

Formulation: A mixture of active ingredient combined during manufacture with inert ingredients.

Inert ingredients: All materials in the pesticide formulation other than the active ingredient. They are added to dilute the pesticide or to make it safer, more effective, and easier to measure, mix, apply, and handle. Some inert ingredients may be toxic or hazardous to people.

Insoluble: Does not dissolve in liquid.

Phytotoxicity: Injury to plants.

Soluble: Able to dissolve in another substance, usually a liquid.

Solvent: A liquid, such as water, kerosene, xylene, or alcohol, that will dissolve a pesticide to form a solution.

Suspension: A substance that contains undissolved particles mixed throughout a liquid.

Volatile: Evaporating rapidly; turning easily into a gas or vapor.

Additional Information

Fishel, F. M. 2011. What are inert ingredients? PI-44. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/pi081. Visited January 2013.