Chemical ripeners for sugarcane have been studied since the 1920s. Ripeners hasten plant maturity and prolong the period of maximum stalk sucrose concentration. Ripeners typically inhibit apical meristem growth. Presumably, this allows energy ordinarily used for vegetative growth to be diverted to the manufacturing and storing of sucrose.

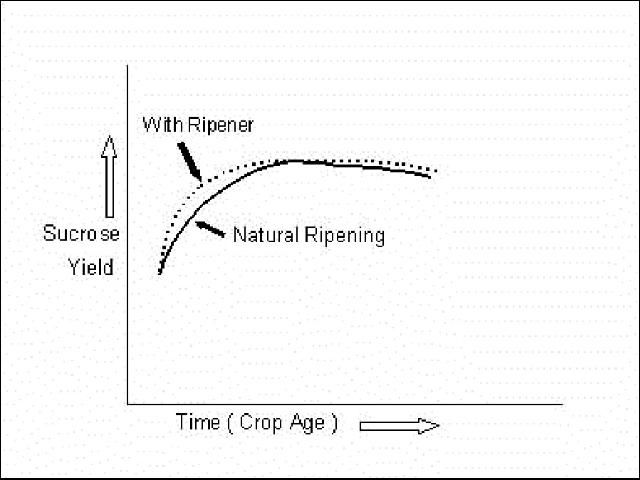

Since ripeners simply accelerate the natural ripening process, ripeners should not be expected to increase the sucrose content of sugarcane beyond the optimum obtainable through natural ripening (Figure 1). Ripener action is highly variable. The most important factors to consider are the sugarcane variety, climate (temperature and moisture conditions), and timing of ripener application in relation to expected harvest.

Ripeners can be incorporated as an important component of sugarcane production management strategy. Natural ripening is induced by low temperatures, water stress, nutrient stress, and a shortening of day length. Natural ripening is usually limited during the early portion of the Florida sugarcane harvest season because of plentiful soil moisture, high levels of plant-available nitrogen, and warm temperatures. Thus, chemical ripening is most effective in sugarcane scheduled for harvest in October and November.

Labeled Ripeners

The products registered for use as a sugarcane ripener in Florida include Roundup WeatherMax, Roundup PowerMax, Roundup PowerMax II, Touchdown HiTech, Touch down Total, and Touchdown CT2. Glyphosate, the active ingredient in these products, has been shown to stimulate sucrose accumulation in sugarcane when applied at sub-lethal rates. In Florida, glyphosate can only be applied to the "last ratoon cane." Use on earlier crops may result in decreased stands in the successive ratoon crops. Roundup WeatherMax, Roundup PowerMax, and Roundup PowerMax II at 5–12 fl oz per acre (0.2–0.4 lbs ae/acre) may be applied 3–5 weeks prior to harvest. Touch- down HiTech should be applied 3–6 weeks prior to harvest at 4–11 fl oz per acre (0.2–0.4 lbs ae/acre). Touchdown Total and Touchdown CT2 should be applied at 4.8–13.4 fl oz per acre (0.2–0.4 lbs ae/acre) 3–6 weeks prior to harvest. Total canopy coverage is important. Avoid drift of either product to non-targeted cane or crops. It is critical to avoid newly planted or freshly cut cane since inadvertent treatment may result in poor stands.

Trinexapac-ethyl, the active ingredient in Moddus, can also be used for sugarcane ripening in Florida. Moddus at 11–19 fl oz per acre (0.2–0.3 lbs ai/acre) can be applied 28–60 days prior to harvest to increase sugar content and/or extend the harvest window. Unlike glyphosate products, which are only applied on the last ratoon in Florida, Moddus can be applied on plane cane to the last ratoon.

Expected Results

When applied as directed, these products will enhance ripening and extend the period of high sucrose in responsive varieties. However, weather conditions may have a dramatic effect on expressed results. For example, rainfall within 6 hours of application has been shown to reduce effectiveness of glyphosate.

Within 2–3 weeks after application, the glyphosate may produce slight yellowing to pronounced browning ("burning") of the leaves. Shortening of the upper internodes and spindle death may also occur. As a result of leaf desiccation, an improved trash burn at harvest may be expected.

Most of the enhanced sucrose content will be concentrated in the top of the treated cane stalk. In order to recover maximum sugar at harvest, the stalk should be topped no lower than the base of the fourth leaf.

It is important to follow a harvest schedule adjusted to the variety and amount of ripener applied. Higher ripener application rates require an earlier harvest (e.g., 3 weeks after application) than sugarcane treated with lighter applications.