The purpose of this publication is to inform farmers and Extension agents about types of anaerobic digester systems used in the United States with various manure-handling systems. We point out digester systems currently being used in Florida and the benefits of managing livestock manure with a digester system.

Introduction

Livestock wastes can be important sources of nutrients for crops, but manure must be managed properly to prevent loss of nutrients to the environment in air or ground and/or surface water. Stabilization of manure is important prior to successfully recycling the organic material back to arable lands.

Methods for stabilizing livestock wastes include composting, aerobic digestion, anaerobic digestion, lime stabilization, and heat drying. The stabilization process reduces the organic matter and water contents, unpleasant odors, concentrations of pathogenic microorganisms, and weed seeds. Anaerobic digestion (AD), which is the topic of this fact sheet, also results in the production of renewable energy in the form of methane-rich biogas.

Using an anaerobic digester on farms helps producers adopt sustainable and environmentally sound agricultural practices in livestock production systems and integrated farms. According to the US Environmental Protection Agency (2014a), there were approximately 239 anaerobic digester systems for livestock manure operating in the United States as of January 2014. An integrated crop-livestock farm is a farm where crops are produced for sale off the farm; some portions of crop also go to feed the livestock unit on the same farm, and the resulting manure nutrients are cycled back to the crop production system.

Waste generated from the livestock unit is processed through anaerobic digesters, and anaerobically digested solids (ADS) and liquid effluents (ADL) are recycled back to fields. The nutrients in the ADS and ADL supplement crop-nutrient needs (e.g., nitrogen (N) and phosphorus (P)). Another product of the digestion process is methane gas (biogas) that can be burned in an engine generator system to produce electricity to be used on the farm or sold to the power grid. The biogas can also be burned for heating water or the farm buildings.

What Is anaerobic digestion?

Anaerobic digestion of organic waste is a microbe-mediated process carried out in the absence of oxygen that breaks complex organic compounds in the manure into simpler compounds. The process produces biogas, which is a mixture of methane (CH4) (60% to 70%), carbon dioxide (CO2) (30% to 40%), and a number of other gases in trace amounts. Stabilized organic products in the form of ADS and ADL are also produced. The stabilized products have altered physical and chemical properties compared with the original manure, and they contain higher mineralized fractions of N and P (Field et al., 1984; Larsen, 1986; Plaixats et al., 1988).

The digestion can be carried out at psychrophilic (15°C to 25°C or 59°F to 77°F), mesophilic (30°C to 38°C or 86°F to 100°F), or thermophilic (50°C to 60°C or 122°F to 140°F) temperatures and occurs in several steps that require a consortium of microorganisms. The complex organic matter is converted to methane and carbon dioxide in four stepwise primary reactions that drive the AD process. These reactions are hydrolysis, acidogenesis, acetogenesis, and methanogenesis. During hydrolysis, polymers—such as cellulose, hemicellulose, pectin, and starch—are broken down by hydrolytic enzymes into oligomers or monomers (smaller sub-units). In the acidogenesis step, the oligomers or monomers are metabolized by fermentative bacteria into volatile organic acids, carbon dioxide, and hydrogen (H2). During acetogenesis, the volatile organic acids are converted to methanogenic precursors, such as acetate, carbon dioxide, and hydrogen. Methanogenesis is the final step of the digestion process, during which the methanogenic bacteria produce methane from acetate or by reducing carbon dioxide with hydrogen (Smith et al., 1992; Wilkie, 2008).

Benefits of Anaerobic Digester Systems

- Beneficial Digester By-Products: The two by-products, namely ADS and ADL, generated from AD can be used as crop fertilizers. The ADS and ADL obtained from anaerobic digestion of beef cattle manure contain high fractions of mineralized N (Prasad et al., 2014), which are readily available for plant uptake. Depending on the size of the livestock farm component, the farm may require a USDA/NRCS comprehensive nutrient management plan for storage, application, or handling of ADS and ADL. Further, the separated solids (ADS) can also be used as livestock bedding or sold as horticultural potting mix because of its high fiber content (WRAP, 2011).

- Reducing Pathogens and Odor: Depending on the operating temperature, anaerobic digester systems reduce pathogens and also help control odors from manure during storage and spreading (Topper et al., 2006).

- Reducing Amounts of Weed Seeds: Manures may contain weed seeds. The digestion process helps reduce the number of viable weed seeds in the resulting product (Penn State Extension, 2014).

- Generating Energy: Biogas produced from anaerobic digestion of manure can be used to run combined heat and power systems for generating electricity. The gas can also be used as a boiler fuel or can be injected into natural gas pipelines after cleanup to remove impurities. The biogas can also be used to warm farm buildings, provide hot water, or even heat the digester. According to the EPA (2014b), US farm anaerobic digesters produced approximately 840 million kilowatt-hours (kWh) of useable energy in 2013, which is equivalent to the electricity used by 74,205 homes for one year (USEIA, 2013).

- Reducing Greenhouse Gases: In 2013, US farm digester systems reduced direct emissions from waste management systems by 1.73 million metric tons of carbon dioxide equivalent (MMTCO2e) and avoided emissions of 0.47 MMTCO2e by displacing the use of fossil fuels. The total emission reduction was equivalent to the carbon dioxide emissions generated from consuming 247.5 million gallons of gasoline or from burning 11,796 railcars worth of coal (EPA, 2014b).

Types of Anaerobic Digester Systems

There are various types of anaerobic digester systems. They differ by degree of complexity and the type of manure being digested. In Florida, two types of digesters are currently in operation: (1) Fixed Film Digester and (2) Mixed Plug Flow Digester. Some of the systems found commonly in the United States are described below.

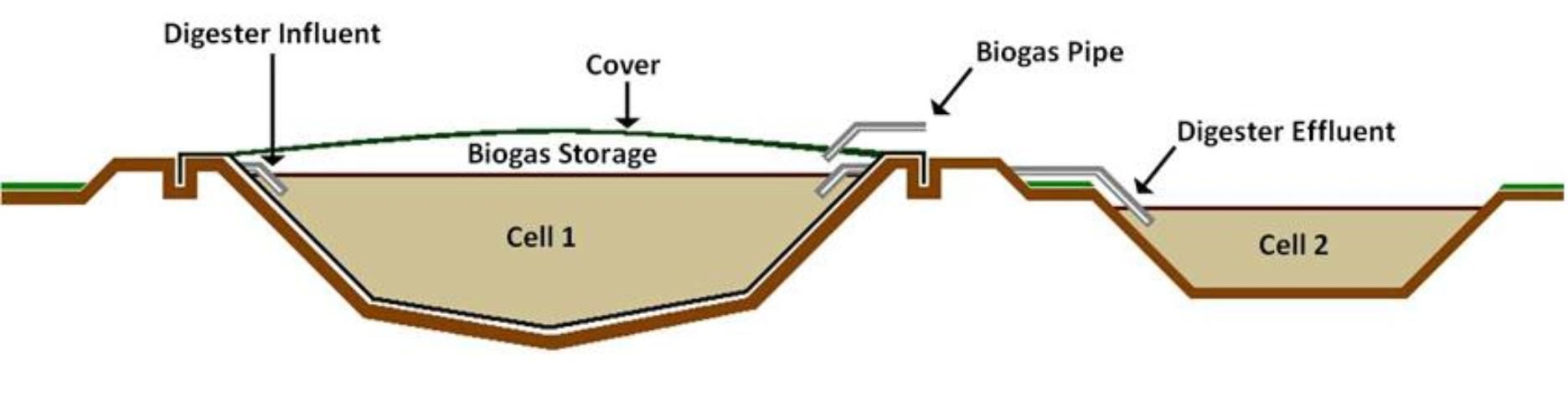

- Covered Anaerobic Lagoon Digester (CALD): A CALD employs a flexible cover to seal the liquid in a large storage system. The biogas generated is recovered and piped to the combustion system. This type of digester is suited for flush manure management systems with solid contents of 0.5% to 2%. Retention time depends on size of the system and varies between 30 to 45 days. Retention time would be higher for cold climate regions.

Credit: EPA, http://epa.gov/agstar/anaerobic/ad101/anaerobic-digesters.html

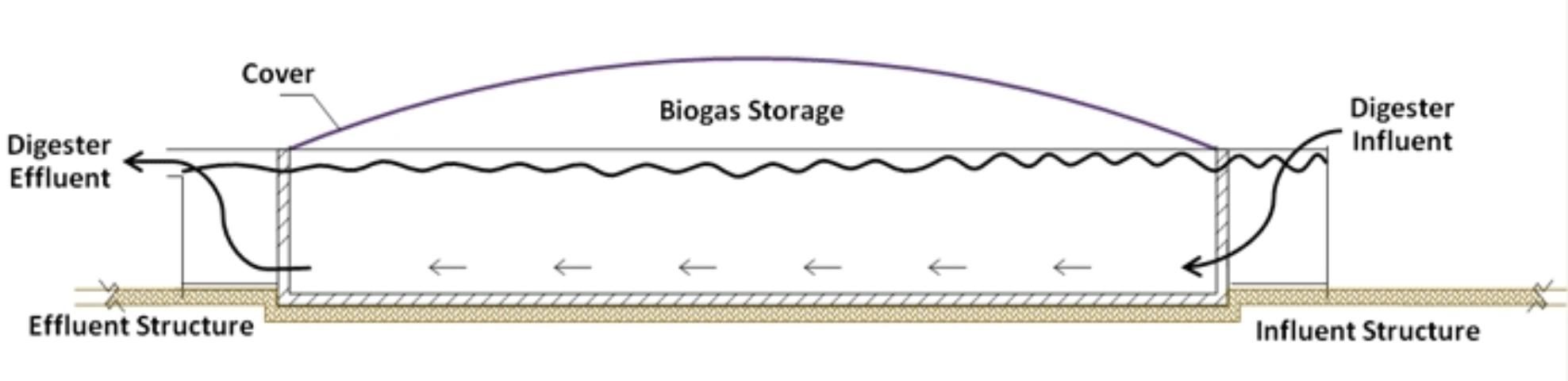

2. Plug Flow Digester: This type of system has long channels with a rigid or flexible cover, in which the manure moves along as a plug where the flow is constant through the digester. These systems are suitable for thicker materials, such as semi-liquid manure with 11% to 13% dry matter or higher. An example may be manure scraped from a dairy barn. The retention time is 15 to 20 days. The plug-flow system has been adapted to the digestion of manure produced by a beef cattle feeding facility and a dairy facility in Florida.

Credit: EPA, http://epa.gov/agstar/anaerobic/ad101/anaerobic-digesters.html

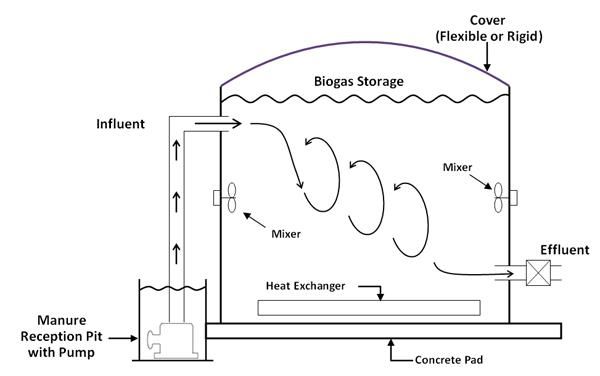

3. Complete Mix Digester: This type of digester consists of a large enclosed, heated tank with a mechanical, hydraulic, or gas mixing system, where fresh material is mixed with an active mass of microorganisms. These systems are suitable for manure with lower dry matter content (4% to 12%) or manure diluted with water. The retention time is 20 to 30 days.

Credit: EPA, http://epa.gov/agstar/anaerobic/ad101/anaerobic-digesters.html

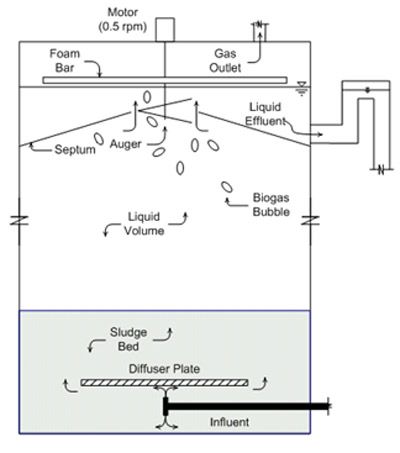

4. Induced Blanket Reactors (IBR): This is a type of digester in which a blanket of sludge is developed that retains anaerobic bacteria, through which a constant flow of influent is maintained. The flow is maintained in such a way that allows smaller particles to wash out and bigger ones to remain in the digester. This kind of system is suitable for manure with 6% to 12% total solids. The retention time is 2 to 6 days.

Credit: Conly Hansen, Utah State University

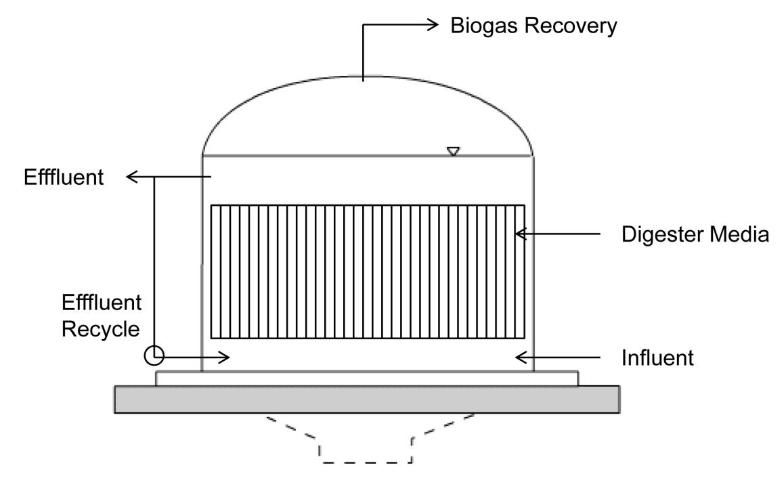

5. Fixed-Film Digesters: This type of system passes influent through a column packed with material, such as plastic media or wood chips, on which bacteria attach and grow. The effluent can be recycled back to maintain a constant upward or downward flow. A solids separator removes coarse fibrous particles from the manure before feeding the digester. The retention time can be less than five days. This kind of system is suitable for manure with 1% to 5% total solids and can be used with flushed dairy manure management systems in Florida.

Credit: Ann C. Wilkie, University of Florida

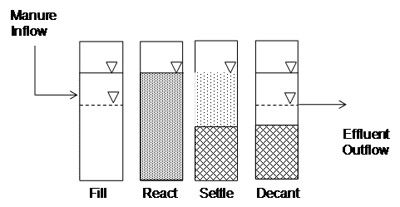

6. Batch Digesters: In this system, manure is added to the reactor as a batch and removed periodically. The digester operates using four phases. First, the manure is fed to the digester, after which it is mixed with microbes and allowed to react. Subsequently, the solids settle, and the effluent is withdrawn in the fourth stage. This cycle is repeated three to four times per day. The retention time can be five days. This kind of system is suitable for manure with < 1% total solids.

Credit: Doug Hamilton, Oklahoma State University

A Florida example of Plug-Flow Digester and its components for a beef cattle feeding facility:

A beef cattle feeding facility in northern Florida has a manure management system comprised of five main components: (1) manure collection, (2) an anaerobic digester, (3) a biogas collection and gas utilization system, (4) storage unit for solid and liquid effluents, and (5) a land application system for solid and liquid effluents. In addition, the system also includes a chopper pump for influent homogenization, solid/liquid separation equipment, and a heat exchanger inside the digester. The five components are described below.

- Manure Collection: The manure (feces and urine) is scraped out of feeding barns along with bedding material (which varies between peanuts hulls, old hay, sawdust, or spent/used horse bedding) and is fed to the digester unit.

Credit: George Hochmuth, University of Florida

2. Anaerobic Digester: The digester used on a farm can be one of several types, as previously described; however, the selection of the digester is based on the solid content of the manure. Figure 8 illustrates a mixed plug-flow digester on a Florida beef farm, in which manure and bedding materials (influents) are mixed and allowed to stabilize via the anaerobic digestion process.

Credit: George Hochmuth, University of Florida

3. Biogas Collection and Utilization Unit: This component of the system comprises the collection and transportation of biogas produced (typically, 60% CH4 and 40% CO2) to fuel the combined heat and power (CHP) system. Excess moisture and H2S must be removed prior to combustion using a gas treatment system.

Credit: George Hochmuth, University of Florida

4. Storage Units for Solid and Liquid Fractions: There are separate storage facilities for solids and liquids resulting from the digestion process. The digested solids are separated via a screw-press mechanical separator and collected in covered storage barns. The liquid effluent is drained to a settling tank (or solids separator) where heavier fractions settle out and the liquid fraction flows to a storage pond or lagoon. Periodically, the solids are mechanically scooped from the settling tank. The liquids can be pumped from the lagoon to crop fields through an irrigation system.

Credit: Rishi Prasad and George Hochmuth, University of Florida

5. Land Application System for Solid and Liquid Effluents: The solids can be applied to arable land using a calibrated manure spreader. The liquid effluent from the lagoon is diluted with water and spread to the land through a center-pivot irrigation system or portable irrigation guns. The solids and liquids should be analyzed before their field application by collecting a representative sample and sending it to the nearest livestock-waste testing laboratory. The field application rates should be determined based on the nutrient content of the solids and liquids and the crop nutrient needs after accounting for losses, such as gaseous losses of N.

Credit: George Hochmuth, University of Florida

Issues Associated with Anaerobic Digesters

There are several issues associated with the operation of anaerobic digesters. Not all digester types are suitable for all types of manures. Producers should carefully consult with knowledgeable specialists about the potential use of anaerobic digestion on their farm in order to select the most appropriate system. There are several issues associated with the operation of anaerobic digester systems. Some considerations include:

- Mixing. Proper mixing of the freshly added manure is essential for optimum digestion as well as preventing plugging, crusting, or foaming problems.

- Temperature. Maintaining the optimum temperature range (35°C or 95°F) is necessary for proper digestion. Hence, cooled-down manure would require additional heating of the digester. However, this is less of a problem in Florida.

- Hazards. There are risks of potential hazards such as explosion, asphyxiation, or hydrogen sulfide poisoning associated with digesters. The operators must be aware and properly trained to operate a digester and know how to take correct preventive measures against dangers.

- Corrosive Gases: Hydrogen sulfide is generated during the anaerobic digestion process when the influents fed to the digester system are rich in sulfur. The gas has corrosive effects on mechanical parts and gaskets. Hence, its removal is important to prevent the corrosive action.

- Souring of Anaerobic Digesters: This condition results when the pH of the manure undergoing digestion drops to the acidic range (pH < 6.5), resulting in inhibition of methane-forming bacteria. To avoid this kind of situation, bicarbonates could be added to maintain optimum pH (7 to 8.5).

References

Field, J. A., J. S. Caldwell, S. Jeyanayagam, R. B. Reneau, W. Kroontje, and E. R. Collins.1984. Fertilizer recovery from anaerobic digesters. Trans. ASAE. 27: 1871–1876.

Hamilton, D. 2012. Types of anaerobic digesters. Available at http://www.extension.org/pages/30307/types-of-anaerobic-digesters.

Larsen, K. E. 1986. Fertilizer value of anaerobic treated cattle and pig slurry to barley and beet. In: Kofoed, A.D., J.H. Williams, and P. L'Hermite (Eds.), Efficient land use of sludge and manure. Elsevier Applied Science Publishers, London, pp. 56–60.

Plaixats, J., J. Barcelo, and J. Garcia-Moreno. 1988. Characterization of the effluent residue from anaerobic digestion of pig excreta for its utilization as fertilizer. Agrochemica 32: 236–239.

Prasad, R., G. Hochmuth, R. Mylavarapu, and M. C. Giurcanu. 2014. In situ nitrogen release dynamics of effluents of anaerobic digestion of beef- cattle manure in sandy soil. (manuscript in preparation for Bioresource Technol.)

Penn State Extension. 2014. An introduction to anaerobic digesters. Available at https://extension.psu.edu/basics-of-anaerobic-digestion. Accessed February 7, 2023.

Smith, W. H., A. C. Wilkie, and P. H. Smith. 1992. Methane from biomass and waste - a program review. TIDE (Teri Information Digest on Energy), 2(1):1–20.

Topper P. A., R. E. Graves, and T. Richard. 2006. The fate of nutrients and pathogens during anaerobic digestion of dairy manure (G-71). Penn State Extension. Available at https://extension.psu.edu/fate-of-nutrients-and-pathogens-during-anaerobic-digestion-of-dairy-manure. Accessed February 7, 2023.

United States Energy Information Administration (USEIA). 2013. Residential Energy Consumption Survey Data, Table CE2.1 Household Site Fuel Consumption in the U.S., Totals and Averages, 2009. Available at https://www.eia.gov/consumption/residential/data/2009/index.php?view=consumption

United States Environmental Protection Agency (USEPA-AgSTAR). 2014a. Operating Anaerobic Digester Projects. Available at http://epa.gov/agstar/projects/

United States Environmental Protection Agency (USEPA-AgSTAR). 2014b. 2013 Use and Benefits of AD in the Livestock Sector. Available at http://www.epa.gov/agstar/documents/2013usebenefits.pdf

Wilkie, A. C. 2005. Anaerobic digestion: biology and benefits. In: Dairy Manure Management: Treatment, Handling, and Community Relations. NRAES-176, Natural Resource, Agriculture, and Engineering Service, Cornell University, Ithaca, NY, pp. 63–72. https://biogas.ifas.ufl.edu/Publs/NRAES176-p63-72-Mar2005.pdf

Wilkie, A. C. 2008. Biomethane from Biomass, Biowaste, and Biofuels. In: Bioenergy, Wall, J. D., C. S. Hardwood, and A. Demain (Eds.), American Society fo Microbiology Press, Washington, DC, pp. 195–205. https://biogas.ifas.ufl.edu/Publs/Bioenergy_CH16_ASM_Press_2008.pdf

WRAP. 2011. New Markets for digestate from anaerobic digestion. Available at http://www.wrap.org.uk/sites/files/wrap/New_Markets_for_AD_WRAP_format_Final_v2.c6779ccd.11341.pdf