A well is any excavation that is drilled, driven, dug, jetted or otherwise constructed when the intended use of such excavation is for the location and acquisition of ground water. The objective of this publication is to present information on different types of aquifers, to discuss the different types of irrigation wells typically constructed in Florida aquifers and to discuss irrigation well construction, development and testing.

Aquifers

The quality and quantity of groundwater varies from place to place. However, water in some quantity can be found beneath the ground almost everywhere. As a result, 97 percent of the world's available fresh water is groundwater.

Major reservoirs of groundwater are called aquifers. Conditions for good water-bearing formation are high permeability, which is the measure of ease with which water can flow through a soil profile, and high drainable porosity, which indicates that large amounts of water can be removed from the water-bearing formation. These features are best characterized by sand and gravel, although fractured rock formations and solution caverns in limestone are also good aquifers.

Aquifers can be located in consolidated or unconsolidated formations. Consolidated formations are composed of solid rock with groundwater in the cracks or caverns. Unconsolidated formations are composed of sand and gravel or loose soil material where the pore space is saturated with water.

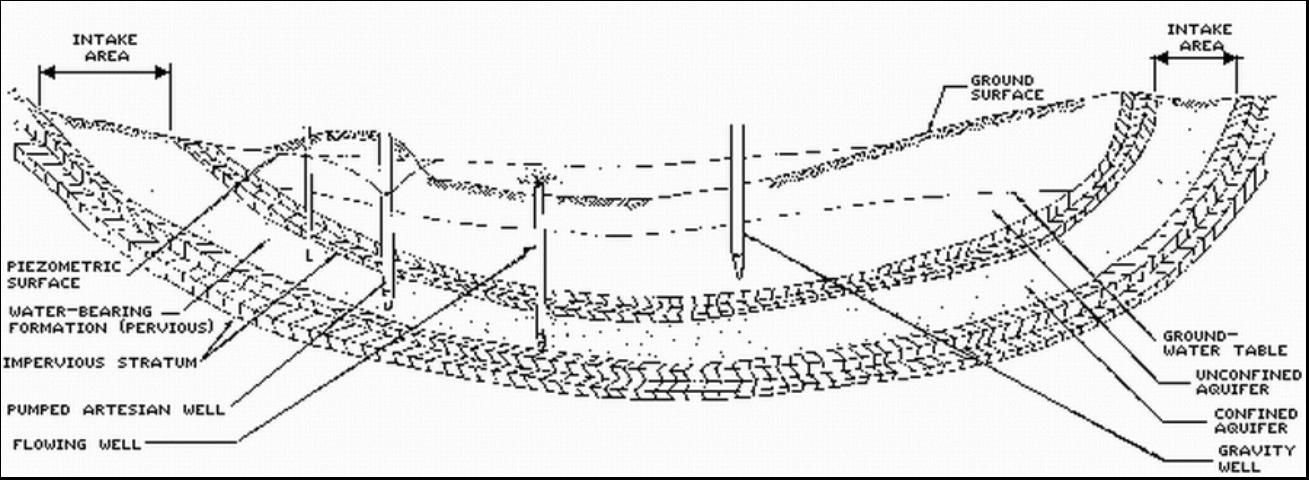

Aquifers can also be classified as confined or unconfined. A confined aquifer is isolated from the atmosphere by an impermeable layer (Figure 1). The surface of groundwater under confined conditions is often subject to higher than atmospheric pressure because it is confined by impermeable layers bounding the aquifer. The elevation to which water rises in a well that taps a confined aquifer is called the potentiometric level and represents the hydrostatic pressure at that point in the aquifer. An imaginary surface representing the confined pressure throughout all or part of a confined aquifer is called the potentiometric surface.

Unconfined aquifers are bounded only on the bottom by impermeable strata and are often referred to as water table aquifers (Figure 1). When no water is being removed by pumping, the water table level in an unconfined aquifer and the piezometric level in a confined aquifer are called static water levels. In Florida, the static water level of unconfined formations is generally near the ground surface and may have significant fluctuations. The recharge of unconfined aquifers results from precipitation or seepage from nearby streams or lakes. Consequently, it depends on the season and on meteorological conditions. The potentiometric surface of a confined aquifer is also subject to change due to recharge and pumping conditions. The potentiometric surface will rise and fall in response to the volume of water in the aquifer. Fluctuation of the water level in an unconfined aquifer or changes in hydrostatic pressure in a confined aquifer should be considered when a new well is being installed.

Well Classification

Wells can be classified as gravity wells, free flowing artesian wells, or a combination of artesian and gravity (pumped artesian wells) (Figure 1). The well type depends on the type of aquifer containing the water. Gravity wells penetrate unconfined aquifers. As a result, the static water level in a gravity well is the same as the level of the water table (piezometric surface of the unconfined aquifer).

If the hydrostatic pressure in an confined aquifer is sufficient to cause the water to rise above the water level in the aquifer, artesian conditions are present. A raised water level in a well indicates that the aquifer is confined and that the water at the surface of the aquifer is under pressure which is greater than atmospheric pressure. This type of well is called an artesian well. If hydrostatic pressure is sufficient to cause the water to rise high enough to flow out on the land surface, a free flowing artesian well exists. The following conditions must exist for any artesian well: 1) the aquifer must be confined, which means impervious strata above and below the water-bearing formation; 2) the recharge area must be located above the top impervious strata; 3) the absence of a free outlet for the water bearing formation at the lower elevation; 4) inclination of the strata; 5) a source for water recharge, such as sufficient precipitation. An artesian well is not necessarily a free-flowing well. The schematic in Figure 1 shows the necessary conditions for both non-flowing and free flowing artesian wells.

Wells can also be classified as shallow or deep. In many areas good irrigation water can be obtained from shallow aquifers. Careful investigation of the shallow water aquifers should be performed prior to well construction. In some instances, when the shallow water table is due to a perched water table, pumping for irrigation can quickly exhaust the water supply.

Well Construction

Florida's water management districts provide standards and criteria for construction, repair and abandonment of wells. In all districts permits are required for any well with a diameter larger than 2 inches. All wells within a district must comply with that district's standards, regardless of whether a permit for a well is required. County and other ordinances may also be applicable and must be followed. For example, some counties prohibit the construction of shallow wells in some areas.

Construction

In general, wells can be classified into three major types according to the method of construction: driven, dug or drilled. Small wells up to 3" in diameter and 60 feet deep can be constructed by driving a well point into unconsolidated material such as sand or gravel. Penetration of the well point may be aided by using a high velocity jet of water at the tip of the driving pipe (jettings).

A dug well is a pit dug to the ground water table. These wells usually do not penetrate the groundwater deep enough to produce high water yield. A dug well pit is often lined with masonry, concrete, or steel for support.

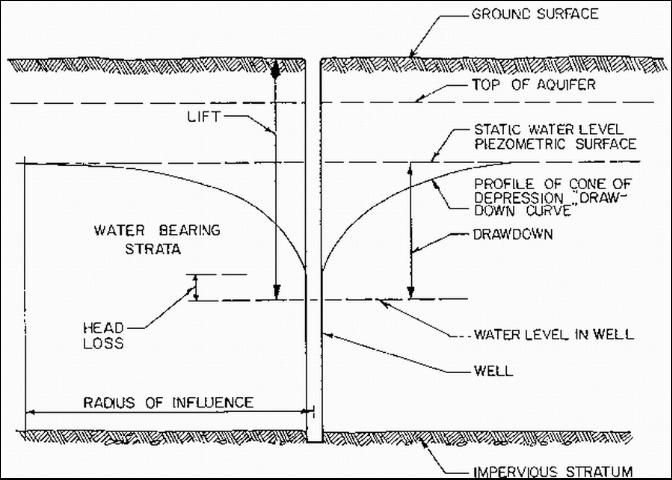

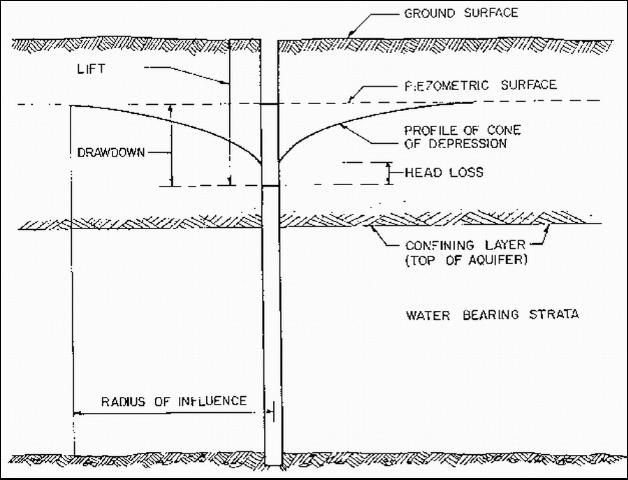

Deeper wells are usually constructed by drilling. Cable-tool or rotary equipment is commonly used. In the first method, a heavy bit is dropped repeatedly to the bottom of the well using cable tools and crushed material is periodically removed with a bailer. Rotary drilling equipment consists of a bit rotated by a string of pipe. Cuttings are removed by continuous circulation of a drilling fluid as the bit penetrates the formation. Drilling fluid is pumped down through the drill pipe and out through the ports or jets in the bit. The cuttings are brought to the surface by a mud slurry outside the drill pipe. Figure 2 illustrates cross sections of a well in a water table aquifer and, Figure 3, in a confined aquifer, respectively. In both cases drawdown is the difference between the water table or potentiometric surface (confined conditions) and the water level in a well during pumping. It represents the sum of the head losses caused by the flow of water through the porous media and the head loss caused by the entrance of water into the well.

The horizontal distance from the center of the well to the limit of the cone of depression is called the radius of influence. Each cone of depression differs in size and shape depending upon the pumping rate, pumping duration, recharge of the aquifer within the cone, and aquifer characteristics such as permeability of the water bearing formation. The cone of depression is affected by pumping of other wells located within the radius of influence of this well.

An irrigation well should penetrate the water-bearing formations quite deeply while keeping costs within economical limits. In Florida, the depth of a well will also be limited by water quality since saline water underlies potable water throughout the state. In coastal areas of Florida, salt water intrusion into the aquifer is frequently encountered. Keeping water quality problems in mind, a well should be sufficiently deep to avoid running dry during drought or during increased drawdown periods such as pumping for freeze protection during winter months. It is also important to remember that deeper wells will usually produce a greater yield of water per foot of drawdown.

The relationship between well diameter and water yield is not linear, and as a result, a doubling of the diameter will not double the amount of water which can be pumped from a well. For residential lawn irrigation systems a 4" well will usually supply enough water. For larger applications and bigger wells, local conditions near the intended well site must be investigated prior to sizing and installing a well.

Standards developed by the water management districts in Florida provide specifications for casing and liner pipe in wells. The function of the well casing is to maintain the borehole at a specified size, to prevent collapsing of the borehole, and to serve as a pump enclosure as well as a conduit for water flow from the well inlet to the pump intake. A liner is a pipe which is installed either within the outer casing to improve, repair, or protect the outer casing or below the outer casing to seal off caving material which may be encountered in a well with an open hole aquifer. Welded, seamless black or galvanized pipe, stainless steel pipe, or approved types of nonmetallic pipe can be used for well casing or liner pipe according to the specifications of the water management districts. A continuous casing should extend from 6 to 12 inches above the land surface to a few feet into the uppermost consolidated layer. For detailed specification on sizes and construction of the casing, the local water management district should be consulted. (Table 1, Table 2) The alignment of a well is important, especially when vertical turbine pumps are used and a vertical shaft is placed in the well. Allowable tolerances in misalignment will also depend on the size of casing in relation to the outside diameter of the submersible or vertical turbine pump.

Screens

Well casing may be solid or slotted (screened). Solid casing has no perforations and is used in the upper regions of a well. Slotted casing or well screens are used in the lower, water-bearing regions of wells. A screen allows water to enter the well from the saturated formation, prevents fine materials from entering the well, and serves as structural support for the unconsolidated aquifer material. Whenever a screen is used it is required that a well screen be attached to the casing with a watertight seal.

In most cases, screens are not required in consolidated formations such as the limestone of the Floridian Aquifer. In limerock the borehole is drilled into a water-bearing consolidated formation and the hole stays open without a well screen. For this reason many wells are relatively inexpensive in central and south Florida.

Grouting

If for any reason there is space between a borehole and casing, a well must be grouted by filling the annular space with materials specified by water management districts. Grouting protects the aquifer from degradation caused by movement of water along the borehole either from the surface to the aquifer or between aquifers. Grouting also prevents loss of artesian pressure in an artesian aquifer. In most cases, a concrete grouting is required. However, in some cases in unconsolidated formations, of such a caving nature by which the annular space is completely filled with existing material only the upper few feet of annular space have to be sealed with grout to provide protection from contaminated surface water.

Well Seals

The well should be sealed with a watertight cover during temporary interruptions in work on the well. This rule also applies to wells that are only used seasonally or periodically. Whenever pumping equipment is removed a well must be covered with a watertight cap or valve. Special rules apply to wells located in a flood plane to prevent groundwater contamination during floods.

All free flowing wells (artesian) should be provided with a valve for controlling the discharge from the well. Also, all abandoned wells are required to be plugged.

Well Development

Newly constructed wells should be developed and tested. The purpose of well development is to provide sand-free water at maximum capacity. The drilling operation alters the hydraulic characteristics of a water-bearing formation in the immediate vicinity of the well caused by compaction, relocation of natural fine materials and/or migration of drilling fluids into the formation. As a result local permeability and hydraulic conductivity may be severely reduced, restricting water flow into the well.

Development of a well reduces compaction and removes fine material from the pore space near the well. By selectively removing the finer fraction of aquifer material, development increases natural porosity and permeability of undisturbed materials near the borehole. In unconfined aquifers, it creates a grated zone of sediment around the screen, thereby stabilizing the formation so that the well will yield sand-free water. Development also removes drilling fluid that coated the borehole or entered the formation during the drilling process as well as relocated clay along the well walls.

The development of a well can be done using several different methods: over-pumping, backwashing, mechanical surging, air development, jetting, acid treatment, or explosions. Often, more than one method is used, especially for larger wells.

Overpumping

For a small irrigation well the most common well development technique used is overpumping. It is recommended that pumping begin at about 25% of the desired well yield and continue until the water is clear. The process should be repeated at 50, 75, 100 and above 100 percent of the desired well yield. The last pumping rate should be at least 25% higher than the desired well yield if possible. A test pump should be used for the overpumping operation. It is recommended that the permanent pump not be used for this operation, if possible, since sand particles may cause excessive wear of the pump.

Backwashing

Backwashing between pumping cycles improves effectiveness of well development. Reversal of water flow through the screen into the formation removes finer fraction and rearranges the remaining particles. Backwashing can be accomplished by starting the pump and shutting it off when the water is lifted to the surface. This allows the water in the pump column to fall back into the well reversing water flow through the screen. A combined overpumping and backwashing technique is often used for well development.

Mechanical Surging

Reversed flow through the screen into the formation can also be accomplished through the use of mechanical devices such as surge block or surge plunger. They are operated up and down in the casing, similar to a piston in a cylinder. Surge devices are inexpensive, easy to use, and quite effective as development tools. They can be used for wells of any depth or diameter.

Air Development

Compressed air can be used for alternately surging and pumping a well. In air surging, compressed air is injected into the well to lift the water to the surface. As water reaches the top of the casing the compressor is shut off and the aerated water column falls back into the well. Sediment is periodically removed from the well using air-lift pumping. This procedure eliminates the need for a pump during development of the well avoiding risk of pump wear caused by the pumping of sand.

Jetting

High-velocity jets of water or air can be used in well development. Jetting is done by using a horizontal jet inside the borehole or a screen. A jetting tool with evenly spaced nozzles is moved up and down along the screen, washing the finer materials free.

Acid Treatment

Development of well and aquifer in limestone or dolomite formations can be done by using acid. The use of acid opens up fractures and crevices in the formation around the open borehole. It increases overall permeability of the aquifer by dissolving materials in the cracks. In Florida, acid development requires special permission from a water management district.

Use of Explosives

Explosives are sometimes used in a rock well (consolidated aquifer) to develop and increase its yield. In Florida the use of explosives in well construction to enlarge the cavity is prohibited unless specifically approved by a water management district.

Testing

Well Testing

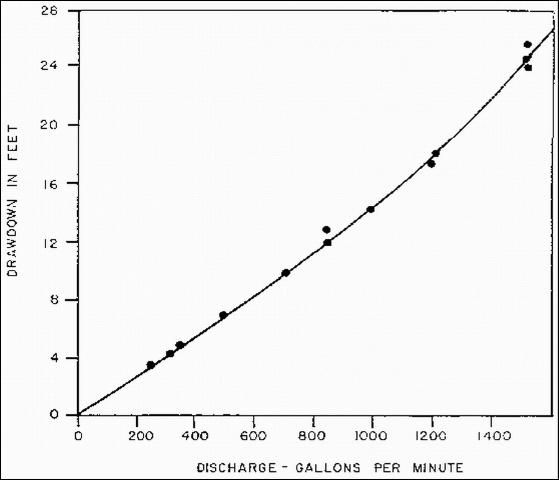

After a well is developed, a pumping test should be performed in order to determine potential well yield, to select an efficient pump, and to determine the drawdown which can influence pump location for submersible or deep turbine pumps.

The well test is performed by measuring the yield and drawdown at certain time intervals during pumping. A capacity/drawdown curve can be developed (Figure 4) that allows efficient selection of a pump for given conditions. Since the drawdown for the required yield is known, the location of the submersible or deep turbine pump can be determined from the chart.

Aquifer Testing

A pumping test can also provide data necessary to determine the hydraulic parameters of an aquifer. An aquifer pumping test requires the measurement of drawdown in nearby observation wells in addition to the capacity/drawdown data from the well. An aquifer test determines the effect of newly installed wells on existing wells, the radius of influence of the well, and the drawdowns in the well for different discharges. The results from this type of test are necessary for proper well spacing and for groundwater investigation and management.

Summary

Different types of wells and their construction and development depending on type of aquifer were discussed in this publication. Different techniques were presented depending on geological conditions, well size and depth. The role of water management districts in Florida in water well regulation was emphasized in this publication.

References

ASAE Engineering Practice: ASAE EP400 - "Designing and Constructing Irrigation Wells." ASAE Standards. St. Joseph, Michigan.

CHAPTER 40 A-3, Florida Administrative Code "Regulation of Wells." 1985. Rules of the Northwest Florida Water Management District. Havana, FL.

CHAPTER 4OR-3. "Water Well Construction." St. Johns River Water Management, Palatka, FL.

CHAPTER 40D-3. "Regulation of Wells." Rules of the Southwest Florida Department of Environmental Regulation. 1982.

Driscoll, F. G. Groundwater and Wells. 1986. Johnson Division, St. Paul, Minnesota 55112 Hornsby, A. G. "Ground Water: The Hidden Resource" Soil Science Fact Sheet No. 1986. IFAS, University of Florida, Gainesville, FL Izuno, F. T., D. A. Haman. "Basic Agricultural Drainage Terminology." Ext. Circular 733, IFAS, University of Florida, Gainesville, FL Pair, C. H., W. H. Hinz, K. R. Frost, R. E. Sneed, T. J. Schiltz. Irrigation. 1983. The Irrigation Association, 1911 North Fort Myer Drive, Arlington, Virginia 22209.

Schwals, G. O., R. K. Frevert, T. W. Edminster, K. K. Barhes. Soil and Water Conservation Engineering. 1981. John Wiley & Sons.