Surviving the FDACS Inspection: Walking through an Inspection

Introduction

How well would your agricultural production facility meet the regulations of Florida's pesticide law? This article will assist agricultural producers in preparing for the day when the inspector arrives at their operation. It reviews the elements that an inspector for the Florida Department of Agriculture and Consumer Services (FDACS) will examine during a routine agricultural establishment inspection.

Role of the Bureau of Inspection and Incident Response (BIIR)

The BIIR ensures consumer protection, worker safety and protection of the environment through inspections of entities that manufacture, sell or apply pesticides, fertilizer, feed, or seed. These inspections are conducted on a routine basis or in response to a complaint from a consumer.

Inspections include a review of application records and an evaluation of product labels to ensure that use, storage, disposal, and safety requirements of pesticides are being followed.

Inspections are necessary to ensure the safety of workers, to protect the environment and natural resources, and to maintain the secure use and storage of agrichemicals.

The Basic Components

A compliance inspection of an agricultural facility is very comprehensive. Besides completing all official documentation forms, inspectors may take photographs for future evidence. The inspector will cover the components included on the Pesticide Use Inspection report and the Worker Protection Standard (WPS) inspection form. Records pertaining to pesticide applications and Florida rules regarding pesticides should also be made available to inspectors. The following sections will discuss each component in greater detail with links to the individual inspection forms.

Inspector Identification

Inspectors will properly introduce and identify themselves once they arrive at a place of business by presenting their BIIR licenses and explaining the reason for the visit. They can arrive at any establishment without a prior appointment, so an establishment manager may already be engaged in some work activity. However, the inspection will go more smoothly with a manager's full cooperation.

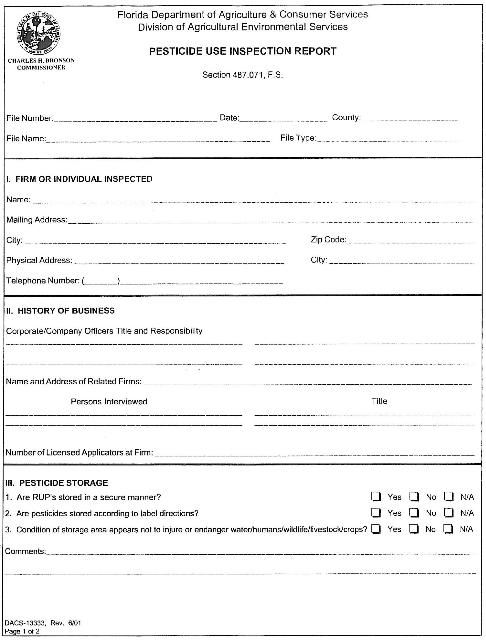

Pesticide Use Inspection Report

Following introductions, the inspector will fill out sections I and II on page 1 of the Pesticide Use Inspection Report for the agricultural establishment's contact information (Figure 1).

Restricted Use Pesticide License Verification

During the early phase of the inspection, the inspector will determine whether restricted use pesticides are used at the establishment and verify that the appropriate license is held.

Pesticide Storage

Ideally, storage would not be an issue if all products could be used within a single season. But the reality for most Florida producers is that pest management is a year-round concern because of the nature of cropping systems and environmental conditions. The main check points the inspector will look for at the storage area are whether the facility appears to be secure, whether pesticides are held according to label directions, and what the overall condition of the facility is, each listed in section III (Figure 1). A secure storage area has a lock and is well-marked with signs (Figure 2).

Credit: UF/IFAS

Although not required by law, the inspector may make a few suggestions including:

- having a spill kit on hand

- keeping an inventory list

- keeping liquid and dry materials apart

- not keeping personal protective equipment (PPE) inside with chemicals

- keeping all materials up off of the floor

The spill kit contains items such as absorbent material and containment snakes to clean up liquid spills. More information about assembling and using a spill kit can be found in UF/IFAS EDIS document PI-159, Pesticide Spill Kits https://edis.ifas.ufl.edu/publication/PI196. An inventory list of the materials held in the facility will provide a record for the length of time they have been held. It is always a good idea to store dry and liquid materials apart. If a liquid spills on a dry material, both materials will have to be disposed of. All materials, regardless of formulation, should be stored up off the floor so that they are protected from water leakage and flooding.

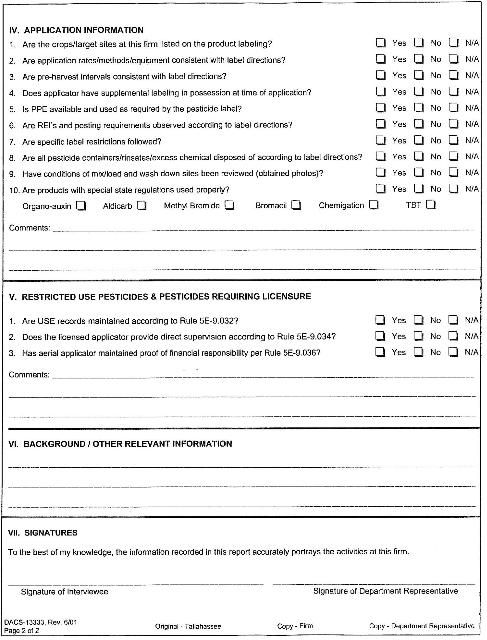

Application Information

After examining the products held in the storage facility, the inspector will select a label from one of the containers which will serve as the basis for the questions asked in section IV, page 2 of the Pesticide Use Inspection Report (Figure 3).

The information that the inspector will verify pertains to the following aspects of the product labeling:

- labeled sites/crops for the application

- proper rates, methods, and equipment used

- pre-harvest intervals followed

- whether supplemental labeling was on-hand, if needed

- whether PPE was available and worn

- whether restricted entry intervals (REIs) were observed where applicable

- whether containers, rinsates, and excess pesticide have been properly disposed of

- whether state specifically regulated pesticides were used properly

- any other specific restrictions that would apply

This particular section will also cover the condition of the mix/load/wash-down site at the facility. The inspector will determine whether an anti-siphon device is installed in the plumbing used for filling tanks to hold diluted pesticides for application, or at least whether an air gap was present at the time of filling.

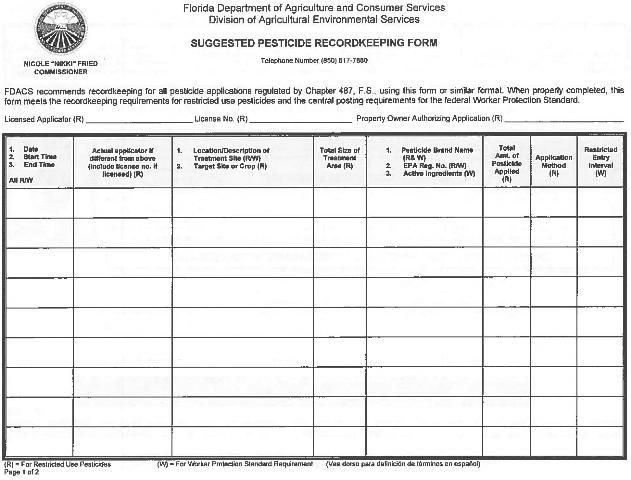

Recordkeeping of Restricted Use Pesticides

This is the point of the inspection when a manager will be asked to provide application records of restricted use pesticides. Records must be complete and must include these elements:

- licensed applicators' names and license numbers

- actual applicators' names if not the licensed applicators

- date of application

- start and end times of application

- location and description of the treated site

- target site or crop

- total size of treated area

- pesticide brand name

- product's EPA registration number

- total amount of product applied

- application method

A sample form for recordkeeping is shown in Figure 4 (Figure 4). However, managers may choose to use software programs or any other recordkeeping system deemed appropriate for their establishment so long as the required elements are included.

When applicable, inspectors will also need to see records pertaining to Florida rules such as the Organo-Auxin herbicide rule (https://edis.ifas.ufl.edu/publication/WG051).

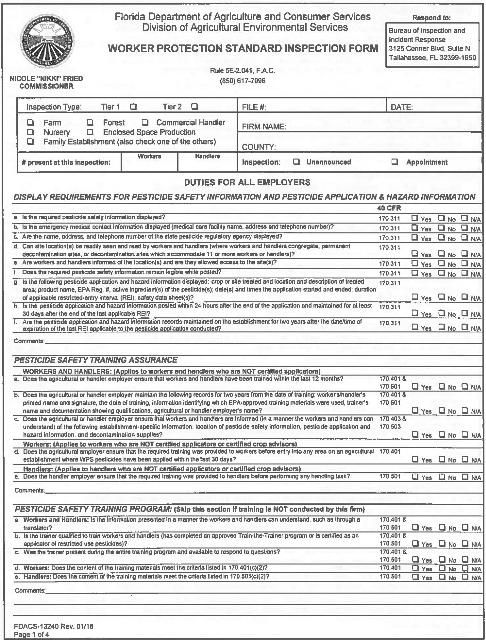

Worker Protection Standard (WPS) Inspection

The inspector will conduct worker and handler interviews to verify the components of the WPS for establishments that employ workers outside immediate family.

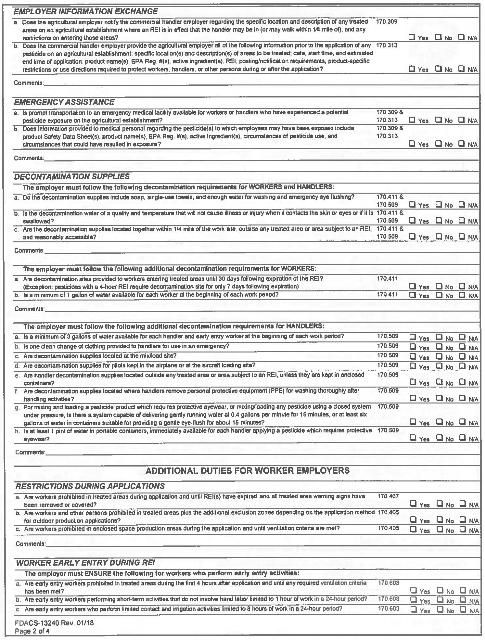

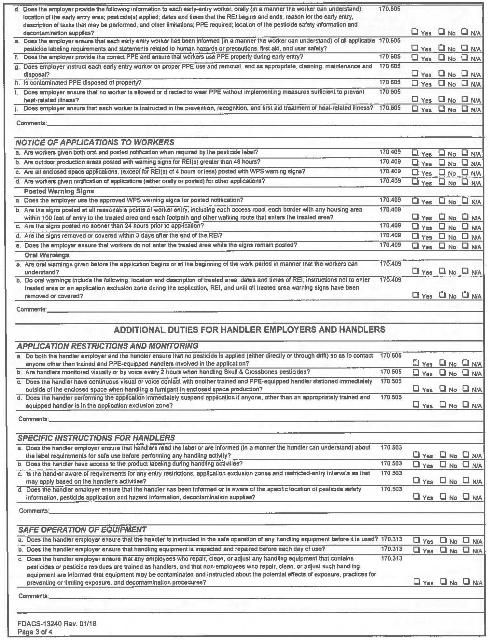

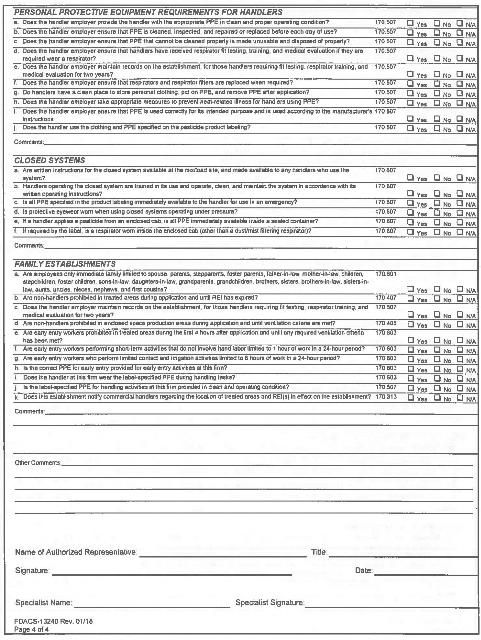

The following WPS components are examined by FDACS inspectors (Figures 5–8):

- Duties for all employers, including:

- Pesticide safety display

- Pesticide safety training assurance and program

- Employer information exchange

- Emergency assistance

- Decontamination supplies

- Additional duties for worker employers

- Restrictions during applications

- Worker early entry into treated sites

- Notice of applications to workers

- Additional duties for handler employers and handlers

- Application restrictions and monitoring

- Specific instructions for handlers

- Safe operation of equipment

- Personal protective equipment requirements for handlers

- Closed systems

- Family establishments

Credit: UF/IFAS

Credit: UF/IFAS

Conclusion

The inspection is not necessarily a one-way street for the inspector. Operators and employees have an opportunity to ask questions regarding the facility, pesticide laws, and making compliance more efficient in the operation. Because a major objective of the BIIR is to serve an educational role, the inspection should be considered a two-way means of communication.

References

American Association of Poison Control Centers, Toxic Exposure Surveillance System, 1996. https://poisoncenters.org

Fishel, F.M. 2006. Worker Protection Standard: Decontamination Supplies. PI-116. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://doi.org/10.32473/edis-pi153-2006

Fishel, F.M. 2006. Worker Protection Standard: Employer Information Exchange. PI-115. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://doi.org/10.32473/edis-pi152-2006

Fishel, F.M. 2006. Worker Protection Standard: Information at a Central Location. PI-112. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://doi.org/10.32473/edis-pi149-2006

Fishel, F.M. 2006. Worker Protection Standard: Notice about Applications. PI-107. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://doi.org/10.32473/edis-pi144-2006

Fishel, F.M. 2006. Worker Protection Standard: Training Workers and Handlers. PI-113. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://doi.org/10.32473/edis-pi150-2006

Florida Department of Agriculture and Consumer Services Bureau of Inspection and Incident Response. http://www.freshfromflorida.com/Divisions-Offices/Agricultural-Environmental-Services/Bureaus-and-Sections2/Bureau-of-Inspection-and-Incident-Response