Introduction to Southern Highbush Blueberry Cultivation in Containers

Blueberry bushes prefer well-drained, acidic soils with high organic matter content. These soil characteristics are not common in many parts of the world. Thus, blueberries are traditionally grown in soils amended with pine bark and supplemental sulfur. The need to create optimum conditions for the roots of blueberry bushes has recently led to blueberry cultivation in containers filled with soilless substrates. Soilless substrates are inert materials of organic or synthetic origin that can be used to grow plants without soil. The intended audience for this publication is commercial southern highbush blueberry growers. The purpose of this publication is to complement existing information sources by introducing the materials and practices used for blueberry cultivation on container-based farms.

Container Selection

Choosing the right container size and shape are important decisions. The first generation of container-based blueberry farms used large nursery pots (10- to 13-gallon capacity). However, current plantings use smaller containers (5- to 7-gallon capacity). Smaller containers are more affordable, take less substrate to fill, and allow for a more even distribution of substrate moisture. Additionally, research has shown that large containers do not improve plant growth or productivity. Containers with abundant holes or grills for drainage are essential to avoid root diseases (such as Phytophthora root rot) and facilitate substrate salinity management (Figure 1). If drainage is appropriate, there appear to be no differences between cultivation in pots and substrate-filled bags. Since blueberry bushes have shallow root systems, containers that are wider than taller are preferred. Wide containers also help prevent large plants from toppling over. There is no consensus about the effect that pot shape (round or square) or color (black or white) have on blueberry root growth. Some growers are experimenting with anchoring pots to the ground to provide additional support during extreme weather events.

Credit: Gerardo H. Nunez, UF/IFAS

Substrate Selection

Soilless substrates are composed of fibrous and coarse components that create a balance between water retention and drainage. Organic fibers, such as sphagnum peat moss and coconut coir, give the substrate its water-holding capacity. There is also interest in using wood-based fibers for this means. Coarse materials like perlite, coconut pith, pine bark, and biochar are used to increase substrate aeration and drainage. The relative proportion of fibers to coarse materials determines the substrate air-filled porosity. Substrates for blueberry production generally have >30% air-filled porosity, compared with ornamental, tree fruit, or blueberry nursery substrates where the target is 10% to 20%. While a decade ago the first container-based farms were mixing their own substrates, today it is commonplace to purchase ready-to-grow mixes with pre-adjusted pH and electrical conductivity (EC). Mixes that contain coconut coir, processed to have fibrous and coarse particles, are rapidly gaining popularity.

pH and Electrical Conductivity

Blueberry bushes have strict pH and EC requirements. Farms should create a program for pH and EC monitoring and correction because substrate conditions can change rapidly. The pour-through method, which can be used to monitor substrate conditions (Figure 2), consists of adding a known volume of deionized water to a saturated container until 50 mL (approximately 1.7 fl oz) of leachate drips from the container. Subsequently, pH and EC are measured from the leachate using calibrated sensors.

Credit: Martin Zapien, UF/IFAS

Soilless substrates do not have pH buffering capacity. Therefore, pH can change drastically in response to irrigation water alkalinity, fertilization, and nutrient uptake. Leachate pH should be maintained in the range 4.5 to 5.5 for optimum productivity. Most water sources in Florida have measurable concentrations of carbonates and bicarbonates (collectively called alkalinity). Water alkalinity can raise substrate pH. Therefore, water alkalinity should be neutralized with nutritionally relevant acids such as sulfuric, phosphoric, or nitric acid. Additional details about alkalinity neutralization can be found in Ask IFAS publication #SL332, “Water Quality Notes: Alkalinity and Hardness.” Acidifying fertilizers, such as ammonium sulfate, should be used. When pH is too low, very light lime applications (under 0.8 oz of lime per gallon of substrate) can be helpful.

Soilless substrates can accumulate salts and create stressful conditions for blueberry roots. Leachate salinity should be maintained below 2.0 dS/m (and even lower for young plants). Fertilization can lead to salinity accumulation because plants take up more water than nutrients. Where high salinity conditions are encountered, substrates should be rinsed with large volumes of acidified water to remove excess salts.

Irrigation

Short and frequent fertigation events should be used to provide adequate moisture for plant growth and prevent nutrient leaching, low oxygen levels in the root system, and salt accumulation in the substrate. Drip irrigation, though expensive, is the most widely used system due to better water control and higher distribution uniformity. Each container is usually equipped with one emitter and two to four stakes that distribute the water as evenly as possible (Figure 3). A more affordable, but less successful, approach is to place irrigation drip lines on top of rows of containers.

Credit: Martin Zapien, UF/IFAS

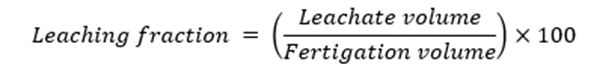

Irrigation based on the leaching fraction is a common practice. The leaching fraction is the proportion of the volume of leachate to the volume of irrigation/fertigation solution applied (Equation 1). Previous research has targeted leaching fractions between 15% and 25%. Leaching fractions higher than 25% are not advisable because they cause excessive nutrient losses and saturated conditions can promote Phytophthora or Pythium root rot diseases. Irrigation scheduling with substrate moisture sensors is an alternative approach that might be less labor intensive.

Credit:

Fertilization

Soilless substrates have two main differences compared to soil: 1) soilless substrates do not contain essential plant nutrients, and 2) soilless substrates only hold onto positively charged nutrients (called cations). Therefore, all essential plant nutrients must be provided in the fertigation solution, and leachate analysis can be used to monitor sufficient supply of nutrients. See Ask IFAS publication #HS1356, “Nutrition and Fertilization Practices for Southern Highbush Blueberry in Florida,” for more details about blueberry nutritional needs. Cations, such as potassium (K+), calcium (Ca2+), and magnesium (Mg2+), are attracted to soilless substrates and are less likely to be lost through leaching. Negatively charged molecules (called anions) are repelled. Consequently, anions such as phosphate (PO4-) and nitrate (NO3-) leach readily from containers filled with soilless substrates. Currently, there are no fertilizer recommendations for container-based blueberry farms. Leaf nutrient analysis according to plant phenology can be used to identify nutrient deficiencies and trigger corrective actions.

Growth, Pruning, and Plant Density

Blueberry plants have vigorous and early growth in soilless substrates. We have observed commercial-level yields in the first year after planting 1-quart liners in 27-liter containers. This vigorous growth pattern welcomes more aggressive pruning than soil-based production. Unfortunately, there are no pruning recommendations for container-grown blueberry at this point. Additional details about prevalent pruning practices for soil-grown blueberry can be found in Ask IFAS publication #HS1359, “Pruning Southern Highbush Blueberry in Florida.” Container-based farms have also experimented with plant density. High-density plantings (over 2,900 plants/acre) often generate higher early yields, which can provide early economic returns. However, high-density plantings do not produce consistently higher yields after the second year. This has been attributed to poor light interception through the canopy and higher pest and disease pressure.

Weed Management

Soilless substrates are manufactured free of weed seeds. However, moist, fertilized substrate is an ideal environment for the germination of seeds that land in the container. When blueberry bushes are young, coarse pine bark (usually called pine nuggets) can be top-dressed in the containers. Pine bark shades the top of the substrate and limits weed emergence. Once blueberry plants are large enough to shade the top of the container, weed pressure is generally minimal.

Conclusion

Material selection and management practices differ between soil-based and container-based blueberry production. The vigor and productivity of this production system needs to be evaluated against crop timing, labor inputs, and cost of production inputs to determine potential profitability for Florida blueberry growers.

Further Reading

Fang, Y., G. Nunez, P. Fisher, and P. R. Munoz. 2022. “Effect of Container Size, Substrate Composition, and Genotype on Growth and Fruit Quality of Young Southern Highbush Blueberry in a Container-based Intensive Production System.” Scientia Horticulturae 302: 111149. https://doi.org/10.1016/j.scienta.2022.111149

Heller, C. R., and G.H. Nunez. 2022. “Preplant fertilization increases substrate microbial respiration but does not affect southern highbush blueberry establishment in a coconut coir-based substrate.” HortScience 57 (1): 17–21. https://doi.org/10.21273/HORTSCI16220-21

Schreiber, M. J., and G. H. Nunez. 2021. “Calcium carbonate can be used to manage soilless substrate pH for blueberry production.” Horticulturae 7 (4): 74. https://doi.org/10.3390/horticulturae7040074