This document is written for commercial producers who are transitioning to or beginning organic production. Home gardeners should refer to EDIS publication HS1215, Organic Vegetable Gardening in Florida, available at https://edis.ifas.ufl.edu/hs1215.

The National Organic Program

Organic farming can generally be described as a method of production that utilizes non-synthetic inputs and emphasizes biological and ecological processes, to improve soil quality, manage soil fertility, and optimize pest management. The development of agriculture as an industry in the 1940s served as a point of departure for farmers who preferred traditional farming practices and desired to minimize synthetic off-farm inputs. When consumer demand for organic food increased, organic industry stakeholders requested the establishment of a national organic program with consistent standards for both farmers and consumers (Treadwell et al. 2003). As a result of this significant grassroots effort, the National Organic Standards Board (NOSB) was created under the authority of the Organic Foods Production Act of 1990, to establish uniform organic production standards and to ensure consumer protection for all products labeled organic in the marketplace. The NOSB, composed of 15 members appointed by the Secretary of Agriculture from across the United States, provides recommendations to the Secretary regarding the implementation of the National Organic Program (NOP). The NOP resides in the Agricultural Marketing Service, an arm of the United States Department of Agriculture (USDA). The NOP maintains a list of certified operations, accredits certifying agents, establishes global import and export policies, manages the National List (see below), investigates and takes action on regulatory violation complaints, oversees the Organic Certification Cost Share programs, and provides training to agents, staff, and stakeholders: https://www.ams.usda.gov/about-ams/programs-offices/national-organic-program.

Certification Process in Brief

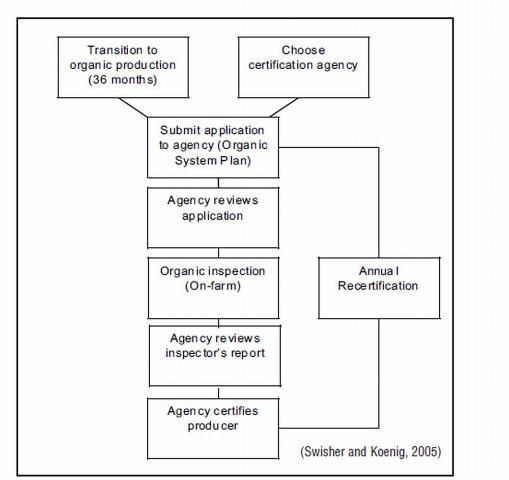

Certified organic production is the process of satisfying and maintaining the stringent production standards established by the NOP rule and validated by an accredited certifying agency (Figure 1). Accredited agencies include private for-profit and non-profit agencies, as well as public state-run certifying agencies. The standards are dynamic, and minor revisions are ongoing through a transparent process involving public notification, public comment, and federal rulemaking. All producers, handlers, and processors who are certified are required to be compliant with the specific sections of the Final Rule that apply to their operation.

Any farmer with gross organic sales greater than $5,000 a year and who advertises products as organic is required to be certified. If gross sales are less than $5,000 a year, certification is optional, and although farmers are allowed to verbally communicate that they are following organic standards, regulations prohibit using the USDA seal or the words “certified organic” on any label or advertisement. False claims are subject to a $11,000 fine and possible legal action for every violation.

The basic steps to certification are listed in Figure 1. Producers are required to design and adhere to an organic system plan (OSP) to ensure they are managing all aspects of agricultural production and handling according to the organic regulations. In brief, land is eligible for certification once it has been free of prohibited substances for at least 36 months. Certification is available for a fee from third-party independent certifying agencies. Producers have the right to select any certifying agency that is accredited by the USDA NOP. A current list of accredited agencies is located at the NOP’s website. When selecting an agency, producers should consider cost of certification, accessibility, and experience, among other factors.

Credit:

Once an operation is certified, its organic status never expires unless it is suspended, revoked, or surrendered. The operation must be visually inspected and the organic system plan recertified annually by the agency. Growers may be certified by any USDA-accredited certifier, and they may switch to another certifier if they are not satisfied with the service or fees associated with their current certifier. There are costs for the initial certification as well as the annual recertification. The cost of certification varies from agency to agency, and growers should explore different accredited certifiers to determine which one fits their needs. Initial fees for a small farm average $750 for the initial year, and subsequent annual fees are less than the initial fee. In addition, the producer typically pays for the inspector’s travel costs to the farm for inspection. The USDA offers the Organic Certification CostShare Program in all states and territories to assist with up to 50% of certification costs, not to exceed $500. In Florida, this program is managed by Florida Organic Growers and Consumers (FOG) in cooperation with the Florida Department of Agriculture and Consumer Services (FDACS). For more information, visit FOG's website: http://www.foginfo.org/.

The Organic System Plan

In organic production, management strategies are selected to restore, maintain, and enhance ecological harmony among the components of the farming system. A common misconception is that organic farming merely involves the substitution of approved inputs for prohibited inputs. However, the misapplication of organic materials or poorly executed cultural pest-control strategies will effectively disrupt the function of ecological and biological cycles and may lead to detrimental outcomes (Lampkin 1990). To ensure natural cycles are managed in a proactive manner, the NOP requires producers to complete an Organic System Plan (OSP). The OSP, or farm plan as it sometimes called, is unique to each operation and is submitted to the certification agency for review and approval. Producers can get assistance with the development of their plan from a UF/IFAS Extension agent or other service providers. It is important to note that certifying agencies cannot provide consultation services to a producer on matters of production, including recommendation of specific input products or service providers, because that would be a conflict of interest. Rather, the responsibilities of certifying agencies are to make decisions on compliance of an operation in accordance to the national standards of the NOP and to provide information about their certification process, including fees. Certifying agencies are allowed to direct producers to publicly available information resources, such as UF/IFAS Extension publications, lists of crop consultants, and approved materials, but they are not allowed to recommend a specific one.

The two main components of the OSP are the soil management plan and the pest management plan. Producers are required to design and subscribe to a soil management plan to ensure they are managing plant and animal materials in a manner that does not contribute to the contamination of crops, soil, or water by crop nutrients, pathogens, heavy metals, or residues of prohibited substances. Rotation, tillage, irrigation, fertility management, and a soil- and plant-nutrient monitoring program are all factors that affect soil and water quality and should be included in the plan. The pest management plan provides producers with a road map to manage pests through mechanical, physical, and cultural control methods. Approved non-synthetic biological, botanical, or mineral inputs may be used to manage pests only if preventative methods fail to provide sufficient control. A producer’s certifying agency will confirm when it is appropriate to use additional inputs for pest management.

Credit: USDA

The OSP is more than just paperwork. It is a management tool that guides farmers to manage anticipated challenges in a proactive manner, thus enabling farmers to manage funds and resources efficiently. The OSP is also a legally binding contract between the farmer and the certification agency; once the OSP is approved, the farmer has a written guarantee from the certifier that the documented practices and materials are acceptable (Baker and Riddle 2019). Records need to be kept for at least five years and made available for authorized federal, state, and/or agency service providers. Changes to the plan should be discussed with the certifying agency before implementation. Specifically, the plan must document items 1–4, and items 5 and 6 are typically required by the certifying agent:

- A description of the record -keeping protocols.

- A plan of all inputs to be used, including documentation of their composition, source, location, and date used.

- The monitoring practices to verify the plan is effectively implemented.

- A description of practices and physical barriers used to prevent the commingling of organic and conventional products on farms with split production. Also, to prevent organic products from contamination with prohibited substances.

- An accurate farm map, including permanent structures, field boundaries, non-crop areas, and hydrologic features, such as wells, irrigation ditches, and ponds.

- Field histories documenting production methods (conventional, transitional, organic), crops, cover crops, all inputs, and field sizes or production areas (if greenhouse or beds).

For operations with split production systems (organic and nonorganic), the plan must define adequate buffer zones (physical structures or natural features) to prevent the possibility of unintended contact with a prohibited substance, establish protocols to prevent commingling of unpackaged organic and noncompliant products, and outline an equipment cleaning protocol for shared equipment.

Information about the NOP regulation, certification, marketing, and technical production assistance may be obtained locally from your local UF/IFAS County Extension agent or a staff member at a certification agency. Several free educational tools are available to assist farmers to complete an Organic System Plan, including those found on the National Sustainable Agriculture Information Service's (ATTRA) website (https://attra.ncat.org/) and on the Sustainable Agriculture and Education program's (SARE) website (https://www.sare.org/). Due to the substantial impact of crop rotation on soil fertility, soil physical structure, soil, organic matter, and pest management, organic producers must implement a crop rotation that provides for some or all of these functions and include this crop rotation plan with the OSP. Crops can include, but are not limited to, sod, cover crops, green manures, and catch crops, in rotation with harvested crops. The length and design of the rotation is dictated by climate cycles, production needs, and market opportunities. For a more complete discussion of rotation and its effects of the production system, visit the ATTRA website or refer to Mohler and Johnson (2009) and Lampkin (1990).

Approved Inputs

The NOP’s National List of Allowed and Prohibited Substances (commonly referred to as the “National List”) specifies the inputs that are allowed for use in organic production, handling, and processing, and is part of the NOP regulation. Substances proposed for use in production, handling, and processing are subject to a rigorous technical review process by the NOSB to determine if the substance satisfies the legal criteria in the Organic Food Protection Act and Final Rule of the NOP. Amendments to the list are updated regularly through a federal register process. A current National List is available from any certifying agency or the NOP website. In general, most synthetic substances are prohibited and most natural products are allowed unless they appear otherwise on the Allowed and Prohibited Substances List.

According to the NOP, the term synthetic is defined as "any substance that is formulated or manufactured by a chemical process." Substances that are created as the "result of naturally occurring biological processes” are referred to as non-synthetic or natural. The National List provides guidance for proper use of materials that are allowed or allowed with restrictions. For example, although arsenic is a natural substance, it is prohibited for use in organic systems. Plastic mulch, a synthetic, is allowed for use, provided the material is not made of polyvinyl chloride and the mulch is removed and disposed of according to local waste management guidelines. The List is organized in specific use categories, such as "Insect Control" and "Soil Amendment." In some instances, a substance or material may be approved for use in one application (sanitation) but prohibited in another (soil amendment).

A second resource that lists allowable synthetic and non-synthetic products for organic producers is the Organic Materials Review Institute (OMRI) Products List. OMRI is a private, not-for-profit organization that serves the organic community by determining if brand name products are compliant with the NOP regulation. Because product labels do not provide complete information about active and inert ingredients, the OMRI Products List is a reliable resource and contains a current and rather complete inventory of allowable products. Companies pay a fee and fully disclose their formulations and other necessary proprietary information to OMRI for a thorough review. Thus, OMRI provides a needed service for manufacturers who do not wish to disclose trade secrets to the general public but desire to sell their products to organic producers. However, because inclusion on the OMRI List is voluntary, omission from the OMRI List does not necessarily mean the substance is prohibited. Many product manufacturers, particularly those selling fertilizer and mineral soil amendments, may seek verification of compliance with another organization that has met the USDA's criteria for material review, such as the input registration programs within the Department of Agriculture in California. Your certification agency will make the final determination of product approval in the context of use and your organic system plan.

Products that have been listed by OMRI as approved for use in organic production carry the label (Figure 3). OMRI makes no claims to product effectiveness; they only verify that the product is approved for use under the NOP. The OMRI Products list is available to the public at no cost on their website at http://www.omri.org.

Organic growers are obligated to comply with mandatory pest or disease treatment programs authorized by federal, state, or local agencies deemed necessary to eradicate a pest or disease. In this rare instance, producers may appeal to the agency initiating the treatment program and offer an alternative pest control program. Producers may also request that synthetic sprays be withheld from land under organic production. The producer’s certifying agency should be notified immediately if this situation occurs. If the treatment includes prohibited pesticides and those substances are used on crops under organic production, those agricultural products cannot be marketed as organic for that season; however, producers are allowed to maintain certification of their land without penalty. For example, if insecticides were mandated by the state to control medfly in all Florida citrus, and those insecticides were applied to organic oranges, the producer would not be able to market the oranges as organic for that harvest cycle but would not necessarily lose his or her certification.

Soil Quality and Fertility Management

In organic cropping systems, it is necessary to plan crop rotations in advance, add organic matter to the soil, and employ suitable tillage practices to ensure crop fertility and preserve soil and water quality. Because plants vary in their nutrient requirements and in their ability to extract nutrients from the soil, rotating crops with different nutrient needs and plant architecture in the field can increase the efficiency of nutrient use and decrease the potential for nutrient leaching or runoff. For example, plants with shallow, fibrous root systems are more efficient at utilizing nutrients mineralized from decomposing organic matter on or near the soil surface. Deep-rooted plants, such as winter cereals, are efficient at extracting nutrients that have moved downward in the soil profile.

Organic production systems rely on biological processes to convert organic forms of nutrients to mineralized, plant-available forms; therefore, nutrients are released slowly over time. In Florida, many soils are low in organic matter content, so the addition of organic materials is important to stimulate the growth and reproduction of soil microorganisms. Regular additions of organic matter increase the size and stability of soil aggregates, as well as reduce soil erosion. Larger aggregates are not as easily moved by wind or rain, and less crusting means more water can infiltrate the soil rather than move over the surface. In rotations, organic matter can be added by including sods, catch crops, plant mulches, and green manures, supplemented by compost or other stable organic materials.

Most cropping systems require tillage to prepare the soil for planting, as well as cultivation during the growing season to control weeds and reduce insects. However, tillage disturbs soil structure and decreases the amount of soil organic matter. To minimize negative effects on soil water-holding capacity and soil fertility, and to prevent losses of topsoil that could occur with an excess of mechanical cultivation for weed control, tillage should be employed judiciously. Employing a combination of practices, including crop rotation, appropriate tillage, and the addition of organic amendments can improve soil quality by:

- maintaining soil fertility,

- improving soil tilth (physical condition),

- reducing soil compaction and erosion,

- increasing soil water-holding capacity (namely, field capacity),

- suppressing some soilborne pathogens,

- increasing predation of weed seeds by soil microbes, and

- providing a source of slow-release plant available nutrients.

Planning and Monitoring a Nutrient Management Program

Due to the broad range of soil types in Florida, the best way to plan for future crop nutritional needs is through periodic soil tests to monitor soil nutrient concentrations.

In general, the rotation schedule will influence the soil sampling schedule. Samples should be collected annually or at least before the start of each rotation when the rotation is short (less than three years). To avoid contamination of surface and groundwater associated with the overapplication of fertility inputs, producers are advised to submit samples of soil amendments to a reputable laboratory for analysis if a guaranteed analysis is unavailable from the supplier.

Crop fertility recommendations are the same in organic as they are in conventional systems, and materials must be applied at rates compliant with existing nutrient-management guidelines and in a manner that minimizes environmental degradation. However, the number of allowed inputs is limited in organic systems. Therefore, producers must be resourceful when selecting inputs to provide sufficient fertility. Most plant nutrients are supplied by natural sources of fertility—including compost, animal manures, and leguminous cover crops—and are supplemented by the application of mined sources of mineral nutrients and various formulations of minor nutrients.

Because the organic fertility sources listed above are slowly available in the soil, nutrient amendments are typically pre-plant incorporated, with occasional side dressing or fertigation, depending on crop production recommendations. To meet the criteria for Florida’s Best Management Practice (BMP) program, no more than 50% of a crop’s recommended nitrogen (N) requirement should be applied at seeding or transplanting (FDACS 2022). When plastic mulch and drip irrigation are used, remaining fertility applications are practically limited to soluble forms. Most fertigation products are fish meals and emulsions, which can be purchased as wettable powders. These products typically have a low N analysis and can be expensive, so providing a substantial fraction of the necessary nitrogen through fertigation may not be economically feasible.

During the growing season, plant tissue analysis is the most accurate method to assess fertility levels. Plant tissue analysis can also provide information on nutrients that are not easily measured in soil analysis, such as N, boron (B), and sulfur (S). Sufficiency ranges for N and potassium (K) content from petiole sap and twelve nutrients from whole leaf samples are available in EDIS publications EP081 Plant Tissue Analysis and Interpretation for Vegetable Crops in Florida https://edis.ifas.ufl.edu/ep081 (Hochmuth et al. 2015) and CV004 Plant Petiole Sap Testing for Vegetable Crops https://edis.ifas.ufl.edu/publication/CV004 (Hochmuth 2015). If nutrient content is less than sufficient, increase fertility as needed. The UF/IFAS Extension Soil Testing Laboratory (ESTL) offers six types of analysis, including soil and tissue analyses, for a modest fee. Interested producers should contact their county Extension office or visit http://soilslab.ifas.ufl.edu/ for more information. In addition to the ESTL, several private laboratories offer similar services.

Recommended steps to a nutrient management plan include (1) using the IFAS recommendation for nutrient application rate; (2) knowing the nutrient analysis of the materials you are applying; (3) accounting for estimated nutrient contributions from pre-season compost applications and legume cover crops; (4) subtracting the estimated nutrient contributions from the seasonal recommended fertilizer rate, while accounting for N, phosphorus (P), and K, as well as secondary nutrients if soil tests indicate a deficiency; and (5) planning to apply nutrients in a manner that will not pose a risk to water quality (Ozores-Hampton 2012). An efficient irrigation system is critical to minimize leaching and retain nutrients in the root zone of crops (Simonne et al. 2015).

Employ the following best practices for nutrient and water management:

- select fertilizers with an estimated release rate that coincides with crop demand,

- use N sources with slower mineralization rates (poultry litter) at the beginning of the season and N sources with faster mineralization rates (feather meal) for established crops before periods of rapid growth or fruit formation,

- limit application rates of nutrient amendments with quickly available N to what the crop will use to minimize risk to groundwater quality,

- split fertilizer applications over time,

- incorporate N into moist but not saturated soil,

- employ soil moisture monitoring equipment to irrigate when soil moisture content falls below field capacity

- irrigate the crop but not the weeds,

- calibrate application equipment,

- cover the surface of beds with plant residues, or plastic mulches to retain soil moisture and suppress weeds,

- calculate application rates of bulk soil amendments based on laboratory nutrient analysis,

- avoid applying N and K before periods of extended rainfall

- plan for effective tillage that retains soil structure and minimizes moisture loss.

Nutrient Sources

Nutrient sources typically used in organic production are discussed below, and a summary of sources is presented in Table 2. All materials sold as "fertilizers" in the state of Florida must be registered with the Florida Department of Agriculture and Consumer Services (FDACS). These products come with a guaranteed analysis clearly stated on the product label. Materials not registered with FDACS are sold as "soil amendments," even though they are commonly used in organic systems to improve soil fertility. The nutrient concentrations in soil amendments vary depending on the method of production and source of materials. Average concentrations of commonly used soil amendments are listed below in Tables 2–4. Bulk fertilizers and soil amendments are generally allowed in organic production if they are natural or mined. Some synthetic micronutrients are allowed with documented nutrient deficiency. Because some forms of these materials may be prohibited, producers should request written confirmation of approval for organic use (request a copy of the OMRI label or validate with the certifying agency).

Compost

Compost is the product of biologically-mediated decomposition in the presence of heat. The NOP requires that compost must be generated according to specific guidelines to reduce pathogens harmful to humans. The NOP guidelines are consistent with the US Environmental Protection Agency (EPA) guidelines for compost manufacture (CFR Title 40, Part 503, Appendix B, Section B). Compost must be manufactured with raw materials that have an initial carbon (C) to N ratio between 25:1 and 40:1. An internal temperature between 131°F and 170°F must be maintained for at least three days for in-vessel or static-aerated systems or for at least fifteen days (and five turnings) for windrow systems. Compost can be formulated to meet the site-specific needs of the system. For instance, some compost formulations can reduce the incidence of plant disease, while composts containing crushed egg or oyster shells can provide a valuable source of calcium (Ca). There are many possibilities, but producers should have a firm understanding of soil biology and chemistry to avoid potential complications.

If animal waste is not composted according to the NOP rule, then it is treated as raw animal manure. Raw animal manure can be applied to a crop that is not for human consumption, applied 90 days before the crop harvest date if the edible portion does not touch the soil, or applied 120 days before the harvest date if the edible portion does come into contact with the soil. This approach is consistent with the current guidance for on-farm compost from the Produce Safety Alliance (https://producesafetyalliance.cornell.edu/).

The average nutrient analysis of common animal manures used in organic production is summarized in Table 2. When using animal manure, there are two important considerations. First, in addition to regular soil tests, producers are strongly encouraged to submit samples of compost and animal waste for analysis before application to avoid the accumulation of P, zinc (Zn), and copper (Cu) in production areas. For example, stockpiled turkey litter applied at a rate of 5 tons per acre to a crop of sweet corn could supply 180 pounds of total N or approximately 54 to 90 pounds of plant-available N. However, phosphorus (as P2O5 equivalent) would provide 400 pounds per acre, while crop removal would be roughly 4% of applied P, or about 16 pounds for a yield of 114 cwt. Similarly, 2.8 pounds of Zn would be added, but crop uptake would be less than 5% or 0.15 pound-per acre. Maintain records on the amount of P and heavy metals applied to soils to avoid crop toxicity and include legume and grain cover crops to diversify sources of nutrients. Soil copper concentration is monitored, and farmers must submit soil test results every few years to demonstrate that soil Cu content is not accumulating over time. Second, repeated applications of animal manure can increase the pH over time. Perhaps most importantly, the amount and timing of nutrient availability is hard to predict because of the many environmental factors that influence the rate of biological processes. These factors include:

-

soil temperature,

-

soil moisture,

-

soil water holding capacity (i.e., field capacity),

-

method of irrigation,

-

percent soil organic matter,

-

previous field history (tillage),

-

concentration of nutrients currently in the soil relative to previous applications,

-

current crop's uptake efficiency, and

-

frequency and type of tillage during the current cropping season.

For animal wastes and cover crops, the current UF/IFAS guidance is to estimate that 50% of the total N in the material will be available to the crop during a typical growing season. However, the actual amount of nutrients available depends on the previously mentioned environmental factors. Spent mushroom compost, a by-product of the mushroom industry in Florida, may be a source of compost for organic producers. If compost or manure is purchased in bulk and stored on site, the storage area must be designed to prevent runoff and leaching during periods of heavy rain. Producers should request records of raw materials and their production history to ensure the compost does not contain residues of prohibited materials, such as the herbicide aminopyralid (Ferrell et al. 2017) or hydrated lime (which is prohibited). Contact the certifier to make sure that any new information regarding commercial compost sources is properly reviewed and approved. The average nutrient content of meals and compost materials used in organic production is summarized in Table 3.

Mined and Other Natural Products

Non-animal fertility inputs approved for use in organic farming systems are applied in their natural, unprocessed state and have a range of solubility rates. Some mined inputs that would not be eligible for use in organic production include certain types of synthetic processing or the addition of a prohibited substance after mining (such as certain pelletizing agents). For example, agricultural lime, including mined dolomitic lime and mined calcium carbonate, are allowed for use in organic systems, hydrated lime (slaked lime Ca(OH)2) and burnt lime (calcium oxide CaO) are prohibited due to their method of manufacture. The average nutrient analysis of commonly mined or natural amendments used in organic production is summarized in Table 4. Nitrogen is frequently the most limiting nutrient in vegetable production systems, and N management can be challenging in organic production systems due to the complexity of interactions among soil texture, temperature and moisture, soil biological diversity, and N source. Naturally-occurring nitrates present in mined N rock—such as sodium nitrate (NaNO3), Chilean nitrate, or bulldog soda—may be used with restrictions, if allowed. Sodium nitrate is under consideration by the NOP for withdrawal from the list of allowable fertility inputs. Sodium nitrate contains approximately 27% sodium (Na), so applications of sodium nitrate should be carefully monitored to avoid excess salt build-up in soil and water.

Sodium nitrate is prohibited under some foreign national standards (European Union, Japan), so if the crop is for export (such as citrus juices) then producers will need to refrain from using sodium nitrate. Other plant nutrients including P, K, Ca, magnesium (Mg), Cu, S, manganese (Mn), and Zn are readily available in commercial products. If producers can document a soil deficiency, then certain synthetic materials with relatively high solubility may be used with approval from their certifying agent, including sulfates, carbonates, oxides, or silicates of Zn, Cu, iron (Fe), Mn, molybdenum (Mo), selenium (Se), and cobalt (Co).

Commercial Formulations

A number of manufacturers have formulated fertilizers for organic cropping systems that are composed of dehydrated granular by-products of animal production. These products are typically composed of materials such as feather meal, bone meal, and poultry litter, plus other mined sources of P, K, and some micronutrients. Examples of available formulations are 8-5-5, 4-2-2, and 4-2-3. The analysis is guaranteed, and the dry granulated forms are easy for producers to calibrate and apply, but these materials can be expensive.

Cover Crops

Cover crops are an integral part of organic production systems and are defined as any crop used for any other purpose other than to harvest as a food product. They are used to improve soil physical properties, add organic matter, reduce erosion, prevent sandblasting, supply nutrients, suppress weeds, and interfere with pest life cycles. Producers should identify specific objectives in the farming system and consider the potentially negative consequences (alternate host to insect or disease, leaches compounds that may be toxic to small seeded annuals) before selecting cover crop species. The cover crop should be easy to establish with minimal to no inputs, satisfy the producer's objective, not compete with the primary crop, be managed with existing equipment and labor resources, and perform well under various environmental conditions.

In Florida, cover crops that have been used successfully for partial N supply are sunn hemp (Crotalaria juncea L.), cowpea (Vigna unguinculata L.), velvetbean (Mucuna deeringiana L.), hairy vetch (Vicia villosia L.), crimson clover (Trifolium incarnatum L.), and jointvetch (Aeschynomene spp.). Other species such as sorghum sundangrass (Sorghum bicolor x S. bicolor var. sudanese (Piper) Stapf) and cereal rye (Secale cereale L. 'FL401'), are effective catch crops and are used for biomass production.

Leguminous species should be inoculated to ensure colonization by N fixing bacteria, unless the native soil has an adequate population. The majority of N that is returned to the soil following incorporation of a green manure is typically water-soluble nitrate. To moderate the potential for nitrate losses, producers can plant a mixture of cereal grains and legumes to increase the proportion of carbon to nitrogen added to the soil.

In most cases, when cover crops are present, weed suppression is attributed to increased competition for light, water, and nutrients. Some species, including rye, exude toxic substances through roots or incorporated stems and leaves into the soil. These substances are effective in killing some species of small seeded annuals and grasses, but may also be toxic to small seeded vegetable crops, such as carrot and onion. In this instance, increasing the time between cover crop termination and vegetable planting, or using transplants rather than direct seed, may reduce the negative effects of plant chemicals. Many species of cover crops do an excellent job of suppressing weeds, though the crop must be managed properly to avoid undesired regrowth.

Some species of cover crops, including sorghum sudangrass and sunn hemp, are known to suppress nematode populations, while others such as hairy vetch (Vicia villosia L.) are associated with nematode population increases. More information on cover crops, including estimates of available nutrients, can be found on EDIS and in the online publication "Managing Cover Crops Profitably" by USDA Sustainable Agriculture Research and Education (SARE) at no charge on their website.

Seeds and Transplants

Seed (including cover crop seed), annual vegetable transplants (annual seedlings), and perennial plants must be certified organic unless the desired variety is commercially unavailable. "Commercially available" is defined by the NOP as any production input in an appropriate form, quality, or quantity to fulfill an essential function in a system of organic production. If no organic variety is available, then conventionally produced untreated seed or seed treated with an approved synthetic or non-synthetic material (i.e., clay) may be used with approval from your certifying agency. Seed used for the production of edible sprouts must be organic; the “commercially available” clause does not apply. Methods used to genetically modify organisms that are not possible under natural conditions or processes are prohibited in organic production. Prohibited methods include recombinant DNA technology, cell fusion, and micro- or macro-encapsulation. Examples of allowable natural methods include traditional breeding, fermentation, hybridization, in vitro fertilization, and tissue culture.

Producers should make a reasonable effort to locate organic seeds and plants, and they will be required to document their search efforts on record. Producers are encouraged to save seed labels with documentation of commercial unavailability. Currently, the demand for organic seeds and transplants frequently exceeds the supply. The higher cost of organic seeds and plants is not considered a valid reason to purchase conventional equivalents. As the demand for organic seed and plants continues to increase, it is anticipated that over time the availability will increase, and costs will decline.

Planting stock is defined as either annual or perennial, and the rules governing each are different. Annual seedlings are plants grown from seed that will complete their life cycle or produce harvestable yield in the same year they were sown. When the seedlings are removed from their original production location, transported, and replanted, they are considered transplants. Producers who grow their own transplants must also satisfy regulations regarding the use of pressure-treated wood in greenhouses and related structures, use of organic materials in soil mixes, and other inputs. Two exceptions exist for the purchase of organic annual seeds and seedlings: (1) if federal or state regulations require seed treatment for phytosanitary reasons, then producers are allowed to use seeds or seedlings treated with prohibited substances; and (2) if original organic transplants were destroyed by an act of nature, fire, or other business interruption, conventional replacement transplants may be used with approval.

Perennial plants are those that will be maintained and harvested for more than two harvest cycles, or sold as a plant. If it is necessary to use non-organically produced planting stock for perennial crops, then produce from that plant, or the plant itself cannot be marketed as organic for at least one year following transplanting. For example, blueberries from non-organic replacement trees or shrubs in an organically produced area can only be sold on the conventional market until all the fruit is harvested from that plant. As always, consultation with your agency is highly recommended prior to purchasing non-certified produced seed or stock to ensure compliance.

Pest Management

Successful pest management strategies will reflect the producers' knowledge of the pests most likely to occur on crops, the life cycles of those pests, alternate plant hosts, approximate time of emergence, method of dispersion, and more. The challenge is to manage the interacting factors of the ecological environment to minimize pest damage to crops. Due to the limited number of approved substances for pest control, sucess is achieved largely through prevention. Regardless of the pest, organic farmers emphasize pest prevention through avoidance strategies, including soil solarization (Gill et al. 2009), crop rotation, the timing of planting, resistant crop varieties, and similar best management practices. In addition to avoidance strategies, producers can employ tactics that exaggerate naturally occurring control mechanisms, such as attracting beneficial insects. Using many complimentary strategies or "many little hammers" to manage pests provides flexibility and strength to the pest management plan.

A three-level approach is used to ensure producers are managing pests using physical, biological, and cultural means prior to relying on approved substances. Although the distinction between the levels is not always clear, the levels are defined by the NOP as follows:

Level One—Management practices that reduce the potential for the development of pests. These are proactive measures the producers must take to eliminate the need for additional management.

Level Two—Involves the use of traditional management practices, primarily cultural and mechanical steps or the use of natural products.

Level Three—Allows for the use of a wider array of biological and botanical products, including allowable synthetics.

Producers must document their efforts toward compliance on the first two levels. Because some proactive measures are also traditional management practices, the distinction between Levels One and Two is often minimal. Producers should develop a pest management strategy to ensure all steps are taken to avoid reliance on Level Three controls. Examples of Levels One and Two practices include alternating plant families or plant growth habits in time and space (rotation, intercropping), establishing predator populations in border crops, selecting resistant varieties, and using row covers. Level Three controls are the producer’s last line of defense and should only be used when all other options have been exhausted. If a producer anticipates the need for curative controls (Level Three), then specific products and their conditions for use should be included in the Organic System Plan. This may occur when the sum of preventative practices are predicted to be insufficient for adequate control.

The UF/IFAS Vegetable Production Handbook maintains current pesticide recommendations for crops and includes OMRI-listed products (https://edis.ifas.ufl.edu/topic_vph). Keep in mind that the Handbook also lists prohibited substances, and it is the farmer’s responsibility to ensure every product used has been approved by their certification agency.

Weed Management

Weeds are frequently cited as the primary pest in organic cropping systems. Due to the limited number of effective herbicide controls, prevention is the best strategy. When devising a weed management plan, producers should consider the weed density and spectrum of species present and avoid locating crops in fields known to have heavy infestations of weeds. Weed populations can be decreased over time with cultural and mechanical practices. An excellent discussion of mechanical weed control implements and their use is found in the SARE publication “Steel in the Field” and is available on the SARE website at no cost.

Small-seeded annuals can be depleted with repeated shallow tillage, soil inversion, and plant and plastic mulches. Large-seeded annuals and perennial weeds often require additional methods, such as rotation or solarization. Weed species that propagate vegetatively, such as nutsedge, are difficult to control in organic systems. Research has demonstrated that solarization, cultivation every two weeks, and ensuring fields are planted in cover crops in a timely basis have has been effective in reducing nutsedge populations. Cover crops suppress weeds by several different mechanisms (Schonbeck 2015). Targeted (drip) irrigation that is direct to the crop minimizes the water and nutrient resources available to the weeds and helps to inhibit the germination of some species.

Insect and Nematode Management

Organic farmers employ ecological pest management strategies. Because each farm is unique in its location, crop rotation, site history, and surrounding land use characteristics, the combination of practices used (and their effectiveness) tends to be site-specific. To avoid infestation and the risk of crop failure, anticipating pests typical for the crop and weather conditions, as well as the life cycle of each pest, is valuable information. Each operation will develop a pest management plan that is effective and appropriate to their needs. Three key strategies to ecological pest management are (1) select, grow, and rotate a variety of crops that have natural pest resistance or are unattractive to the pest typical of your operation, and provide crops with adequate nutrition to alleviate plant stress and optimize growth; (2) stress the insects by interrupting their life cycles, remove alternate food sources, and confuse them with various visual cues or pheromones; and (3) enhance populations of beneficial insects that attack insect pests by providing them food and habitat (Altieri et al. 2005).

Cover crops in rotation with primary crops can interrupt insect life cycles and confuse some pests, discouraging colonization. Cover crops also attract many predatory and parasitoid beneficial insects that reduce pest populations. Beneficial insects can also be purchased from commercial suppliers and released on -site and can be used to colonize an area for the first time or to augment existing populations. Beneficials should have adequate food and shelter in the field if released before immigration of their preferred host (insect pest), and this can be accomplished using strips or borders of suitable plant species. Orders should be made in advance, as it may take several weeks for the order to arrive. Nematode management is primarily preventative. Once present, multiple strategies are needed to keep crop damage below economic thresholds (Krueger and McSorley 2014).

Disease Management

As with insect pest management, an understanding of the disease cycle is precursory to developing a control plan. Sanitation, crop diversification through rotation, biological controls, and other cultural practices are common approaches to disease prevention. Sanitation practices during crop production should be followed, such as cleaning then disinfecting tools and equipment after use. Several materials, including peracetic acid, hydrogen peroxide, peroxyacetic acid, chlorine (as calcium or sodium hypochlorite), and chlorine dioxide are included on the National List of synthetics allowed for sanitation, given they are used for specific activities (contact surfaces, wash tanks, etc.) as described in the regulation. Residual concentrations of active ingredients (chlorine) must meet federal water quality standards under the Safe Drinking Water Act.

Diseases caused by bacteria, such as bacterial spot on tomato and pepper (Xanthamonas campestris pv. vesicatoria) and common scab on potato (Streptomyces scabies), are controlled mostly with cultural practices. Few curative controls are available. Resistant varieties should be selected, and if not available, small-seeded vegetable crops can be treated with hot water before planting. Because bacterial diseases can be spread by splashing water, drip irrigation is preferred.

Diseases caused by fungi and similar organisms are avoided by using the strategies listed above, with some special considerations. Because many fungal organisms can remain in the soil for many years, rotation is especially important. Rotating with Brassica species that have high concentrations of glucosinolates can be effective in reducing black scurf (Rhizoctonia solani) when incorporated as a green manure prior to potato (Caldwell et al. 2005). Crops that are alternate hosts to the disease organism should be avoided, with special attention to removing weedy hosts. Avoid crop-to-soil contact by staking or mulching, and manage soil moisture with raised beds and drip irrigation to prevent excess soil water retention.

Biological controls are increasingly becoming an important tool to manage disease in organic systems. Products such as PlantShield HC made from Trichoderma harzianum were effective in suppressing early blight in tomato in recent research (Caldwell et al. 2005). A beneficial fungus Coniothyrium minitans (Contans) reduces the survival rate of sclerotia (Sclerotina sclerotiorum) when applied preplant or during an infection of white mold in solanaceous crops (Caldwell et al. 2005). In addition to commercially available products, compost may contain organisms that reduce some pathogens.

Copper is commonly used in a number of formulations depending on the crop and disease organism, but reports on the effectiveness of copper varies with the site. In addition, the over-application of copper on some sites can lead to copper toxicity in crops as well as copper resistant pathogens. For this reason, rotate copper-containing formulations with different modes of action when possible.

Food Safety

All crop and livestock producers are held to the same federal food safety standards regardless of production method. Due to the vigorous record-keeping protocols required for USDA-certified organic producers, obtaining additional certification for a farm food-safety program may not require an additional significant time investment. Based on current research data, organic and conventional production systems are subject to many of the same risks, and it is not possible to generalize that food safety risks due to contamination by enteropathogens such as E. coli are greater in one system compared to the other (Winter and Davis 2006; Smith-Spangler et al. 2012; Forman and Silverstein 2012). However, use of compost, manure, and other biologically active inputs does require additional care to ensure consumer safety.

The Federal Food Safety Modernization Act (FSMA)'s Produce Safety Rule includes a suite of practices designed to ensure a safe food supply. FSMA recognizes soil amendments in three categories: chemical (sodium nitrate), physical (perlite), and biological (organic matter). Organic farmers will want to pay close attention to FSMA regulations surrounding biological soil amendments of animal origin, including manures, compost, and compost tea. Specific best practice recommendations and a calendar of food safety training opportunities for farmers is available on the Southern Center for Training, Education, Extension, Outreach and Technical Assistance to Enhance Produce Safety's website (http://sc.ifas.ufl.edu/).

Proper postharvest handling and packaging of produce can reduce risk of pathogens as well as minimize harvested product losses due to poor quality (Sargent and Treadwell 2015; Watson et al. 2016).

Economics of the Organic Industry

In 2020, farmers implemented organic strategies on 185 million acres in 190 countries; 76 of those countries have fully implemented regulatory programs (FiBL and IFOAM, 2022). Although the regulatory details among countries vary, all imported organic agricultural products must satisfy criteria established by the USDA’s NOP before they can be marketed as organic in the United States. Similarly, exported organic agricultural products must also satisfy the organic regulations of the importing country. Industry experts predict the organic industry will continue to expand in the United States and there is no consensus about when market saturation may occur.

Sales of organic fresh produce exceeded $9 billion in 2021 (Organic Produce Network [OPN], 2021). Produce sales in the US Southern Region increased 7.6% over 2020, and accounted for $2.86 billion (OPN, 2021). Approximately 82% of US households purchased organic products at least occasionally, according to Nielsen data of UPC product scans (OTA 2016). Organic packaged salads, berries, lettuce, carrots, potatoes, citrus, bananas, apples, and herbs and spices contributed to both sales and volume increases in 2021 (OPN, 2021).

As reported by the OTA, the USDA Foreign Agricultural Services Global Agricultural Trade System cited US imports of organic crops at $25 billion and exports less than $650,000 in 2020, however, independent studies documented higher sales numbers for both imports and exports (OTA, 2022b). Statistics on US imports and exports of organic products are inconsistent, partly because the organic product codes have not been added to all products due to USDA restrictions on allocating harmonized codes.

In Florida, over 457 operations totaling over 17,912 acres are certified under the NOP (USDA 2022). Much of this crop acreage is in citrus production, with the remainder in mixed vegetables, herbs, and ornamentals. In addition, there are several certified organic livestock operations in the state. Due to the increased consumer demand, direct sales opportunities have increased in recent years and include farmer’s markets, subscription sales (Community Supported Agriculture or CSAs), and a minor share to restaurants. Traditional wholesale market opportunities account for the majority of gross sales for producers.

Additional Information

To view the entire National Organic Standards, see the following website: The National Organic Program (NOP): https://www.ams.usda.gov/about-ams/programs-offices/national-organic-program

For a list of OMRI approved materials, see the following website: https://www.omri.org/

To obtain recommendations and information on organic production, visit the following websites:

- UF/IFAS Small Farms and Alternative Enterprises: http://smallfarms.ifas.ufl.edu/

- Florida Organic Growers and Consumers, Inc.: http://www.foginfo.org/

- eOrganic's Organic Agriculture Resource Area: https:// www.eorganic.org/

- Appropriate Technologies Transfer for Rural America (ATTRA): https://attra.ncat.org/

- USDA's Sustainable Agriculture Research and Education: https://www.sare.org

- The Rodale Institute's Farm Resource Area: https://rodaleinstitute.org

For more information on the economics of the organic industry, visit the following websites:

- USDA's Economic Research Service, Organic Agriculture: https://www.ers.usda.gov/topics/natural-resources-environment/organic-agriculture.aspx

- International Federation of Organic Movements: (IF-OAM) https://www.ifoam.bio/

- The Organic Trade Association: https://www.ota.com/

Literature Cited

Altieri, M. A., C. I. Nicholls, and M. A. Fritz. 2005. "Manage Insects on Your Farm: A Guide to Ecological Strategies." Sustainable Agriculture Network, SARE. Beltsville, MD.

Baker, B. and J. Riddle. 2019. Organic System Plan Overview. eOrganic National Resources for Farmers and Ranchers. https://eorganic.org/node/325 eOrganic Publication No. 3251. http://articles.extension.org/pages/20975/organic-system-plan-overview

Caldwell, B., E. B. Rosen, E. Sideman, A. Shelton, and C. Smart. 2005. Resource Guide for Organic Insect and Disease Management. Cornell University. New York State Agricultural Experiment Station, Geneva, NY. 169 pp.

Ferrell, J., P. Dittmar, and B. Sellers. 2017. Herbicide Residues in Manure, Compost, or Hay. AG416. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/ag416

Florida Department of Agriculture and Consumer Services (FDACS). Agricultural Best Management Practices. Accessed Sept. 20, 2022. https://www.fdacs.gov/Agriculture-Industry/Water/Agricultural-Best-Management-Practices

Forman, J., and J. Silverstein. 2012. Organic Foods: "Health and Environmental Advantages and Disadvantages." Pediatrics. 130(5): E1406–E1415. https://doi.org/10.1542/peds.2012-2579

Gill, H.K., R. McSorley, and D. Treadwell. 2009. "Comparative Performance of Different Plastic Films for Soil Solarization and Weed Suppression." HortTechnology 19(4): 769–774. https://doi.org/10.21273/HORTSCI.19.4.769

Hochmuth, G., D. Maynard, C. Vavrina, and E. Simonne. 2015. Plant Tissue Analysis and Interpretation for Vegetable Crops in Florida. EP081. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/publication/ep081

Hochmuth, G. 2015. Plant Petiole Sap-Testing For Vegetable Crops. CV004. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/publication/cv004 Lampkin, N. 1990. Organic Farming. Ipswich, UK: Farming Press Books

Krueger, R., and R. McSorley. 2014. Nematode Management in Organic Agriculture. NG047. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/ng047

Kulesza, S.B., L.C. Gatiboni and K. Hicks. 2022 N.C. Agricultural Chemicals Manual, Chapter IV, Fertilizer Use. Tables 4-9 and 4-15A. https://content.ces.ncsu.edu/static/publication/js/pdf_js/web/viewer.html?slug=fertilizer-use

Mohler, C., and S. Johnson (eds.). 2009. "Crop Rotation on Organic Farms: A Planning Manual." Sustainable Agriculture Research and Education (SARE). Available at: http://www.sare.org/Learning-Center/Books/Crop-Rotation-on-Organic-Farms

Organic Trade Association. 2016. "Percentage of US Households Purchasing Organic Products." Accessed July 7, 2017. https://ota.com/sites/default/files/indexed_files/ HouseholdPenetrationOnly.pdf

Organic Trade Association (OTA) 2022a. "2022 Organic Industry Survey" https://ota.com/organic-market-overview/organic-industry-survey

Organic Trade Association (OTA). 2022b. US Organic Trade Data and Trends: 2016-2020. https://www.ota.com/tradedata/

Organic Produce Network (OPN). State of Organic 2021. https://www.organicproducenetwork.com/education

Research Institute of Organic Agriculture (FiBL) and the International Federation of Organic Agriculture Movements (IFOAM)-Organics International. The World of Organic Agriculture 2021. https://www.fibl.org/fileadmin/documents/shop/1150-organic-world-2021.pdf

Sargent, S., and D. Treadwell. 2015. Guide for Maintaining the Quality and Safety of Organic Vegetables and Melons during Harvest and Handling Operations. HS396. Gainesville: University of Florida Institute of Food and Agricultural Sciences. http://edis.ifas.ufl.edu/hs396

Schonbeck, M. 2007. Integrated Pest Management Concepts for Weeds in Organic Farming Systems. https://eorganic.org/node/2318

Schonbeck, M. 2019. Twelve Steps Toward Ecological Management in Organic Vegetables. https://eorganic.org/node/2320

Simonne, E. R. Hochmuth, J. Breman, W. Lamont, D. Treadwell, and A. Gazula. 2015. Drip-Irrigation Systems for Small Conventional Vegetable Farms and Organic Vegetable Farms. HS388. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/hs388

Smith-Spangler, C., M. Brandeau, G. Hunter, C. Bavinger, M. Pearson, P. Eschbach, V. Sundaram, H. Liu, P. Schirmer, C. Stave, I. Olkin, and D. Bravata. 2012. "Are Organic Foods Safer or Healthier than Conventional Alternatives?" Annals of Internal Medicine. 157:348–366. https://doi.org/10.7326/0003-4819-157-5-201209040-00007

Sullivan, P. 2001. "Alternative Soil Amendments". NCAT ATTRA Publication #IP054. http://www.attra.ncat.org/alternative-soil-ammendments/

Swisher, M.E., and R. Koenig. 2005. Understanding the National Organic Standards: What Service Providers Need to Know. UF/IFAS Extension Bookstore. http:// ifasbooks.ifas.ufl.edu/p-314-understanding-the-national-organic-standards-what-service-providers-need-to- know.aspx

Treadwell, D.D., D.E. McKinney, and N.G. Creamer. 2003. "From philosophy to science: A brief history of organic horticulture in the United States". HortScience. 38: 1009–1014. https://doi.org/10.21273/HORTSCI.38.5.1009

Treadwell, D., S. Park Brown, J. Stephens, and S. Webb. 2016. Organic Vegetable Gardening in Florida. HS1215. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/hs1215

[USDA] United States Department of Agriculture. 2019 Organic Farm Data. "Table 1. Farms, Land, and Value of Sales on Certified Organic Farms: 2019". https://www.nass.usda.gov/Publications/AgCensus/2017/Online_Resources/Organics/organics_1_001%20_001.pdf

Watson, J., D. Treadwell, S. Sargent, J. Brecht, and W. Pelletier. 2016. Postharvest Storage, Packaging and Handling of Specialty Crops: A Guide for Florida Small Farm Producers. HS1270. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/hs1270

Winter, C.K. and S.F. Davis. 2006. "Scientific Status Summary: Organic Foods." J. Food Science 71(9): R117–R124. https://doi.org/10.1111/j.1750-3841.2006.00196.x

Zublena, J.P., J.V. Baird, and J.P. Lilly. 1997. "Soil Facts: Nutrient Content of Fertilizer and Organic Materials." North Carolina Cooperative Extension Service. Pub. # AG-439-18. http://www.soil.ncsu.edu/publications/Soilfacts/AG-439-18/AG-439-18.pdf (June 2013)

Average nutrient content of meals and compost materials used in organic production (Percentage on a dry-weight basis).1