Introduction

Over 47,000 farms in the state of Florida produce nearly 300 different commodities, most of which are considered specialty crops, defined as fruits and vegetables, tree nuts, dried fruits, horticultural, and nursery crops. In Florida, agriculture is a multi-billion dollar per year industry. The state has several commodities that rank in the top 3 in the United States in total value of production including oranges ($709 million), grapefruit ($72 million), and strawberries ($399 million). Florida ranks first in the total value of production for many vegetables such as snap beans ($83 million), fresh market cucumbers ($40 million), sweetcorn ($208 million), and fresh market tomatoes ($324) (Florida Department of Agriculture and Consumer Services 2022). The value of these crops is an important component of the well-being of the state's producers and also to Florida's economy. The most recent United States Census of Agriculture (2018) revealed that 92.7% of farms in Florida had less than $350,000 in gross receipts, qualifying them as small farms according to the United States Department of Agriculture (U.S. Department of Agriculture, 2024). For small farmers, delivering fresh, high-quality produce presents significant challenges in regard to handling, storage, and packaging. These challenges may be caused by a lack of access to financial capital, information and knowledge, and proper equipment. To ensure that product quality is maintained throughout the distribution environment, guidelines regarding short-term postharvest storage, packaging, and handling are necessary.

For producers, the fruits of their labor culminate with a specific process each season depending on the crop, cultivar, and various environmental conditions. This process, known as the harvest, is the gathering of mature crops or yield from one growing season. The harvest marks the end of the growing season and represents significant social importance to communities as they celebrate its arrival each year. However, harvest time also creates challenges for producers trying to deliver fresh, high-quality produce to market. If not dealt with correctly, these challenges become barriers within the distribution chain, resulting in loss of revenue. Optimum postharvest practices for a given commodity serve to establish appropriate cold chains that maintain optimal temperatures, relative humidity, and slowing of respiration rates and ethylene production while utilizing appropriate packaging and following safety and sanitation protocols.

Indeed, it is the postharvest handling activities that maintain fruit quality as fresh produce travels throughout the supply chain. However, depending on the size of the farming operation and its economic situation, different specific practices are most appropriate to achieve these ends. The objective of this publication is to provide postharvest storage, packaging, and handling recommendations for small farm specialty crop producers that sell directly to consumers and through institutional marketing channels such as schools that participate in Farm to School (F2S) programs. These programs benefit children by providing them with healthy, nutritious fresh fruits and vegetables while offering producers alternative marketing opportunities and reducing price uncertainty.

Regardless of where a product is sold, proper handling and food safety practices must be observed. With these considerations, this publication serves as a general guideline for small farm specialty crop producers involved in the short-term storage, packaging, and handling of a variety of specialty crops commonly grown within the state of Florida. The recommendations in this publication are not intended to replace a comprehensive postharvest food safety plan.

Postharvest and Storage Management

Fruit and vegetable growers work diligently to ensure that they bring the best quality products to market. They possess the necessary skills to improve the value of their crops during the growing season. However, once the harvest begins, good postharvest handling practices must be used to safeguard the product throughout the distribution environment. According to Watkins and Nock (2012), the primary objective of postharvest handling is to maintain quality by

- reducing metabolic rates that result in undesirable changes in color, composition, texture, flavor and nutritional status, and undesirable growth such as sprouting or rooting;

- reducing water loss that results in wilting, shriveling, softening, and loss of salable weight and crispness;

- minimizing bruising, friction damage, and other mechanical injuries;

- reducing spoilage caused by decay, especially of damaged or wounded tissues, and preventing contamination by human pathogens that can cause food poisoning; and

- preventing development of freezing injury or physiological disorders, such as chilling injury or senescent (i.e., aging-related) disorders.

In practice, "products must be harvested at optimum maturity or quality, handled carefully to avoid mechanical injury, cooled quickly to remove field heat, stored in modified atmospheres if appropriate for the product, and maintained at acceptable temperatures during storage, distribution and marketing"(Watkins and Nock 2012, 12).

Products should always be harvested, if possible, when they are free of moisture, or they should be immediately dried off after harvest. Prolonged wetness almost always leads to a wide range of problems, such as excessive decay, mold, and cosmetic blemishes that render the product unsalable. Proper ventilation and maintaining proper relative humidity during storage are essential to maintaining the highest possible postharvest quality.

Postharvest Ripening and Maturation

A fruit is the mature ovary of a plant, whereas a vegetable is considered the edible portion of an herbaceous plant, such as the leaf, stem, root, tuber, bulb, immature fruit, or flower. Some fruits are commonly referred to and marketed as vegetables. Examples of ripe fruits typically categorized as vegetables are tomato, pepper, and acorn squash, and examples of immature fruits categorized as vegetables are okra, summer squash, and snap bean. Normally, fruit are regarded as fleshy, sweet structures with seeds, whereas vegetables are other edible parts of the plant. Many times, plants may be categorized as a fruit or a vegetable such as with tomato. It often depends on whether a plant is described in biological terms or is being used for culinary purposes. Producers are often concerned with the quality of their crops and the development of horticulturally mature fruits and vegetables. As a result, this guide will refer to fruits and vegetables in regard to the biological processes that affect their quality and not in reference to their culinary meaning. The term "horticulturally mature" means that the plant organ has developed to whatever stage is typically most desirable for human consumption. For the purpose of this guide, fruits and vegetables are considered to be the horticulturally mature, edible portions of a plant intended for distribution.

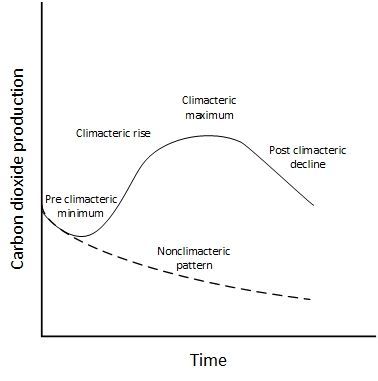

Fruits are classified in terms of two categories: (1) climacteric and (2) nonclimacteric fruits and vegetables, based on differences in their patterns of respiration and ethylene production that impact their optimum postharvest handling practices (Rees et. al 2012). Climacteric fruits are those whose ripening is accompanied by a distinguishable increase in the respiration rate and is generally associated with elevated ethylene production, ethylene being the natural ripening hormone in plants. After the respiration and ethylene production rates peak (the climacteric peaks), both decrease significantly. Examples of climacteric fruits commonly grown in Florida are tomatoes, avocados, peaches, and muskmelons. Nonclimacteric fruits do not exhibit this behavior; but rather, the respiration rate undergoes a gradual decline during ripening and aging, and there is no increase in ethylene. Examples of nonclimacteric fruits commonly grown in Florida are citrus, grapes, strawberries, peppers, and watermelons.

The respiration rate differs markedly among different fruits and vegetables, reflecting the intensity of the metabolic processes that they are undergoing (Saltveit 2004). Thus, the respiration rate is strongly related to the relative perishability of different crops, with those harvested when fully mature tending to be less perishable than those harvested when immature and undergoing rapid developmental changes. Temperature, in addition to stage of development, strongly influences plant metabolism, and thus respiration rate. Respiration rates are also strikingly elevated when stress or physical injury is inflicted on the product. As seen in Figure 1, the respiration rate, as measured by carbon dioxide production, increases during ripening in climacteric fruits before reaching a peak and ultimately entering a post-climacteric decline. Nonclimacteric fruits and vegetables do not undergo this process.

Credit: Adapted from Salveit (2004).

As a general rule, horticultural maturity of climacteric fruits occurs when they are mature enough to be ripened off the plant with acceptable quality (from the pre-climacteric minimum shown in Figure 1 onward). Although climacteric fruits can be left to ripen on the plant, they often are not because the ripe fruit is more difficult to handle successfully. On the other hand, nonclimacteric fruits will not ripen once picked and therefore must be allowed to ripen on the plant before harvest.

Because of their ripening behavior, when climacteric fruits can be harvested mature but unripe, the onset of ethylene production and ripening rate is delayed, and the fruit can be stored for extended periods of time or transported over relatively long distances. Some fruits are exposed to ethylene gas to initiate more uniform ripening (e.g., tomato) or to enhance fruit color (as in the degreening of citrus). Not all climacteric fruits benefit from being harvested mature but unripe. Blueberries—although climacteric, must ripen fully on the plant to attain acceptable flavor. Employing these strategies with climacteric fruits can prove to be advantageous when products require longer storage durations, transportation over great distances, or when growers want to take advantage of favorable market conditions.

The storage life of commodities varies inversely with the respiration rate, which itself increases with an increase in temperature. In other words, the higher the temperature, the greater the respiration rate, and the more rapidly the commodity deteriorates, which reduces shelf life. The respiration rates for a given temperature and the ethylene production for selected Florida-grown commodities are listed in Table 2. Higher-ethylene-producing commodities such as avocadoes should not be stored near ethylene-sensitive crops, such as broccoli, celery, or watermelons, or any unripe climacteric fruits that one wishes to keep from ripening. Similarly, commodities that produce medium or moderate amounts of ethylene, such as tomatoes or cantaloupes, should be kept away from ethylene-sensitive commodities. In USDA Handbook 66, Salveit (2004) provides a summary of respiration rates for nearly all fruits and vegetables over a range of temperatures and indicates their relative ethylene production rates.

Temperature Management

Florida's mild winter temperatures allow for the cultivation of fruit and vegetable crops when other production areas in the country are not yet viable. Warm temperatures are required for production, but they can be detrimental to commodities during postharvest handling, promoting spoilage, waste, and ultimately a loss of revenue.

In fresh food systems, "maintaining the cold chain" is a term used to describe the management of temperature during postharvest handling. Among the various factors that affect the quality of fresh produce, temperature is without a doubt the most important. According to Kader (2002), "temperature management is the most effective tool for extending the shelf life of fresh horticultural commodities."

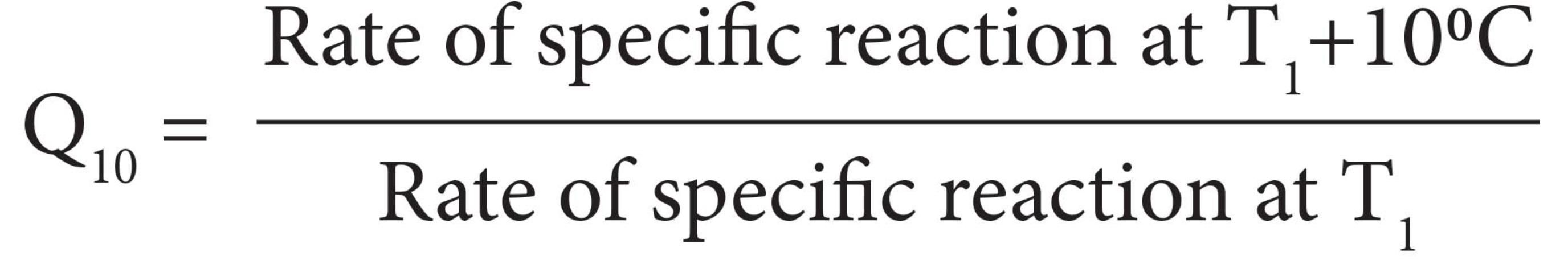

Upon harvest, products should be cooled to their optimum storage temperature range as quickly as possible for optimum postharvest quality. Failing to cool products will increase the rate of respiration and thus the rate of senescence, or aging, and related deterioration. Methods for rapidly cooling fresh fruits and vegetables to remove field heat and the appropriateness of the different methods for various commodities are described later in this guide. According to Nunes and Emond (2002, 238), "the respiration rate of fresh fruits and vegetables is often used as a predictor of the effect of temperature on the overall metabolism of plant tissue." A value called the Q10 temperature coefficient is often used to characterize these rates of respiration. The Q10 temperature coefficient is a measure of the changes, or rates of reactions, for a biological system as a result of a temperature increase of 10°C. Mathematically, the Q10 value is defined as the following:

In most postharvest applications, the Q10 value is often used as an evaluation method for predicting the effect of a temperature increase on respiration rates and, inversely, on shelf life. Within a temperature range of 5°C–25°C, the Q10 value for most crops will be around 2.0 to 2.5; however, some highly perishable crops such as sweetcorn and mushrooms have Q10 values of 4 to 5 in the same temperature range. Therefore, if the Q10 is 2.0 to 2.5, for every 10°C increase in temperature, the respiration rate will increase by a factor of 2.0 to 2.5, and the expected shelf life will be 50%–60% shorter. If the producer wishes to promote or facilitate fruit ripening, it may be desirable to maintain produce at warmer temperatures, but unless the goal is to speed ripening, warm temperatures should be avoided at all costs.

For small-scale producers, appropriate practices for managing postharvest temperatures can include harvesting crops during cooler times of the day, such as early morning (even before dawn), immediately moving the harvested product out of direct sunlight and, in the absence of refrigeration, quickly transporting the produce to a cool storage area such as an insulated structure. The higher the harvest temperature, and the higher the respiration rate and Q10 of the product, the more critical postharvest temperature management becomes—and the more of a priority it should be for a small farmer to invest in refrigerated storage. With regard to refrigerated storage, small window air conditioning units are relatively inexpensive; therefore, small-scale producers may find it advantageous to purchase a window unit and retrofit one into their storage facilities. These can be used in a variety of buildings such as insulated storage sheds or garages, marine cargo containers, or other similar facilities. Additionally, moisture loss can be mitigated by placing plastic liners over stacked boxes of product.

While changes in temperature will affect the respiration rates of fruits and vegetables, extreme temperatures can also cause physiological damage to fresh horticultural products, depending on the commodity. Commodities vary considerably in their temperature tolerance (Food and Agriculture Organization of the United Nations 1989). Symptoms of extreme heat injury in produce include bleaching, surface burning or scalding, uneven ripening, excessive softening, and desiccation (water loss). Higher-than-recommended temperatures may be satisfactory for certain commodities in short-term storage conditions, but over longer terms will almost certainly damage produce. For example, warmer temperatures (with high humidity) may promote healing, such as with storage potatoes, but potato tubers intended for fresh market become extremely susceptible to bacterial soft rot if held at normal late spring or summer-time temperatures. Similarly, for some tropical and subtropical crops, extreme cold temperatures can result in chilling injury. The optimum postharvest temperature for most fruits and vegetables is the lowest temperature that does not freeze the commodity. But some commodities are susceptible to chilling injury, which occurs at temperatures above freezing, but below a characteristic threshold temperature. It is important to know that this injury is cumulative, with multiple low temperature exposures, even before harvest, contributing to development of chilling injury symptoms. Chilling injury symptoms may include pitting, surface decay, internal browning, surface scald, as well as poor flavor, aroma, and color (Wilson, Boyette, and Estes 1999). These symptoms may take some time to develop. For chilling-sensitive crops, such as tomatoes, peppers, squash, eggplants, and citrus fruits, the optimum postharvest temperature shown in Table 1 is the chilling threshold temperature. Recommendations for optimum postharvest temperatures for additional fresh fruits and vegetables can be found in USDA Handbook 66 (U.S. Department of Agriculture 2014).

Fruit and Vegetable Packaging

There are as many types of packages available as there are products to put in them. Packaging systems are available in a variety of materials such as plastic, corrugated fiberboard, wood, and even sustainable materials such as bioplastics and fibers that decompose. One of the most common plastic packaging containers is the clear clamshell, manufactured from polyethylene terephthalate (PET) and other plastics using mechanical or vacuum thermoforming. Although plastic containers are necessary for certain commodities, corrugated and non-corrugated fiberboard is the dominant material used in fresh produce packaging. Wooden containers, usually wirebound, are a traditional form of produce packaging. They are an option for growers, although their use has gradually diminished over time because they are relatively heavy, expensive, and abrasive to the fruits and vegetables, and because they can present disposal issues. Sustainable packaging options are becoming increasingly more common and offer many advantages over traditional packaging containers. While beneficial to some, they are not appropriate for every operation. While there are a variety of functional packaging options available to growers of fresh fruits and vegetables, it is important to select the appropriate format for each specific commodity. Regardless of the material used, for a given commodity, it is important to use standard packaging sizes during the postharvest process so that growers can readily calculate total harvest by weight, count, and volume and thus more easily communicate production volumes to their buyers (Daniels and Slama 2010). Also, some buyers require that packaging footprints conform to the dimensions of the standard grocery pallet, which measures 40 x 48 inches (101.60 x 121.92 cm).

Packaging plays an important role in the fruit and vegetable distribution chain. According to Watkins and Nock (2012), packaging serves four main functions:

- Containment. Containment is the basic requirement for movement of a product from one point to another. The package type and size will be a function of the product and market requirements.

- Protection and Preservation. Packages provide protection for the product against environmental factors such as dust and water, as well as impact and compression bruising, and friction injuries that can occur during handling and transport.

- Convenience. Products are packaged in sizes convenient for handlers and for the consumer. Consumer packages are often contained within larger containers for transport because of economies of scale. The product may be removed from the container and placed in a display as single consumer units or repackaged for sale.

- Communication. In addition to advertising the type and source of the product, the package lists gross and net package weight, unit size of the product, and any additional information required by government regulations.

Another important feature of packaging for produce is that it should be designed with venting that facilitates cooling and temperature management during storage and transport so that field heat and respiratory heat can be efficiently removed.

Bulk Bins

Bulk bins allow producers to store, handle, and transport a large amount of product with relative ease. Bulk bins are manufactured from plastic polymers, wood, or corrugated fiberboard. Plastic and wood bulk bins are often only used on the farm because they are quite heavy and bulky (Figure 2). In terms of transportation, this restricts the amount of product available for shipping because each state imposes weight limits on transported goods. All types of bulk bins require heavy lifting equipment, such as forklifts, to move the product from field to packinghouse or storage because the contents often weigh in excess of 1,000 pounds.

Credit: Mark Ritenour

Despite their weight, bulk bins have many advantages. They allow for easy movement of large quantities of product and are usually stackable. The ability to stack product is oftentimes essential for operations that are limited by the size of their packinghouse or floor space. Bulk bins also eliminate the waste that results from smaller, compartmentalized packaging containers that are single use and require more material to contain the same amount of product. Bulk bins produced from corrugated fiberboard (Figure 3) are typically used by wholesalers, retailers, or other repacking operations because they are lightweight, may be collapsible, and even sometimes reusable. Corrugated fiberboard bulk bins can also have graphics on the side walls that can be customized for a specific commodity or with producer information.

Credit: Jeffrey Brecht

For safety and sanitation, plastic bulk bins are preferred to wooden bulk bins and containers. The plastic surfaces are easier to clean, which should be done after every use. Because of their porous surface, wooden bulk bins and containers are very difficult, if not impossible, to clean and sanitize. If using a wooden container to transport product from the field to the packinghouse, you should wash the product after it has been removed from the wooden bulk bin. Alternatively, plastic liners may be used with wooden bins—both to reduce potential contamination and to minimize abrasion damage to the product from rough wood surfaces. Fasteners such as screws, nails, and bolts can also result in punctured and damaged product, requiring regular inspection of wooden bins. Corrugated fiberboard bins can be used more than once but are more susceptible to damage than plastic and wooden bins. If reused, these bins should be inspected for cleanliness and covered in a plastic liner after the initial use in order to reduce the risk of cross-contamination. Alternatively, if the corrugated fiberboard bin has structural, water, or microbial damage, discard it immediately and use a new container in its place.

When determining whether to use bulk bins, consider the size and scale of an operation, the cost associated with the purchase and maintenance of the bins, as well as the commodity being packed. Smaller operations may have little use for large bulky bins, or they may pack product directly into retail containers. Bulk bins, specifically those produced from plastic and wood, may be too expensive for some smaller producers. For commodities that are highly susceptible to bruising and mechanical damage during transportation and handling, the use of bulk bins would be inappropriate. However, other commodities, such as potatoes and watermelon, would be considered ideal candidates for bulk bins because they are able to resist most of the damage that occurs throughout the distribution chain. Considering these choices will help producers determine the best course of action for their specific operational needs.

Wooden Wirebound Containers

Throughout history, wood has been used for packaging, transporting, and storing a variety of products, including fresh produce. Because they are porous and absorbent, wood containers are often thought not to be hygienic and therefore not suitable for fresh food products. However, it has been shown that certain species of wood, such as oak and pine, exhibit excellent antibacterial properties (Milling, Kehr, Wulf, and Smalla 2005). While wooden wirebound containers will not completely eliminate the risk of product contamination from the spread of microorganisms, if properly maintained, they provide a cost-effective short-term option for packing some commodities. Therefore, wood containers are a viable alternative for packaging, transporting, and storing fresh produce.

Wood containers come with or without handles and in a variety of sizes, shapes, and colors. Wood containers are available in several forms: barrels, baskets, hampers, or trays. Depending on the container, there may be a weave or specific design that can facilitate airflow for ventilation and rapid cooling. One of the most common forms of wood containers are the 1 1/9-bushel wirebound containers (Figure 4). This type of container is commonly used for commodities such as beans, sweetcorn, and potatoes.

Credit: Mark Ritenour

Wood containers have many advantages that make them an excellent material for fresh produce. Wood containers are sturdy and thus able to endure mechanical stress and support heavier products in stacked loads. Wood containers are reusable if properly handled, maintained, cleaned, and sanitized, providing significant savings for the growers. Compared to fiberboard, wood containers are a better option for products that come into contact with water because they are more resistant to moisture. However, dry wood can absorb moisture from produce, causing items to shrivel when they come into contact with the dry wood. Compared to plastic, wood containers are more affordable and result in significant savings from that of reusable plastic containers (RPCs). Wooden wirebound containers should be packed correctly by an experienced worker; otherwise, overpacking may cause bulging and present problems for transporting. Unfortunately, wood will eventually deteriorate and decay and must be replaced. Depending on the commodity, a wood container may be a good alternative for small farmers who sell locally and can easily retrieve used containers, assuming that the distribution environment, application, and cost factors are also favorable.

Corrugated Fiberboard Cartons

Corrugated fiberboard cartons are comprised of a paper-based material manufactured from the Kraft paper pulping process. As seen in Figure 5, corrugated fiberboard cartons are commonly made of single wall design with an inside and outside liner surrounding a fluted medium. The size of the flute determines the thickness of the corrugated fiberboard carton. Double wall and triple wall cartons are sometimes used for heavier and bulkier products because they provide added strength and rigidity. Traditionally, the strength of corrugated fiberboard cartons was measured using a burst test. However, burst tests measure the paper tensile strength whereas the stiffness and compression are typically the more desirable characteristics of corrugated fiberboard cartons. As a result, edge crush compression tests offer more valuable means of determining the performance of a corrugated fiberboard carton under compressive loads, which is important for containers holding products like fruits and vegetables that are commonly stacked.

Credit: Jeffrey Brecht

Some produce is packaged into fiberboard cartons fitted with anti-moisture barriers to prevent the liquids from penetrating the fiberboard. As a result, corrugated fiberboard cartons with anti-moisture barriers are ideal for products that may be exposed to water at some point during postharvest handling. Traditionally, wax has been the primary substance applied to the fiberboard to prevent moisture from either entering or leaving the carton. However, it is rather difficult to recycle corrugated fiberboard that is saturated with wax. RPCs are an alternative method of packaging for a variety of fruits and vegetables, especially those that are commonly exposed to water.

Corrugated fiberboard varies in flute size, burst strength, and edge crush strength, as well as surface treating and coatings. A few examples of products that are packaged into corrugated fiberboard include tomatoes, cucumbers, and sweet peppers; corrugated fiberboard is also used for the master containers of products like strawberries and grape tomatoes that are commonly packed first into plastic clamshells.

Custom-ordered corrugated fiberboard cartons may be too expensive for some producers. However, generic versions are available for lower cost. Some small farmers reuse cartons from larger operations, dismantling them, turning them inside-out to hide the original company's identity, and reconstructing them. This practice is not advised because the corrugated fiberboard cartons are prone to decay and there are food safety risks related to the cross-contamination of microbes carried on the reused cartons.

Reusable Plastic Containers (RPCs)

Reusable plastic containers (Figure 6) are becoming more prevalent in the fresh produce distribution system because producers and companies are trying to minimize their carbon footprint while simultaneously reducing costs. For many, RPCs have replaced corrugated fiberboard cartons as the preferred container for shipping fresh produce. Reusable plastic containers come in a wide variety of shapes and sizes, chosen primarily for their application to a specific commodity. Products that are hydrohandled or hydrocooled are especially suitable for packing in RPCs because RPCs are unaffected by moisture exposure. Reusable plastic containers are more durable and more rigid than their corrugated fiberboard counterparts. They are also weather resistant. As the name implies, RPCs can be utilized over and over again with very little wear, compared to most corrugated fiberboard cartons, which are used only once and then discarded. Most RPCs fold flat to minimize required space for storage and transport. Reusable plastic containers are produced from recyclable polymers, such as polypropylene (PP) or high-density polyethylene (HDPE), and therefore can be melted and reformed into new products.

Credit: Jeffrey Brecht

RPCs can either be purchased or leased. Depending on the frequency of use, purchased RPCs can provide a significant cost savings over single-use corrugated fiberboard or wooden containers. While the initial cost of purchase and maintenance may seem too expensive, frequent use and economies of scale can allow for lower, long-term savings. Decide whether to use RPCS by considering the size and scale of the farming, packing, or shipping operation and the types of commodities with which the operation deals. Produce handlers must also have either closed distribution systems or return agreements with their receivers in order to utilize purchased RPCs. Otherwise, it will not be possible to recover the RPCs after they have been used (i.e., shipped).

RPCs must be cleaned between each use because residues from previous crops can lead to contamination of new harvests. Adhering to strict sanitization and cleaning procedures is necessary in order to reduce the risk of contamination when RPCs are reused. Chemicals, such as detergents, acids, or alkalis, can be used to remove dust, dirt, product residues, and various other debris items from the surface. Scrubbing while also using chemicals increases the probability of eliminating any contaminants that may lead to foodborne illnesses. Note that cleaning procedures alone cannot guarantee the complete removal of all microorganisms. In order to reduce or eliminate microorganisms, the RPCs must also be treated with sanitizers or disinfectants. Sanitizing agents, such as chlorine-based compounds, iodine compounds, or ammonium compounds, are most often applied to food contact surfaces to destroy or reduce the number of microorganisms.

While RPCs can provide significant savings to some producers, not all operations justify their utilization. The choice to purchase RPCs is dependent on the ability of the handler to maintain and clean those containers. Some producers may have the equipment and capacity to maintain and clean RPCs, while others may not. If a distribution system does not allow a handler's RPCs to be easily recovered, or if cleaning, sanitizing, and maintaining purchased RPCs is not feasible for an operation, then leasing is the better option. Leased RPCs are returned to the supplier by the receiver; the supplier is then responsible for cleaning and sanitizing the containers before reintroducing them into the distribution system. Producers should conduct a thorough cost analysis that considers customer (receiver) buy-in, material requirements, labor, transportation, inspections, maintenance, and cleaning before purchasing RPCs.

Insert Trays

Insert trays are used for a variety of reasons when packing fresh produce. Insert trays are typically formed from molded plastic or pulp to create an insert for a master container that has multiple cavities to contain individual fruit (Figure 7). The cavity is designed to accommodate a specific size and/or variety of commodity as well as to maximize the number of fruit per tray. Insert trays are relatively inexpensive, costing only pennies per tray and providing additional protection to the product to minimize damage.

Credit: Jeffrey Brecht

Plastic insert trays are usually thermoformed by placing large, heated, pliable sheets of plastic into molds where they conform to a customer's specified dimensions. This process is very similar to clamshell thermoforming. However, the sheets of plastic thermoformed for insert trays are much thinner than those used for clamshells. Plastic insert trays are typically formed from polypropylene (PP). Foam trays manufactured from expanded polyethylene (EPE) and other polymers are common as well. Molded paper pulp insert trays are produced by combining water and recycled or reclaimed newsprint or corrugated paper to form a slurry. The slurry is then formed in a mold to produce a tray with cavities for the intended commodity.

Insert trays provide additional physical protection to the product, facilitate hand sizing of produce items in field-packing operations, and prevent fruit-to-fruit spread of decay. Plastic insert trays help minimize abrasion damage, localize decay to individual fruit, and reduce moisture loss. Conversely, paper pulp insert trays do not perform well when wet. On the other hand, moisture retention in plastic trays, as a result of condensation or improper drying before or during the time of packing, can create areas of free moisture that encourage decay. This is a problem when the product rests in water trapped in the bottom of the plastic tray. Whether plastic or paper pulp, each tray is often used only once and then discarded. Therefore, the risk of food contamination is relatively low.

While plastic and pulp trays both serve to separate the products and keep them from coming into contact with one another, paper pulp and plastic foam insert trays have an additional benefit. Molded pulp and foam insert trays provide more cushioning and support than plastic sheet insert trays. By absorbing shocks, the molded-pulp and foam insert trays protect the product from bruising during transportation and handling, therefore further minimizing postharvest losses. Both plastic sheet and foam insert trays exhibit disposal issues. Paper pulp insert trays are oftentimes produced from recycled materials, making them a more eco-friendly choice. However, if a producer's distribution system allows retrieval, plastic insert trays can be cleaned, sanitized and reused. Overall, insert trays are an attractive option for packers and producers because they are low cost, hygienic, can be environmentally friendly, and result in fewer postharvest losses.

Clamshells

Clamshell containers (Figure 8) are used extensively as consumer packages for a wide variety of commodities such as strawberries, blueberries, kumquats, and cherry tomatoes. A clamshell is a one-piece container consisting of two halves, forming the top and bottom, joined by a hinge with interlocking fasteners or snaps designed for closure. Clamshell containers are manufactured from a variety of different polymers such as polystyrene (PS) and polyvinyl chloride (PVC). However, one of the most common polymers used in clamshell containers is polyethylene terephthalate (PET) because it is highly transparent and easily recycled. Properly designed clamshells have a sufficient number of vent holes to facilitate cooling, to allow the product to "breathe" (i.e., allow exchange of respiratory heat and gases), and to allow for excess moisture to escape. The structure is often made using thermoforming or injection molding and can be customized into a variety of desired shapes and sizes.

Credit: Jeffrey Brecht

Clamshell containers also provide an area for attaching labels that include required information such as nutrition, weight, and manufacturer identification in addition to marketing and consumer information. Some of the advantages of clamshell containers include complete product visibility, product security, and increased perceived value. The container also prevents the contents from being handled by multiple individuals throughout the distribution chain, providing an extra degree of food safety. Although they are recyclable, clamshell containers are produced from non-renewable fossil fuels. Therefore, the polymers used to manufacture the containers are not the most environmentally friendly. However, clamshells made from biodegradable biopolymers such as polylactic acid (PLA), which is derived from corn starch or sugar cane dextrose, are available.

Choosing clamshell containers as the preferred method of packaging is often dependent on the commodity, industry standards, and consumer demand. Historically, smaller, open-air containers were used before clamshells. However, clamshells are the preferred choice for producers and packers alike.

Clamshells may be too expensive, however, for small farm operations. An alternative to clamshells might be perforated plastic bags with hand-punched holes for ventilation. Although bags do not provide protection from physical injuries like clamshells, they do protect produce from moisture loss and abrasion. A master container of some sort would also be required to hold consumer-size bags during handling between the farm and point-of-sale. However, perforated plastic bags would not be acceptable for many types of products grown by small farmers. For example, with tomatoes and peppers, the weight of the product would limit use of perforated plastic bags because the bags may stretch, damaging their integrity, and ultimately breaking. However, perforated plastic bags would be an ideal choice for leafy greens, grapes, or radishes.

Sustainable Packaging

Sustainable produce packaging is becoming increasingly more common in the marketplace, driven, in part, by consumer demand and government regulation for environmentally friendly materials. While fresh produce is healthy and good for human consumption, many packaging options used to protect fresh products do not contain environmentally friendly materials. Much of that packaging is used only once and then discarded, never to be recycled or reused.

Broadly, sustainable packaging is intended to be functional, but it should also be cost effective. A drastic increase in costs, relative to traditional packaging options, may render it too expensive for use. Sustainable packaging may also fulfill more specific objectives in its design and functionality. For example, reducing or minimizing materials will reduce the weight or volume that the packaging occupies while maintaining logistics efficiency throughout the products' life cycle in the distribution chain will reduce waste. Logistics efficiency involves efficient transportation, design space utilization, and reduced tare weight. The use of biodegradable materials or reusable packaging can minimize the amount of packaging destined for landfills or recycling streams, ultimately resulting in a lower amount of accumulated waste.

There are many reasons why producers choose sustainable packaging options. Economic, environmental, or even ethical concerns can justify choosing sustainable packaging over other options. Ultimately, each producer must weigh the costs and benefits of adopting sustainable packaging formats in order to determine which option is most appropriate for them.

Cooling Methods

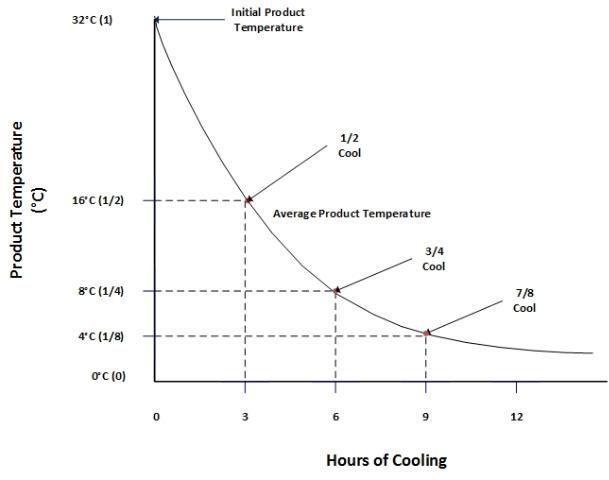

Freshly harvested fruits must be rapidly cooled by removing field heat with a compatible cooling method. Excess heat causes fruits and vegetables to have higher respiration rates, ultimately resulting in a faster deterioration of their quality. The rate of cooling is directly related to the temperature difference between the cooling medium and the product (Thompson 2014). However, in order for cooling to be effective, at least 7/8 of the field heat should be rapidly removed from the harvested crop. The time it takes to remove this amount of heat is known as the "7/8 Cooling Time" (Sargent et al. 2007). In the example of the room cooling of pears illustrated in Figure 9, the 7/8 cooling time has been achieved after 9 hours. Further cooling results in diminishing returns, as can be seen in the figure.

Credit: Adapted from Thompson et al. (2008)

There are a variety of different cooling methods available to producers, although not every method is appropriate or compatible for each commodity. Recommendations for the appropriate cooling methods for different commodities can be found in Sargent et al. (2007). The most common forms of cooling are room cooling, forced-air cooling, hydrocooling, contact icing, and vacuum cooling (Boyette, Wilson, and Estes 1989; Thompson et al. 2008). Vacuum cooling, while very fast and best suited for leafy crops, is not covered here since it is very expensive and used almost exclusively by large operations. Recommendations for the most appropriate cooling methods for larger commercial operations are provided in Sargent et al. (2007). Cooling systems for small-scale fruit and vegetable producers are described by Kitinoja and Thompson (2010). The following section will describe these cooling methods in more detail.

Room Cooling

Room cooling involves placing produce in an insulated room that is refrigerated to a desired temperature. This form of cooling can be used for any commodity. However, room cooling is best for relatively non-perishable commodities and for when marketing is rapid. Room cooling may be too slow for high-respiring commodities, which require quick cooling in order for them to be successfully marketed. If properly designed, a room cooling system can be energy efficient and inexpensive. This type of cooling can be very effective for smaller operations. A room that is only used to store previously cooled produce requires a relatively small refrigeration unit. However, if the room is used to initially cool the produce, a larger refrigeration unit is required. An explanation of how to determine the refrigeration capacity and fan performance needed to accomplish room cooling can be found in Thompson et al. (2008).

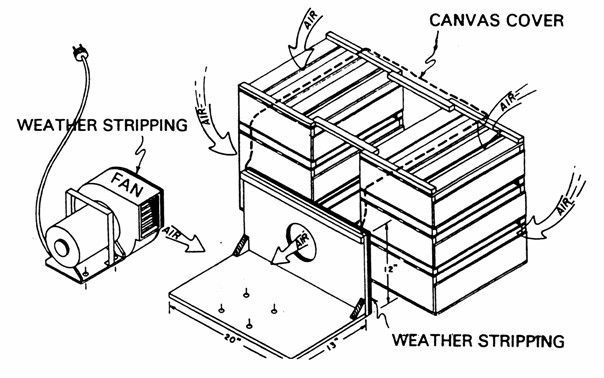

Forced-Air Cooling

Forced-air cooling is used in conjunction with a refrigerated room and can be very effective for rapidly cooling most packaged produce. In contrast to room cooling, in which cool air circulates around containers or pallets of produce, in forced-air cooling the cool air is drawn through the packages and thus comes in direct contact with the produce within the packages. This is accomplished by stacking palletized produce containers in front of vents placed in a false wall with a fan behind the wall. As seen in Figure 10, a canvas or plastic cover or tarp is pulled over the space between adjacent rows of pallets so that, when the fan is running, cooled room air is pulled through the containers to reach the fan; that air, carrying the heat removed from the produce, is then re-cooled by the room refrigeration unit (Parsons and Kasmire 1974).

Credit: R.A. Parsons and R.F. Kasmire (1974).

The cooling rate for forced-air cooling depends on the air temperature and the rate of airflow through the packages. The airflow rate is determined by the pressure differential between the room side and the fan side and requires a tight seal around the pallets so that cold room air cannot bypass the produce to reach the fan. The difference in pressure forces air through the containers of product, removing field and respiratory heat (Talbot and Fletcher 2006). Forced-air cooling systems are normally equipped with a thermostat on the fan that automatically shuts off the fan when a desired temperature is reached, in order to reduce the energy consumption and water loss of the product. As a means of heat removal, forced-air cooling can be extremely effective, cooling fruits and vegetables typically four times faster than room cooling (Brecht 2003). Additionally, water loss is lower for forced-air than for room cooling because forced-air cooling brings the individual produce items near to the room air temperature more quickly, which minimizes the driving force for water loss from the tissues.

The refrigeration capacity must be greater in a room used for forced-air cooling than for room cooling because a greater amount of heat needs to be removed in a shorter period of time. Thompson et al. (2008) provide guidelines for converting a regular refrigerated storage room into a forced-air cooler, including how to estimate the refrigeration requirements. Plans are also available for constructing small-scale, portable forced-air coolers that can be placed within a cold room (Boyette and Rohrbach 1989) or used with integral refrigeration (Talbot and Fletcher 2006).

Hydrocooling

Hydrocooling is the process of rapidly removing heat from a product using chilled water. The product may be immersed individually in a tank or flume of cooled water (Figure 11) and then carried downstream with the current or packaged product may be conveyed upstream against the current. Alternatively, the produce packed in bulk bins or water-resistant packages may be placed under a perforated pan of chilled water that showers onto the produce (Figure 12). For both designs, the water, carrying the heat removed from the produce, is collected and pumped through a refrigeration unit and recirculated for further product cooling. Water can remove heat about 15 times faster than air, although the actual efficiency of hydrocooling systems is lower. Hydrocooling typically cools produce 5 to 10 times faster than forced-air cooling. The rate of cooling in a hydrocooler is strongly related to the amount of contact that occurs between the cool water and the product being cooled. For this reason, tank and flume hydrocoolers are more efficient than shower hydrocoolers, and loose produce is cooled fastest, followed by produce in bulk bins, then individual packages, then palletized produce.

Credit: Jeffrey Brecht

Credit: Jeffrey Brecht

Because the water is recirculated during hydrocooling, it must contain a sanitizer; otherwise, microorganisms carried on some produce items will be spread to all of the produce being hydrocooled, ultimately resulting in increased decay and spoilage and possible contamination by human pathogens. Chlorine is widely used in conventional operations and levels must be carefully managed during hydrocooling to provide a constant 100 to 150 ppm of free chlorine, adjusted to pH 6.5–7.0. While minimum chlorine concentrations must be maintained to effectively kill pathogens in the water, excess chlorine can produce surface bleaching, rendering the product undesirable. More information about options for organic operations is available from Sargent and Treadwell (2015).

For small operations, ice can be substituted for mechanical refrigeration in carrying out hydrocooling. This approach includes both recirculating systems using block ice and manual drench systems using crushed ice. The key is using sufficient ice to maintain the desired water temperature. However, it is necessary to point out that water sanitation is critical even for a small-scale hydrocooler. Also, while hydrocooling can be used for many commodities, it cannot be used for those that are sensitive to wetting, particularly onions and garlic.

Contact Icing

Contact icing is used to cool a variety of commodities, although the application procedure may vary, and is particularly suitable for the smallest produce operations. Contact icing can be applied as top icing, in which crushed ice is added over the top of the product either by hand or by machine application (Figure 13). An ice and water mixture is a much more efficient cooling medium than ice alone, and a slurry can be injected into packaged produce through the vents or handholds without disturbing the structure of the palletized product (Figure 14). The key for this method to be effective is that the produce-package venting must be designed so that the package is filled with the ice-water slurry as it is injected, then the water can drain out the bottom of the package, leaving crushed ice evenly distributed through the product. Usually this means using corrugated fiberboard cartons, but some RPCs have venting that is suitable for cooling with ice-water slurry. Corrugated fiberboard cartons require wax coatings to be effective when used with ice so that the water is unable to penetrate and reach the fiberboard.

Credit: Jeffrey Brecht

Credit: Jeffrey Brecht

Icing is very effective on dense packages that cannot otherwise be effectively cooled using the forced-air method. Because the ice has a residual cooling effect as it melts over time, this method works well to reduce the deterioration of commodities that have a high respiration rate, such as sweetcorn. Ice can be considered a form of storage for thermal energy. When melted, one pound of ice will have absorbed 144 Btu of heat. The amount of ice required to cool fresh produce depends on the heat of the commodity and the amount of heat that passes through the package from the outside. Wilson, Boyette, and Estes (1999) state that for most compatible commodities, one pound of ice can cool about 3 pounds of produce from 85°F to 40°F (27°C to 5°C).

Conclusions

While the quality of a product cannot be improved after harvest, it can be maintained with proper postharvest sanitation, cooling, packaging, handling, storage, and management. This primarily means reducing metabolic rates and water loss because those can lead to reductions in quality and weight, and ultimately reduced sales. Minimizing friction, mechanical damage, and bruising will reduce spoilage of salable product. Proper sanitation practices minimize spread of decay and contamination by human pathogens that cause food poisoning. For more information see the Food Safety on the Farm series (https://edis.ifas.ufl.edu/topic_series_food_safety_on_the_farm). Without question, temperature is the most important factor in determining fruit and vegetable quality. When temperatures are too cold, chilling injury may occur. When temperatures are too warm, fruits and vegetables have higher respiration rates and consequently deteriorate much more rapidly. Proper storage temperature is typically commodity specific and, when maintained appropriately, can extend the shelf life of that product. To successfully market their products, produce operations should consider all these factors and how they affect their particular crops.

While storage and handling are critical steps that must be taken in order to maintain fruit quality, appropriate packaging is equally important. Each produce operation must choose a packaging format based on the product's target market and intended use, the qualitative aspects of the package, and the cost of the packaging materials being used. In some cases, especially in terms of size and shape, industry standards dictate the type of container to be used. Most packaging containers are manufactured from plastic polymers, wood, or corrugated fiberboard, but they all serve to protect and contain the produce while providing the consumer with information and convenience. These options include corrugated fiberboard cartons, insert trays, RPCs, bulk bins, and wooden containers of various dimensions. Sustainable packaging options are becoming increasingly more popular due partly to consumer demand as well as government regulation. While these environmentally friendly options are available to producers, they are oftentimes expensive and increase costs for producers that run low profit margin operations.

In terms of cooling methods, small-scale producers have a few options. However, each option presents advantages and disadvantages, and no single cooling method will work for all commodities. Some commodities, such as peaches, may be cooled using hydrocooling, forced-air cooling, or room cooling depending on the shelf life required for the marketing system. Alternatively, hydrocooling is the best choice for removing heat from squash and snap beans, both because those are relatively perishable products, and thus benefit from more rapid cooling, and because they tolerate contact with water. Contact icing is also a cheap, effective means of cooling fresh produce once harvested; however, as with hydrocooling, the commodity must be able to withstand some contact with water. Additionally, using ice for cooling would not be compatible with any crop that is sensitive to chilling injury. Vacuum cooling, while efficient at removing heat, is too expensive and, therefore, is not likely to be a viable cooling option for smaller produce operations.

Works Cited

Brecht, J.K. 2003. "Harvesting and handling techniques." Postharvest Physiology and Pathology of Vegetables, 2nd edition, edited by J.A. Bartz and J.K. Brecht, 404. New York: Marcel Dekker.

Boyette, M.D., and R.P. Rohrbach. 1989. Cool and Ship: Low-Cost Portable Forced-Air Cooling. AG-414–7. North Carolina Agricultural Extension Service, North Carolina State University, Raleigh (USA). (No longer available online.)

Boyette, M.D., L.G. Wilson, and E.A. Estes. 1989. Introduction to Proper Postharvest Cooling and Handling Methods. AG-414-1. North Carolina Agricultural Extension Service, North Carolina State University, Raleigh (USA). (No longer available online.)

Daniels, W., Diffley, A., Fiser, D., Hollbach, D., Korane, A., Koan, J., et al. (2010). Wholesale Success: A Farmer's Guide to Selling, Postharvest Handling and Packing Produce. (J. Slama, Ed.). (No longer available online.)

Florida Department of Agriculture and Consumer Services. 2022. "Florida Agriculture by the Numbers." https://ccmedia.fdacs.gov/content/download/114369/file/Florida-Ag-by-the-Numbers-2022-Final.pdf

Food and Agriculture Organization of the United Nations. 1989. "Post-harvest damage to fresh produce." Prevention of Post-harvest Food Losses: Fruits, Vegetables and Root Crops. Rome (Italy): Food and Agriculture Organization of the United Nations. http://www.fao.org/docrep/T0073E/T0073E02.htm#4.10%20Post-harvest%20damage%20to%20fresh%20produce

Gross, K.C., Wang, C.Y., and Saltveit, M.E. 2016. "Respiratory Metabolism." The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks. USDA Agriculture Handbook 66. https://www.ars.usda.gov/is/np/CommercialStorage/CommercialStorage.pdf

Kader, A.A. 2002. "Biology and Technology: An Overview." In: Postharvest Technology of Horticultural Crops. Univ. Calif., Berkeley, Calif. Publ. 3311.

Kitinoja, L., and A.A. Kader. 2003. "Storage of horticultural crops." Small-Scale Postharvest Handling Practices: A Manual for Horticultural Crops, 4th Edition. Postharvest Horticulture Series No. 8E.

Kitinoja, L., and J.F. Thompson. 2010. "Pre-Cooling Systems for Small-Scale Producers." Stewart Postharvest Review 6.2, 1–14.

Milling, A., R. Kehr, A. Wulf, and K. Smalla. 2005. "Survival of bacteria on wood and plastic particles: Dependence on wood species and environmental conditions." Holzforschung, 59(1), 72–81.

Nunes, M.D.N., J. Emond, J. Bartz, and J. Brecht. 2002. "Storage temperature." In: Postharvest Physiology and Pathology of Vegetables, Vol. 123, 238. CRC Press.

Parsons, R.A., and R.F. Kasmire. 1974. Forced-Air Unit to Rapidly Cool Small Lots of Packaged Produce. University of California Cooperative Extension, OSA# 272. Tubers.

Rees, D., G. Farrell, and J. Orchard. 2012. "Introduction." Crop post-harvest: Science and technology, Vol. 3, 2: Perishables. John Wiley & Sons.

Saltveit, M.E. 2004. "Respiratory Metabolism." The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks. USDA Agriculture Handbook 66. https://www.ars.usda.gov/is/np/CommercialStorage/CommercialStorage.pdf#page=78

Sargent, S.A., M.A. Ritenour, J.K. Brecht, and J.A. Bartz. 2007. Handling, Cooling and Sanitation Techniques for Maintaining Postharvest Quality. HS719. Gainesville: University of Florida Institute of Food and Agricultural Sciences. http://ufdc.ufl.edu/IR00001676/00001

Sargent, S.A., and D.D. Treadwell. 2015. Guide for Maintaining the Quality and Safety of Organic Vegetables and Melons During Harvest and Handling Operations. HS1148. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://doi.org/10.32473/edis-hs396-2009

Talbot, M.T., and J.H. Fletcher. 2006. A Portable Demonstration Forced-Air Cooler. CIR1166. Gainesville: University of Florida Institute of Food and Agricultural Sciences. http://ufdcimages.uflib.ufl.edu/IR/00/00/45/11/00001/AE09600.pdf

Thompson, J.F. 2014. "Pre-cooling and Storage Facilities." In: The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks. USDA Agriculture handbook, (66). https://www.ars.usda.gov/is/np/CommercialStorage/CommercialStorage.pdf#page=21

Thompson, J.F., et al. 2008. Commercial Cooling of Fruits, Vegetables, and Flowers. Oakland, California: UCANR Publications. Publ. #21567.

U.S. Department of Agriculture. 2014. The commercial storage of fruits, vegetables, and florist and nursery stocks. https://www.ars.usda.gov/is/np/CommercialStorage/CommercialStorage.pdf#page=9

U.S. Department of Agriculture. 2024. 2022 Census of Agriculture: Florida State and County Data U.S. Department of Agriculture. https://www.nass.usda.gov/Publications/AgCensus/2022/Full_Report/Census_by_State/Florida/index.php

Watkins, C.B., and J. Nock. 2012. "Production guide for storage of organic fruits and vegetables." New York State Department of Agriculture & Markets, Publ. #10. http://nysipm.cornell.edu/organic_guide/stored_fruit_veg.pdf

Wilson, L.G., M.D. Boyette, and G.A. Estes. 1999. Post-Harvest Handling and Cooling of Fresh Fruits, Vegetables and Flowers for Small Farms, Leaflets 800–804. North Carolina Cooperative Extension Service. 17pp.

Table 1. Recommended storage guidelines for selected Florida-grown commodities.

Table 2. Respiration and ethylene production rates for selected Florida-grown commodities.