Introduction

Currently, slow-acting enzyme-inhibiting aquatic herbicides such as fluridone are often applied as whole-lake treatments. However, before these types of herbicides were available, many aquatic herbicide treatments were applied using the "bottom acre-foot method," which utilizes weighted trailing hoses to inject herbicides into the lower portions of the water column to manage hydrilla and other submersed plants.

For example, consider a 7- to 10-foot-deep lake that has been colonized by early-season growth of 3 to 4 feet of hydrilla. Before the development of slow-acting systemic herbicides, contact herbicides such as diquat, copper, and endothall were used for hydrilla management and were injected through hoses into the lowest portion of the water column (Figure 1). This targeted delivery of herbicide into the plant bed at the bottom of the lake (as opposed to the entire water column) resulted in less herbicide applied to the lake and reduced aquatic weed control costs. Although not entirely accurate, the term "bottom acre-foot method" was used to describe this process of herbicide injection into the lower portion of the water column. This publication describes the benefits of using the "bottom acre-foot method" of applying herbicides with weighted trailing hoses and details the construction of the weighted trailing hose system used by the University of Florida Center for Aquatic and Invasive Plants (CAIP).

Credit: Line illustration drawn by Lyn Gettys and colored by Josh Huey

Advantages of Using the Bottom Acre-Foot Treatment

The main goal of the bottom acre-foot treatment is to position the herbicide where the weeds are growing. In other words, why treat the upper half of the water column when the weeds are only present in the lower half? This philosophy explains why granular versions of several products have been developed: to facilitate the placement of herbicides directly into targeted beds of weeds. The use of weighted hoses also allows contact herbicides to be placed below the thermocline, which is the area that separates the epilimnion (warm upper) and hypolimnion (cool lower) "layers" of the water. Temperatures above the thermocline can get extremely warm, especially on hot, still, summer days, and herbicides applied on or just below the surface of the water don't mix with the cooler water below the thermocline. As a result, surface-applied herbicides only come into contact with the upper 1 to 2 feet of topped-out submersed plants and don't reach the lower portion of the weeds. This allows regrowth to occur quickly from roots and crowns that have not been exposed to herbicides. Using weighted hoses allows applicators to ensure that contact herbicides are delivered to the lower portions of weeds below the thermocline; this system may be slightly more time-consuming than regular surface application, but provides much better, longer-term control of weeds.

If weeds are distributed throughout the water column—for example, if 8-foot-tall weeds are present in water that is 10 feet deep—most contact herbicides (such as diquat at 370 ppb or endothall at 3 ppm) should be applied uniformly throughout the water column. Weighted hoses can readily be used for uniform application of herbicides or other substances throughout the entire water column of the lake to be treated (Figure 2). The research plots used by CAIP to test experimental aquatic herbicides are typically 8- to 10-foot-deep ponds. We employ three hoses (one each of 4, 8, and 12 feet in length) attached to a single boom that is the same width as the boat (8 feet) to avoid damage to diving boards and docks.

Credit: Line illustration drawn by Lyn Gettys and colored by Josh Huey

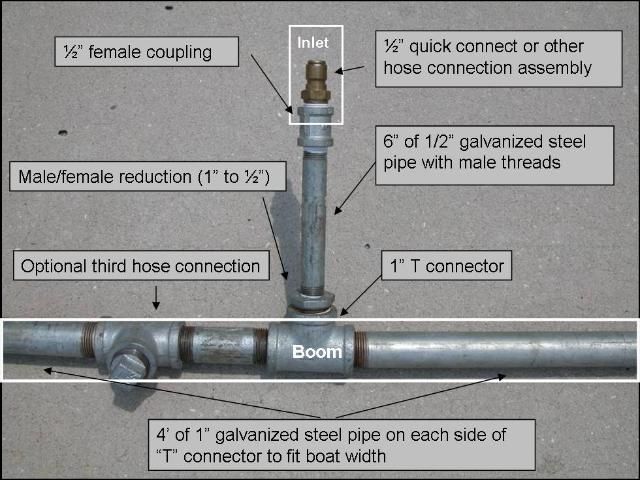

The Construction of a Weighted Trailing Hose System

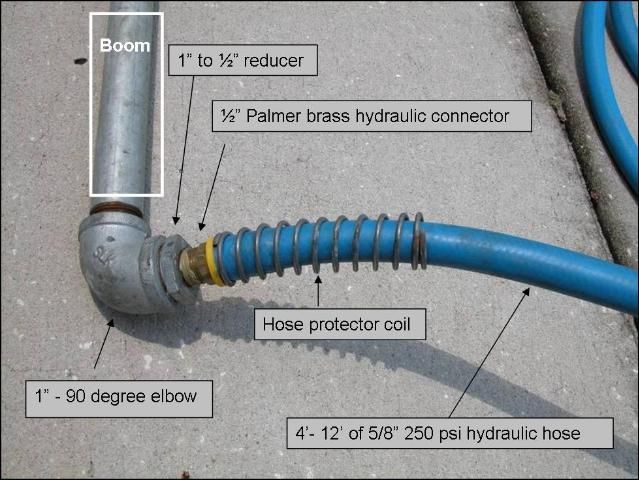

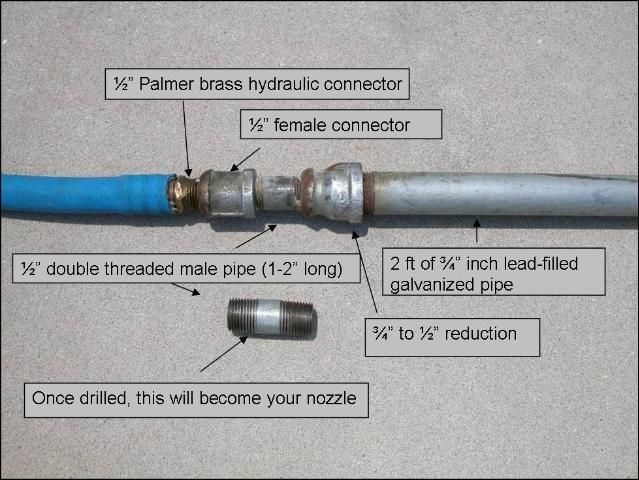

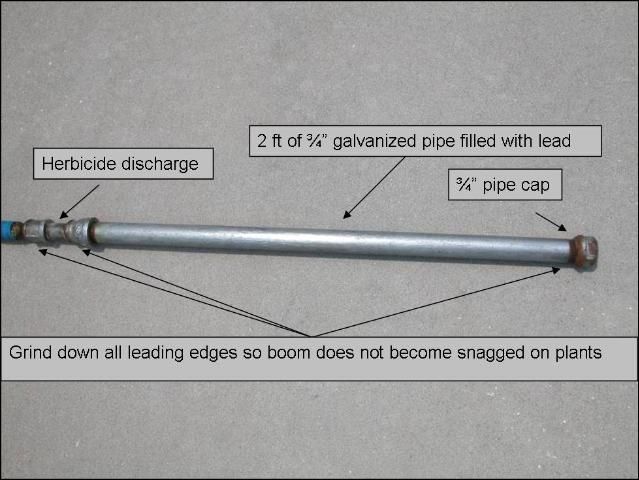

At CAIP, we use a standard Hypro pump with a 100-gallon tank set to pump about 5 gallons per minute (GPM). Pumps with greater output (for example, 10 to 15 GPM) can be used instead, but these require a much larger orifice ("nozzle hole") than the one shown in Figure 3. The inlet to the 1” galvanized manifold (or boom) is shown in Figure 4. We use 1” galvanized steel because it is much stronger than smaller diameter pipes; strength is important because the manifold should remain intact if a trailing hose becomes snagged on a stump or the hose becomes tangled in weeds. The 1” boom is reduced to 1/2” at each hose (Figure 5). The hydraulic hose connector is a key component and must be used, but note there is no hose clamp or metal connection where the hose attaches to the brass connector (the yellow band is simply a washer). The hose and brass connector (sold as Parker Push Lok 250 psi, 5/8") is designed so that the hose locks into the connector without any clamps; once locked, the hose will not come off. All hydraulic shops should have this or a similar product in stock and may be willing to insert the connectors. The spring shown in Figure 5 serves as a hose protector coil and prevents the hose from rubbing on the bow. The loose lower end of the hose is connected to a lead-filled weighted 3/4" pipe as shown in Figure 6. It is important to ensure that there are no ridges or hose clamps in this area, as rough surfaces or imperfections increase the likelihood of a hose becoming snagged in weeds. It is also good practice to grind the edges and burrs from the brass connector, the female connector, and the enlarging connector to prevent hydrilla and other weeds from getting caught on the weighted hose.

Credit: Greg Reynolds

Credit: Greg Reynolds

Credit: Greg Reynolds

Credit: Greg Reynolds

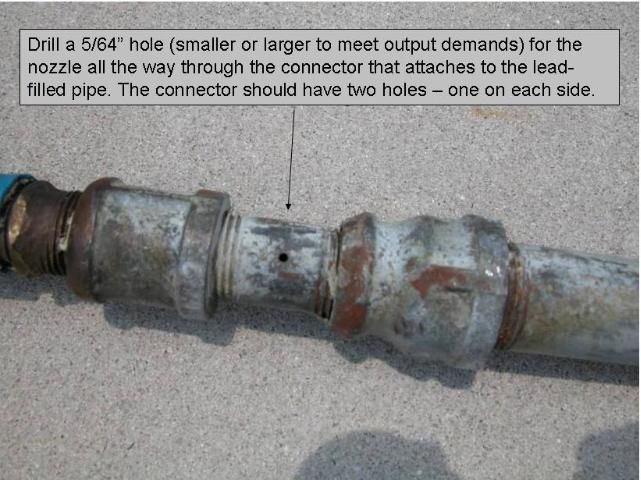

The weighted end of the hose is shown in Figure 7. The 3/4" pipe is two feet long and filled with lead. Molten lead is dangerous to handle, so have a local plumbing shop fill these pipes with molten lead for you. We have found that a 2-foot-long, 3/4" pipe is about right for our treatments based on boat speed and the weeds we treat; a 1/2" pipe is not heavy enough and 3-foot-long pieces of pipe are unwieldy. A lower cap may not be necessary if the lead remains in the pipe; if a cap is needed, be sure to grind the edges off to prevent snagging weeds. Figure 3 shows the ground edges of the pipe fittings and the nozzle hole where the herbicide is discharged into the water. Herbicide would be discharged into the sediment if the hole is on the bottom of the lead-filled pipe, but the goal of this setup is to apply the herbicide in the weeds or water column instead of the bottom of the pond, hence the positioning of the nozzle hole. If the pipe is vertical, herbicide discharges two feet from the bottom of the pond; however, the pipe is not vertical when it is being dragged, so the herbicide usually is released approximately 12” above the bottom of the pond, resulting in a treatment zone of the bottom acre-foot.

Credit: Greg Reynolds

Summary

It is likely that the engineers among our aquatic applicators will find ways to improve on this design. However, there are a few cautions to keep in mind when using weighted trailing hoses to apply herbicides. First, don't drag the hoses when the boat is travelling quickly and on plane. Second, travel slowly to keep the hoses on the bottom of the pond. Finally, avoid tight corners or the long hoses will collect lots of weeds. A good way to reduce the chance of this happening is to pull on the hoses every few minutes to shake loose and release any clinging weeds. Experience is the best guide when working with weighted hoses. Once you become familiar with this system, you'll appreciate how effective it is.