Introduction

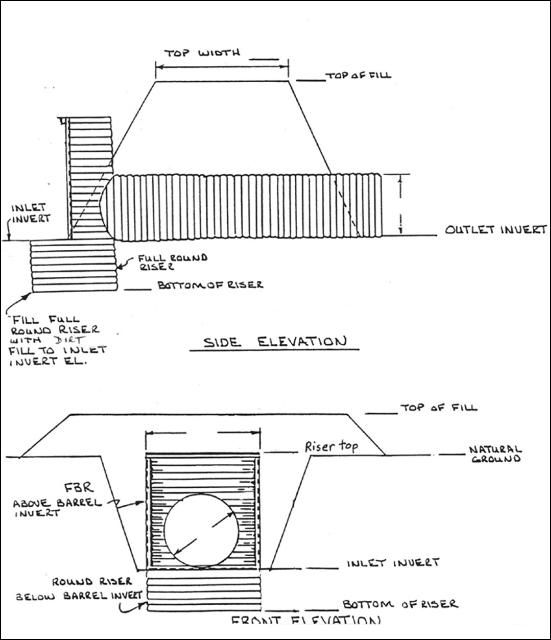

Water discharge structures are used to control water table levels and surface water levels in drainage and irrigation ditches within flatwoods citrus groves. The type of structure selected can significantly influence the quality of water discharged. With flashboard risers (Figures 1 and 2), water is forced to flow over the top board. This flow path creates a low current area toward the bottom of the ditch on the upstream side, which facilitates the deposition of sediments and their accompanying nutrients or pesticides, facilitating their removal from the discharges. Conversely, screw-gate structures (the other type of discharge structure) do not create this dead-current zone. Because they open from the bottom, sediments (and their accompanying loads) are swept out along with the discharge water.

Credit: NRCS-ENG-523 (Rev. 12-97)

Credit: PCW

Environmental Benefits

Use of riser-board water control structures increases deposition of suspended soil, organic debris, and other solids within grove ditches upstream of the structure. Proper removal of these accumulated sediments prevents their discharge into public canals and ultimately into Florida's estuaries. A description of benefits associated with sediments, nutrients, and pesticides follows.

Sedimentation

By using flash-board risers, the magnitude of several problems associated with sediments can be reduced. One of the most visible problems associated with sediment deposition is the reduction in water-carrying capacity in drainage ditch and canal systems. For example, 1 ft of sediments in a 200 ft long section of a typical drainage ditch (20 ft wide, 5 ft deep) reduces the ditch water-holding capacity by 20% in that section.

The formation of sandbars and shoals near grove discharge points are visible indicators of sediment losses. Unfortunately, only the larger-sized particles are usually left at the sandbar or shoal. The finer silt and clay soil fractions (< 0.002 mm diameter) require several hours to settle out of the water column under stagnant conditions. If the water is moving (as during discharge events), the very fine particles can move very long distances before settling out. These sediment fractions have been shown to damage benthic (bottom) habitat needed for healthy aquatic ecosystems in the Indian River Lagoon and St. Lucie estuaries, as well as in other freshwater and estuarine water bodies in Florida and throughout the United States. Routine, careful removal of deposited sediments is an important practice in preventing their resuspension and discharge downstream.

Nutrients

Sediments can store many forms of phosphorus, rendering them unavailable to the water column. However, sediments may also release many forms of phosphorus into the water column. Phosphorus exists in three primary forms: ortho-phosphates, polyphosphates, and organically bound phosphates. Ortho-phosphates are very soluble in water, but may become less soluble when applied to soil, depending on the soil properties. Polyphosphates are chains of phosphate molecules connected together that can break apart, releasing ortho-phosphates. Polyphosphates are commonly found in commercial cleaning preparations. The organically bound phosphates occur in tissues of organisms (i.e., plants and animals) and are released when those organisms decay. Riser-board structures facilitate the deposition of many phosphorus-containing, insoluble materials, preventing their discharge from the grove.

Reducing nutrient releases from groves should help reduce the number and severity of algal blooms in estuaries and other receiving water bodies. Algal blooms block sunlight and lower dissolved oxygen levels when they die and degrade, contributing to fish kills and loss of other marine life. Maintaining water clarity is essential for the production of healthy seagrass meadows and other productive habitats on the estuary floor.

Pesticides

Many of the pesticides used for citrus production are not very soluble in water. These compounds may preferentially associate with organic materials and/or soil particles in the grove or within ditches. When washed into waterways and water bodies, many of these sediment particles may be ingested by aquatic organisms foraging for food. Ingestion of pesticide-containing sediment particles can harm these organisms. In addition, some pesticides that are initially bound to sediment/soil particles may bleed off into the water column where they can harm sensitive organisms. Prevention of sediment discharges, followed by careful collection from grove ditches and replacement on bed tops, lowers the opportunities for adverse environmental impacts downstream from the grove.

Use and Operation

Design and Construction

Proper design and construction of riser-board structures are important for gaining maximum environmental benefits. Riser-board structures should be designed to suit the hydraulic conditions under which they will be used. Different designs may be needed for different areas of the grove, depending on factors such as soil type, the depth from citrus tree roots to the water table, and anticipated flow volumes. Local Soil and Water Conservation Districts and/or the US Department of Agriculture-Natural Resources Conservation Service (USDA-NRCS) can provide guidance on proper planning and site design elements. Suitable designs may also be available from structure manufacturers.

NOTE: Structures should be installed on the upstream side of culverts passing under roadbeds. Installation on the downstream end of a culvert may restrict water flow through the culvert as sediments deposit behind the structure (underneath the road in this case). Removal of sediments inside the culvert may be very difficult.

Construction Materials

Most riser-board structures are constructed of aluminum or steel. Those constructed of steel may be galvanized, coated with a variety of materials, or aluminized.

The predicted life expectancy of the structures may differ significantly, depending on the pH and resistivity of the surrounding soil. Generally, regardless of construction materials, the life of all structures is shortened when installed in acidic soils, as compared to neutral soils. Experience suggests that under Indian River area conditions, the typical service life generally ranges from 10–20 years. Provide measurements of soil pH and resistivity (measured at the site for the new installation) to the manufacturer to select construction materials most suitable for your budget and local conditions. Also, see FDOT (2017) for predicted service life spans.

Installation

Protect side-banks surrounding new and older installations with vegetative cover. If this is not possible due to local conditions, stabilize the soil with gravel, geoweb, gabions, interlocking blocks, or other materials. See Wilson et al. (2002) for more details and options.

Permits

Consult local water control and/or regional water management districts to determine whether or not a permit is required for new installations, retrofits, or structure renovations.

Operation

Proper operation of riser-board water control structures is essential for gaining optimal environmental benefits. The following points should be considered:

- Always keep at least one board in the bottom of the riser to trap nearby sediments.

- Use of a long-handled tool (Figures 3 and 4) can facilitate board manipulations and reduce safety hazards for operators.

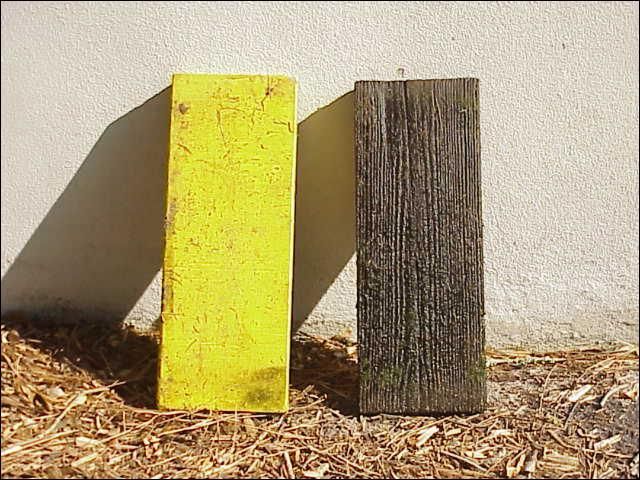

- Construct and use a weighted top board to prevent boards from floating. These boards are typically made of concrete or wood with metal bands attached and are called "sinker" boards (Figures 5a and 5b). A sinker board should be installed on top of regular wooden boards to prevent them from floating up. Ideally, maintain one wooden board underneath a sinker board at the bottom at all times. Add additional wooden boards underneath another sinker board as needed to maintain water levels (Figure 5c).

- Only use boards that are easily removed/installed (6"–12" height maximum). Boards should be cut 1/2–3/4 of an inch shorter than the maximum width of the board slot on the structure.

- Provide storage for boards not in use (Figure 6). This storage should be conveniently located close to the structure.

- The number of boards in the riser-board structure establishes the height of the water table underneath the citrus grove. Care should be taken to maintain water table levels underneath the citrus root system to avoid root damage. Water table levels throughout the grove can be monitored using water table wells. Refer to your local USDA-NRCS office and Boman and Obreza (2002) for more information on water table monitoring.

Credit: PCW

Credit: PCW

Credit: PCW

Credit: PCW

Credit: PCW

Credit: PCW

Maintenance

Proper maintenance of riser-board water control structures and associated ditches/canals is essential for properly managing the grove water table and minimizing sediment discharge from the grove.

Structure

- Replace all warped or damaged boards. Warped boards cause the structures to leak and may also be more difficult for workers to place them in or remove them from the structure.

- Keep vines and other weeds from growing inside the structure or along the boards. These weeds may make removing/replacing boards more difficult. They may also increase safety hazards associated with snakes and other wildlife.

Ditch (upstream)

The primary water quality benefit derived from using these structures is increased sedimentation of suspended materials within grove ditches. Consideration should be given to the amount of sediment that will be deposited. Deposited sediments should be removed when the ditches are the driest so that sediments disturbed during sediment removal can settle out before discharge events occur. Do not remove sediments when water is being discharged from the ditch.

Safety Concerns

Because riser-board structures are exposed to a variety of environmental conditions, several safety hazards may exist. To reduce the threat of harm to personnel operating the structures, make sure to do the following:

- Provide safe and stable access to the structure. Catwalks should be constructed of a non-slippery material such as textured aluminum, with adequate width to allow operators easy access to the structure. Caution should be taken if wooden catwalks are used. Wood deteriorates relatively quickly in the environment, resulting in reduced load capacities. In addition, wood tends to be more slippery when wet. If wood is used, inspect it routinely for signs of weakness and replace it as necessary.

- Provide a safe/stable area for operators to remove/replace boards. Installation of a removable foot piece over the top opening of the structure can safely facilitate manipulations (Figure 7).

- Use caution when reaching for boards due to poisonous spiders, insects, and snakes.

- Rotate boards to control slippery growth.

- Always wear gloves when removing boards by hand, or when reaching around the structure (Figure 8).

- Use a long-handled tool (such as modified ice tongs) if possible, to facilitate removal/insertion of boards (Figures 3 and 4).

- Plan ahead for storm events. Waiting too late may make it impossible to remove boards due to the increased head pressure associated with rising water levels. However, do not remove all boards from the structure in anticipation of rainfall events. Actively monitor the water table depth (Boman and Obreza 2002) below tree roots to determine the appropriate height of boards needed.

- When removing weeds from inside the structure and along the riser boards, use a long-handled pruning hook, potato rake, or other appropriate device. The long handle will provide safety to the operator and allow pruning of weeds or vines at the operational water level.

- Sharp edges on the structure should be rounded to prevent harm to personnel.

Credit: PCW

Credit: PCW

Economic Considerations

Replacement of screw-gate structures with riser-board structures can be expensive but should be considered. Several state- and federal-sponsored cost-share programs are available for offsetting replacement costs. Riser-board structures should be installed in areas where new installations are needed. New riser-board structures range in price from a few hundred to several thousand dollars, depending on construction materials, details, and size. Proper use of riser-board structures requires less intense management as compared to screw-gate structures. Providing proper access and tools can facilitate manipulations and increase operator efficiency.

References

Boman, B., and T. Obreza. 2002. Water Table Measurement and Monitoring for Flatwoods Citrus. Circular 1409. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/ch151

Florida Department of Transportation. 2017. Drainage Manual. Office of Design, Drainage Section. Tallahassee, FL. https://fdotwww.blob.core.windows.net/sitefinity/docs/default-source/content2/roadway/drainage/files/2017jan-drainagemanual.pdf?sfvrsn=a62263e5_0

NRCS Florida Conservation Practice Standards: Structure for Water Control, Code 587 (June 1998). http://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/stelprdb1046933.pdf

Wilson, C., L. Scotto, B. Boman, and J. Hebb. 2002. Flatwoods Citrus Best Management Practice: Soil Stabilization. SL195. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/ss408

Acknowledgement

We would like to thank Mike Ziegler (Agricultural Resources Management) for his input and guidance with the development of this document.