This publication is part of SL253, Nutrition of Florida Citrus Trees, 3rd Edition. For references, a glossary, and appendices, please refer to the full document at https://edis.ifas.ufl.edu/ss478.

Common Elements of Precision Agriculture

The term precision agriculture includes equipment that improves citrus management for high-quality fruit production. Proper water management is a key component for efficient nutrient management, and precision agricultural tools may improve nutrient- and water-use efficiencies. In turn, producers can anticipate lower production costs through effective nutrient and water resource management with the expectation of sustained high yields and improved chance for profit.

- Remote sensing applies to nondestructive measurements. Remote sensing typically involves acquiring and processing satellite or aerial images photographed in the visible or near-infrared portions of the spectrum. Useful information derived from remote sensing includes grove variability, tree canopy size and health, soil type, and water stress in trees. Today, many more tools are available including ultrasonic and laser scanners for canopy volume or electromagnetic soil sensors for detecting profile properties below ground.

- A geographic information system (GIS) is a computerized "graphic database" allowing storage, retrieval, display, and processing of digital images or drawings with known positions on the earth's surface. Several technologies are involved with GIS. Maps of an area can be digitized and used to plot positional information captured from global positioning system receivers. Differences in spectral reflectance of groves from aerial or satellite images can be used by grove managers to locate high-yielding or low-yielding areas within a grove.

- By obtaining signals from several satellites, a global positioning system (GPS) can be used to precisely locate a position on the earth's surface, a position within a grove, or specific trees within a grove. This system works equally well to locate the path of a vehicle through the grove. Position location (georeferencing of data, observations, objects, maps, and images with GPS) is essential for meaningful processing and display on a GIS.

- Mobile computing and data storage: Portable computers collect and analyze sensor data, GIS information, and GPS data streams. The integration of these technologies allows for decision management on the fly as a vehicle moves through the grove. Handheld computers are valuable for making and recording field observations during scouting, leaf sampling, or soil surveying. When used in conjunction with a GPS and GIS software, a handheld computer can be used to navigate through the field, which allows location and marking of trees, plots, soil types, or other information already contained in the GIS.

- Soil mapping: Once the purview of the USDA-Natural Resource Conservation Service (NRCS), most county soil surveys and related maps have been digitized. These maps can be used as one of the layers in a GIS decision management system. Soil mapping with geophysical survey or electromagnetic induction instruments such as the EM38 (Geonics, LTD) or the Veris 3000 (Veris Technologies) allows rapid collection of digital geo-referenced map data correlated with chemical and physical properties of soil profiles.

- Variable-rate inputs: Using the technologies described above, grove managers can use additional controllers on traditional agricultural equipment to precisely apply fertilizers and other chemicals at spatially varying rates as needed.

Objectives of Precision Agriculture for Nutrient Management

Many possible objectives exist for different precision agriculture programs. Four important objectives related to citrus nutrient and irrigation management are:

- Reduce fertilizer amounts per unit land area to lower citrus production costs.

- Increase fertilizer nutrient-use efficiency to lower environmental impacts.

- Increase fruit yield and quality through optimal nutrient and water management.

- Automate and digitally record grove operations to speed data analysis and increase efficiency and convenience.

Remote Sensing

Field Measurements of Soil Electrical Conductivity

Soil profile properties can be measured remotely using geophysical survey or electrical conductivity (EC) sensors. The use of EC sensors for nutrient management is an indirect measurement, reflecting the dissolved salt and hence also the ion concentrations in the soil. Because fertilizers are salts, changes in dissolved and adsorbed fertilizer can be sensed as changes in electrical conductivity. Because the measurement involves all salts in the soil, the portion attributed to fertilizer can only be estimated, but this estimation has been attempted for some crops in uniform soils with relatively small changes in salinity. Both nutrients and salts from other sources (e.g., saline well water) are measured by this remote sensing equipment. Distinguishing salty water from fertilizer salts can be difficult, especially if the soil varies naturally throughout the grove.

Another use of this type of sensor is to detect limiting layers in soil profiles. A soil must provide sufficient soil volume for proper tree root growth and nutrient uptake. Improper soil volume for tree root growth may lead to tree stunting, with resulting loss of yield and quality, or to tree mortality. Common soil profile limitations in citrus production are described below.

- Along the central Florida Ridge production area, soils are deep and well-drained but infertile and droughty.

- In citrus Flatwoods production areas, root damage may result due to shallow (perched) water tables and associated capillary rise.

- Flatwoods production areas also exhibit shallow clay layers and/or cemented spodic horizons that restrict or prevent root growth.

- In most citrus production areas, soils are sandy with low organic matter content and fertility, especially in the E-horizon of the subsoil.

- Sandy soils are often prone to soil compaction due to vehicular traffic.

Because field EC can be measured with mobile sensors, these data can be linked with GPS information to create relevant maps of each grove.

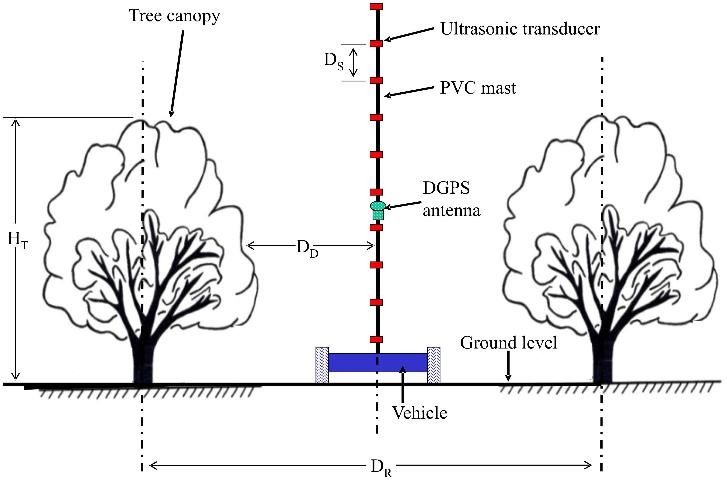

Ultrasonic Canopy Measurements

Citrus tree canopy height and volume can be measured remotely from airborne platforms or with ground equipment using laser scanners or ultrasonic ranging sensors—for example, a vertical sensor array that sends out ultrasonic pulses and detects the distance to the tree canopy (Figure 1). The sensor array has a differential global positioning satellite system (DGPS) instrument that records its position within the grove. Both the DGPS and ultrasound readings are recorded and processed by a computer program to create a map of the canopy volumes within the grove (Figure 2).

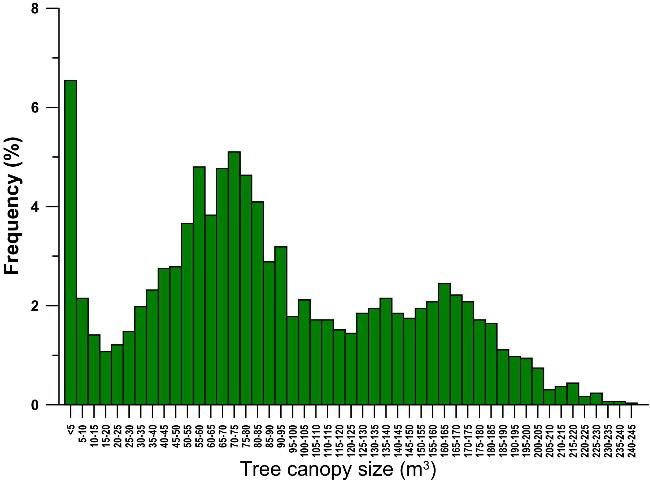

Calculated canopy volumes (light green) are superimposed on an aerial photograph of the grove (Figure 2), which has a considerable number of resets. From this map, tree canopy sizes can be displayed on a frequency diagram (Figure 3). When shown in this manner, new resets, resets planted in 1989 after a freeze, and original grove trees can be identified.

Because citrus yield is directly related to canopy volume, this type of diagram can help growers make decisions concerning long-term operations within their groves. For example, this grove has a wide range of canopy volumes and can be expected to have a considerable range in yield as well. Managing for somewhat less canopy volume variability in this grove could improve yields and reduce environmental impacts of agrichemicals.

Canopy volume measurements can also be used to aid other management strategies, such as changes in irrigation for drought or delineation of wet zones within the grove, soil textural changes that influence tree growth in production, or the impacts of debilitating diseases like citrus HLB.

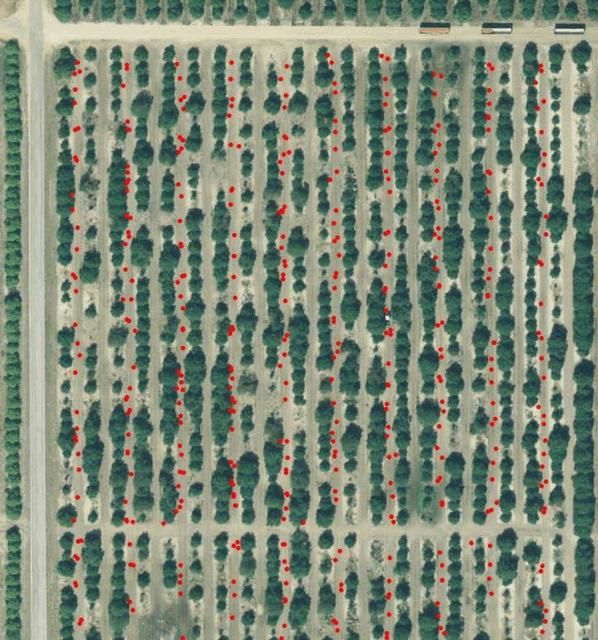

Citrus Yield Mapping

An automatic tub position logger can record the grove position where fruit was harvested using GPS technology (Figure 4). One tub (red dot) is equivalent to 10 boxes of fruit. Yield maps produced from the positioning data and the number of tubs per unit grove area can be used to identify both high and low production sites within the grove. In the example shown in Figure 5, the high-yield locations are dark green (maximum yield of 543 boxes/acre). Low-yielding locations (light yellow) produced only 181 boxes per acre. The average for the entire grove was 336 boxes per acre.

Precision Nutrient Application—Variable-Rate Fertilization

After determining canopy volume and yield throughout the grove, the next step is to apply fertilizers only where supplemental nutrients are needed. Variable-rate fertilizer spreaders can reduce fertilizer use in citrus groves by as much as 40%. In addition to reducing production costs, risk of nutrient movement from the grove is minimized. In variable-rate fertilization of citrus groves, granular fertilizer is accurately placed in independent left and right "bands" under the trees. The amount of fertilizer is regulated according to either a GPS-guided prescription map, or by the number of sensors that detect a tree canopy in left- or right-hand rows.

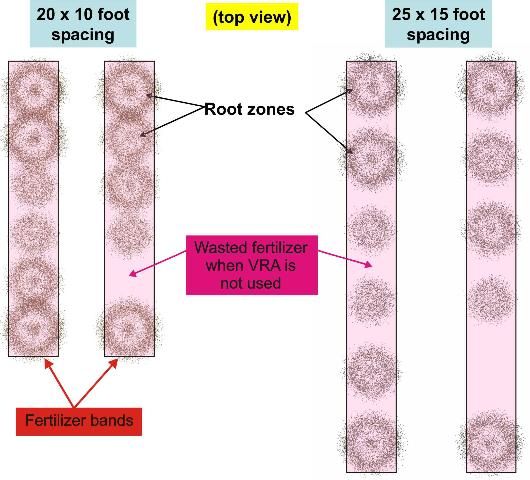

Roots are the primary target for fertilizer applications, and their growth pattern in the soil follows tree canopy volume growth above the surface. Fertilizer should not be placed where roots are not present. Tree spacing and bedding also affect root growth patterns. Immature trees or resets should not receive the same fertilization as mature trees (see Chapter 8). If dry fertilizer is uniformly band-applied to a grove with varying tree sizes, fertilizer will be wasted (Figure 6). This problem can be solved with variable-rate application equipment that uses canopy sensors in a look-ahead mode, rapidly positioning fertilizer dispenser valves on each side of the spreader to:

- Avoid dispensing fertilizer where there are no trees.

- Adjust the applied fertilizer rate based on tree size (canopy volume).

- Make these measurements and valve adjustments in a synchronized fashion as the spreader is moving through the grove.

Sensing and valve adjustment must be automatically synchronized with the speed of the application equipment to apply fertilizer properly to the correct trees. Variable-rate fertilization is most effective in groves with high spatial variability, because the technology is designed to exploit variability. Perfectly uniform groves with no gaps between canopies would not benefit from variable-rate technology. A grove containing a mixture of mature trees, young trees, and/or resets (such as that in Figure 3) will benefit the most from using this technology to apply fertilizers.

Not all variable-rate applicator controllers perform well on the fly. Some commercial controllers do not support the look-ahead feature to allow accurate fertilizer placement under trees while avoiding other locations where fertilizer is not needed. Other controllers and their valves have response times that are too slow to cope with the rapidly changing fertilizer requirements of a variable grove.

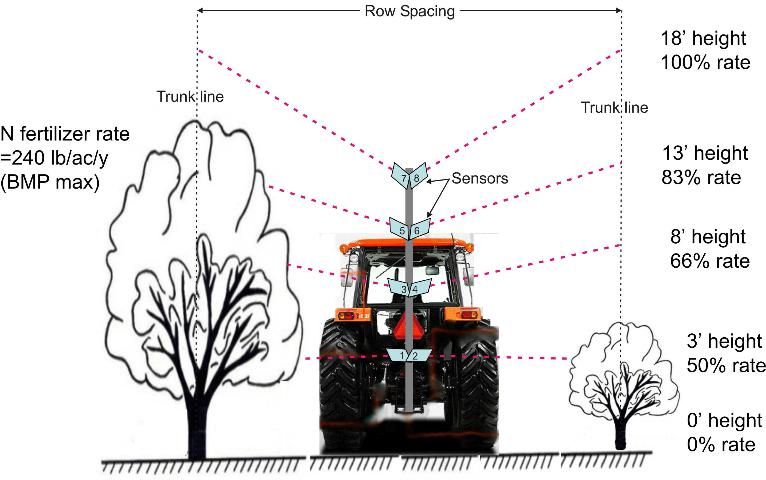

Figure 7 shows the use of photoelectric diffuse reflectance sensors with look-ahead and tree-height sensing capabilities. Sensor angle increases with vertical height, allowing sensors to be placed lower than the height of the tallest trees. For smaller trees, the angle of the sensors is decreased. Trigonometry calculations allow the estimate of sensor height to be calculated accurately as a function of the sensor angle. Compare the benefits of this sensor arrangement with that in Figure 1, and note the reduced height of the sensor array in Figure 7.

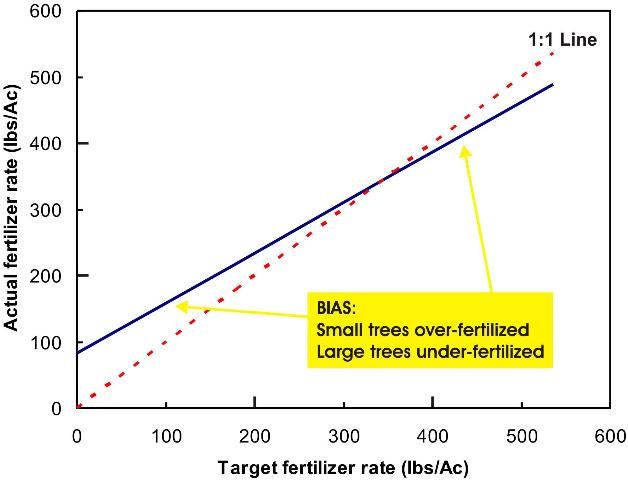

Because canopy volume is related to yield and tree height, fertilizer rates can be adjusted based on tree height. The proportion of fertilizer to be applied is shown as a function of tree height in Figure 7. The look-ahead sensing capability must be coupled with the mechanical parts of the fertilizer application equipment. Calculations must be based on the ground speed of the vehicle, the height of the tree, and the time delay for the equipment to respond to the demand for changing fertilizer rates. Slow reaction time for a variable-rate application system means that fertilizer will be applied at the wrong rates (Figure 8). To avoid this bias in fertilizer application, the variable-rate application system must be responsive and properly tuned. When purchasing a variable-rate spreader, insist on rapid response times and look-ahead sensing using well-matched components. The target rate is the UF/IFAS-recommended fertilizer rate proportioned using the percentages shown in Figure 7 for applicable tree heights in this particular example.

Summary

- Precision agriculture tools can add considerable strength to grove management decisions.

- Sensing devices can be used to determine water table depth and other soil properties that aid in irrigation, drainage, and fertilizer management decisions.

- Tree-sensing equipment can be used to estimate canopy volume and canopy height.

- Canopy volume and tree height can be used when planning tree replacement strategies, fertilizer management, and zone irrigation decisions.

- In combination with variable-rate applicators and appropriate look-ahead technology, fertilizers can be applied accurately based on tree need and production. Accurate application of dry fertilizers to root zones is particularly important for HLB-impacted trees because the root system is compromised. The costs of citrus production are also inflated by HLB disease, which makes the agrochemical savings achieved by variable-rate applicators especially important.

- Grove managers should consider use of precision agriculture tools to keep production costs low and improve citrus yields while avoiding potential environmental concerns.