Microirrigation involves the slow, controlled application of water to a crop using low pressures. Therefore precise and accurate placement of water to the crop can be achieved through proper design, installation, and management. In sandy soil vegetable production systems, tubing is placed along the plant row either on or slightly below the soil surface. In mulched bed production systems, the tubing is used to maintain desirable moisture conditions within all or most of the bed.

The intent of this publication is to provide the user with design and management information regarding the application rates and depths associated with microirrigation tubing and its use in mulched bed production systems.

Tubing Characteristics

Line source microirrigation tubing may be disposable or reusable and is generally made of polyethylene, although plastic, paper and rubber products have been used. Other characteristics of the tubing such as emission rate and longevity vary among manufacturers, however some similarities exist. Some types of tubing have emission openings which have been formed as part of the tubing during the extrusion process. They collapse when empty and are thus often referred to as tapes. This type of tubing is generally lightweight and considered to be disposable. Wall thickness may range from 4 mils for lightweight tubing to 15 mils for more durable tubing. Other manufacturers use physical emission devices which have either been welded into the tube (in-line emitters) or are attached to the outside of the tubing. These types of tubes are generally more durable and have wall thicknesses which may range from 15 mils to 50 mils or more. Wall thickness, which is related to tubing weight and to manufacturing characteristics, will influence the cost of the tube. In general, the cost of a tube increases as the weight of the tube and the number of required physical devices increases. Therefore, the tapes are usually less expensive.

The water discharge characteristics of microirrigation tubes will depend upon the physical characteristics of the emission openings or emitter devices and the operating pressure of the system. In general, emitter discharge will increase as pressure increases. However, some emitters are designed to be pressure compensating such that the discharge rate remains relatively constant over a wide range of operating pressures. In addition, some tubes are designed to operate within low pressure ranges such as 6 to 15 psi, while other tubes are designed to operate within the 15 to 40 psi range.

The discharge characteristics of a line source type of microirrigation tube must be known to determine application rates and for irrigation scheduling. These characteristics may be provided in terms of gallons per minute per 100 feet of run (gpm/100 feet) or in terms of gallons per hour (gph) per emitter. This publication will work with the units of (gpm/100 feet). However, if the emitter spacing is known, Table 1 can be used to convert from gph per emitter to (gpm/100 feet). This type of information should be provided by your irrigation supplier.

Application Rates and Depths

Irrigation scheduling involves the timing (frequency and duration) of irrigation events. Determination of the duration of irrigation events may be based on the availability of water or power, the size of the irrigated root zone and the available water holding capacity of the soil, the time required to supply a certain chemical through the system, or any combination of these and perhaps other factors. Knowledge of the rate of water application to the irrigated area will be in these scheduling procedures.

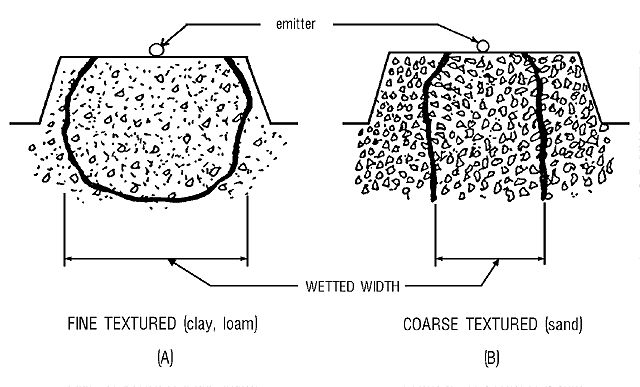

The wetted width (Figure 1) of the irrigated area must be known to determine the rate of application. Soil type and compaction will influence the lateral movement of water away from an emitter. Do not use emitter or plant spacings as values for the wetted width. This property should be determined from field or laboratory observations. Sandy soils will generally have wetted widths in the range of 12 to 24 inches. Coarse sand may only have wetted widths of 12 inches while a finer textured loamy or clayey type of soil may have a wetted width of 36 inches or more. Once the wetted width is known, it can be combined with the tubing discharge characteristics to determine the application rate of water to the irrigated area (Table 2).

Because the soil has a limited capacity to hold water, irrigation depths limit the duration of irrigation applications. The depth of application should not exceed the water holding capacity of the soil in the irrigated zone. The depth of this irrigated zone may be based on the entire root zone of the crop, an upper percentage of the root zone, or some other factor. Sometimes over-irrigation is necessary to move excess salts out of the root zone, however this is not the general practice. Irrigation depths (as applied to the irrigated areas) can be obtained from Table 3 by entering the system application rate from Table 2 along with the duration of application. If the depth of application exceeds the available water holding capacity of the irrigation zone, then the total irrigation duration should be scheduled into two, three, or more cycles of shorter duration. The timing of the start of each cycle should be such that the irrigation zone would have sufficient capacity to hold the water applied during that cycle. For example a two hour irrigation may need to be divided into two cycles, one in the morning for an hour and one in the afternoon for an hour.

Sometimes irrigations are scheduled to apply a certain volume of water per bed, per 100 feet of bed, or per acre. It is still necessary to schedule these volumes of water such that over-irrigation does not occur. The wetted width and the volume of water to be applied in gallons per 100 feet of bed can be used in Table 4 to determine the application depth to the irrigated area. As before, if the volume to be applied exceeds the water holding capacity of the irrigated zone, then two or more shorter duration or smaller volume cycles may be necessary.

Although microirrigation systems are designed to apply water only to the mulched beds, the gross acreage application depths are sometimes beneficial for budget or scheduling purposes. Table 5 can be used to obtain the application depth over the gross acreage as if all of the irrigation water were distributed uniformly over the entire area. The discharge per gross acre can be estimated by multiplying the length of tubing used per acre by the tubing discharge characteristics of the tube. The following equation can be used for this purpose: Q(acre) = Q(tube) * L(tube) 100 where Q(acre) =Discharge per gross acre (gpm/acre), Q(tube) =Tubing discharge per 100 feet (gpm/100 ft), and L(tube) =Length of tubing used per acre (feet).

Example: A tube which discharges 0.48 gpm per 100 feet of length is used on a production system which uses 5800 feet of tubing per acre. The discharge per acre is: Q(acre) = 0.48 * 5800 100 = 27.8 gpm per acre Therefore, 10 acres of production requires a water delivery system capable of supplying 278 gpm.

Summary

Characteristics of line-source type of microirrigation tubing were presented in terms of application rates, depths, and system requirements. This information is supplied to help the irrigation system manager schedule and operate the system to optimal capacity. With proper management and operation, microirrigation systems can apply precise amounts of water to the crop for maximum effectiveness at high levels of efficiency.

Emitter discharge in gallons per minute (gpm) per 100 feet of bed as related to gallons per hour (gph) per emitter.

Application rate to the irrigated area based on the wetted width and discharge rates of line source emitters.

Irrigated area depth of application (inches) based on application rate and time of operation.