One may ask: Why should I be concerned with the uniformity of my irrigation system? Why is it important to maintain high uniformity? This is important because high uniformity signifies that all the plants in the irrigated zone will receive almost the same amount of water in a given time. For sprinkler irrigation, it means that the depth of water application throughout the entire irrigated area is about the same. Consequently, uniform water application is necessary to maximize the efficiency of water use in the nursery and save water.

Low uniformity in sprinkler systems can be due to numerous factors, such as:

- Inadequate selection of delivery pipe diameters (submain, manifolds, and lateral).

- Too high or too low operation pressure.

- Inadequate selection of sprinkler heads and nozzles.

- Inadequate sprinkler overlap.

- Wind effects on water distribution.

- Changes in system components with time, such as changes in pump efficiency, pressure regulation, or nozzle size.

- Nozzle clogging.

There is a simple method to evaluate the uniformity of irrigation and the test should be performed at least once a year. The uniformity may change with time, and often simple repairs or changes can improve system performance.

Nursery Evaluation of Sprinkler Irrigation Uniformity

Uniformity of water application with sprinkler irrigation systems is often reported as Distribution Uniformity (DU). It is an indicator of how equal (or unequal) the application rates are in the nursery. A low DU (below 60%) indicates that application rates are very different, while a high DU (80% or higher) indicates that application rates over the area are similar in value and the water is distributed evenly to all the plants. Distribution Uniformity is based on the low quarter of the irrigated area. The calculation of DU requires that the catch-can test be performed in the irrigation zone. The following is an example of the catch-can test.

Example

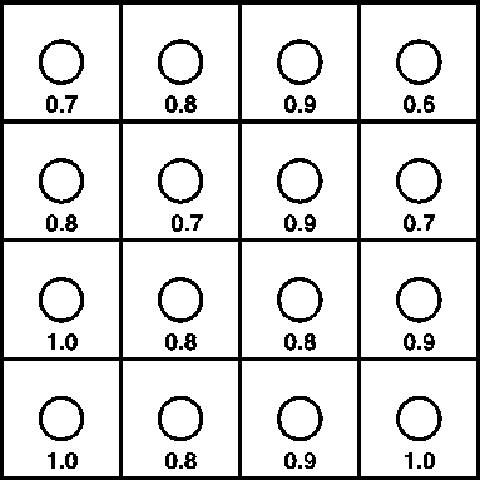

In Figure 1, 16 straight-sided catch cans have been placed in the irrigation zone. The depth of water collected in these cans after running the system for one hour is presented below each can. The average application rate in this zone is the average depth collected in the cans and is equal to 0.8 in/hr.

(0.7 + 0.8 + 0.9 + 0.6 + 0.8 + 0.7 + 0.9 + 0.7 + 1.0 + 0.8 + 0.8 + 0.9 + 1.0 + 0.8 + 0.9 + 1.0) / 16 = 0.8 in/hr

Now, to calculate Distribution Uniformity, the lowest one-fourth or quarter of the measurements from our example are selected. The other value we must know is the average depth of application during the test which was calculated above.

DU = (average low quarter depth / overall average depth) x 100%

For the application rates presented in Figure 1.

Average low quarter depth = (0.6 + 0.7 + 0.7 + 0.8) / 4 = 0.7 in/hr

DU = 0.7 / 0.8 x 100% = 87.5%

For high value crops, such as container-grown nursery plants, it is recommended that the DU be greater than 80%. When DU falls below the acceptable value, system repairs and adjustments should be performed as soon as possible.