The Importance of Ladder Safety

Ladders are essential for many types of workplace operations. Folding ladders, extension ladders, and built-in ladders are all used regularly in many types of work. For example, in agricultural settings, these ladders may be encountered in packinghouses, food processing facilities, and chemical or equipment company establishments. Safe ladder use is necessary to prevent serious injury or death.

Falls, including falls from ladders, are among the top three causes of workplace-related injury and death (NSC 2021). More than 500,000 people per year are treated for injuries related to falls from ladders—with about 300 deaths. Surprisingly, most ladder fall-related deaths involved a fall of less than ten feet (CDC 2014). This is a serious concern for both workers and employers. The estimated cost of these injuries each year is $24 billion, which includes the cost of medical and legal services, lost work, liability, and pain and suffering judgments.

For these reasons, the Occupational Safety and Health Administration (OSHA) has established standards for the ladders that workers use in the workplace to help prevent unsafe equipment use and falls or other injuries from ladders. OSHA Standard 1910.23—Ladders covers all categories of workplace ladders, including portable, fixed, and mobile ladders (OSHA 2019). OSHA Standard 1910.28 covers fall protection and falling object protection. This publication summarizes the parts of the OSHA Standard 1910.23 and 1910.28 that apply to fixed ladders.

This article is for interested residents who use fixed ladders for either work or non-work-related purposes.

General Employer Responsibilities

The requirements of the standard are the employer’s responsibility. Employers are required to ensure that ladder equipment is in good condition and that employees use ladders safely. Daily safety precautions include the following:

- Ladders may only be used for the purposes for which they were designed.

- Ladders must be inspected before use in each work shift, and more frequently as necessary, to identify any visible defects that could cause employee injury.

- Any ladder with structural or other defects must be immediately tagged "Dangerous: Do Not Use" (or with similar language) and removed from service until repairs are completed.

Some ladders are not covered by OSHA Standard 1910.23. These include:

- Ladders used in emergency operations (e.g., firefighting, rescue, and law enforcement operations) or training for these operations.

- Ladders that are designed into or are an integral part of machines or equipment (e.g., the ladders built into large machinery such as harvesters). These ladders are covered by other standards.

Fixed Ladders

OSHA defines a fixed ladder as “a ladder with rails or individual rungs that is permanently attached to a structure, building, or equipment” (OSHA 2016). Before using a fixed ladder, make sure that it meets general structure, structural integrity, and general safety standards.

Fixed Ladder Surfaces

Ladder surfaces must be free of puncture and laceration hazards, such as sharp edges, metal spurs, or splinters. Fixed ladders having a pitch greater than 90 degrees from the horizontal should not be used.

Fall Protection for Fixed Ladders

Fixed ladders must have structural protections for climbers. Employers must provide fall protection for employees on fixed ladders. OSHA Standard 1910.29 gives the criteria for fall protection.

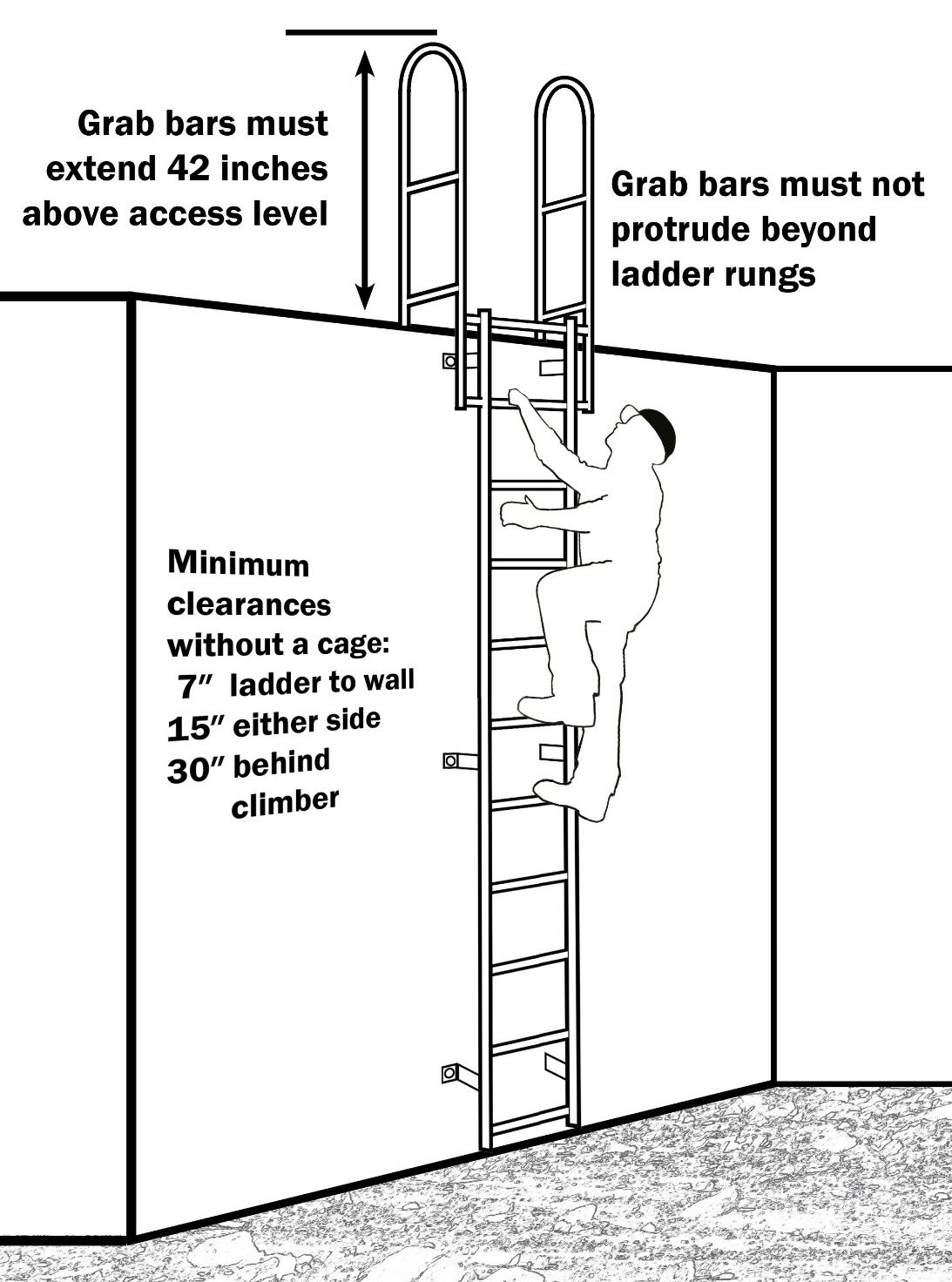

A fixed ladder should have a cage or a well. If a fixed ladder does not have a cage or a well, it must have the following:

- A clear width of at least 15 inches (38 cm) on each side of the ladder centerline to the nearest permanent object.

- A minimum perpendicular distance of 30 inches (76 cm) from the centerline of the steps or rungs to the nearest object on the climbing side (i.e., behind the climber). When unavoidable obstructions are encountered, the minimum clearance at the obstruction may be reduced to 24 inches (61 cm), provided deflector plates are installed.

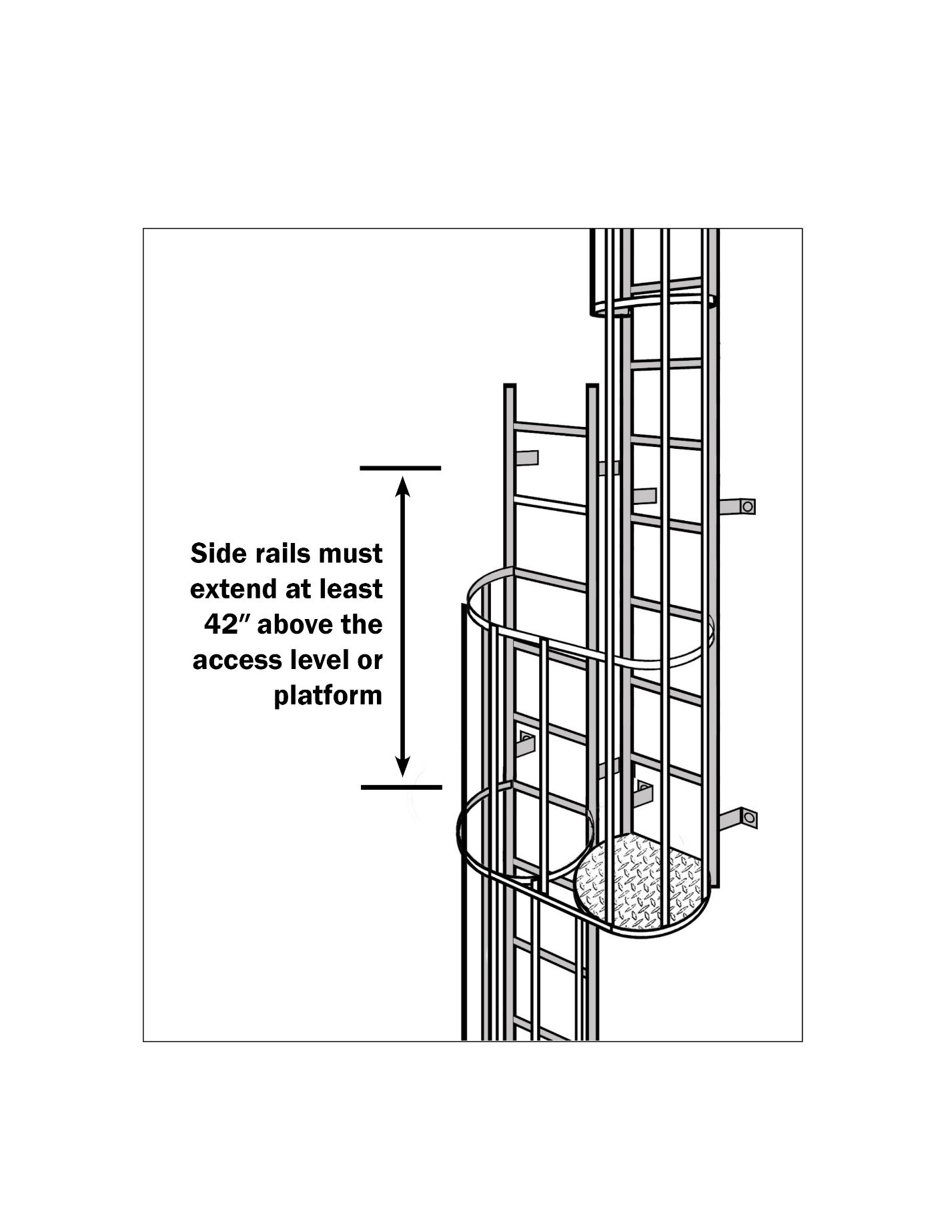

Fixed ladders that extend more than 24 feet (7.3 m) above a lower level must be equipped with:

- A personal fall arrest system, ladder safety system, cage, or well (existing fixed ladders installed before November 19, 2018).

- A personal fall arrest system or a ladder safety system (new fixed ladders installed on or after November 19, 2018).

- A personal fall arrest system or ladder safety system (on and after November 18, 2036). After this date, the cage or the well will not be allowed to be used as a form of fall protection.

Proper Installation of Fixed Ladders

Basic Fixed Ladders

Grab bars must not protrude on the climbing side beyond the rungs of the ladder that they serve. Grab bars extend 42 inches (1.1 m) above the access level or landing platforms served by the ladder. The minimum size (cross-section) of grab bars is the same size as the rungs of the ladder.

When a fixed ladder terminates at a hatch, the hatch cover opens with sufficient clearance to provide easy access to or from the ladder; it opens at least 70 degrees from the horizontal if the hatch is counterbalanced.

Credit: Charles Brown, University of Florida

Through Ladders

The minimum perpendicular distance from the centerline of the steps or rungs, or grab bars, or both, to the nearest permanent object behind the ladder is 7 inches (18 cm), except for elevator pit ladders, which have a minimum perpendicular distance of 4.5 inches (11 cm).

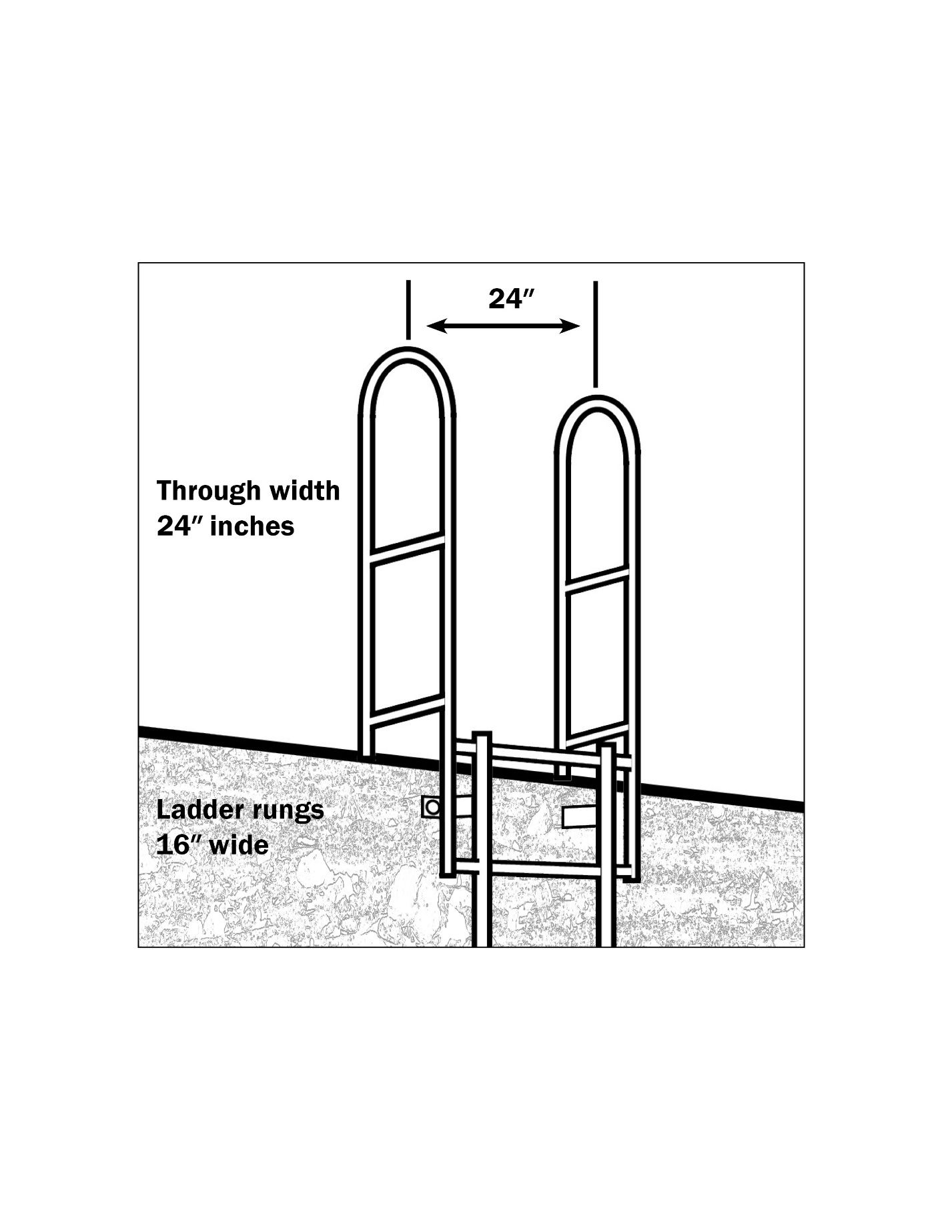

For through ladders, the steps or rungs are omitted from the extensions, and the side rails are flared to provide no fewer than 24 inches (61 cm) and no more than 30 inches (76 cm) of clearance. When a ladder safety system is provided, the maximum clearance between side rails of the extension must not exceed 36 inches (91 cm).

The side rails of through ladders extend at least 42 inches (1.1 m) above the top of the access level or landing platform served by the ladder. For parapet ladders, the access level is:

- The roof, if the parapet is cut to permit passage through the parapet; or

- The top of the parapet, if the parapet is continuous.

Credit: Charles Brown, University of Florida

Side-Step Ladders

The side rails of side-step ladders extend at least 42 inches (1.1 m) above the top of the access level or landing platform served by the ladder. For parapet ladders, the access level is:

- The roof, if the parapet is cut to permit passage through the parapet; or

- The top of the parapet, if the parapet is continuous.

For side-step ladders, the side rails, rungs, and steps must be continuous in the extension.

Credit: Charles Brown, University of Florida

Rungs, Steps, and Cleats: Treads, Spacing, and Width for Fixed Ladders

For all ladders, the employer must ensure that rungs, steps, and cleats are parallel, level, and uniformly spaced. Rung, step, or cleat means the cross-piece of a ladder on which an employee steps to climb up and down (OSHA 2016). The standard specifies the spacing and width.

Spacing Requirements for Rungs, Steps, and Cleats

The employer must ensure that all ladder rungs, steps, or cleats are evenly spaced between 10 inches (25 cm) and 14 inches (36 cm) measured between the centerlines of the rungs, cleats, and steps.

Spacing Exceptions

- Elevator shafts: Ladder rungs and steps in elevator shafts must be evenly spaced between 6 inches (15 cm) and 16.5 inches (42 cm) measured along the ladder side rails.

- Telecommunications towers: Fixed ladder rungs and steps on telecommunications towers must be evenly spaced between 6 inches (15 cm) and 18 inches (46 cm) measured between the centerlines of the rungs or steps.

Width Requirements for Rungs, Steps, and Cleats

Fixed ladder rungs, steps, and cleats must have a minimum clear width of 16 inches (41 cm) (measured before installation of ladder safety systems).

Width Exceptions

- Attached manhole entry ladders: Rungs and steps of manhole entry ladders that are supported by the manhole opening must have a minimum clear width of 9 inches (23 cm).

- Telecommunication centers: Rungs and steps on rolling ladders used in telecommunication centers must have a minimum clear width of 8 inches (20 cm).

Individual-rung ladders must be constructed to prevent the employee's feet from sliding off the ends of the rungs.

The step-across distance from the centerline of the rungs or steps is:

- For through ladders—no fewer than 7 inches (18 cm) and no more than 12 inches (30 cm) to the nearest edge of the structure, building, or equipment accessed from the ladders.

- For side-step ladders—no fewer than 15 inches (38 cm) and no more than 20 inches (51 cm) to the access points of the platform edge.

Working Safely with a Fixed Ladder

Know your fixed ladder’s intended maximum load, and do not exceed it.

The total maximum load must accommodate the total weight of the employee and all tools, equipment, and materials the employee is carrying.

References

Centers for Disease Control and Prevention (CDC). 2014. “Occupational Ladder Fall Injuries — United States, 2011.” Morbidity and Mortality Weekly Report 63(16): 341–346. https://www.cdc.gov/mmwr/preview/mmwrhtml/mm6316a2.htm

National Safety Council (NSC). 2021. “Top 10 Preventable Injuries.” Itasca, IL: National Safety Council. https://injuryfacts.nsc.org/all-injuries/deaths-by-demographics/top-10-preventable-injuries/

OSHA. 2016. “Walking-Working Surfaces: Scope and Definitions.” Standard Number: 1910.21. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.21

OSHA. 2019. “Walking-Working Surfaces: Ladders.” Standard Number: 1910.23. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.23