Introduction

Growth promoting implants offer beef cattle producers one of the most cost effective and greatest cost-to-benefit ratio management technologies available to increase enterprise profitability. Implants consistently increase body weight gain in nursing calves and stocker cattle across a wide range of production systems. The positive benefits of implants are appreciable, but adoption in the cow-calf and stocker segments of the industry is still limited. As greater amounts of protein are needed to feed a growing population, technologies that increase lean tissue production will become increasingly important.

The What and Why of Implants

Since their introduction in the early 1950s, growth promoting implants have been used extensively in beef production systems throughout the United States to increase efficiencies in growth and stimulate lean tissue synthesis. Growth promoting hormones are found naturally within the body regardless of implant treatment and work in conjunction with a variety of environmental and genetic factors to control growth and development. Despite consumer perception, administering growth promoting products to cattle only increases the amount of endogenous hormone already present, which the body utilizes in a cascade of metabolic pathways to increase protein accretion.

Mechanism of Action

Within the industry, there are three main types of implants utilized: estrogenic, androgenic, and combination implants that use both estrogenic and androgenic compounds to elicit a growth response. Within these main categories there are currently five natural and synthetic anabolic hormones approved for use in beef cattle; estradiol, zeranol, progesterone, testosterone, and trenbolone acetate (TBA). The specific mode of action that enables the anabolic implant to improve growth efficiency depends upon the type of implant administered.

Estrogenic growth promoting implants primarily work in an indirect manner by stimulating the animal to secrete growth hormone, which subsequently increases the production of insulin-like growth factor (IGF-1) in the muscle. IGF-1 is well-known to be one of the most important muscle growth factors that help existing muscle cells increase in size and number. Conversely, androgenic agents are believed to work more in a direct fashion on the muscle by binding with hormone receptors in the cell to initiate protein synthesis (Buttery and Sinnett-Smith 1984).

Combination implants that contain both estrogenic and androgenic compounds work via additive affects to regulate growth and increase protein accretion. Additionally, the synthetic hormones used in growth-promoting implants are thought to increase muscle mass more by reducing the rate of protein degradation rather than enhancing the rate of protein synthesis in cattle (Buttery and Sinnett-Smith 1984).

Regardless of the implant choice, adequate nutrition of the animal is essential to capture the benefits of the implant. This means that dams of nursing calves must produce enough milk to support growth of the calf. Likewise, post-weaning nutrition of an implanted calf needs to meet energy and protein nutritional requirements to meet gain potential and appreciate the added growth the implant can provide.

Implant Administration

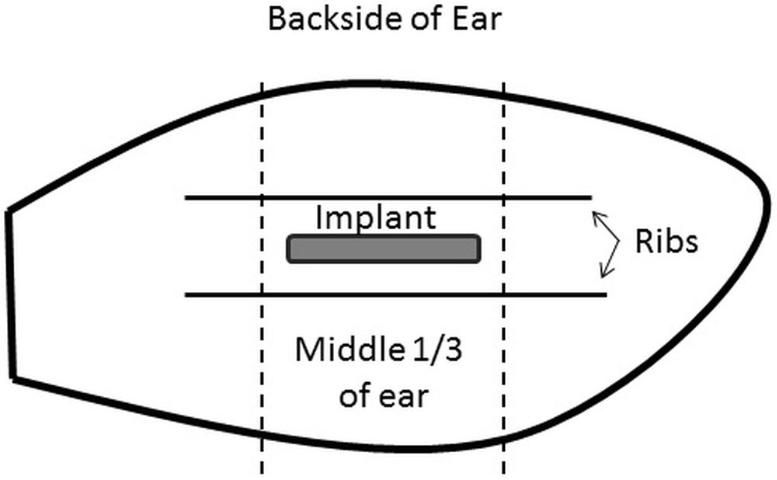

When using implants in cattle, always follow best management practices and follow Beef Quality Assurance guidelines found in Florida Cow-Calf and Stocker Beef Safety and Quality Assurance Handbook: Quality Control Points (https://edis.ifas.ufl.edu/pdffiles/AN/AN17300.pdf ). Read the label instructions of the selected product because it will provide valuable information regarding age, sex, weight of the animal, as well as other specific instructions. Most implants utilize a product specific applicator (referred to as an implant gun), so make sure that you have the correct tool. Implants are applied under the skin on the back of either ear (Figure 1).

Credit: Matt Hersom

Sanitation of the equipment and the animal's ear are important to minimize the chance for implant site infection, which can reduce the effect of the implant. When implanting cattle make sure that

- the animal's head is adequately restrained;

- the needle is clean, sharp, and free of burrs and is securely attached to the applicator;

- the ear is clean (free of manure and dirt); and

- the ear selected for implanting is the one without or with the fewest ear tags, tattoos, or notches.

To administer the implant. grasp the ear to be implanted with one hand and hold the applicator parallel to the backside of the ear. Pierce the skin with the need and then lift the skin to avoid going into the cartilage of the ear. The needle will form a space for the implant to reside. Once the needle is fully inserted, pull back the needle 1/8 to1/4 of an inch, depress the trigger, and slowly withdraw the needle from the ear. The implant pellets will be deposited in the space created by the needle. Gently feel for the row of pellets to ensure proper placement. Improper implant placement can decrease the effectiveness of the implant or lead to infection.

Available Implants

Implants approved for use in nursing calves and stocker cattle are shown in Table 1.

Expected Response

Nursing Calves

Most implant products are licensed with the label claim to increase rate of weight gain and improve feed efficiency for the approved class of animal. Implanting suckling calves with estrogen-progesterone or zeranol will improve their gain performance from birth to weaning by 4 to 6% compared to non-implanted calves. This improvement in calf performance is attributable to a 0.10 lb/day improvement in steer average daily gain and 0.12 lb/day improvement in heifer average daily gain (Selk 1997). If calves are implanted before 3 months of age, the payout of the implant may cease before the calf is weaned. In that case, a second implant may be used, or the two implants with longer payout may be warranted. If calves are greater than 3 months of age at implanting, a second implant prior to weaning is not recommended.

Stocker Calves

Implanting stocker calves (heifers or steers) can increase weight gains by 8 to 18% or 15 to 40 lbs across a grazing season (Kuhl, 1997) compared to non-implanted calves. The response is greater in stocker cattle than in nursing calves and greater in steers than in heifers. If the stocker program is long enough, re-implanting should be considered and likely is economical. The re-implant window is 90 to 100 days depending upon the products used. The growth response to the implant regime will be greater with improved nutritional status of the cattle. Adequate intake of energy and protein will support the improved growth potential associated with the implant. The use of multiple management strategies to improve stocker cattle performance can be additive. Coupling implants with supplementation and ionophores (see Application of Ionophores in Cattle Diets) can increase stocker cattle performance.

In an economic analysis, Lawrence and Ibarburu (2008) estimated that the use of implants in stocker cattle increased average daily gain by 12.9% and decreased the breakeven price by 2.31% compared to the average daily gain and breakeven price for cattle not implanted. The improvement in performance coupled with the decreased breakeven price associated with the use of implants means that implanted calves increase $18.19 more in value compared to their non-implanted counterparts.

Issues of Concern

Breeding Cattle

There are no implants labeled for the use in bull calves intended for retention as herd bulls. Application of implants to intact males can negatively affect testicular development, reduce libido, and affect semen quality. Implanting heifers that are destined to be retained for development into cows should also be avoided. Implants early in life can have minimal impacts, but applications of implants after 3 months of age can have varied and negative effects on heifer reproductive development. Implants do not improve any reproductive characteristics in heifers and thus provide no substantial benefit.

Food Safety

The Food and Drug Administration (FDA) has determined that no withdraw period is required for implants prior to slaughter in cattle. Implants function to replace or supplement the hormones in the calf's body. Hormones are naturally produced by cattle and humans as part of their everyday life. As such, there is no such thing as hormone-free beef or any other meat. Beef from cattle implanted with estrogenic implants has very low concentration of estrogen (4.3 nanograms per 4 oz serving) compared to beef from non-implanted cattle (2.5 nanograms per 4 oz. serving).

References

Buttery, P. J., and P. A. Sinnett-Smith. 1984. "The Mode of Action of Anabolic Agents." Current Topics in Vet. Med. and Anim. Sci. 26: 221–228.

Kuhl, G. L. 1997. "Stocker Cattle Response to Implants," in Symposium: Impacts of Implants on Performance and Carcass Value of Beef Cattle, 51-62. Stillwater, OK: Oklahoma Agricultural Experiment Station. Accessed August 26, 2015. http://beefextension.com/proceedings/implant_97/97-8.pdf

Lawrence, J. D., and M. A. Ibarburu. 2008. "Economic Analysis of Pharmaceutical Technologies in Modern Beef Production." Iowa State University Department of Economics. Accessed November 30, 2012. http://www2.econ.iastate.edu/faculty/lawrence/pharmaeconomics2006.pdf

Selk, G. 1997. "Implants for Suckling Steer and Heifers Calves and Potential Replacement Heifers" in Symposium: Impacts of Implants on Performance and Carcass Value of Beef Cattle, 40–50. Stillwater, OK: Oklahoma Agricultural Experiment Station.