Personal protective equipment (PPE) is one of the most important factors in pesticide safety. This is especially true when protecting the eyes, which are critically sensitive to pesticide exposure. As such, pesticide labels will specify if protective eyewear is necessary during product use and will oftentimes state the type of protective eyewear needed. It is important to note that if the label requires "protective eyewear," that does not mean simply wearing sunglasses or other vision-correcting glasses. Protective eyewear, at a minimum, should meet or exceed impact-resistance specifications established by the American National Standards Institute (ANSI) Z87.1 eye protection standard. There are situations during pesticide applications where protective eyewear might be prudent, even if the label doesn't require it. It is never okay, or legal, to wear less PPE than specified on the pesticide label, but it may be beneficial to go beyond label requirements in certain situations. This document describes the various eye PPE options and how to properly use them.

Types of Eyewear

Safety Glasses

This type of eyewear is designed to protect the eyes from debris and impact. Although safety glasses can protect against some splashes, this eyewear does not provide complete protection from liquids or dusts. Some safety glasses can be shielded on the top and bottom and/or the sides to provide additional protection. If a label calls for "goggles," safety glasses are not sufficient. The lenses on safety glasses come in a variety of tints, depending upon their application. For example, UV-protective lenses might be a better choice for outside use than clear lenses.

Credit: Brett Bultemeier, UF/IFAS

Goggles

Safety goggles wrap around the eyes and seal above and below to prevent chemicals from getting to the eyes. With any eyewear intended to seal around the eyes, proper fitting is crucial. Many safety goggles will have venting to reduce or prevent fogging, but that is not a requirement. Some vent systems are designed to be "one way," meaning fog/condensation can get out, but chemicals or fumes can't get in. Most brands will also have impact protection ratings equal to safety glasses and can provide both impact and chemical protection. Like safety glasses, safety goggle lenses can come in a variety of tints. It may be important to trial several brands, styles, and sizes to ensure proper fit and comfort.

Credit: Brett Bultemeier, UF/IFAS

Face Shield

A face shield can either be attached to a hardhat or other headwear, or worn as a simple "ratchet" style headband. Face shields protect the eyes and face and are particularly helpful during high-risk activities like pouring or loading chemicals into a tank. Some face shields have chin guards that curl in toward the face near the bottom of the shield to prevent splashes from below from getting to the face. Pesticide labels might require protective eyewear and a face shield during certain activities. If both are listed in the PPE section of the label, then both must be worn. There are a variety of face shield materials available, so care should be taken to ensure that the face shield matches the type of application. Face shields are interchangeable on most types of headgear, so changing the shield type to match circumstances is easy. For instance, a wire-screen face shield would not be adequate protection for chemical applications.

Credit: Brett Bultemeier, UF/IFAS

Full-Face Respirator

For instances where the pesticide label calls for safety goggles, a face shield, and a respirator, it might be more efficient to combine these into a single piece of PPE, like a full-face respirator. This can improve comfort while wearing all of the necessary equipment (a separate respirator, goggles, and headgear can often rub against each other and create blisters). As with goggles and respirators, ensuring proper fitting of a full-face respirator is paramount. Oftentimes, full-face respirators will come with adhesive shield protectors that can be removed and replaced if damaged. This will reduce the likelihood of permanent scratches and extend the life of the equipment. The use of any respirator requires a yearly medical evaluation and OSHA-approved fit testing. This is required anytime a respirator is worn, even if a label doesn't require it.

Credit: Brett Bultemeier, UF/IFAS

Use and Maintenance

Proper fit and comfort are important for all PPE, especially PPE related to eyewear. Constant adjusting of PPE while in the middle of an application is distracting and risks exposure to pesticide via contaminated gloves. Furthermore, being distracted by uncomfortable PPE can cause accidents or mistakes because of one's attention not being fully on the task at hand. Be sure to properly adjust, fit, and test all PPE before use in the field.

Caring for your PPE ensures it will last as long as possible. This maintenance begins with proper cleaning. Be sure to rinse eyewear in the field as soon as the work is complete. This initial rinse will reduce cross contamination or exposure to any materials being used. A more thorough cleaning should be done on a routine basis, using soap and water or other appropriate cleaning agents (detergents, bleach, vinegar, etc.). Always refer to the manufacturer's guidelines for appropriate cleaning solutions. Always inspect PPE after cleaning and before use for any damage or signs of significant wear that could cause PPE failure in the field.

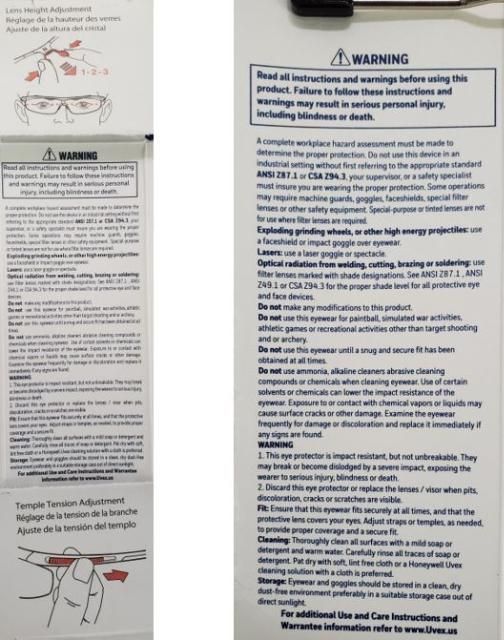

It is common for manufacturers to include guidance, instructions, and information with their equipment. For instance, the safety glasses and goggles from Figures 1 and 2 had the accompanying information in the packaging (Figure 5). Similarly, these goggle instructions discuss what materials they can protect against and provide guidance on proper use. As with a pesticide label, be sure to read all instructions before you use any piece of equipment.

Credit: Brett Bultemeier, UF/IFAS

The eyes are one of the most sensitive parts of the body, and protecting them from pesticide exposure is critical. Always follow the instructions provided on the label when selecting appropriate PPE for pesticide applications. By selecting the appropriate type of equipment, fitting it properly, and maintaining it in clean working order, one can consistently rely on one's safety eyewear to reduce the risk of pesticide exposure.