The Safe Tractor Operations series contains six articles devoted to tractor safety:

- Foundations of Tractor Safety

- Dangers of Extra Riders

- Road Safety for Tractors and Farm Machinery

- Loading and Towing

- More Tractor Safety Tips

- Tractor Operator Checklist

The agricultural sector has one of the highest on-the-job annual death rates, partially due to deaths involving tractors. According to the Bureau of Labor Statistics data, in 2022, the national fatality rate for agriculture, forestry, and fishing was 18.6 deaths per 100,000 full-time equivalents (FTE)—over five times the job-related fatality rate for all industries (BLS 2023a). Agricultural fatality rate for Florida was reported as 11.3 deaths per 100,000 FTEs (BLS 2023b).

Agriculture fatality rates and the number of fatalities related to tractors have remained relatively consistent over more than 30 years. Safer tractor operations and the use of protective equipment could prevent many deaths and injuries involving tractors. Owners, managers, and tractor operators all play a major role in making tractor operations safer. Owners have responsibilities for providing a safer environment and safer equipment. Managers coordinate maintenance designed to ensure the safety of equipment, as well as safety policies and programs. The final responsibility for making the operation of tractors safer lies with the tractor operators themselves.

It is often only when an incident occurs that people become focused on what might have prevented injury or loss of life.

This publication aims to familiarize new and beginning farmers, Extension agents and specialists, and the public with safe tractor operations. It gives guidance about how everyone in an agricultural operation can work together to make using tractors safer.

Foundations of Tractor Safety: Safer Operators, Safer Tractors, Safer Environments

The three major elements that must be considered when developing programs to make tractor operations safer are:

- The tractor operator

- The tractor

- The environment

We have control over a few aspects of these elements. For example, setting up fields with adequate turning room at the ends of rows is a safety factor entirely within human control. The speed at which the tractor is operated and the use of a Rollover Protective Structure (ROPS) and seat belt are also within human control. However, there are elements over which we have no control. In those cases, operations must be modified to ensure that the job is completed safely.

Deaths and injuries result from hazards. A particular driver may be safety-conscious and driving a tractor equipped with safety features, yet this operator might drive into a hazardous environment with a false sense of security; or because an environment is considered “safe,” an owner or driver might tolerate an unsafe tractor. Either of these situations is an incident waiting to happen. Preventing incidents means recognizing hazards and avoiding them, or at least taking appropriate precautions if the hazards are unavoidable.

A well-trained operator using good safety practices on a tractor equipped with safety features reduces the chances of injury or death.

Part 1: A Safer Operator

Consider the following in selecting (or being) a tractor operator:

- Seek an operator who has already demonstrated dependability with you or other employers.

- Seek a driver with a positive disposition and positive attitude toward safety, both of which have been found to correlate with reduced workplace incidents.

Age is a factor. The federal Fair Labor Standards Act and related regulations (29 USC 201 and 29 CFR 570.70-72, respectively) require that individuals operating a tractor with more than 20 power takeoff (PTO) horsepower must be at least 16 years old. There are exceptions for 14- and 15-year-olds who are engaged in an approved agricultural education program, or who have completed training and received a certificate in a formal program such as the 4-H Federal Extension Service Training Program or a U.S. Office of Education Vocational Agriculture Training Program.

Youths of any age can be employed by their parents to work on a farm that the parents own or operate. However, the exemption does not eliminate the hazard.

Don’t take safety for granted. Managers should not take an operator’s knowledge of safety practices for granted. All employees who operate agricultural tractors should be informed of safer operating practices when first assigned to operate a tractor and at least annually thereafter. Brief "tailgate sessions" on a weekly or monthly basis can help maintain safety awareness, express management’s commitment to employee safety and well-being, and build a culture of safety. The following rules apply to all tractor operators employed in agribusinesses under the jurisdiction of the Occupational Safety and Health Act of 1970. Although these rules do not govern everyone, they should be applied to all tractor drivers.

- If the tractor has a ROPS, the operator should securely fasten the seat belt. Do not use seat belts on tractors that do not have ROPS.

- Where possible, avoid operating the tractor near ditches, embankments, and holes.

- Reduce speed when turning and crossing slopes and on rough, slick, or muddy surfaces.

- Stay off slopes that are too steep for safe operation.

- Watch carefully for obstacles and other hazards in the tractor's path, especially at the end of rows, on roads, around trees, and in other blind spots.

- The only person on a tractor should be the operator, unless the operation requires a rider, as in the case of transplanters and harvesters, or for instruction, and only if there is a built-in instructional seat available. For more information, see the "Dangers of Extra Riders" section of this publication.

- Operate the tractor smoothly. Avoid jerky turns, starts, or stops.

- Hitch only to the drawbar and hitch points that the manufacturer recommends.

- When the tractor is stopped, set the brakes securely and use the park lock, if the tractor is equipped with it.

- Lower hydraulic equipment. If hydraulic lines lose pressure, raised equipment lowers suddenly, crushing anything—or anyone—underneath.

- Only authorized personnel should be permitted to operate a tractor.

- The tractor operator has the responsibility of being aware of other workers and machines and of not endangering them.

- Common hand signals should be used to communicate with others in the area.

More Tractor Operator Tips

- Never dismount from a tractor when the engine is running unless the operation requires it.

- Properly mount and dismount from the tractor; slips and falls cause many injuries.

- Do not consume alcohol or drugs, including medications that may impair judgment, during work hours or for four hours before starting work.

- Use hearing protection.

- Headaches can be a sign of carbon monoxide hazards. Check to see if the exhaust is in a location that exposes the operator to exhaust fumes. There have been instances of carbon monoxide exposure using an open-station tractor in the field.

Operating a tractor is a privilege. Tractor operators must have a clear understanding of all instructions and rules. They need to recognize that repeated violations of safety practices may result in their reassignment to a position that does not involve driving a tractor.

Report all safety issues. Tractor drivers should report all unsafe conditions to their immediate supervisor. The goal is to prevent property damage and injuries. Close calls should also be reported.

Supervisors must maintain a safety culture. Supervisors have the responsibility of seeing that all tractor operators have a complete understanding of all instructions and rules. They also need to verify that the instructions are followed, and that appropriate corrective action is taken when intentional or unintentional violations occur.

Operator's Responsibilities

Managers should explain the following responsibilities to tractor operators.

Operators are responsible for daily pre-operational checks of their tractors, even if a shop mechanic is responsible for servicing it. This pre-operational check needs to include at least the following:

- Check oil, fuel, and other fluid levels.

- Check for any oil, fuel, or fluid leaks.

- Check tire condition and inflation levels.

- Make sure that platforms and steps are clean and free of debris and tools.

- Check to see that the lights, brakes, and steering mechanism are working properly.

- Make sure that all gauges are giving proper readings and that the engine transmission and hydraulic system are not making any unusual sounds.

A tractor might require additional pre-operation checks. The operator should know what those additional checks are and should perform them daily or more frequently. The operator can determine which checks are needed by reviewing the maintenance manual for the tractor.

A tractor is not the only “machine” that needs a pre-operation check. The operator does, too. If the answer is yes to the following questions, the operator should not drive.

- Is the operator unfit to drive?

- Is the operator too sick, tired, or angry to drive?

- Does the operator have medications or other substances in their body that might adversely affect judgment, attention, or reaction time?

Important Checks

Operators should conduct a pre-operational check of their clothing.

- Clothing should be comfortable and close fitting, with no loose ends or strings that could easily be caught in moving parts.

- Shoes should have protective steel-tipped toes and skid-resistant soles.

- The condition of any other personal protective equipment the operator is wearing should be checked. These items may include a respirator, eye and ear protection, protective clothing, headgear, gloves, and boots.

- Keep long hair contained in a cap. Long hair can easily be caught in moving parts, resulting in scalping injuries.

- Avoid smoking when fueling the tractor, working around dry materials, or working with pesticides.

The operator should make periodic safety checks throughout the day, stay alert, and remain as comfortable as possible.

- Discomfort can be distracting and tiring.

- Take short breaks frequently.

- Stretch and move around.

- Drink small amounts of non-alcoholic beverages frequently.

- Eat moderately.

- Exhaustion means, “Stop working.”

- The incident you prevent might save your life and the lives of others.

Shortcuts are short-sighted; invest seconds, save lives!

Stepping over a power takeoff instead of walking around the tractor might seem like a time-saving shortcut, but it exposes the operator to a much greater risk of injury or death.

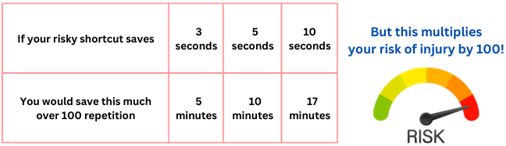

Often, there is a recommended safe way of doing a task, and then there is another way that seems quicker but is more hazardous. Many people use the more dangerous shortcut to save time. However, time and effort invested in occupational health and safety not only help in preventing injuries and possible deaths but also financially benefit employers (Mustard and Yanar 2023).

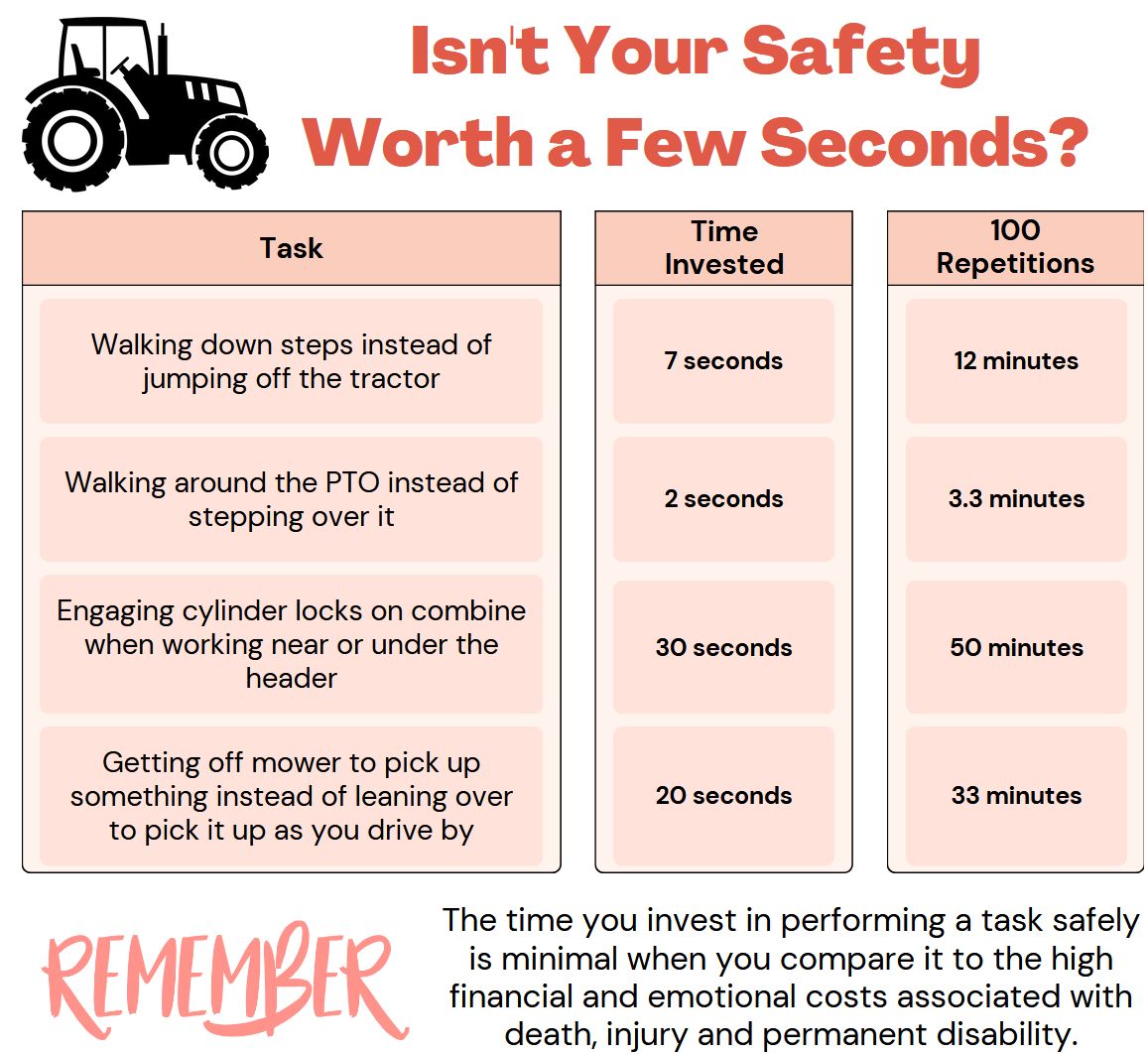

Here are some examples of the small amount of time it takes to be safe. To put these times in perspective, the total time invested for 100 repetitions of a task was calculated. Note that 100 repetitions may occur over an entire year or season. For example, stepping over the PTO may take 2 seconds less time than walking around it. Therefore, if this was done 100 times in a season, the operator would save only 3.33 minutes. However, each of those 100 times, the operator runs the risk of injury or death. See Figure 1 and Figure 2 for examples of shortcuts that save little time but expose a worker to significant risk.

Credit: Serap Gorucu, UF/IFAS

Credit: Serap Gorucu, UF/IFAS

Part 2: A Safer Tractor

Modern tractors are much safer than tractors from 20 or 30 years ago. ROPS and seat belts now prevent many deaths and injuries from tractor overturns. Improved hitch designs and weight distribution have made tractors more stable. Improved shielding of power takeoff shafts, better hydraulic designs, improved brakes, wider wheelbases, better visibility, and other features such as running lights and adjustable seats have also contributed to safer tractors.

Despite modern safety improvements, there are still dangers that come with driving a tractor. These dangers can be reduced if the tractor operator understands the tractor and maintains and operates it properly.

A few modern features, however, have increased potential danger:

- Increased rear axle torque increases the risk of rear overturns.

- Faster tractors increase the danger of side overturns due to centrifugal force on curves or corners.

- Faster tractors increase the danger of losing control during road travel.

Management has the responsibility of providing operators with safer tractors. Consider the following ways to improve tractor safety.

The Importance of Rollover Protective Structures (ROPS)

Side Overturns

Nearly one-half of tractor-related deaths are due to tractor overturns. The side overturn is the most frequent type of overturn. Studies indicate that 75%–85% of overturns are to the side (Abubakar et al. 2010). A tractor has a high center of gravity. Thus, sharp turns and/or high loads can cause the tractor to overturn quite easily and at relatively low speed. Centrifugal force can cause a tractor to overturn if the direction of travel changes. For example, when a tractor's right front wheel veers into the road ditch, the natural reaction of the operator is to steer it back onto the roadway; however, the forces will pull the tractor over on its side.

Rear Overturns

The second type of overturn is to the rear. These overturns may be less frequent, but without a ROPS, they are the deadliest. It is estimated that, without a ROPS, 85% of rear overturns result in the operator's death. Rear overturns occur when the tractor cannot move forward, and the rear axle torque causes the tractor to pivot around the rear axle. The tractor can reach the point of no return in as little as 0.75 seconds. The entire event can happen in as little as 1.5 seconds. There is no time for the operator to react. Rear overturns are often due to pulling a load uphill, being stuck in the mud, or attempting to pull a load that has been hitched above the drawbar.

When possible, operate a tractor equipped with a Rollover Protective Structure (ROPS). All tractors manufactured since 1976 should be equipped with a ROPS and a seat belt. However, certain tractors are exempt, including:

- Tractors built before October 1976

- Tractors with less than 20 horsepower

- Tractors on which equipment is mounted that would be incompatible with ROPS

- Low-profile tractors used in groves, farm buildings, or greenhouses where the vertical clearance would interfere with normal operations (However, it is recommended to use tractors with ROPS in these situations because most manufacturers offer ROPS that can fold down when necessary for clearance.)

Exemptions are not an excuse for not using safety features. If the use of the tractor permits ROPS and seat belts, they need to be provided. An exemption does not eliminate hazards.

Always wear a seat belt on a tractor with a ROPS. If an overturn occurs, the seat belt helps keep the driver within the safety zone that the ROPS creates. Without a seat belt, the driver may be thrown around in the cab, which can result in severe injuries or unconsciousness. Seat belts are not to be used on tractors without a ROPS because, in that case, an operator constrained in the seat would be crushed. Either of these could make it impossible for the driver to escape the cab, which could be fatal, especially if the tractor has overturned into a canal.

Steep Slopes

Sometimes a tractor must operate on a steep slope. Backing up or driving down slopes can help prevent rear overturns. If a tractor must be operated across the slope, use the widest possible wheel adjustment, very slow speeds, and extra caution in watching for obstacles that the wheels might hit. Turn the front wheels downhill at the first indication that the tractor may be becoming unstable.

Frequently Asked Questions about ROPS

How common are tractor overturn injuries?

Tractor overturns are the leading cause of work-related deaths in agriculture.

Can overturn injuries be prevented?

The use of a ROPS and seat belt is 99% effective in preventing deaths and injuries from overturns.

Why is a seat belt needed with the ROPS?

A ROPS provides a zone of protection for the tractor operator, and during an overturn, a fastened seat belt keeps the operator in that zone. If you must use a tractor without a ROPS, do not use a seat belt. Without a ROPS, there is no zone of protection, and wearing a seat belt in this situation eliminates any chance of operator survival.

How do I know if a ROPS is available for my tractor(s)?

Your local tractor dealer can advise you about ordering a ROPS and seat belt for your tractor. Also ask them about professional installation. It will be a few dollars more, but correct installation can make all the difference at the critical moment when a ROPS is needed to save a life.

I cannot afford ROPS for all my tractors, but I want to reduce my risk of being hurt in an overturn. What can I do?

Safety can be improved by using a tractor equipped with a ROPS. Depending on the funding availability, the National ROPS Rebate Program (NRRP), a voluntary program, can provide rebates for approximately 70% of the cost of purchasing and installing a ROPS (https://www.ropsr4u.org/).

If ROPS are so great, can I make my own?

Homemade ROPS are unlikely to provide protection during an overturn. Think about the weight of a tractor. The dynamic forces that act upon a ROPS during a tractor overturn make it crucial that a ROPS be properly designed, manufactured, and installed. This requires professional engineering. The ROPS and tractor must work together as a system to stay together as a unit in the event of an overturn.

The likelihood of a homemade ROPS providing protection is very small. Only ROPS that have been tested to meet specific standards are acceptable. Tractors with ROPS that have not been approved can split during an overturn. Anything less than an approved ROPS provides a false sense of security. Altering a ROPS by welding something onto it or by drilling holes in it can make it less effective.

Will a ROPS limit the way I can use my tractor?

Few owners remove a ROPS because of interference. ROPS that fold down are available for many tractors.

Some of my tractors have cabs. Is the ROPS a part of the cab frame?

Many older tractors may have what is known as a weather cab, meaning that a ROPS is not part of the frame. In an overturn, these cabs can be deadlier because they provide no chance for escape, thus increasing the chances of being crushed.

How do I know if the cab on my tractor has a ROPS as part of its structure?

Look for a label indicating it has an OSHA-approved ROPS. Most tractors manufactured after 1976 should have this label, but the label is not always clearly visible. Additionally, the cab may cover the label up. Look for a seat belt. Manufacturers only install seat belts on ROPS-equipped tractors. Consult the dealer.

More Tractor Safety Tips

- When a tractor has adjustable wheel widths, operate it with the widest wheel adjustment that is practical for the task at hand.

- Add weights to the tractor to make it more stable.

- Check that shields for the power takeoff and other moving parts are in place and are in good condition.

- Check the brakes individually, and then check the brakes locked together with the tractor operating at a transport speed to ensure it will stop in a straight line.

- Inspect the condition and fit of hydraulic lines. Sudden failure of hydraulics could result in loss of control of the tractor or equipment. Serious injury could result from being sprayed with hot, high-pressure hydraulic fluid. Check for holes by holding a piece of cardboard above the hoses. Keep hands clear of hydraulic leaks; using the hand can result in serious burns or in hydraulic fluid being injected directly into the hand.

- Be sure that running lights are properly mounted, clean, and visible. Two headlights and two taillights, both widely spaced, should be visible to other traffic. See Ask IFAS publication ABE302, “Lighting and Marking of Agricultural Equipment on Highways: Summary of ASAE Standard S279.18.”

- Mount the slow-moving vehicle (SMV) emblem in the center of the rear of all tractors and machinery that will be used on public roads. The emblem indicates that the vehicle travels below 25 miles per hour. The bottom edges of the emblem should be no higher than six feet off the ground.

- Always clean the SMV emblem before entering a public road. Dust and dirt greatly decrease its reflective ability.

- Replace the SMV emblem if it begins to fade.

- Mount a fire extinguisher with an ABC rating on all tractors.

- Mount a dustproof and waterproof first-aid kit on all tractors.

- If tractors are used in dusty conditions or for applying pesticides, equip them with cabs that provide filtered air. Check what the filter is designed to do. The operator must have personal protective equipment in the cab in case leaving the tractor becomes necessary.

- Perform pre-operational checks daily, following the guidelines within the operator's manual.

- Avoid bypass starting.

Dangers of Bypass Starting

Shortcuts are common in agriculture, but they are dangerous. Bypass starting is a very dangerous shortcut. It bypasses all the safety-start and neutral-start switches in the tractor's electrical and hydraulic systems. The problem comes when someone tries to bypass-start a tractor or other piece of equipment that is in gear. The person can then get pulled down by the drive wheel and be crushed. The runaway tractor can also injure or kill others in the area.

Frequently, operators or mechanics bypass-start an engine because of a maintenance problem with the tractor's neutral-start switch. It is a good idea to immediately repair mechanical problems that might make bypass starting tempting. Remember that every death or injury due to bypass starting could have been avoided.

Safety Switch Check

Periodically check switches to make sure they are in working condition. This helps avoid the temptation of trying to bypass-start an engine. Following the steps below only takes a few seconds.

- Make sure that no one is standing near the tractor and that no obstructions are around it.

- Depress the clutch and brake pedals. Attempt to start the tractor with the gears engaged and the PTO in neutral. The starter should not engage.

- Depress the clutch and brake pedals. Attempt to start the tractor with the gears in neutral and the PTO engaged. Again, the starter should not engage.

- On tractors equipped with clutch-mounted start switches, depress the brake pedal but not the clutch pedal. Place the transmission and PTO in neutral. The starter should not engage.

- If either switch is malfunctioning, replace it before further use. See the dealer for parts or service.

- Talk to the dealer about getting decals to apply to farm machinery that warn about the dangers of bypass starting. Such decals act as a frequent reminder to operators.

Having one driver per tractor is ideal

Scheduling one operator to one tractor has several advantages. Operators assigned to drive different tractors tend to become confused in crisis situations. The controls may be different, and a split-second delay in reacting to a crisis can result in an overturn or other incident.

When more than one operator drives the same tractor, employees no longer consider the tractor “theirs.” Care of the tractor diminishes, and the blame for lack of maintenance and/or damage is shifted to the "other person." It is also easier for an operator to not check things by assuming that another driver has taken care of them.

Part 3: A Safer Environment

Tractor overturns in canals, ditches, and washouts are common. The steep slopes and loose soils in these environments are serious hazards. Other hazards are found on public roads, blind corners, narrow bridges, culverts, sharp turns, steep terrain, and slippery surfaces.

Inspect the environment in which tractors will be used. Identify the hazards and take action to eliminate them. Implement the following recommendations to reduce the environmental hazards:

- Increase the turning area at the ends of rows. Give the tractor operator room for safe turns without driving too close to ditches and canals.

- Move field roads farther from canals and ditches. Equipment needs to be kept behind the shear line of the soil and embankment. The minimum distance recommended for operating machinery near embankments is a 1:1 ratio to the depth of the embankment. In other words, the tractor should be no closer to the edge than the depth of the embankment. Following this recommendation prevents bank collapse, which can cause tractors to overturn and crush operators or drown them in canals. This distance increases with adverse soil conditions such as sandy or wet soil.

- Control vegetation that can hide hazards. Clearly mark the location of canals, ditches, and other hazards.

- Maintain field roads.

- Widen narrow roads and bridges (where practical).

- Eliminate sharp, blind corners or curves, and rough or slippery surfaces.

- If travel on public roads is absolutely necessary, travel when vehicle traffic is light and visibility is good.

- Use proper marking and lighting on all tractors and attached equipment.

- Prune hedges or trees to improve visibility and reduce the danger of incidents caused by tree limbs hitting the operator.

- Remove tree stumps and other field obstacles.

- Conduct walk-through inspections for washouts before beginning tractor operations. Clearly mark or fill washouts.

- Inspect the farmstead and machinery storage and service area.

- Correct dangerous traffic patterns around hazards.

- Be aware of the location of overhead power lines, especially when towing equipment that may have high points, such as boom sprayers.

Additional Safety Resources

Websites

For more information about these and many other safety topics, contact your county’s UF/IFAS Extension office, or visit the Florida Agricultural Safety and Health Program website at https://abe.ufl.edu/agsafety/.

Consult Tractor Fundamentals: Best Practices, North American Guidelines for Children's Agricultural Tasks. For more information, contact the National Children's Center for Rural and Agricultural Health and Safety at http://www.marshfieldresearch.org/nccrahs.

Consult the Outdoor Power Equipment Institute at http://www.opei.org.

Consult the National Agricultural Safety Database at http://www.nasdonline.org.

Safety Standards

"Hand Signals for Agriculture," ASAE Standard S351

"Operator Controls on Agricultural Equipment," ASAE Standard S335.4

"Roll-Over Protective Structures (ROPS) for Wheeled Agricultural Tractors," ASAE Standard S383.1

"Symbols for Operator Controls on Agricultural Equipment," ASAE Standard S304.5

"Roll-Over Protective Structures (ROPS)," Occupational Safety and Health Administration, OSHA Standard 1928.51

Safety Decals

"No Riders" decals may be purchased from various tractor supply companies.

References

Abubakar, M. S. A., D. Ahmad, and F. B. Akande. 2010. “A Review of Farm Tractor Overturning Accidents and Safety.” Pertanika J. Sci. Technol. 18:377–385.

BLS. 2023a. “Bureau of Labor Statistics, US Department of Labor, Census of Fatal Occupational Injuries, December 2023.” Accessed May 16, 2024. https://www.bls.gov/iif/

BLS. 2023b. “Bureau of Labor Statistics, US Department of Labor, Fatal Injury Rates by State of Incident and Industry, 2022.” Accessed May 16, 2024. https://www.bls.gov/iif/state-data/fatal-injury-rates-by-state-and-industry-2022.htm

Mustard, C. A., and B. Yanar. 2023. “Estimating the Financial Benefits of Employers’ Occupational Health and Safety Expenditures.” Safety Science 159:106008.