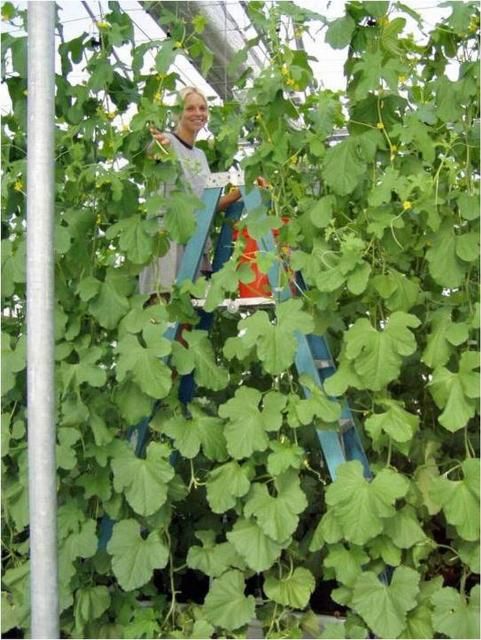

A significant greenhouse vegetable industry has flourished in Florida for almost 25 years. The University of Florida conducted a statewide survey in 1991 and determined that 66 acres of greenhouse vegetables were produced in Florida. European seedless cucumber (Figure 1) and tomatoes (Figure 2) represented 96% of the total acreage at that time. Another survey conducted in 2001 indicated the total statewide acreage had increased to 95 acres. However, tomato (https://edis.ifas.ufl.edu/topic_greenhouse_tomato) and cucumber (https://edis.ifas.ufl.edu/cv268) represented only one-third of the total acreage in 2001. The leading greenhouse vegetable crop was colored bell pepper (https://edis.ifas.ufl.edu/hs228). Herb production (primarily basil) had increased to nearly 17 acres—greater than European seedless cucumber (12 acres) and only slightly less than tomato (18 acres). Lettuce was produced in 7 acres of greenhouse space and strawberry in 1 acre. The complete details of these surveys are available in the Proceedings of the Florida State Horticultural Society (Tyson, et al., "A decade of change in Florida's greenhouse vegetable industry: 1991-2001". 114:280-283. 2001).

Credit: UF/IFAS

Credit: UF/IFAS

In addition to the "big three" greenhouse vegetable crops in Florida (pepper, European seedless cucumber, and tomato), other alternative crops have become very important in greenhouses throughout the country. This is especially evident in Florida and is driven by the unique markets in the Sunshine State. Large urban centers, such as Orlando, Palm Beach, Miami, Tampa, Jacksonville, Ft. Lauderdale, and Daytona, provide marketing opportunities for many high-value alternative greenhouse crops (Figure 3) for local markets, restaurants, and specialty ethnic markets. The abundant Florida cruise ship industry also provides a close market for many high-value specialty crops. The demand for the highest-quality fresh product is often difficult to meet by any other production system than greenhouse culture.

Credit: UF/IFAS

Much of the recent expansion of the greenhouse hydroponic industry in Florida is a result of small farmers seeking to enter the marketplace with locally grown fresh produce. In many cases, these growers are part-time farmers and see this strategy as an affordable way to get into farming on small tracts of land. The marketing strategy for local sales generally means a small grower needs to produce a variety of crops, rather than one or two for a larger wholesale market. Direct sales to consumers are generally higher when the grower has a mix of crops to sell at the market. Several crops other than the "big three" are being successfully grown and marketed now, and the University of Florida is continuously evaluating others.

In 2012, it was estimated that 500 acres or more of all edible crops were being grown in some type of protected culture in Florida. This publication discusses some of the alternative or specialty crops being grown and marketed, other than traditional greenhouse tomato, cucumber, and pepper. The discussion will, however, include nontraditional types of the "big three."

Mini Cucumber

Mini cucumber, also known as Beit Alpha or Persian type (Figure 4), is smaller than the standard European seedless cucumber and has become a popular new crop (https://edis.ifas.ufl.edu/cv277). The Beit Alpha cucumber is relatively new to the United States and is the main cucumber type grown in Israel and Spain and exported to Europe. There is also extensive production in Mexico and Canada. The Beit Alpha cucumber originated in Israel but is now being sold throughout the world.

Credit: UF/IFAS

Beit Alpha cucumbers are gynoecious (all female), parthenocarpic (develop fruit without pollination) hybrids, and they have a gene for flower clustering, which means many fruit set at each internode (Figure 5). The fruit is seedless and has a thin skin like the traditional longer European cultivars. It does not require plastic shrink wrapping to prevent dehydration after harvest. Many consider the flavor as tops among all fresh cucumber types. Fruit are harvested at a very immature stage for highest quality. This is a major advantage in the cost of postharvest handling and marketing. Fruit production is prolific for Beit Alpha cultivars; many of the small fruits are set on each node and on the laterals. Yields can be compact (10 harvests or less) or continuous (more than 30 harvests), depending on the season. Beit Alpha cultivars grow well under extreme environmental conditions, especially under the high temperatures (90°F–95°F) common much of the year in Florida greenhouses. These cucumbers are sensitive to low temperatures, especially in the seedling stage. They can be produced on a year-round basis, provided temperatures inside the greenhouse are not permitted to drop below 35°F.

Credit: UF/IFAS

The University of Florida has conducted several production and postharvest trials in Gainesville, Citra, and Live Oak. Several cultivars have produced very high marketable yields, equivalent to and occasionally higher than standard European cucumber types. Most Beit Alpha types produce fruits 5–8 inches in length. The specific fruit size is important in certain ethnic markets. Management of powdery mildew was a primary production challenge in the past. Most early released cultivars were very susceptible to the disease; however, newer releases have excellent tolerance. Several cultivars have been evaluated at the Suwannee Valley Agricultural Extension Center near Live Oak, and horticultural sciences faculty members in Gainesville have evaluated a dozen others. Cultivars such as 'Manar' and 'Jawell' have consistently performed well. For current cultivar recommendations, contact your county Extension agent or greenhouse vegetable seed dealer.

Lettuces and Other Leafy Green Vegetables

The traditional greenhouse lettuce crop in Florida and elsewhere is a bibb-heading type normally grown in nutrient film technique (NFT) channels (Figure 6) or in a floating system (Figure 7). The product is usually sold as a "living plant" with the roots still attached and packaged in a bag or special plastic clam shell. Lettuce is also produced for baby greens and salad types. Lettuce is a fast-growing crop, typically taking 30–35 days from seeding to harvest.

Credit: UF/IFAS

Credit: UF/IFAS

Growing lettuce in the warm season in Florida makes the disorder known as leaf tip burn more difficult to manage. Environmental controls for temperature, light, cultivar selection, and good calcium nutrition are all critical to properly managing leaf tip burn.

Even though demand for bibb lettuce is still very high, there are new opportunities for greenhouse and outdoor hydroponic growers to see other specialty leafy green vegetable crops, especially at local upscale markets. Recent educational programs in Florida have connected growers with restaurant chefs. These programs revealed great interest among chefs to purchase specialty salad greens and fresh herbs. Developing production systems and timing production schedules for these markets can be very challenging. Many small hydroponic growers whose crops grow inside greenhouses, high tunnels, under shaded structures, and even outdoors in Florida are producing several specialty lettuces and other leafy greens to be sold directly to consumers on the farm and at local farmers markets. In these cases, a wide variety of colors and lettuce types have become popular, including loose leaf, romaine, and summer types. In addition to lettuce, many growers report great demand locally for other leafy greens, such as Swiss chard, spinach, kale, and mustard (Figure 8).

Credit: Kevin Osburn

Culinary Herbs

In the last two decades, there has been a dramatic increase in greenhouse herb production in Florida, from virtually none in 1991 to nearly 17 acres in 2001. The most popular herb now grown in Florida greenhouses is basil; however, dozens of other herbs are also being grown, including chives. Herbs have a long history of human use. In ancient times, as well as today, herbs were used for medicinal, cosmetic, and culinary purposes. The demand for fresh-cut herbs is expected to continue to increase, in part because of health-conscious consumers and increasing consumption of ethnic cuisine. Greenhouse production of herbs offers several production and market advantages, including more rapid plant growth, the ability to provide specific cultural and nutritional requirements, wintertime production when market prices are highest, and a clean product. The clean hydroponic product may not require washing prior to shipment, which contributes to a longer shelf-life and a high-quality appearance. Seventy-eight percent of herb buyers responding to a national survey rated quality as the most important factor in selecting herb suppliers.

The University of Florida conducted studies at Live Oak to document the marketable yield of selected fresh-cut herbs (Figure 9) from fall through spring in a vertical hydroponic greenhouse production system (Verti-Gro®). Herbs included in the trial were arugula (Eruca vesicaria), basil (Ocimum basilicum), purple basil (Ocimum basilicum), chervil (Anthriscus cerefolium), dill (Anethum graveolens), lemon balm (Melissa officinalis), sweet marjoram (Origanum majorana), oregano (Origanum vulgare), parsley (Petroselinum crispum), Italian (flat leaf) parsley (Petroselinum crispum), sage (Salvia officinalis), and thyme (Thymus vulgaris). The best overall performers in the vertical systems were basil, oregano, parsley, sweet marjoram, and thyme. Basil, the most popular herb among local consumers in Florida, is commonly grown for fresh-cut harvest in a wide variety of containers filled with soilless media and also grown for whole-plant sales in NFT systems (Figure 10). Other successful trials for herb production have included mints and chives in lay-flat bags filled with perlite. As with most greenhouse specialty crops, growers must become especially knowledgeable about the differences in herb pricing, packaging, postharvest handling, and marketing for success and profit.

Credit: UF/IFAS

Credit: UF/IFAS

'Galia' Muskmelon

'Galia' muskmelon (Cucumis melo Reticulatus group L.) could become another hydroponic crop favorite (https://edis.ifas.ufl.edu/hs147). The 'Galia' melon is a green-fleshed muskmelon with a golden to yellow netted rind at maturity (Figure 11). 'Galia' fruits have a unique aroma and sweet flavor, and they show promise as a greenhouse specialty melon (Figure 12). The quality of 'Galia' fruit grown hydroponically in a protected structure can surpass the quality of field-grown orange muskmelons because of their bold aroma and high sugar content, which leads to higher market value. The secret to successful multiple fruit production is pruning, which is labor intensive (Figure 13). Newer 'Galia' cultivars ship well and are more disease resistant.

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

The Florida field vegetable industry is facing many challenges, including the loss of the soil fumigant methyl bromide; increased regulations on food safety, water, fertilizer, and pesticide use; increased urbanization and loss of production land in southern Florida; challenges from weather, including freezes, wind, and rain; and increased regional and global market competition. Alternative growing methods, such as protected agriculture in nontraditional growing regions of Florida, are necessary to stay competitive, as are new specialty commodities like 'Galia' melon.

In Europe, 'Galia' melons are in high demand and well known for their superior quality and high soluble solids; furthermore, 'Galia' has become an identifiable trade name.

University of Florida researchers have evaluated several aspects of 'Galia' muskmelon production, including cultivar selection, nutrient management, soilless media, disease and insect management, pruning methods, and pollination. Disease and insect management can be especially challenging in greenhouse muskmelons grown in Florida. Currently, this is a very specialized niche market in Florida; however, as production challenges are solved and consumer acceptance increases, 'Galia' muskmelon may become a viable alternative greenhouse crop in the future. They must be harvested at half or full slip (tearing at the peduncle end) to achieve maximum flavor and sweetness. Presently, some field-grown 'Galia' melons are harvested very immature and thus never achieve any flavor, sweetness, or aroma.

'Charentais' Cantaloupe

Popular in France, 'Charentais' cantaloupes boast an extremely fragrant and sweet, orange flesh (Figure 14). In the United States, 'Charentais' melons were not widely grown because of their short shelf-life and susceptibility to powdery mildew. Recently, however, new cultivars have been released with longer shelf-life and better powdery mildew resistance. 'Charentais' cantaloupes are produced in a similar fashion to 'Galia' melons. Average fruit number can be greater than four per plant. Soluble solids content (sugars) can be greater than 16°Brix, which is excellent in melons.

Credit: UF/IFAS

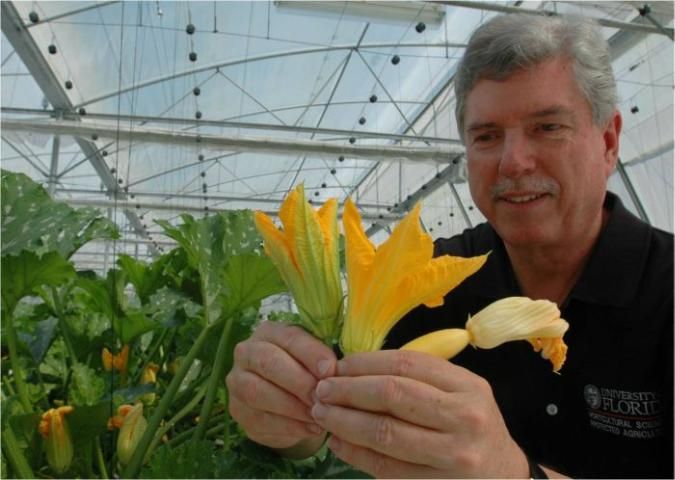

Baby Squash and Squash Flowers

Mini or "baby" vegetables have become increasingly popular items for restaurant chefs and retail sales. Squash (Cucurbita pepo) are generally cultivated in open fields where climate, insect, and disease pressures create challenging conditions for growers and shippers who produce and market this delicate, immature fruit. Squash cultivars, including zucchini, yellow summer, patty pan/scallop, and cousa, can be grown hydroponically in a greenhouse (Figure 15).

Credit: UF/IFAS

Squash are graded as "baby" when they are less than 4 inches in length for zucchini, yellow summer, and cousa and less than 1.5 inches in diameter for round and patty pan/scallop. The use of commercially available bumble bees is important for good pollination and uniform shape. Zucchini produce between 16 and 25 baby-sized fruit per plant. Yellow summer squash have produced more than 45 baby fruit per plant in University of Florida trials. Patty pan/scallop squash production ranged from 50 to 67 baby-sized fruit, and cousa produced approximately 30 baby-sized fruit per plant. Squash plants can produce numerous high-quality baby-sized fruit when grown hydroponically in a reduced pesticide greenhouse environment where they can be harvested, packaged, and distributed to buyers daily. Field cultivars 'Hurricane', 'Raven', 'Gold Rush', 'Goldy', 'Sunray', 'Seneca Supreme', 'Supersett', 'Butter Scallop', 'Sunburst', 'Patty Green Tint', 'Starship', 'Magda', and 'HA-187' have all been successfully used for hydroponic baby squash production. While the female flower is harvested for baby fruit, the male flower is in high demand by top-end restaurants (Figure 16). The male flower should be harvested with complete stamens, either on the day before or the morning of opening, then bagged and cold stored before rapid delivery to the intended buyer. Because of high demand and lack of supply, prices are exceptionally high for quality male squash flowers, up to $1 per flower.

Credit: UF/IFAS

Strawberry

Strawberry production in a greenhouse (Figure 17), high tunnel (Figure 18), or in an outdoor hydroponic system has captured the imagination of many over the past several years. This crops many attributes make the greenhouse concept appealing, including high fruit values, protection from freezing temperatures, high value in the off season, difficulty with labor harvesting (low crop culture), and the challenge of finding suitable alternatives to soil fumigation.

Credit: UF/IFAS

Credit: UF/IFAS

The greatest adoption of nontraditional strawberry production methods in Florida has been with outdoor vertical hydroponic systems and production in simple high tunnels. Strawberries are produced inside high tunnels with both in-ground and soilless culture (https://edis.ifas.ufl.edu/hs407).

Recent University of Florida research has focused on cultivar selection as well as new production and pest management systems for greenhouse and high-tunnel strawberry. In particular, greenhouse strawberries are more susceptible to pests, such as spider mites and powdery mildew. Insects and mites can be managed using biological control measures, and powdery mildew can be controlled with sulfur applications.

Specialty Cut and Edible Flowers

As consumers demand highly specialized crops, greenhouse producers should consider meeting these needs. Often the local market demands crops in a condition or at a time that can only be met by using the protection of a greenhouse. Among these specialty crops being grown on small commercial acreage in Florida, primarily for local sales, are fresh-cut flowers and edible flowers.

University of Florida efforts near Live Oak have been successful in refining a production system for cut flowers similar to that used for vegetables. This project evolved out of greenhouse vegetable growers wanting to produce other profitable greenhouse crops and diversify their offerings at local markets. The crops that have the most potential are those specialty cut flowers that are difficult to ship from other larger, distant production areas (Figure 19). These include flowers such as zinnia (Figure 20), snapdragon, sunflower, delphinium, stock, dianthus, and lisianthus. Small growers in Florida have been successful in producing top-quality flowers, targeting local sales at both farmers markets and florists. Expansion of these local marketing efforts depends upon growers being able to grow several different species to maximize the number of specialty cuts sold on a weekly basis. Flowers that continue to branch and produce more cuts on the same plant over a long period of time have shown to be the most profitable candidates. Zinnia and snapdragon, for instance, have this type of growth habit. In some cases, growers need to be sure to provide special lighting requirements during certain times of year.

Credit: UF/IFAS

Credit: UF/IFAS

Edible flowers can be good companion crops for local greenhouse growers, especially herb producers. Although the demand is small, the value is high and the opportunity to provide high-quality edible flowers to chefs in urban Florida restaurants is great. Postharvest handling and packaging are very important in successfully adding edible flowers to a grower's list of specialty crops. Vertical production (Verti-Gro®) of these has been highly successful in trials at the Suwannee Valley Agricultural Extension Center near Live Oak. Edible varieties of nasturtium (Figure 21), viola (Figure 22), stock, and marigold have all been successfully produced in trials at Live Oak.

Credit: UF/IFAS

Credit: UF/IFAS

Microgreens and Baby Greens

Frequently called "vegetable confetti," microgreens (https://edis.ifas.ufl.edu/hs1164) are young, tender greens that are used to enhance the color, texture, or flavor of salads, or to garnish a wide variety of main dishes (Figure 23). Harvested at the first true leaf stage and sold with the stem, cotyledons (seed leaves), and first true leaves attached, they are among a variety of novel salad greens available on the market that are typically distinguished categorically by their size and age (Figure 24). Sprouts, microgreens, and baby greens are simply those greens harvested and consumed in an immature state. Based on size or age of salad crop categories, sprouts are the youngest and smallest, microgreens are slightly larger and older (usually 2 inches tall), and baby greens are the oldest and largest (usually 3–4 inches tall). Both baby greens and microgreens lack any legal definition. The terms "baby greens" and "microgreens" are marketing terms used to describe their respective categories. Sprouts are germinated seeds and are typically consumed as an entire plant (root, seed, and shoot), depending on the species. For example, sprouts from almond, pumpkin, and peanut reportedly have a preferred flavor when harvested prior to root development. Sprouts are legally defined and have additional regulations concerning their production and marketing because of the relatively high risk of microbial contamination compared to other greens. Growers interested in producing sprouts for sale need to be aware of the risks and precautions summarized in the FDA publication Guidance for Industry: Reducing Microbial Food Safety Hazards for Sprouted Seeds (http://www.fda.gov/Food/GuidanceRegulation/GuidanceDocumentsRegulatoryInformation/ProducePlantProducts/ucm120244.htm).

Credit: UF/IFAS

Credit: UF/IFAS

The crops used for microgreens usually do not include lettuces because they are too delicate and wilt easily. The kinds of crops that are selected for production and sale as microgreens have value in terms of color (like red or purple), unique textures, or distinct flavors. In fact, microgreens are often marketed as specialty mixes, such as "sweet," "mild," "colorful," or "spicy." Certain microgreen crops germinate easily and grow quickly. These include cabbage, beet, kale, kohlrabi, mizuna, mustard, radish, Swiss chard, and amaranth. As many as 80–100 crops and crop varieties have reportedly been used as microgreens. Others that have been used include carrot, cress, arugula, basil, onion, chive, broccoli, fennel, lemongrass, popcorn, buckwheat, spinach, sweet pea, and celery. Growers should evaluate various crop varieties to determine their value as microgreens. Many seed companies are very knowledgeable about the crops and varieties to grow, and a number of them offer organic seed.

Microgreens can be grown in a standard, sterile, loose, soilless germinating media (Figure 25). Many mixes have been used successfully with peat, vermiculite, perlite, coconut fiber, and others. Partially fill a tray with the media of choice to a depth of 1/2 inch to 1 or 2 inches, depending on irrigation programs. Overhead mist irrigation is generally used in this media system. A commonly used commercial production system uses one of several materials as a mat or lining to be placed in the bottom of a tray or longer trough (Figure 26). These materials are generally fiber-like and provide an excellent seeding bed.

Credit: UF/IFAS

Credit: UF/IFAS

The commercial marketing of microgreens is mainly targeted toward restaurant chefs or upscale grocery stores. Microgreens are ready for harvest when they reach the first true leaf stage, usually at about 2 inches tall. Time from seeding to harvest can vary greatly by crop from 7 to 21 days. Production in small trays will likely require harvesting with scissors, which is a very time-consuming part of the production cycle and is often mentioned by growers as a major drawback. The seeding mat type of production system has gained popularity with many growers because it facilitates faster harvesting and in some cases can be sold directly to chefs, allowing them to harvest as needed.

Specialty Cultivars of Solonaceous Crops (Pepper, Tomato, and Eggplant)

Colored peppers (Figure 27) and beefsteak (Figure 28) or cluster tomatoes are considered traditional greenhouse vegetable crops. These crops, along with their relative, eggplant, can also provide alternative crop opportunities for small greenhouse growers if nontraditional cultivars are used. Such examples being produced in Florida include heirloom tomatoes (Figure 29), hot or other specialty peppers, and unusual types of eggplants. In some cases, producing many specialized varieties of vegetable crops at the same time in the field can be very difficult because of diseases, insects, or weather problems. The controlled greenhouse environment may create opportunities to produce specialty crops, like heirloom tomatoes, off-season specialty pepper, or tender eggplant varieties. These are typically opportunities for small and more specialized greenhouse operations. Heirloom tomatoes are in very high demand among upscale restaurants and local direct-to-consumer markets (Figure 30). These highly perishable fruit command high prices of $3–$6 per pound in certain markets. However, heirloom tomatoes are very challenging to grow because they have limited or no disease tolerance, are very susceptible to cracking, have relatively low yields, do not set fruit in very high temperatures, have highly variable fruit quality, and are difficult to prune and train to a production system. These production challenges create an advantage to the excellent growers who can better manage these difficulties. Other specialty tomato types being grown include grape (Figure 31), cocktail (Figure 32), cherry, and cultivars with varying colors of all types.

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

Greenhouse peppers are generally sold as a large bell pepper, typically red, yellow, or orange in color (https://edis.ifas.ufl.edu/hs228). However, many other specialty peppers can easily be grown in protected culture (Figure 33). Recently, there has been an increase in pepper production under open-shade systems (https://edis.ifas.ufl.edu/hs368) to extend production well into the heat of Florida's summers (Figure 34). This system has mainly been used to extend the season for green bell peppers. Colored peppers seem to require more environmental controls as provided by the shelter of greenhouses or high tunnels.

Local demand for specialty peppers seems highly variable in the state, but examples of specialty peppers that are gaining popularity include poblano, jalapeno, cubanelle, hot Datil (Figure 35), unusual sweet types, and small colored types.

Credit: Kevin Osburn

Credit: UF/IFAS

Credit: UF/IFAS

Eggplant is not normally considered a greenhouse crop. However, in diversified operations, eggplants have found a place among the offerings. The types being grown are slender, long, mild fruit types or ones with unusual colors or color patterns (Figure 36). Eggplants have higher light requirements for fruit set but can tolerate high temperatures.

Credit: UF/IFAS

Summary

The eye-appealing combinations of fruit size, color, and shapes among tomato, pepper, and eggplant at local market displays make this group of traditional crops very nontraditional and popular among consumers. Many small operations have been successful with a crop diversification approach when selling directly to consumers at farmers markets or other retail markets (Figure 37). High-quality greenhouse tomato, cucumber, or pepper accompanied by lettuce, cut flowers, baby squash, strawberries, herbs, and specialty leafy greens and other vegetables can make a great crop mix at a local market for a small but talented greenhouse grower (Figure 38). For additional reading on many of the crops being researched and grown in Florida greenhouses, see http://smallfarms.ifas.ufl.edu/crops/hydroponics/index.html and http://www.hos.ufl.edu/protectedag/index.htm.

Credit: Kevin Osburn

Credit: UF/IFAS