Introduction

This publication focuses on the adjustment of potato seed piece spacing of table-stock cultivars for Florida production. The aim is to provide management strategies that minimize potato seed costs, increase yield, and reach the marked demand for specific tuber size distribution, all of which are important factors for the table-stock potato industry. The guidelines presented are a result of field-based research conducted by UF/IFAS for three years (Andrade et al. 2021). This publication's target audience is potato growers, Extension agents, crop consultants, representatives of the fertilizer industry, state and local agencies, students, instructors, researchers, and all interested Florida citizens.

Production practices that maximize crop yield may be in tension with input usage, and determination of the economic return of a new practice is a critical factor in any agricultural enterprise. Potato seed accounts for approximately 13% of the total cost of table-stock potato production in Florida (Smith and Taylor 2011), and small changes in seed piece spacing decisions can lead to a significant increase in the cost of seed and transportation. For example, if a grower decides to reduce the in-row seed piece spacing from 8 to 6 inches, the seed quantity required at planting will increase from 24.50 to 32.67 cwt/acre considering 40-inch row spacing and an average seed weight of 2 ounces. If seed cost is $15/hundred weight (cwt), this would translate to an additional seed cost of $123/acre without including freight expenses.

The decision of which potato seed piece spacing to select may take into consideration important points such as cultivar-dependent tuber size distribution characteristics, consumer demand, market requirements, seed supply, and the necessity to return higher revenue to growers and marketers. Along with market preferences, the accurate combination of environmental conditions, cultivar, and seed piece spacing may be used for optimizing the economically viable yields. Because the conditions for potato cultivation and market preferences range across production regions in the United States, economically optimal seed piece spacing for a specific cultivar also differs across regions.

The general recommendation of in-row seed piece spacing in the Vegetable Production Handbook of Florida (Zotarelli et al. 2022) ranges from 7 to 10 inches; however, this does not account for variation in tuber size distribution across different cultivars. This current publication encompasses the seed piece spacing recommendation for six representative table stock cultivars commonly planted in north Florida. More information on the seed piece spacing for chipping varieties can be found in HS1317, “Seed Piece Spacing Adjustment for Florida Chipping Potato,” at https://edis.ifas.ufl.edu/publication/HS1317 and in Krupek et al. (2017).

Tuber Yield, Specific Gravity, and Quality Characteristics of Table-Stock Potato Cultivars Planted at Different Seed Piece Spacing

Tuber Yield and Tuber Size Distribution

This section summarizes the results obtained for six table-stock potato cultivars commonly grown in north Florida: ‘Actrice’, ‘Envol’, ‘Natascha’, ‘Purple Majestic’, ‘Red LaSoda’, and ‘Satina’, planted using four different in-row seed piece spacings—6, 8, 10, and 12 inches—at the UF/IFAS Hastings Agricultural Extension Center in Hastings, FL during the spring production seasons of 2018, 2019, and 2020. All trials were planted with a 40-inch spacing between raised beds. Seed piece weight was approximately 2 ounces for all cultivars and production seasons. After harvest, all tubers were graded using USDA standards and classified into five different classes according to diameter: A3 (3.4 to 4.0 inches), A2 (2.5 to 3.3 inches), A1 (1.9 to 2.49 inches), B (1.5 to 1.89 inches), and C (0.5 to 1.5 inches).

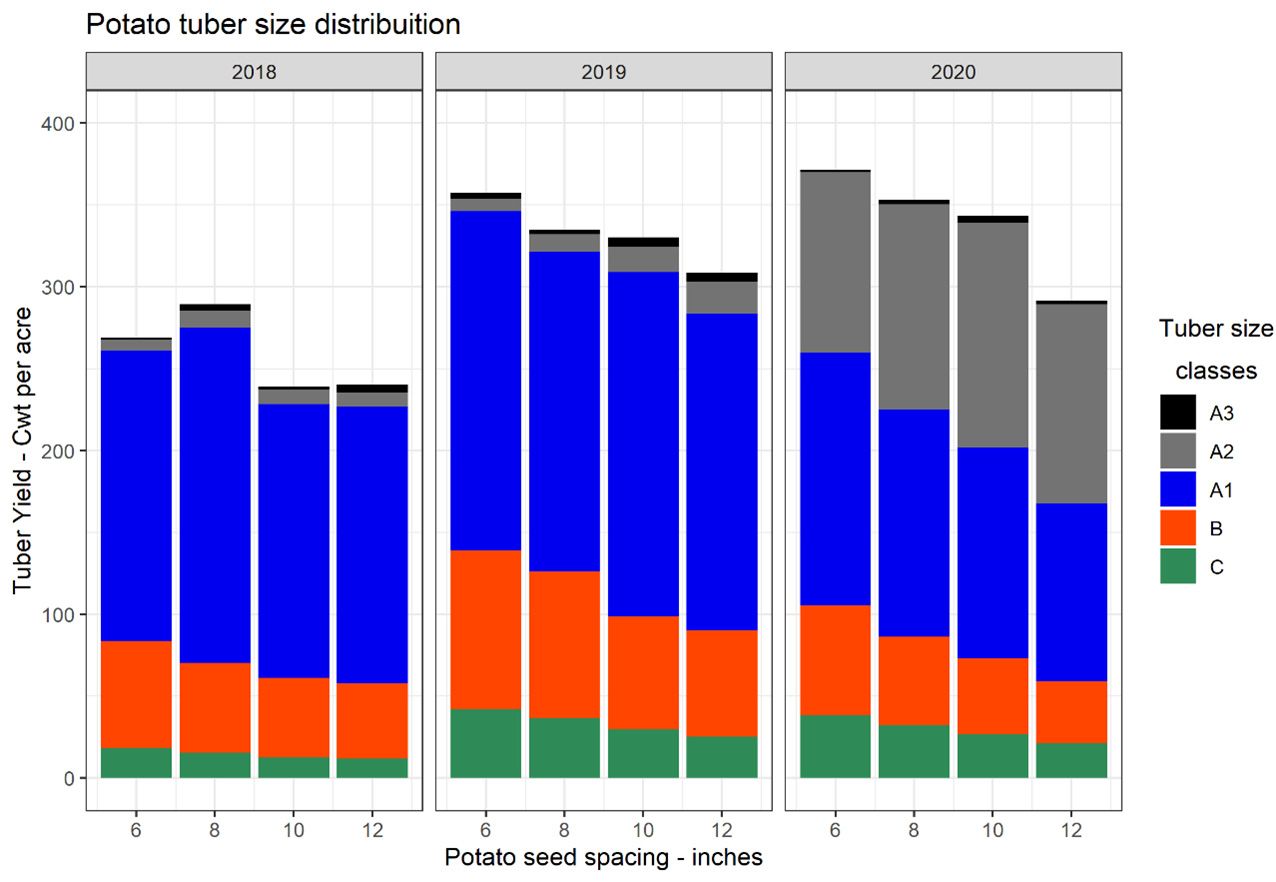

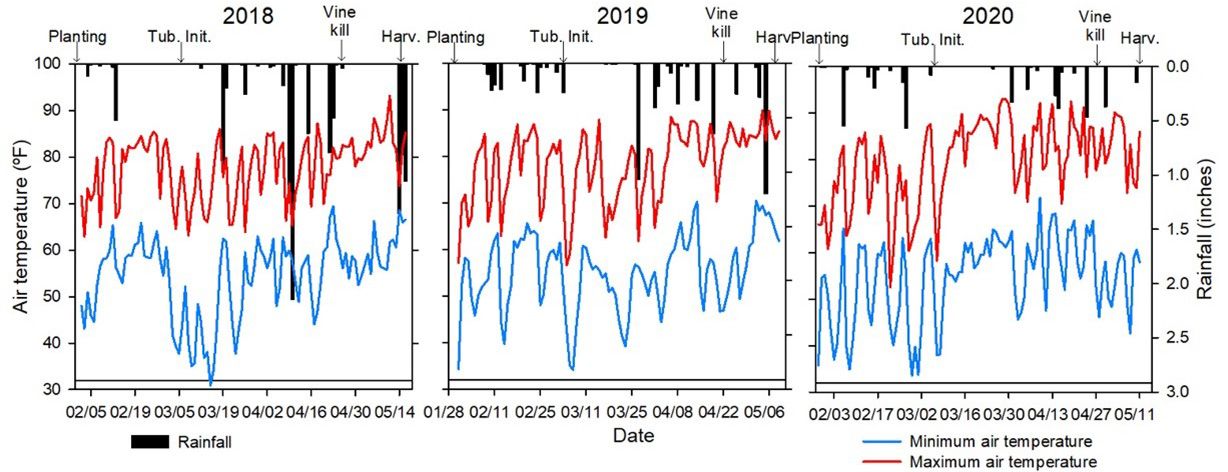

Results from these studies showed that total tuber yield (combined weight of all tuber size classes) increased as seed piece spacing decreased in all seasons. However, the yield differences among seed spacing treatments varied across production seasons (Figure 1). For example, in 2018, total yield was lower compared to the two other seasons, mostly due to unfavorable weather conditions as shown in Figure 2 (e.g., freezing at the beginning of the season and uneven rainfall distribution). The 8-inch seed piece spacing showed the highest yield in 2018, with 289 cwt/acre production. The 6-, 10-, and 12-inch seed piece spacings yielded 269, 239, and 240 cwt/acre, respectively. Tuber yields for the 2019 and 2020 seasons were similar, with a reduction in total tuber yield with the increase in seed piece spacing. In 2019, the total yield was 357, 335, 330, and 309 cwt/acre, and in 2020, total yield was 371, 353, 343, and 292 cwt/acre, for 6-, 8-, 10-, and 12-inch seed piece spacings, respectively. Although there were yield differences across production seasons, the performance of all cultivars tested were similar under the different seed piece spacings within each production season (Table 1).

Credit: Mario Andrade, UF/IFAS

Credit: Lincoln Zotarelli, UF/IFAS

Tuber size distribution is also an important trait for table-stock potato production due to the different market demands. Seed piece spacing and cultivar (Figure 1 and Table 1) affected the tuber size distribution. For production of B class tubers, 6-inch seed spacing had the highest yield in all seasons. In addition, there was a tendency for yield to decrease for this tuber class as seed spacing widened (Figure 1). The 6-inch seed spacing showed an increase of 14%, 28%, and 35% compared to 8-, 10-, or 12-inch seed spacings, respectively (Table 1). The average yields for tubers classified as B size were 65, 97, and 68 cwt/acre for 2018, 2019, and 2020 seasons, respectively.

The results for tuber yield of the C size class were similar to those found for the B class. The narrow spacing had higher yields in all seasons, with a slight difference between the seasons 2018 and 2019–2020. In 2018, seed piece spacings of 6 or 8 inches had the highest yields (19 and 16 cwt/acre, respectively), while the highest yields in the C size class were 42 and 38 cwt/acre in 2019 and 2020, respectively, using the 6-inch seed piece spacing.

The impact of seed piece spacing on yield of tubers classified under the A size class (diameter > 1.9 inches) was not consistent across the seasons (Figures 1 and 2). For A1 tuber size, seed piece spacing of 8 inches had the highest yield in 2018 (205 cwt/acre). In the 2019 season, all tested spacings had similar results for A1 class (201 cwt/acre). For the 2020 season, the seed spacings of 6 or 8 inches had the highest yields (154 and 139 cwt/acre, respectively). The production of A2 class was less affected by seed piece spacing, only presenting differences in yield for the 2019 season. For the A2 class, the 12-inch seed piece spacing resulted in higher yield for that class than to the other spacings, with an average of 20 cwt/acre; all the other spacings averaged 11 cwt/acre.

It is noteworthy that the production of tubers classified as A2 was much higher in 2020 compared to the other two seasons, with an average 37% of total tuber yield classified as A2. In 2018 and 2019, A2 production represented only 4% of total yield. Otherwise, the proportion of B and A1 tuber size in 2020 was below the average of the other seasons, with 15% and 38% of total production classified as B and A1, respectively in 2020, and 22% and 65% on average for 2018 and 2019, respectively. These results can be explained due to differences in time for the bulking stage. In 2020, vine kill occurred 91 days after planting, while in 2018 and 2019 the vine kill was 84 and 81 days after planting, respectively. When weather conditions are favorable, later vine kill will allow the tubers to bulk to larger sizes, as long as the vines are still green without clear indication of vine senescence. The seed piece spacing did not increase the incidence of internal disorders or affect tuber specific gravity. Despite differences among cultivars regarding specific gravity (Table 1), all spacing treatments yielded similar tuber specific gravity results.

Calculation of Potato Seed Requirement

Calculation of potato seed requirement per acre is essential to budget the capital required accordingly prior to planting. There are differences in crop management practices for potatoes cultivated in north Florida. The interrow spacing may change the final plant stand depending on the soil drainage characteristics. On soils irrigated using subirrigation (seepage), the common between-row spacing is generally 40 inches; row beds are 12–14 inches high with water furrows spaced 60 feet apart to improve water drainage. On well-drained soils (Florida Panhandle), growers use narrower between-row spacing (e.g., 36 inches) compared to seepage areas (moderate drainage). Moreover, no furrow system is required in the Panhandle region because overhead sprinkler irrigation is the predominant irrigation method in well-drained soils. The narrow between-row spacing allows a higher plant population per acre. Table 2 describes the seed requirement across different seed spacings, row spacings and seed weights common in north Florida. Table 3 provides the plant populations for different seed spacings and row spacings.

An example of the calculation used to estimate seed requirement and plant population is provided below. The example will help specialists, agents, or potato producers to calculate seed requirements and plant population according to their customized seed, row spacing, and seed weight.

Example:

What are the seed requirements for 36-inch between-row spacing with 6-inch seed spacing for an acre when the seed weight is 1.5 ounces? Also, calculate the plant population.

Solution:

No of seeds per acre = area of acre in ft2 / [(row spacing in inches/12 inches) × (in-row plant spacing/12 inches)]

1 acre = 43,560 ft2

No of seeds per acre = 43,560 ft2 / (36 inches/12) × (6/12) = 29,040 seed pieces per acre

To calculate the weight in pounds with seed weight of 1.5 ounces = 29,040 seed pieces/acre × 1.5 ounces / 16 ounces/pound = 2,723 pounds

Hundred weight per acre = 2,723 lb/100 = 27.23 cwt

Note: Mechanical potato seed cutters may result in seed pieces of different sizes depending on the machine and adjustments. Adjust the seed cutter to the specific target seed size and evaluate the average weight of tuber seeds. Perform a test by cutting a known weight of tubers (e.g., 10 lb) and counting the number of tuber pieces. Divide the weight of tubers by the number of tuber pieces cut to determine the average tuber size.

Final Considerations

Potato growers can optimize their production and net revenue by choosing the right seed piece spacing and cultivar. According to the findings outlined in this study, narrower seed spacing of 6 and 8 inches (i.e., increased plant population) produced higher total tuber yield. The tuber size distribution can also be managed accordingly to the seed piece spacing. Depending on desired tuber size, the following seed piece spacing should be used: 6 inches for B and C sized tubers, 6 or 8 inches for class A1, and finally, wider spacing of either 10 or 12 inches for A2- and A3-sized tubers.

Regardless of seed piece spacing, performance of the cultivars showed a similar trend across years. However, it is noteworthy that cultivar selection could optimize tuber class distribution. The cultivars ‘Natascha’ and ‘Purple Majesty’ are prone to produce more tubers classified as B and C size. ‘Red LaSoda’ and ‘Satina’ yielded more tubers with a diameter bigger than 2.49 inches (A2 and A3 classes), while cultivars ‘Envol’ and ‘Actrice’ showed a more uniform production across different tuber size classes. These results demonstrate the importance of the cultivar selection, in conjunction with the seed piece spacing, as a management practice to optimize yield alongside targeting specific tuber sizes.

These results and the table for calculation of potato seed requirement should assist growers in the decision-making process of determining the most suitable seed spacing for their conditions, optimizing production and income.

References

Andrade, M. H. M. L., A. L. B. R. da Silva, L. G. Pesantes, C. T. Christensen, and L. Zotarelli. 2021. “Seed Piece Spacing for Early-Maturing Table-Stock Potato Grown under Subtropical Conditions.” American Journal of Potato Research 98:246–254. https://doi.org/10.1007/s12230-021-09838-z

Krupek, F. S., C. T. Christensen, C. E. Barrett, and L. Zotarelli. 2017. “Seed Piece Spacing for Spring Chipping Potato Cultivars in Florida.” HortScience 52 (2): 230–235. https://doi.org/10.21273/HORTSCI11431-16

Smith, S. A., and T. G. Taylor. 2011. “Production Costs and Commodities Budgets for Selected Florida Vegetables – Potatoes: FE436, 02/2011.” EDIS 2011 (4). https://ufdcimages.uflib.ufl.edu/IR/00/00/41/61/00001/FE43600.pdf and https://fred.ifas.ufl.edu/pdf/iatpc/files/HastingsTablePotato09.pdf

Zotarelli, L., P. J. Dittmar, P. D. Roberts, J. Desaeger, and B. Wells. 2022. “Chapter 14. Potato Production: VPH Ch. 14.” EDIS 2022 (VPH). https://doi.org/10.32473/edis-cv131-2022

Table 1. Average of total tuber yield, tuber size distribution, and specific gravity, for ‘Actrice’, ‘Envol’, ‘Natascha’, ‘Purple Majesty’, ‘Red LaSoda’, and ‘Satina’, planted at 6-, 8-, 10-, or 12-inch seed piece spacings in 2018, 2019, and 2020 spring production seasons in Hastings, FL.

Table 2. Potato seed requirement per acre with two common between-row spacings in Florida across different seed spacings and seed weights.

Table 3. Determination of plant population based on between-row spacing and seed piece spacing.