Introduction

Muscadine grape (Muscadinia rotundifolia [Michx.]) is a fruit crop native to America; it was the first grape species cultivated in the country. Muscadine grapes (Figure 1) adapt well to a wide range of biotic and abiotic stresses and have thus been grown and vinified throughout the southeastern US for centuries. Currently, southeastern farmers grow approximately 5,000 acres of almost 100 improved muscadine-grape varieties for commercial use. Muscadine grapes are commonly consumed fresh or processed into juice, wine, or jam. Recent research demonstrated the fruit’s significant contribution of beneficial phytochemicals to the typical American diet; and thereafter, the demand for muscadine grapes considerably increased. Many consumers now consider muscadine grapes a favorable, healthy food due to their unique blend of bioactive compounds and antioxidant properties. Its thick peels and seeds, though, have prevented wider public consumption. This publication aims to introduce growers, Extension agents/specialists, and the general public to the potential for a new, value-added product that makes muscadine grapes much easier to eat and may diversify the food processing industry.

Credit: Dustin Huff, UF/IFAS

Anatomy and Characteristics of Muscadine Grapes

Muscadine fruit have a tough, leathery skin called the epicarp or exocarp (Figure 2). The epicarp can be either bronze or dark purple, depending on the cultivar and stage of maturity (Figure 3). Beneath the epicarp lies the bronze or purple, fleshy mesocarp, which makes up most of the fruit’s volume. The mesocarp contains the sweet juice and pulp of the fruit, which are responsible for its unique flavor and aroma. At the center of the fruit is the endocarp, which is the thin layer (testa) surrounding the seeds. The muscadine peel is a rich source of antioxidants, dietary fiber, flavonoids, and other beneficial phytochemicals including high levels of resveratrol, a polyphenolic compound reported to have antioxidant and anti-inflammatory properties. The fruit’s other beneficial compounds include anthocyanins and ellagic acid. Although the anatomy of muscadine grapes is like that of other grape types, its fruit are typically larger, with thicker peels and larger seeds.

Credit: Dustin Huff and Ali Sarkhosh, UF/IFAS

Credit: Ali Sarkhosh, UF/IFAS

The Problem with Muscadines: Consumers’ Challenge to Consumption

Regardless of its nutritional benefits, the peel can be difficult to chew and swallow—a fact people often cited as the reason why they do not consume the peel, discarding it instead (Figure 4). The peel’s thickness also makes it difficult to extract the juice; and muscadines are primarily used in juices. The seeds within the fruit are tough, difficult to chew, and very bitter, further discouraging peel consumption. Starting educational and promotional programs on the health benefits of the muscadine peel may foster more consumption of this underutilized fruit part.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Dried Fruit Benefits

Drying muscadines reduces their perishability, extending fruit shelf-life and facilitating commercialization. By reducing water activity to about 20% moisture content (wet weight basis [wwb]) for chewy products and below 12% moisture content (wwb) for crispy products, the drying process effectively transforms perishable crops into stable products. The process prevents microbial spillage and retards undesirable biochemical reactions that reduce quality and nutritional levels. In today’s globalized world, having proper facilities for the storage, handling, and transportation of dried fruits to distant markets is also essential. Additionally, drying can help to reduce waste and postharvest losses, making it possible for the food industry and distribution sectors to absorb the entire production. Furthermore, dried fruits that significantly retain their original flavor and aromatic properties while offering the convenience of ready-to-eat products can be sold at higher prices. Overall, drying has been a valuable strategy for increasing the commercial potential of tropical and perishable fruits while reducing their waste. Thus, drying can be beneficial for muscadine fruit and could lead to its consumption rather than disposal.

Disadvantages of Traditional Drying Methods

Drying lowers fruit quality, a major concern that limits market demand. The nutritional levels of phenolics and antioxidants in fruits are often negatively impacted by postharvest procedures including trimming, extended times required for drying, and packaging prior to storage. (The last procedure typically occurs under ambient temperatures.) Product shrinkage during drying can change the structural and textural appearance of fruit, again diminishing fruit quality.

Advantages of Freeze-Drying Technology

Freeze-drying may dramatically increase muscadine consumption; the process retains the fruit’s health benefits while making it more palatable to consumers. Freeze-drying is a dehydration process that eliminates water through the sublimation of ice in the frozen muscadine (Figure 5). This technique is highly recommended for crops that contain heat-sensitive antioxidant compounds such as tocopherols, ascorbic acid, carotenoids, and plant phenolics. Not only does freeze-drying increase the shelf-life of fruits by halting microbial growth and slowing lipid oxidation; it also can be utilized on an industrial-scale for long-term food preservation. Freeze-drying is a popular technique for drying foods because it preserves many of the quality characteristics of fresh samples, including shape, appearance, color, flavor, texture, porosity, nutrients, and biological activity (Figure 5).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

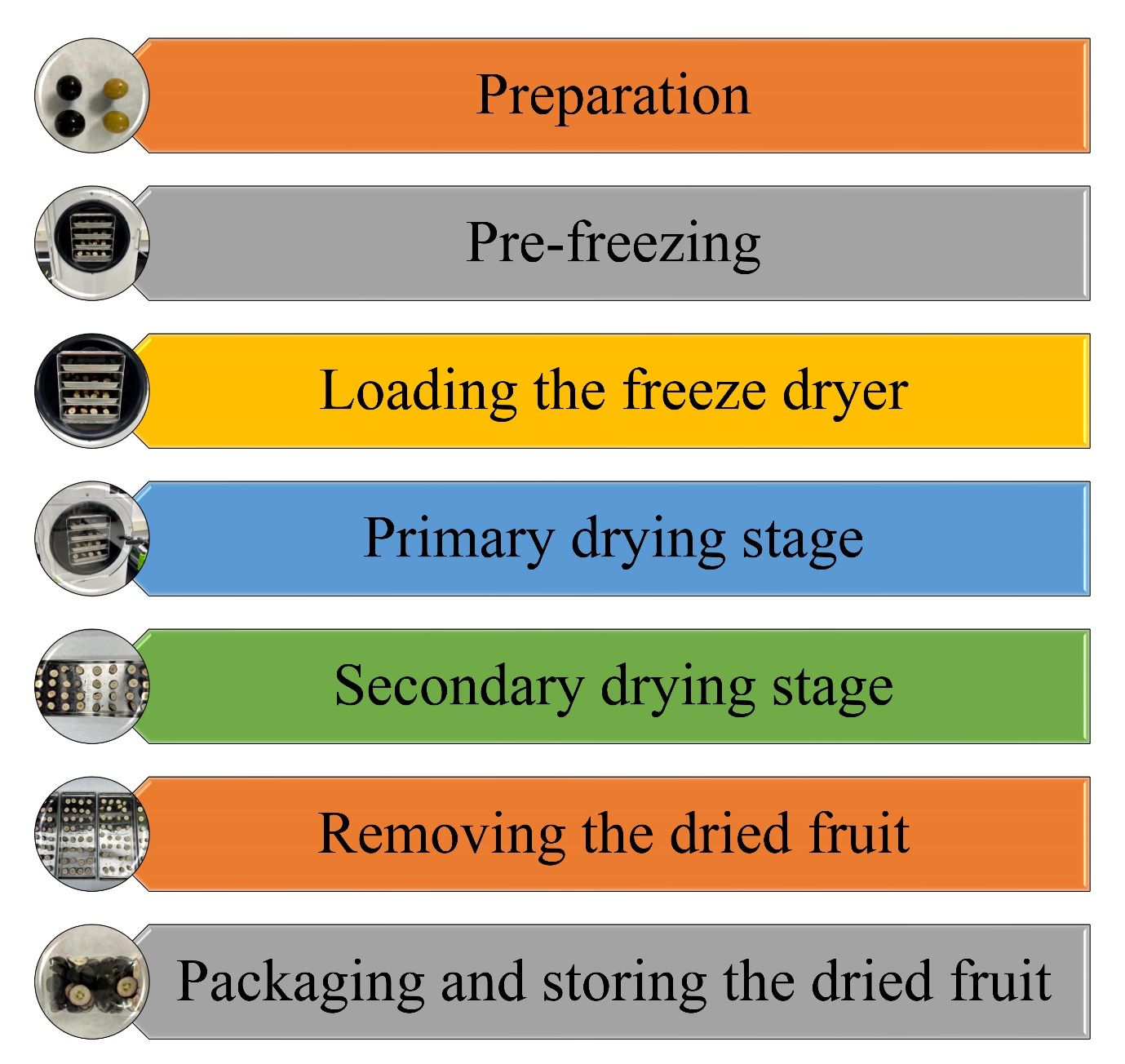

Several steps are involved in the freeze-drying process for muscadine fruit (Figure 6):

- Preparation: The fruit are first washed to remove any dirt or debris, then sliced into halves to ensure even drying. (The seeds are removed.)

- Pre-freezing: The sliced fruit are then placed on a tray or sheet pan in a freezer until the fruit is completely frozen. This pre-freezing step ensures that the fruit dehydrate quickly and evenly during the primary drying stage.

- Loading the freeze dryer: The frozen fruit are quickly loaded onto trays or shelves inside the freeze dryer. It is important to leave enough space between the pieces of fruit to allow for adequate air circulation during the drying process.

- Primary drying stage: The freeze dryer’s vacuum pump is turned on, and the temperature inside the chamber is lowered to below freezing. This causes the water molecules in the frozen fruit to sublime (i.e., to transition from a solid to a gas directly, bypassing a liquid phase). The frozen fruit are dried until their moisture content has been lowered to about 5%, resulting in a crispy final texture.

- Secondary drying stage: Once the primary drying stage is complete, the temperature and pressure inside the freeze dryer are slowly increased. This helps to remove any remaining moisture from the fruit. This stage typically takes several hours to complete.

- Removing the dried fruit: Once the secondary drying stage is complete, the crispy-textured fruit are removed from the freeze dryer, ready to be packaged and stored.

- Packaging and storing the dried fruit: The dried fruit are packaged in an airtight container to prevent the product from reabsorbing moisture. The dried fruit can be stored at room temperature for several months or in the refrigerator or freezer for an even longer shelf life.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Although often costly, freeze-drying offers several advantages, such as the production of superior-quality dried products with porous structures. Unlike other drying techniques, the frozen state of water during freeze-drying protects the primary structure of the product, resulting in minimal shrinkage and changes in shape (Figure 7). Additionally, the low temperatures employed during the process further preserve essential constituents like minerals and vitamins while retaining the original flavor and aroma of the product (Figure 8).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Disadvantages of Freeze-Drying

Freeze-drying requires a great deal of time, typically more so than conventional drying methods, because the vapor pressure driving the freeze dryer is lower. The investment cost of freeze-drying is also higher than conventional methods; however, with proper management, operational costs can be lowered. While slower than oven drying, freeze drying is faster than sun drying, which requires 3–4 days of sunny weather and frequent turning during that time. Despite these challenges, the benefits of freeze-drying make it a valuable process for the preservation of food materials.

Freeze-Dried Muscadine Fruit as a New Product and its Benefits to the Food Industry

One of the main benefits of freeze-drying muscadine grapes is the preservation of the high levels of beneficial phytochemicals and antioxidants found in the fruit, including resveratrol, anthocyanins, and ellagic acid. Unlike traditional drying techniques, freeze-drying retains the primary structure of the fruit, minimizing changes in its shape and reducing shrinkage. The low temperatures used in the process also (1) contribute to the preservation of vitamins and minerals and (2) help to retain the original flavor and aroma of the fruit. A convenient and nutritious snack, freeze-dried muscadine fruit can be an excellent source of these health-promoting compounds. Freeze-drying can also extend the shelf-life of muscadine fruit products under ambient temperatures, allowing for greater accessibility and availability throughout the year (Figure 9).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

In addition to its health benefits, the production of dried muscadines also presents opportunities for the food industry to develop new, value-added products. The development of dried muscadines that retain their sensory properties while offering the convenience of ready-to-eat products could contribute to their commercialization. However, it is important to note that the high initial investment and potentially high operational costs associated with freeze-drying should also be taken into consideration when evaluating the economic feasibility of this drying technique.

Overall, the potential benefits of drying muscadine fruit make it an area of interest for researchers and industry professionals alike. Considering that it is unknown whether freeze-dried muscadine fruit can be economically produced, future studies should consider consumer testing to determine if people would like to eat this product and whether they are more likely to eat freeze-dried muscadines or the fresh fruit.

References

Barta, J., C. Balla, and G. Vatai. 2012. “Dehydration preservation of fruits.” In Handbook of Fruits and Fruit Processing, edited by N. K. Sinha, J. S. Sidhu, J. Barta, J. S. B. Wu, and M. P. Cano. 133–151. https://doi.org/10.1002/9781118352533.ch9

Campbell, J., A. Sarkhosh, F. Habibi, P. Gajjar, A. Ismail, V. Tsolova, and I. El-Sharkawy. 2021. “Evaluation of Biochemical Juice Attributes and Color-Related Traits in Muscadine Grape Population.” Foods 10 (5): 1101. https://doi.org/10.3390/foods10051101

Ciurzyńska, A., and A. Lenart. 2011. “Freeze-Drying—Application in Food Processing and Biotechnology—a Review.” Polish Journal of Food and Nutrition Sciences 61 (3): https://doi.org/10.2478/v10222-011-0017-5

Hickey, C. C., E. D. Smith, S. Cao, and P. Conner. (2019). “Muscadine (Vitis rotundifolia Michx., syn. Muscandinia rotundifolia (Michx.) Small): the Resilient, Native Grape of the Southeastern US.” Agriculture 9 (6): 131. https://doi.org/10.3390/agriculture9060131

Marques, L. G., M. M. Prado, and J. T. Freire. 2009. “Rehydration Characteristics of Freeze-Dried Tropical Fruits.” LWT–Food Science and Technology 42 (7): 1232–1237. https://doi.org/10.1016/j.lwt.2009.02.012

Olien, W. C. 1990. “The Muscadine Grape: Botany, Viticulture, History, and Current Industry.” HortScience 25 (7): 732–739. https://doi.org/10.21273/HORTSCI.25.7.732

Shofian, N. M., A. A. Hamid, A. Osman, N. Saari, F. Anwar, M. S. Pak Dek, and M. R. Hairuddin. 2011. “Effect of Freeze-Drying on the Antioxidant Compounds and Antioxidant Activity of Selected Tropical Fruits.” International Journal of Molecular Sciences 12 (7): 4678–4692. https://doi.org/10.3390/ijms12074678