Introduction

Persimmons belong to the genus Diospyros, family Ebenaceae, and are known for their sweet and flavorful taste. The genus Diospyros encompasses different species, including D. kaki (persimmon), D. virginiana (American persimmon), and D. lotus (date-plum, Caucasian persimmon, or lilac persimmon). Persimmon (D. kaki) (Figure 1) is known by several names, including Japanese persimmon, Oriental persimmon, Chinese Persimmon, or Kaki persimmon. It is native to Asia, specifically China, and was first grown in Florida in the 1870s. China, South Korea, Japan, and Spain are currently the leading persimmon producers worldwide. However, persimmons are still not as popular in the United States as other fruits. This may be due to limited availability or lack of widespread promotion and education about the persimmon fruit. However, interest in persimmon has been growing in recent years, and it is possible that they may become more popular in the future.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

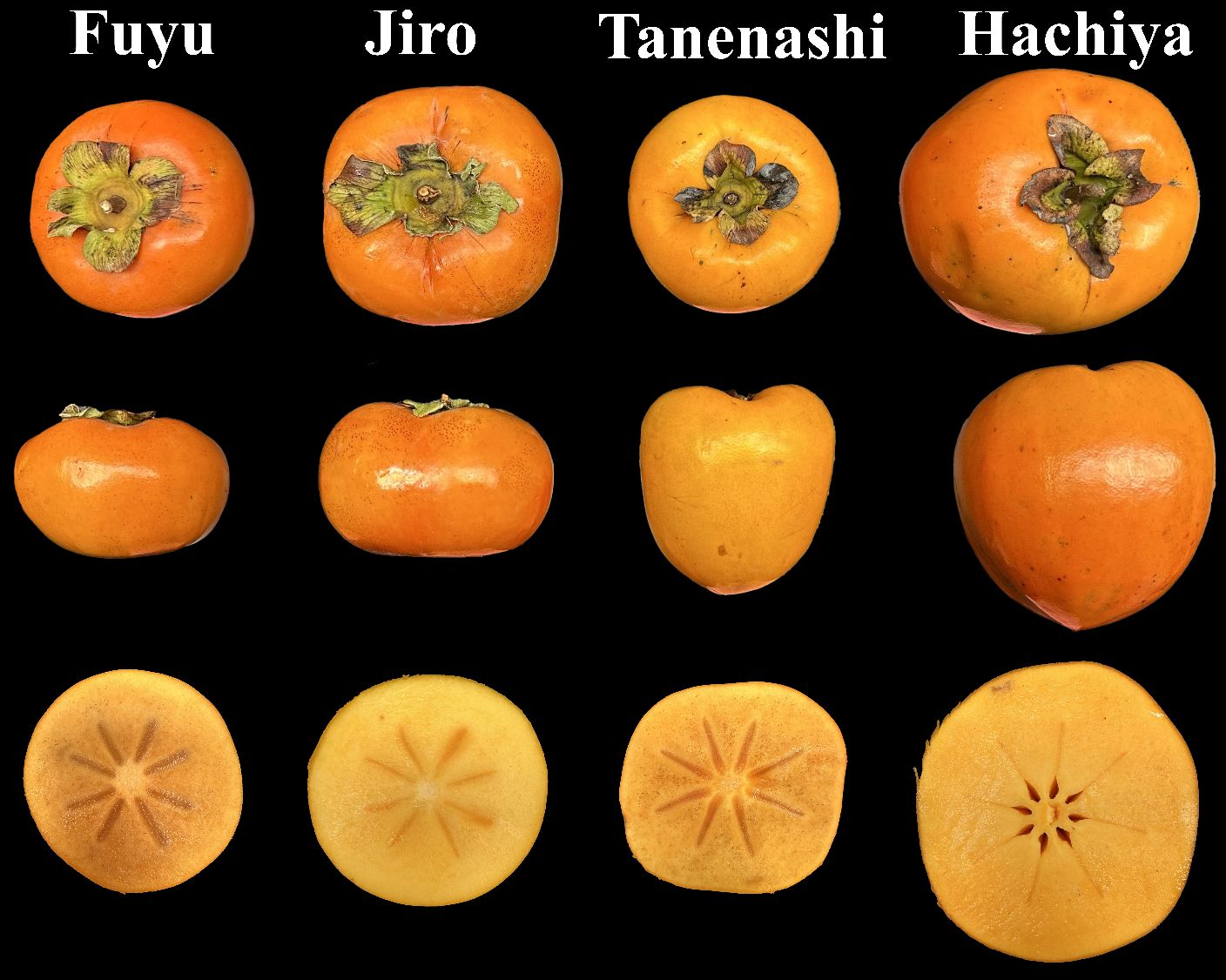

Persimmon fruits are generally classified into astringent and non-astringent types. Astringent varieties have a taste that puckers the mouth, numbs the tongue, and constricts the throat. This taste is caused by astringent substances such as tannins. Astringent varieties must be fully ripe (soft) or artificially treated to remove astringency and make them suitable for eating (Figure 2). Fruit of the non-astringent types lose astringency prior to initiation of ripening and, thus, can be eaten firm or soft. On the other hand, unripe persimmons can be toxic if consumed in large amounts due to their high tannin levels. Moreover, unripe persimmons can form a hard mass in the stomach, known as a diospyrobezoar, which may block the digestive tract and require surgery for removal. While ripe persimmons have lower levels of this compound and are safe to eat, unripe ones may cause adverse reactions. Symptoms of persimmon tannin poisoning can include nausea, vomiting, and diarrhea. Therefore, it is advisable to avoid the toxicity of unripe persimmons by waiting until they are fully ripe before consumption or by peeling and cooking them, as this can reduce the tannin content and prevent the formation of diospyrobezoars. Intact fruit and cross-sections of some non-astringent and astringent persimmon varieties are shown in Figure 3.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Persimmons are a rich source of essential nutrients, including vitamin A, vitamin C, carbohydrates, dietary fiber, minerals, carotenoids, phenolic compounds, and antioxidants. Nutritive value and the bioactive profile of different astringent and non-astringent persimmon cultivars was reported by Murali, Shams, and Dar (2023). However, specific values for bioactive compounds may vary based on factors such as cultivars, ripeness, growing conditions, and so forth. They are also low in calories and fat, making them a healthy snack option. Persimmons may contribute to improved digestive health, support the immune system, and offer potential cardiovascular benefits. Persimmon fruit are climacteric, meaning they can be harvested upon reaching physiological maturity and ripened off the plant. Unripe persimmons are sensitive to temperatures from 41°F to 59°F (5°C to 15°C), and when stored and/or shipped in this range, they will develop chilling injury symptoms, characterized by poor ripening and flesh browning. Therefore, they can be stored for up to a month at lower, non-freezing temperatures of 30°F to 40°F (-1°C to 4.5°C) or held at room temperature until they ripen. Once ripe, they should be consumed within a few days or refrigerated for slightly longer shelf life. Persimmons are good for fresh eating, and the non-astringent types are excellent in fruit or vegetable salads.

To extend their reach beyond the fresh fruit markets, persimmons can be processed into many baked goods and snack foods. Drying is a common method to preserve and extend the shelf life of persimmons. Drying can also enhance the flavor, color, and nutritional value of persimmons by concentrating the sugars, acids, and phytochemicals in the fruit. There are different methods to dry persimmons, including traditional and modern methods. For the production of high-quality dried fruit products, dehydration and freeze-drying are two of the most common and effective methods. Dried persimmons are an ideal snack for people who want a portable and convenient fruit option; they shrink in size and weight, making them easy to carry and store. The aim of this publication is to explore dried persimmon fruit as a year-round product available to producers and consumers.

The Anatomy of Persimmon Fruit

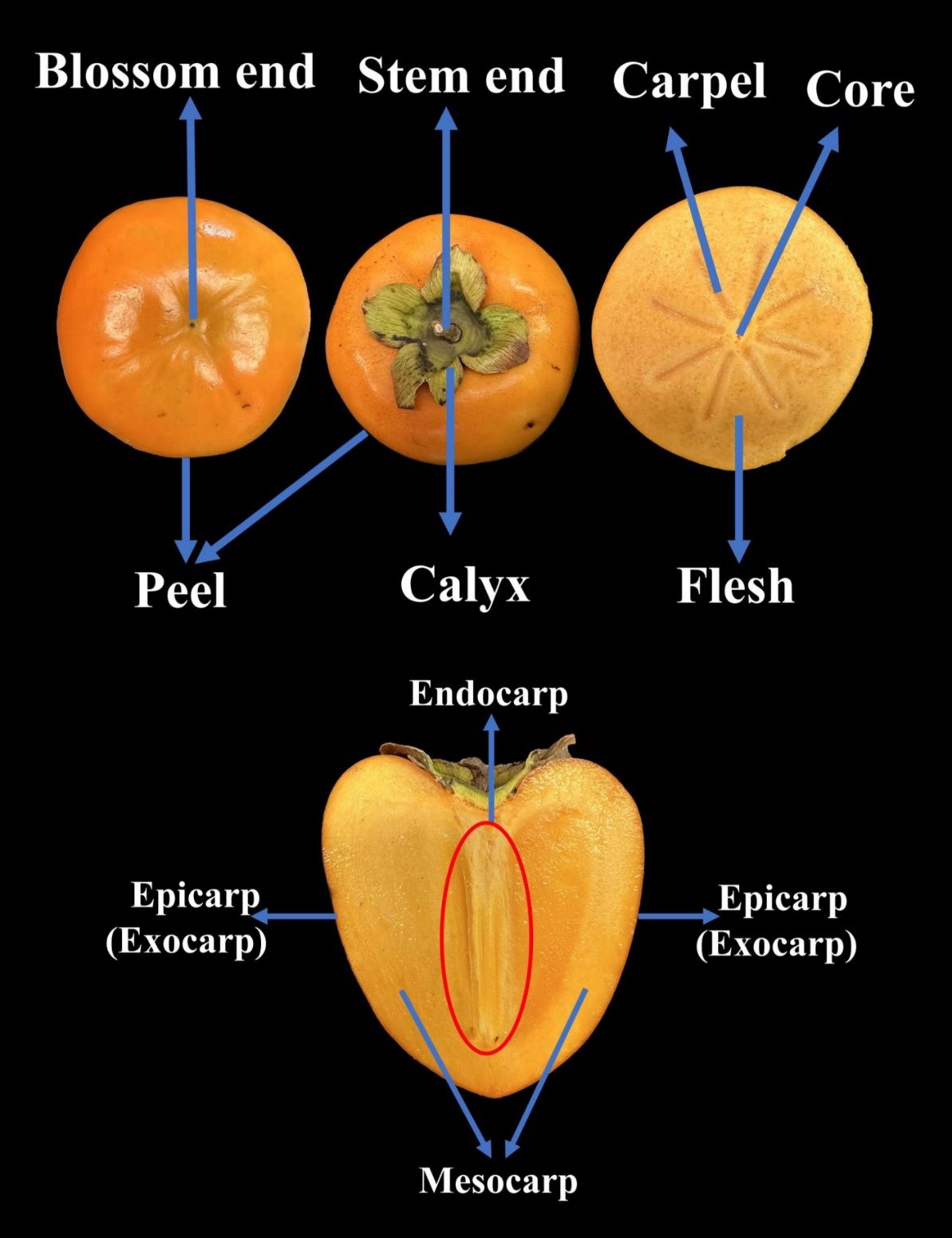

Persimmon fruit develop from the ovary of a flower and have a fleshy structure, which is comprised of three distinct layers. The epicarp (also known as exocarp) is the outermost layer, the mesocarp is the middle layer, and the endocarp (carpel) is the innermost layer (Figure 4). The calyx is the small, leafy structure at the stem end of the persimmon fruit. The epicarp of a persimmon fruit is the smooth, thin peel or skin of the fruit, and it can vary in color (red, orange, or yellow), depending on the variety and ripeness stage. The peel is edible and becomes sweeter as the fruit ripens. The mesocarp of persimmons is the flesh or pulp of the fruit and is the main edible part of the fruit. It is usually thick and juicy, with a sweet and slightly tangy flavor. The color of the flesh can range from pale yellow to deep orange, depending on the variety. The mesocarp contains sugars, acids, and nutrients, as well as the tastes and aromas that give the fruit its characteristic flavor. The endocarp, which surrounds the seeds, contains the tannins that give the fruit its astringency. Many commercial persimmon varieties produce seedless fruit through parthenocarpy. However, some varieties contain several flat, hard, and inedible seeds (Figure 5). Seeds can be round or oval, while others are flat or winged. The number of seeds can also vary, depending on the variety.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Advantages of Dried Persimmon Fruit

Since the astringent type of persimmons must reach an extremely soft state before being edible, they are not well-suited for drying. Depending on the variety, fresh non-astringent persimmons can be perishable within as little as a few days, which limits their availability and consumption (Figure 6). Therefore, the drying process significantly extends the shelf life of those persimmons, enhancing their storability and reducing the risk of spoilage. In addition, this preservation method concentrates the natural sweetness and flavor of the fruit, rendering dried persimmons a delectable and satisfying snack. When dried to the desired moisture content, persimmons retain not only their flavor but also their nutritional content, comprised of vitamins, minerals, and dietary fiber, rendering them a healthy snack option. Dried persimmons are a more convenient and practical option for storage and transportation under ambient temperatures. They are lightweight and occupy less volume than fresh persimmons, facilitating easier packaging, storage, and shipping. This can help reduce transportation costs and minimize the probability of physical damage during handling. Dried persimmons also contribute to reducing food waste, particularly when an abundance of fresh persimmons is at risk of going unused. These advantages collectively position dried persimmon fruit as a convenient, nutritious, and sustainable food option in the realm of dried fruits.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

There are different methods to dry persimmons, including traditional methods and advanced technologies. Among these methods, dehydration and freeze-drying are two of the most effective and widely used techniques to produce high-quality, dried persimmon products (Figure 7).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Traditional Drying Methods

Traditional drying methods, including solar and air drying, are cost-effective, demanding minimal investment in equipment and technology, and environmentally friendly by making use of sunlight and natural air circulation. However, drying persimmon fruit using traditional methods has several disadvantages that need to be considered. One of them is the time-consuming nature of these methods. Whether relying on air drying, sun drying, or open fires, it may take days or even weeks to effectively remove moisture from persimmons. This leads to extended exposure to environmental contaminants and spoilage risks. In particular, the open-air drying process exposes persimmon fruit to potential contamination from dust, insects, microorganisms, and other environmental infections, which can impact the quality and safety of the dried product. Another limitation is the dependency on weather conditions. For instance, sun drying is highly dependent on sunny and dry weather, which can be unreliable in places such as Florida that are prone to rain, humidity, or cloudy days. Another challenge of drying persimmon fruit using traditional methods is maintaining consistent product quality. As factors like temperature, humidity, and airflow can vary during the drying process, they can lead to uneven drying and potential risks of over-drying or under-drying, which can affect the overall quality of the dried persimmons. Moreover, traditional drying methods for persimmons offer limited control over the drying process, further contributing to uneven results. If open fires or stoves are employed to provide the heat for drying, substantial amounts of energy may be consumed. Space requirements for outdoor drying are another consideration, as traditional methods necessitate a significant amount of open space, which can be problematic in urban areas or regions with limited available space. Another disadvantage of drying persimmon fruit using traditional methods is nutrient loss. Prolonged exposure to heat and sunlight during traditional drying can lead to the degradation of nutrients such as vitamin C, potentially reducing overall nutritional value. While traditional drying methods hold historical significance, modern technologies, such as electric dehydrators and freeze-drying, offer more efficient and controlled alternatives for preserving the quality of dried persimmon products.

Dehydration Technology for Dried Persimmon Fruit

Dehydration is an active process that evaporates the water from fruit by applying heat with circulating air. A fruit dehydrator is a machine that uses a heating element and a fan or airflow system to circulate heated air around slices of fruit on trays or racks. Adjustable air vents control the airflow and moisture release during the drying process. These vents allow excess moisture to escape while maintaining a controlled environment inside the machine. The heat and the airflow help to efficiently remove moisture from the fruit tissue, greatly accelerating the drying process compared to traditional sun drying. Temperature and time controls are necessary features of the dehydrator machine. The optimal temperature is usually between to promote effective moisture 122°F to 158°F (50°C to 70°C)e removal without causing excessive heat damage to the fruit. The proper duration of the drying process is determined by the thickness of the fruit slices and the desired level of dehydration. During the dehydration process, the machine constantly monitors the temperature and airflow to maintain steady and optimal drying. Some advanced dehydrator models may offer additional features such as timers and automatic shut-off functions. Once persimmons have reached the desired moisture level of typically 10% to 20%, the drying process is complete. The dehydrated slices can then be removed from the dehydrator and allowed to cool before storage. The choice of final moisture content results in different styles of dried persimmons, from a soft and somewhat gooey product to an almost leathery texture.

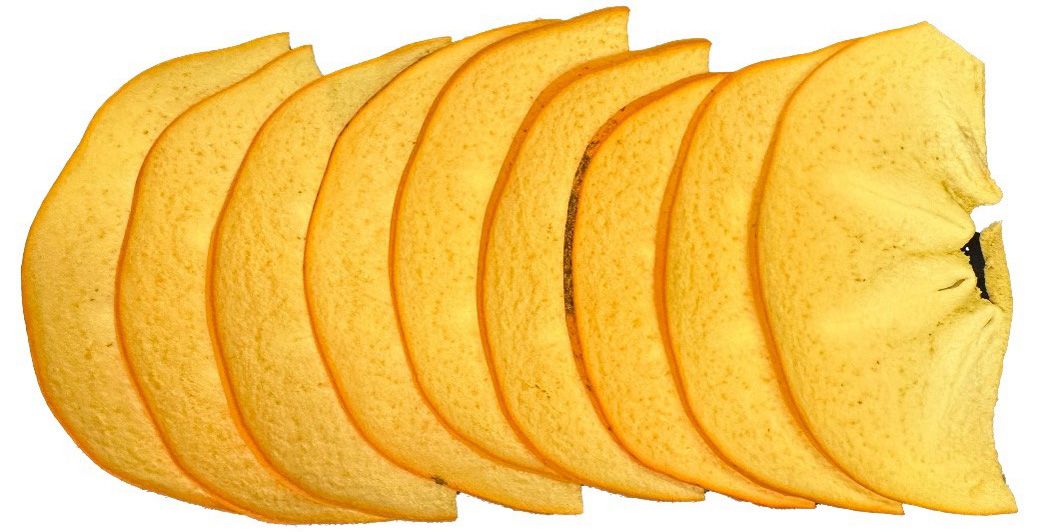

Dehydration technology plays a significant role in preserving and enhancing persimmons, but it comes with its own set of advantages and disadvantages for this fruit. Dehydrated persimmons become more portable and convenient for consumption as they shrink in size and weight, making them an ideal snack (Figure 8). Furthermore, dehydration can change texture, often rendering persimmons softer or chewier, which individuals may find either more or less appealing compared to the fresh fruit’s natural texture. The initial cost of dehydration equipment and energy consumption can be expensive and must be considered, especially for both small-scale and commercial-scale operations. Overall, dehydration technology offers substantial benefits for persimmons’ preservation and convenience but requires careful control to maintain their flavor and nutritional value.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Freeze-drying Technology for Dried Persimmon Fruit

Freeze-drying is a process that removes the water from fruit by freezing and sublimating it under low pressure. Sublimation means that the frozen water transitions directly from the solid state to the gas state without going through the liquid state. In a freeze drier, the fruit slices are quickly frozen to a very low temperature, usually -40°C (-40°F). When the slices are fully frozen, the chamber is evacuated. This lowers the pressure, allowing sublimation of the ice in the fruit tissue to take place. This process will remove most of the moisture from the persimmons (typically leaving less than 7% moisture content). Low-temperature refrigeration coils inside the vacuum chamber collect and condense the water vapor as ice, maintaining a low humidity in the chamber that favors outward movement of moisture from the fruit tissue. The final step in the freeze-drying process is called desorption. It involves gradually increasing the temperature of the vacuum chamber to aid in the removal of any remaining moisture. Throughout the freeze-drying process, it is essential to monitor and control the various parameters such as temperature, pressure, and drying time. Proper control of these variables ensures optimal drying efficiency and maintains the quality of the freeze-dried persimmons.

Freeze-drying technology has become a popular method for preserving persimmon fruit due to unique advantages, although it also has some disadvantages. This technology is especially well-suited for fruits that contain heat-sensitive antioxidant compounds, such as tocopherols, vitamin C, carotenoids, and phenolic compounds. The process gently removes moisture while preserving the fruit’s structure, resulting in a light and crispy texture (not chewy) along with an intense and concentrated taste (Figure 9). Compared to fresh or traditionally dried persimmons, freeze-dried persimmons are known for their long shelf life, which makes them a convenient and accessible snack (Figure 10). However, some disadvantages include the relatively high cost and energy consumption associated with freeze-drying equipment. Despite these challenges, freeze-drying continues to be widely used for preserving persimmon fruit. It yields nutritious, flavorful, and durable persimmon products that can be enjoyed year-round. Also, this method is particularly effective for soft astringent persimmons when they reach a ripe and soft consistency at room temperature. The fruit can be transformed into a delightful crunchy product by blending the fruit into a puree and then freeze-drying it (Figure 11); therefore, freeze-drying technology offers a promising way to substantially increase persimmon consumption well beyond the traditional harvest season. This method not only helps retain the health benefits of persimmons but also enhances their appeal to consumers and offers a unique and enjoyable way to incorporate them into a healthy product.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Differences in Appearance between Freeze-dried and Dehydrated Persimmon

Freeze-dried and dehydrated persimmons exhibit distinct characteristics (Figure 12). Freeze-dried persimmons possess a remarkably low moisture content of less than 7%, offering a delicate, crisp texture akin to potato or corn chips. In contrast, dehydrated persimmons maintain a relatively higher moisture content of 10% to 20%, yielding a chewy and denser consistency. Furthermore, freeze-drying uniquely preserves the original persimmon tissue structure, minimizing shrinkage and alterations in shape. This method’s lower moisture content imparts an extended shelf life, inhibiting microbial growth and maintaining quality over time. When it comes to color, freeze-dried persimmons tend to retain a more vivid and vibrant hue, as this process effectively safeguards the fruit’s natural pigments. Consequently, freeze-dried persimmons are visually appealing, boasting an intense and lively color. On the other hand, dehydrated persimmons undergo slight color changes due to heat exposure and prolonged drying, resulting in a less vibrant appearance compared to their freeze-dried counterparts. Traditional sun-dried fruit darken even more during that slow drying process, resulting in a dark brown product (like raisins).

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Differences in Flavor between Non-astringent and Astringent Dried Persimmons

Tannins are the compounds responsible for the astringency of persimmon fruit. Tannin binds to the proteins on the surface of the tongue and makes them coagulate, which reduces the saliva and creates a puckering feeling. Tea, coffee, and chocolate are other products that are high in tannins. Persimmons have high levels of soluble tannin in their cells, which makes them very astringent when they are unripe or immature. However, as persimmons ripen, the tannin becomes insoluble and less reactive, and the fruit become sweeter and softer. Astringent persimmon varieties, such as ‘Haychia’ and ‘Tanenashi’, are larger and pointed-shaped and must be fully ripe (very soft) before they can be eaten without astringency. Non-astringent persimmon varieties, such as ‘Fuyu’ and ‘Jiro’, have much lower levels of tannins, are round with a more flattened shape, and can be eaten when they are at full maturity (crisp but unripe), up until they reach a full ripe (soft) state.

The astringency of persimmons can be reduced by both freeze-drying and dehydration methods. Dehydrated persimmons exhibit less astringency than freeze-dried persimmons, indicating that dehydration might be a more effective method for mitigating astringency.

Marketing Potential

Dried persimmon fruit is a value-added product that can extend the shelf life and availability of fresh persimmons while reducing postharvest losses (Figure 13). This means that dried persimmons can be used as a snack, ingredient, or functional food, as they retain the nutritional and bioactive properties of fresh persimmons, such as vitamins, antioxidants, and dietary fiber.

Credit: Fariborz Habibi and Ali Sarkhosh, UF/IFAS

Therefore, dried persimmon fruit has promising market potential that can offer consumers a year-round product with a variety of benefits and applications.

Conclusion

Dried persimmon fruit is a nutritious and delicious snack that can be made by using either freeze-drying or dehydration methods. Both methods remove the moisture from the fruit and extend its shelf life, but they have different effects on the quality, texture, and flavor of the product. Freeze-drying preserves more nutrients, color, and aroma of the fruit, but it is more expensive and time-consuming than dehydration. Dehydration is cheaper and faster, but it may cause some browning, loss of vitamins, and shrinkage of the fruit. Therefore, the choice of the drying method depends on the preferences and goals of the producers and consumers. Dried persimmon fruit is a versatile and valuable food that can be enjoyed in various ways, such as snacks, desserts, or preserves.

Further Reading

Kurt, A., and E. Kaya. 2020. “Medical and Cosmetic Applications of Persimmon (Diospyros Kaki): Toxicity Assessment—A Review.” International Journal of Traditional and Complementary Medicine Research 1 (3): 162–176. https://dergipark.org.tr/en/pub/ijtcmr/issue/58250/774361

Chandra, S., and D. Kumari. 2015. “Recent Development in Osmotic Dehydration of Fruit and Vegetables: A Review.” Critical Reviews in Food Science and Nutrition 55 (4): 552–561. https://doi.org/10.1080/10408398.2012.664830

Dağdeviren, A., B. Acar, A. Alhammadi, K. Roshanaei, T. Coşkun, O. İnanç, and M. Özkaymak. 2021. “Freeze-drying of Persimmon (diospyros kaki) Slices Investigation of Drying Characteristics.” Journal of Polytechnic 26 (2): 487–494. https://doi.org/10.2339/politeknik.949139

Ma, Y., J. Yi, X. Jin, X. Li, S. Feng, and J. Bi. 2022. “Freeze-drying of Fruits and Vegetables in Food Industry: Effects on Phytochemicals and Bioactive Properties Attributes - A Comprehensive Review.” Food Reviews International 39 (9): 6611–6629. https://doi.org/10.1080/87559129.2022.2122992

Matheus, J. R. V., C. José de Andrade, R. F. Miyahira, A. E. C. Fai. 2022. “Persimmon (Diospyros kaki L.): Chemical properties, Bioactive Compounds and Potential Use in the Development of New Products – A Review.” Food Reviews International 38 (4): 384–401. https://doi.org/10.1080/87559129.2020.1733597

Megías-Pérez, R., J. Gamboa-Santos, A. C. Soria, M. Villamiel, and A. Montilla. 2014. "Survey of Quality Indicators in Commercial Dehydrated Fruits." Food Chemistry 150: 41–48. https://doi.org/10.1016/j.foodchem.2013.10.141

Murali, P., R. Shams, and A. H. Dar. 2023. “Insights on Nutritional Profile, Nutraceutical Components, Pharmacological Potential, and Trending Utilization of Persimmon Cultivars: A Review.” Food Chemistry Advances 3: 100431. https://doi.org/10.1016/j.focha.2023.100431

Padilha de Toledo, A., F. Hurtado Rodrigues, M. Rocha Rodrigues, D. Tiemi Sato, R. Nonose, E. F. Nascimento, and C. A. R. Martinez. 2012. “Diospyrobezoar as a Cause of Small Bowel Obstruction.” Case Reports in Gastroenterology 6 (3): 596–603. https://doi.org/10.1159%2F000343161

Sagar, V. R., and P. Suresh Kumar. 2010. “Recent Advances in Drying and Dehydration of Fruits and Vegetables: A Review.” Food Science and Biotechnology 47: 15–26. https://doi.org/10.1007/s13197-010-0010-8

Sarkhosh, A., P. C. Andersen, and D. M. Huff. 2020. “Japanese Persimmon Cultivars in Florida: SP101/MG242, rev. 2/2020.” EDIS 2020 (1). https://doi.org/10.32473/edis-mg242-2020

Sarkhosh, A., F. Habibi, and S. A. Sargent. 2023. “Freeze-dried Muscadine Grape: A New Product for Health-conscious Consumers and the Food Industry: HS1468, 7/2023.” EDIS 2023 (4). https://doi.org/10.32473/edis-HS1468-2023

Serna-Cock, L., D. P. Vargas-Muñoz, and A. A. Aponte. 2015. “Structural, Physical, Functional and Nutraceutical Changes of Freeze-dried Fruit.” African Journal of Biotechnology 14 (6): 442–450. https://doi.org/10.5897/AJB2014.14189

Vilhena, N. Q., R. Gil, E. Llorca, G. Moraga, and A. Salvador. 2020. “Physico-Chemical and Microstructural Changes during the Drying of Persimmon Fruit cv. Rojo Brillante Harvested in Two Maturity Stages.” Foods 9 (7): 870. https://doi.org/10.3390/foods9070870

Wang, R., X. Shi, K. Li, A. Bunker, and C. Li. 2023. “Activity and Potential Mechanisms of Action of Persimmon tannins according to Their Structures: A Review.” International Journal of Biological Macromolecules 242 (3): 125120. https://doi.org/10.1016/j.ijbiomac.2023.125120