This article is part of a series entitled Florida Biosolids. The rest of the series can be found at https://edis.ifas.ufl.edu/topic_series_florida_biosolids.

Introduction and Purpose

Biosolids are the liquid, semisolid, and solid fractions of the treated waste stream from a domestic wastewater treatment facility (WWTF). Biosolids may also be known as "sewage sludge" or "domestic wastewater residuals." On August 29, 2010, the Florida Department of Environmental Protection (FDEP) formally adopted its new rule for the management of wastewater biosolids, Chapter 62-640, Florida Administrative Code (F.A.C. 2010). The new rule includes major revisions to the old management system, most notably requiring permits for land application sites and changing the term "Domestic Wastewater Residuals" to "Biosolids." This document reviews the definition of biosolids classes under the new regulation.

Terms

Applicability

The new Chapter 62-640 F.A.C. (rule) applies to the following:

-

Domestic wastewater treatment facilities that generate, treat, or manage biosolids.

-

Biosolids management facilities that generate, treat, or manage biosolids.

-

Appliers or distributors of biosolids or producers of biosolids-containing products.

-

Application sites that receive biosolids.

-

Septage management facilities treating more than 10,000 gallons (gal) per day monthly average daily flow or greater than 20,000 gal in a single day.

-

Septage appliers and sites that receive septage from permitted facilities.

-

Composting facilities that use biosolids and apply the compost to land or distribute and market the compost.

-

Biosolids and biosolid products generated outside the state of Florida.

At the adoption of the rule in 2010, all land application sites, regardless of permit expiration date of the facilities using the sites, were to be permitted under this rule by January 1, 2013.

Intent of Chapter 62-640 F.A.C.

The intent of the new rule is to ensure the protection of public health and the environment through regulation by the FDEP of the use, management, and land application of biosolids.

History

The 1987 Clean Water Act (CWA) amendments set the requirement for regulations on biosolids. The regulations were formally adopted in 1993 by Title 40 of the Code of Federal Regulations (C.F.R.) Part 503-Standards for the Use or Disposal of Sewage Sludge (C.F.R. 1993). Part 503 was updated and adopted in 2007.

The state of Florida originally regulated biosolids under solid waste regulations adopted in 1984. The state adopted Chapter 62-640, F.A.C. in the early 1990s to bring its regulations into line with the CWA amendments. Chapter 62-640, F.A.C. was then revised and adopted in 1998 to better align with the revised Part 503. Further refinements to Chapter 62-640, F.A.C. were made in 2010.

Biosolids Classes

All biosolids applied to the land or distributed and marketed must be treated with a process designed to reduce pathogens and achieve vector attraction reduction (VAR) (F.A.C. 2010). Also, they must not exceed specific metal contaminant concentrations. Florida biosolids are assigned to one of three classes: Class B (least treated), Class A, and Class AA (highest treatment). The classes are based, in part, on the degree of pathogen reduction. Although all biosolids classes have been treated to substantially reduce pathogen indicators below levels characteristically found in manure, Classes A and AA biosolids have the least. Pathogen density reductions are calculated in numbers per unit mass of biosolids. Even class B biosolids contain pathogens at densities that are typically below public health and environmental threats. All three class designations must meet and adhere to specific pathogen reduction, vector attraction reduction (VAR) requirements, and metal contaminant limits, as described below.

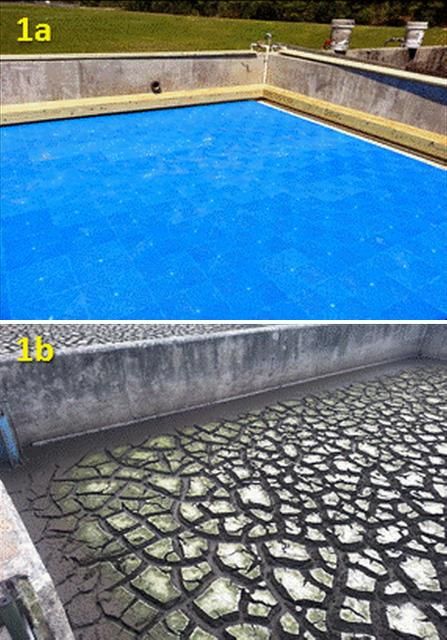

Credit: John Hallas, UF/IFAS

Pathogen Reduction

Table 1 lists three methods, called alternatives, for achieving a Class B biosolids designation with respect to pathogens, as defined by 40 C.F.R. Part 503.32(b) (Table 1). Table 2 presents five processes to significantly reduce pathogens (PSRP) (Table 2), in order to achieve a B classification under Alternative 2 in Table 1.

The Class A designation uses treatments to reduce pathogens below detectable levels at the time of biosolids disposal or use, while also meeting at least one VAR requirement. To meet Class A or AA designations, biosolids must be treated by at least one of the alternatives for pathogen reduction presented in Table 3. Title 40 C.F.R. Part 503.32 lists six alternatives, but Florida did not adopt Alternative 4. Processes to further reduce pathogens (PFRP) are considered equivalent options for consistently reducing pathogens below detection limits (Table 4). As described by the US Environmental Protection Agency (EPA), a PFRP must reduce enteric (intestinal) viruses to below 1 plaque forming unit (PFU) per 4 grams of total solids (dry weight basis) and reduce the density of viable helminth ova (parasitic worm eggs) to below 1 per 4 grams of total solids (dry weight basis). In Florida, potential new treatment processes may be reviewed for PFRP equivalency through the federal Pathogen Equivalency Committee (PEC).

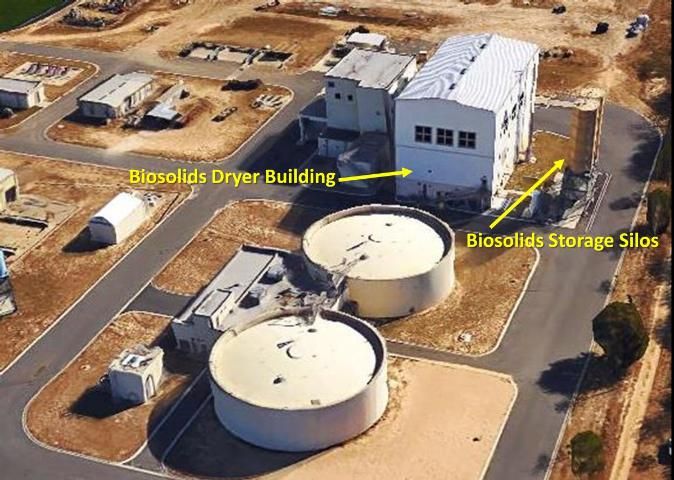

Credit: Map data ©2015: Google, DigitalGlobe

Vector Attraction Reduction

The purpose of VAR is to reduce the likelihood of a vector contacting biosolids and harboring or transferring pathogens. The VAR is typically implemented in conjunction with pathogen reduction. Biosolids must meet one of the vector attraction reduction requirements of 40 C.F.R. Part 503.33(b) (1) through (10) for Class A or B biosolids and of 40 C.F.R. Part 503.33(b) (1) through (8) for Class AA biosolids (Table 5). These vector attraction reduction requirements reduce the potential for pathogen regrowth.

Metal Contaminants

In addition to meeting the pathogen and VAR requirements, all biosolids (Class B, A, AA) must not exceed the single sample element concentrations given in Chapter 62-640.700(5)(a), F.A.C. (Table 6). In addition, Class AA biosolids must not exceed the monthly average element concentrations given in Chapter 62-640.700(5)(b), F.A.C (Table 7).

In addition, Class AA biosolids must not exceed the monthly average element concentrations given in Chapter 62-640.700(5)(b), F.A.C. (Table 7).

Summary

Biosolids are the liquid, semisolid, and solid fractions of the treated waste stream from a domestic wastewater treatment facility. Florida biosolids are classified, in terms of potential pathogens and metal contaminant concentration reductions from least to greatest, as Class B, A, or AA, respectively. On August 29, 2010, FDEP formally adopted its rule for the management of wastewater biosolids (also known as domestic wastewater residuals or sewage sludge) in Chapter 62-640, F.A.C. (2010). The permitting deadline for biosolids land application sites was January 1, 2013. The revised regulations aim to improve site management and accountability in order to better protect public safety and the environment. The part 503 rule continues to act as a safeguard against biosolids misuse while allowing the return of organic matter and essential plant nutrients to the soil.

Further Reading

Florida Department of State. 2010. "Chapter 62-640, Florida Administrative Code (F.A.C.), Biosolids." https://www.flrules.org/gateway/ChapterHome.asp?Chapter=62-640

Kane, P. 2007. Residuals, Biosolids, Sludge: What's in a Name? 2nd edition. Accessed October 10, 2014. www.lulu.com/content/163583

United States Environmental Protection Agency (USEPA). 1994. A Plain English Guide to the EPA Part 503 Biosolids Rule. Washington, DC: US Environmental Protection Agency, Office of Wastewater Management. https://www3.epa.gov/npdes/pubs/owm0031.pdf

United States Environmental Protection Agency (USEPA). 1993. "Title 40, Code of Federal Regulations, Part 503: Standards for the Use or Disposal of Sewage Sludge." Federal Register 72(57). Last modified April 9, 2007. http://www.gpo.gov/fdsys/pkg/FR-2007-03-26/html/07-1455.htm