This publication is part of SL253, Nutrition of Florida Citrus Trees, 3rd Edition. For references, a glossary, and appendices, please refer to the full document at https://edis.ifas.ufl.edu/ss478.

Applying Dry Fertilizers

The choice of fertilizer application method becomes important as growers seek to improve nutrient-use efficiency and reduce losses to leaching and runoff. Dry-solid fertilizer spreaders should apply materials directly over the root zone, avoiding the row middle. It may be necessary to prune tree skirts to improve the spreading pattern and uniformity. When applying fertilizers to young trees, managers should take advantage of manual or electronic spreader adaptations that deliver fertilizer rates accurately to small tree root zones while leaving out the area between trees where roots are not present. Effort should be made to reduce surface movement of applied fertilizers by rainfall or wind.

Aerial application of micronutrients and other sprays is an accepted practice in Florida's citrus industry, but this application method is not recommended for dry fertilizers.

For economical and efficient fruit production, it is essential that spreaders be calibrated to apply exact amounts of fertilizers per acre. Plant nutrients should be applied according to individual crop requirements. Reduced yield may result from insufficient nutrient application, while excess nutrient application can lead to accumulation in soils and adjacent surface or groundwater.

Equipment needed to calibrate a typical grove spreader such as that shown in Figure 1:

- A tray (catch pan) that slides under the opening where the chain pulls fertilizer from the hopper. This tray fits just above the fans.

- A spring scale or balance to weigh the fertilizer.

Calibration steps:

- Position the empty tray so it will catch the fertilizer that comes out of the hopper during calibration.

- Drive the tractor and spreader along a row middle or edge of a block as if fertilizing normally for a distance of exactly five trees. Record the speed, RPM, and gear of the tractor.

- Collect the fertilizer discharged into the tray and weigh it.

- Repeat the above procedure several times until a reliable average weight is obtained.

- Use this equation to convert the weight of material to application rate in lb/acre, assuming the spreader is fertilizing two rows at a time:

Fertilizer material application rate (lb/acre) =

Weight collected (lb)

-------------------------------------------

[10 trees ÷ tree density (trees/acre)]

For example, if an average of 27 lb of fertilizer were collected and the grove density was 145 trees/acre, the application rate would be:

28 lb ÷ (10 ÷ 145) = 406 lb/acre

Credit: Mongi Zekri, UF/IFAS

Fertigation

Fertigation is the application of soluble fertilizers with irrigation water. Advantages of fertigation:

- Fertilizer is placed in the wetted area where the most active roots are located.

- Fertilizer may be applied more frequently in small amounts so that it is available when the tree needs it.

- Increased fertilizer application frequency can increase fertilizer efficiency and reduce leaching.

- Compared with conventional ground application, fertigation can produce similar or better tree growth, yield, and fruit quality with less fertilizer.

- Application cost is lower than that of dry or foliar fertilizer application because fertilization is incorporated into the normal irrigation schedule.

Disadvantages of fertigation:

- Fertilizer application uniformity and coverage depend on proper design, installation, and maintenance of the irrigation system.

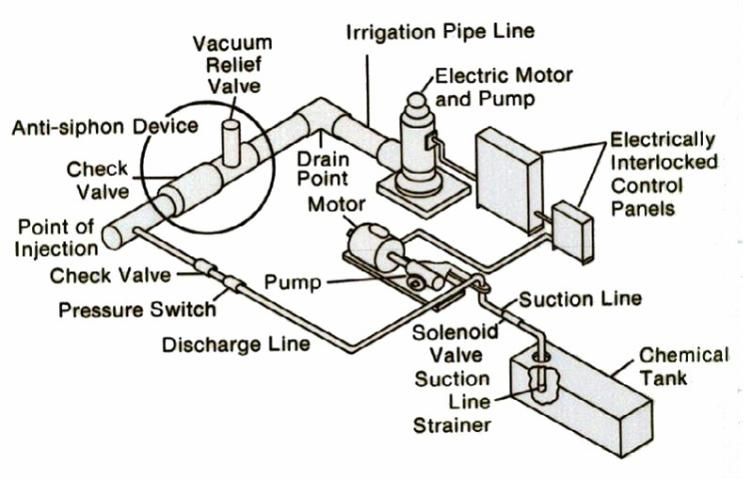

- Extra equipment (injection device, tank, backflow prevention system) must be added to the irrigation system (Figure 2).

- Soluble fertilizers are more expensive than granular fertilizers.

- Fertilizers injected into an irrigation system may contribute to emitter plugging.

To effectively fertigate citrus trees, growers must properly maintain their microirrigation systems to apply water and fertilizer uniformly (see Obreza 2004). In addition, growers must determine:

- the most suitable fertilizer formulations for injection;

- the most appropriate fertilizer analysis for different age trees and specific stages of growth;

- the fertilizer amount to apply during a given fertigation cycle or event; and

- the timing and frequency of applications per season.

Credit: Mongi Zekri, UF/IFAS

Properly managed applications of plant nutrients through irrigation systems significantly enhance fertilizer efficiency while maintaining or improving yield and fruit quality. On the other hand, poorly managed fertigation may result in substantial yield loss. Keep in mind that if a very wet soil is fertigated when following a predetermined fertigation schedule, fertilizer and water will be wasted because water and nutrient uptake are drastically reduced if the soil is saturated.

Nutrient solutions for fertigation are available in different forms and concentrations. Formulations usually contain two or more nutrients, and the solubility of various formulations vary significantly. Fertilizer solubility is critical when preparing stock solutions for fertigation, especially when dissolving dry materials in water. Preparing "homemade" nutrient stock solutions from dry fertilizers may require considerable time and effort and can generate sediments. Therefore, commercially prepared true-liquid fertilizer solutions are preferred.

Solutions are convenient because they can be directly injected into the irrigation water stream with a variable-rate injection pump. Although transportation cost makes liquids more expensive, they save time and labor and prevent problems associated with handmade mixes. They also eliminate problems caused by insoluble materials found in some dry fertilizers.

Be careful when injecting fertilizers containing P or S into microirrigation systems. These elements may react with dissolved calcium and magnesium in the irrigation water to form insoluble precipitates that can clog irrigation lines and emitters. However, phosphoric acid can be safely injected into most water sources because it acidifies the solution, preventing precipitation. Most N sources have low clogging potential except for ammonium phosphate. This material increases water pH, which may cause Ca and Mg to precipitate.

Injected fertilizers must remain in solution throughout the entire time that the irrigation system is running. To help avoid plugging, a properly designed microirrigation system should include:

- a method of filtering irrigation water;

- a means of injecting chemicals into the water;

- equipment for flushing the system; and

- in some cases, a settling basin to allow aeration and the removal of solids.

Most fertilizers are highly corrosive and are a potential health threat where in contact with human skin. When fertigating, take these safety precautions:

- Wear appropriate protective clothing and eyewear when handling liquid fertilizers.

- Inspect all system components including pumps, injection devices, lines, filters, and tanks prior to use.

- Establish a routine fertigation monitoring program that emphasizes the start-up and shutdown periods in particular.

- Calibrate and frequently recheck injection rates and times to ensure proper system operation.

- Prevent leaks, runoff, excess applications, and application to areas near surface water.

- Flush all system components with clean water following each fertigation.

Fertilizer salts in irrigation water can burn leaves even if relatively low-salinity water is used. When injecting fertilizers, check the electrical conductivity (EC) of the irrigation water-fertilizer mixture and try to maintain it below 1.5 dS/m (mmhos/cm), which is equivalent to about 1000 ppm total dissolved solids. It is preferable to inject small doses of fertilizer more frequently rather than less frequent injections of larger doses.

It is essential to have legal backflow prevention devices installed in the irrigation system to keep fertilizer from siphoning back into the water supply (Figure 3). Managers should consult state and local regulations that address their equipment needs based on the type of water supply and selected injection device.

The injection system should be made of corrosion-resistant materials like reinforced ethyl vinyl acetate (EVA) hoses, nylon or polypropylene fittings, and polypropylene or fiberglass tanks. The injection device should have its own check valve plus a screen to prevent nondissolved particles from entering the system. Fertilizer injection should take place upstream of filters so that any contaminants or precipitates can be filtered out. Injection should stop during filter backwashing. If the system has a filter that uses part of the supply water to continuously backwash, fertilizer must be injected downstream of it. Injection of highly acidic or corrosive materials should take place downstream of filters that may be subject to corrosion.

Fertigation rates and timing should be calibrated for each irrigation zone. A single injection should last at least as long as the time it takes for water to travel from the injection point to the farthest emitter when the system is operating at normal pressure and flow rate. There is a large increase in EC when fertilizer is present in irrigation water, so fertilizer movement through an irrigation system can be traced by following changes in EC with a portable EC meter. The time from the beginning of an injection to a sudden increase in EC at the farthest emitter from the injection point indicates the travel time of the fertilizer. For many systems, this time is 20 to 30 minutes. Flush time should be longer than travel time so that nutrients do not remain in the tubing; otherwise microbial growth will be enhanced. An alternate method to determine travel time is to inject liquid soap and observe the time it takes for bubbles to appear at the farthest emitters.

The maximum injection time depends on soil type, nutrients, and water requirement of the trees. Flush time should not be too long, so as to avoid the application of too much water, because excessive water leaches plant nutrients below the root zone. Furthermore, too much water saturates the soil, causing damage to roots.

Fertilizer injection rates can be measured with a chemical flow meter or volumetrically. If a chemical flow meter is used on the high-pressure side of an injector, the flow meter should be rated for the pressure used. Volumetric measurements can be made by determining the time needed to inject a known volume of fertilizer under normal operating conditions.

For all fertigation methods, the required fertilizer injection volume can be calculated with the equation:

Volume = (Acres × N) ÷ (F × Density)

where

Volume = volume of fertilizer to be injected (gal)

Acres = grove area to be fertigated (acres)

N = amount of N to be applied per acre (lb N/acre)

F = percentage of N in the fertilizer expressed as a decimal (e.g., F = 0.08 for an 8-0-8 analysis)

Density = fertilizer solution density (lb/gal)

The weight per gallon of the liquid fertilizer solution can be obtained from the supplier. Alternately, a known volume of solution can be weighed and converted to a weight per gallon. Appendix D lists the density of many common fertilizer solutions.

Example

- The desired N rate is 150 lb/acre/year.

- Fertilizer is to be applied in 20 equal doses.

- The fertilizer solution is an 8-0-8 analysis made from ammonium nitrate and muriate of potash.

- The fertilizer solution density is 9.7 lb/gal.

- The grove to be fertilized is 80 acres with a 12.5 ft × 24 ft tree spacing (145 trees per acre).

- Each tree is irrigated with microsprinklers discharging 10.5 gal/hr at operating pressure.

Calculations

Dividing the annual rate of 150 lb N/acre into 20 fertigations results in a single-dose application rate of 7.5 lb N/acre. The volume of fertilizer to be injected is then calculated from the equation:

Volume = (80 acres × 7.5 lb N/ac) ÷ (0.08 N × 9.7 lb/gal) = 773 gal

Injecting the fertilizer during a 60-minute period would require 773 gal/60 min = 12.9 gal/min. Alternately, 10 gal/min of fertilizer could be injected for 77 minutes, resulting in 770 gallons injected. Injection rates may have to be adjusted to compensate for equipment capacities. If 10 gal/min is above the range of the injection system, increase the injection time and/or fertigate more frequently.

In mature groves irrigated with typical microsprinklers that apply water between 0.10 and 0.15 inches/hr within the irrigation pattern, fertigation and flush cycles should be completed in 2 to 3 hours. Injection intervals that are too short result in tree exposure to high rates of salinity, and salt burn may result if the irrigation pattern contacts lower leaves and fruit. Injection times that are too long may result in leaching if the water-holding capacity of the root zone soil is exceeded before irrigation is completed.

Special attention is needed when fertigating young trees equipped with downspray microsprinklers that confine the irrigation pattern to a 3-to-4-foot diameter circle. The water application rate of these emitters can result in excessive irrigation and nutrient leaching. For example, a 15 gal/hr emitter with a 4-foot diameter wetted area has an effective application rate of 1.9 inches/hr. This rate may result in leaching even if a fertigation-flush cycle requires only 1 hour to complete. To minimize leaching while downsprays are attached to emitters, post-injection irrigation must be the minimum required to flush the lines.

As trees mature and the root system expands to a much larger soil volume, the wetted area must be increased for fertigation to succeed. The wetted area for a mature tree should cover most of the area under the canopy, or at least 50% of the total land area. Patterns that irrigate less than 30% of the total land area may be unable to supply nutrients to enough of the root zone and may cause leaching. Knowledge of the application rate of the irrigation system and the soil water content prior to irrigating is critical to fertigation management. The use of soil moisture sensors may be beneficial, particularly those that measure water content at multiple depths.

Applying Suspension Fertilizers

Suspension fertilizers are applied with a standard herbicide boom that places the fertilizer directly over the root zone (Figure 4). Nozzles used to apply suspension fertilizers are larger than those typically used to apply herbicides (e.g., flooding or flood-jet nozzles). It is important to continuously agitate fertilizer in the tank to ensure application uniformity. Air sparging or mechanical recirculation can be used for agitation.

Credit: Stephen Futch, UF/IFAS

Boom application equipment should be modified with manifolds and nozzles made of a salt-resistant material like stainless steel. Applying fertilizer with a boom provides the opportunity to apply other agrichemicals like herbicides, insecticides, and fungicides at the same time. The salt effect of the liquid fertilizer can complement residual herbicides by burning existing weeds. However, care should be taken to avoid incompatibility when mixing materials.

Applying Foliar Fertilizers

Foliar nutrient application to citrus trees is common for economic and environmental reasons. Under specific conditions, it can improve nutrient uptake efficiency because nutrients are directly absorbed by the leaves. Foliar spraying can provide specific nutrients on a timely basis during critical stages of tree growth, flowering, and fruit development.

A well-planned foliar nutrition program can supplement soil fertilizer applications, especially when the citrus root system is unable to keep up with crop demand or when soil nutrients are unavailable. In some cases, a significant portion of nutritional needs can be met with a foliar program. Foliar application is not intended to replace a soil-applied N-P-K fertilization program. However, some macronutrients can be foliarly applied at rates sufficient to influence young tree growth, yield, and fruit quality.

Foliar application is an excellent means to supply plant requirements of secondary and micronutrients like Mg, Zn, Mn, Cu, B, and Mo. Foliar application of micronutrients is more effective than soil applications with the exception of Fe. Foliar sprays are taken up more rapidly by the tree, but their effects typically last only as long as it takes for the targeted growth flush to mature.

Foliar application can be integrated into an annual citrus nutrition program. It can be used to help trees through short but critical periods of nutrient demand, such as bud differentiation, flowering, fruit set, and fruit development. It is also useful when soil or environmental conditions are unfavorable for nutrient uptake by roots, such as cold weather, prolonged wet or dry soils, calcareous soil, or any other condition that decreases the tree's ability to take up nutrients when there is a demand. Foliar spraying is particularly useful when a nutritional deficiency is diagnosed, because it is the most rapid way to effect nutrient uptake by citrus trees.

Foliar fertilizers are usually applied to citrus trees with a conventional grove airblast sprayer (Figure 5), typically in 100 to 500 gal of water per acre. The goal of airblast spraying is to replace the air contained within in the tree canopy with spray-laden air. Sprayer travel speed must be slow enough to create air momentum to penetrate the canopy. However, unlike fungicide or miticide applications, it is not necessary to achieve highly uniform spray coverage of leaves or fruit. In many cases, nutrient sprays can be applied exclusively from the bed tops in 2-row bedded Flatwoods groves and from alternate row middles in Ridge groves.

Credit: P. Chris Wilson, UF/IFAS

Nutrient absorption is most rapid during the first several hours after application. Environmental conditions that cause stomata (leaf openings) to close reduce nutrient uptake efficiency. It is best to apply foliar sprays when air temperature is cool and humidity is high, such as early morning or late evening. Applying fertilizer during these times also decreases the chance of leaf burn. Maximum benefit of Zn, Mn, and Cu is obtained when spraying young leaves that are two-thirds to nearly fully expanded, but before hardening off. Treating the spring flush is preferable to later growth flushes.

Micronutrient and other nutrient sources including chelates and nitrate-based materials are often applied together with pesticides, spray oils, surfactants, and other products. Sometimes the chemistry of these mixes combined with the environmental and tree conditions at the time of application causes phytotoxicity and sometimes abscission of foliage and fruit. Reduced product efficacy may also occur. Information on compatibility of various product mixtures in the spray tank and the interaction of the components following deposition on the foliage and fruit surface is scarce. Poor-quality water, particularly due to salinity and/or high pH, can also contribute to the problem. Additives with strong penetrant activity should not be included in foliar-spray tank mixes. Reducing the number of components in tank mixes and spraying when trees are under minimal stress should reduce the potential for damage.

When applying foliar nutrients, it is important to ensure that the pH of the spray solution is between 6 and 7. Solution pH control is particularly important when applying urea. If the pH of a urea spray solution exceeds 7, free ammonia may be generated that dramatically increases the potential for leaf burn. Take this precaution especially when growing fruit for the fresh market, where fruit blemishes (burn) can substantially reduce marketable yield.