Introduction

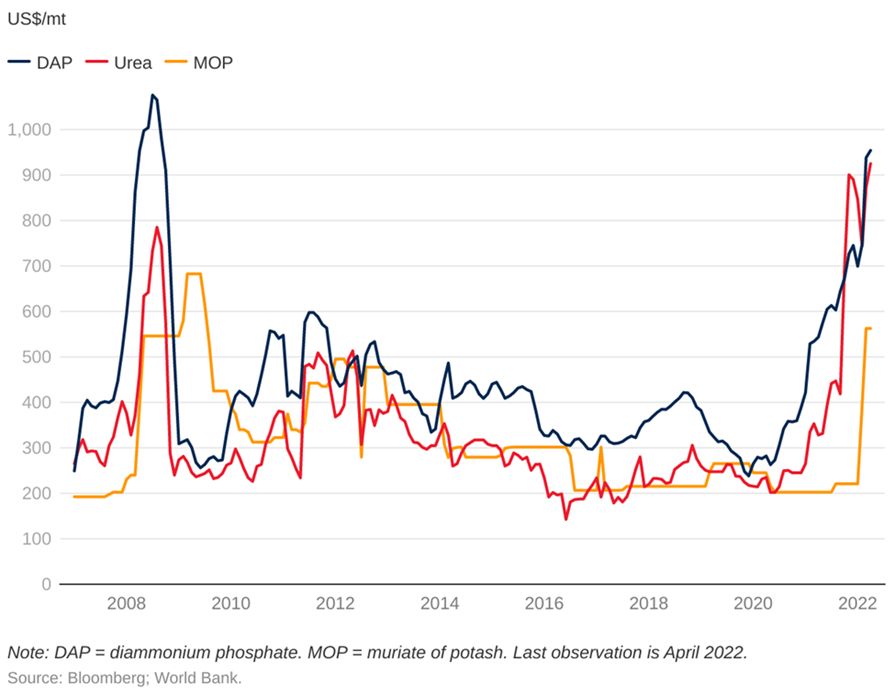

With recent geopolitical instability and supply chain challenges associated with fertilizer, growers are finding it difficult to source affordable fertilizer for crop production. The price of fertilizer has increased by 30% in the first quarter of 2022, after jumping 80% the year before (Figure 1). There is little expectation that fertilizer prices will fall in the near term (Baffes and Koh 2022). Because of these soaring prices, growers throughout the world are exploring alternatives to inorganic fertilizers, which have been the primary plant nutrient source for commercial growers since the 1950s. Many are exploring organic fertilizers as an option to lower their costs while ensuring their crops receive the proper nutrients to be productive (Merrigan 2022).

Credit: Baffes and Koh (2022)

Bagasse could be an economically feasible fertilizer alternative to inorganic products. It is a dry and fibrous residue of sugarcane left after the sugar juice extraction. In this paper, we explore the potential of utilizing bagasse as a nutrient source to potentially reduce inorganic fertilizer inputs in the sugarcane production system. Information provided in this article will be useful to commercial sugarcane growers, crop consultants, and fertilizer manufacturers in helping them explore alternative fertilizer options. This paper provides important and timely information for the target audiences, considering the recent, rapid rise in fertilizer prices.

The assessment of expenses includes macro- and micronutrient costs based on published estimates of the nutrient concentration of bagasse (Xu et al. 2021). While costs associated with logistics and application as well as batch inconsistency can adversely affect a grower’s decision to adopt bagasse in sugarcane production, we explore the reductions in fertilizer costs when bagasse is applied as an alternative viable nutrient source.

The application of fertilizers in agriculture has been accepted as a fundamental requirement for crop production. The use of inorganic fertilizers that aim to boost productivity dates to the latter half of the 20th century, whereas traditional (mostly organic) fertilizer practices have been used for many millennia (Hergert, Nielsen, and Margheim 2015). The continuous use of inorganic fertilizers is expensive, and it can reduce land productivity (Yusuf et al. 2018). Research has shown that not all the fertilizer (mostly inorganic) applied to the soil is taken up by the crop. The rest either remains in the soil or is lost through leaching, physical wash-off, fixation by the soil, or release to the atmosphere through chemical and microbiological processes (Hera 1996). Recycled organic residues are underutilized in modern agricultural systems, yet research has shown that the application of organic amendments in conventional farming can provide long-term benefits (van Zwieten 2018). The interactions in soil between organic amendments and inorganic fertilizers are complex. Organic amendments such as bagasse and compost will offset at least a portion of the cost of inorganic fertilizers and are documented to reduce nutrient loss and increase fertilizer use efficiency (Yusuf et al. 2018; Vanlauwe et al. 2011).

When a grower considers adoption of a new production practice, one of the most important questions asked is “how is this going to affect my bottom line?” To understand the financial impact of an alternative production decision, a grower needs to know the estimated changes in costs or revenues to accurately determine profitability. Additionally, the grower needs research-based information to evaluate the effectiveness of a new practice and how it can be incorporated into their existing cropping production system. We provide a theoretical cost-assessment to include the economic factors related to utilization of bagasse as a nutrient source in sugarcane production. The use of bagasse likely has additional environmental and social benefits that are not calculated in this study. For example, Xu et al. (2022) reported that amending mineral soils with bagasse could reduce total organic carbon, nitrogen, and phosphorus leaching below the plant root zone, thus retaining more nutrients for plant uptake and minimizing nutrient losses to adjacent water bodies.

Benefits of Bagasse

Approximately 18 million tons (mt) of sugarcane were produced in Florida in 2020 (USDA NASS 2021), which corresponds to nearly 2.8 million mt of bagasse by-product (Bhadha et al. 2020). There exists an opportunity for utilizing the material as a soil amendment when applied on mineral soils, possibly offsetting some of the cost of inorganic fertilizer inputs (Figure 2). Typically, south Florida’s mineral soils are low in nutrient content due to their low soil organic matter content and nutrient retention capacity as shown in Table 1. Bhadha et al. (2020) have previously summarized the potential benefits of utilizing bagasse as a soil amendment in sugarcane production in south Florida (EDIS #SL477). Bagasse can alter the soil physiochemical properties, enhance soil quality, and increase crop yield (Xu et al. 2021). Its low bulk density (0.06 oz/in3) and low pH (4.0 + 0.1) can be beneficial when applied to mineral soils with high pH. Bagasse has high organic matter (95%) and high water-holding capacity (>50%) (Xu et al. 2021). Bagasse also has a high nutrient content that could be beneficial for plant growth (Table 2) and is a food source for soil biota. Previous studies have reported an increase in microbial biomass and communities in the soil where bagasse mulch was applied (Miura et al. 2013; Silvia 2014).

Credit: Stewart Swanson and Jehangir Bhadha, UF/IFAS

Cost-Assessment Method

We conducted a theoretical cost-assessment based on the total amount of macronutrients (N, P, K, S, Ca, Mg) and micronutrients (B, Cl, Cu, Fe, Mn, Mo, Ni, Zn) present in a typical mineral soil (siliceous, hyperthermic Mollic Psammaquents) in Clewiston, Florida. It is a common agricultural soil that is used for commercial sugarcane production in this area. Thus, it has been fertilized in the past based on the fertilization recommendations from the U.S. Sugar Corporation. The soil samples used for this study were collected before sugarcane was planted; thus, the last fertilization was done at least one year before sample collection. Bagasse samples were obtained from the U.S. Sugar Corporation sugarcane mill in Clewiston, Florida. Multiple bagasse samples were analyzed for elemental concentration (lb/ton) of N, P, K, Ca, Mg, B, Cu, Fe, Mn, Zn, and Si (Table 1). Total nutrients for all the soil and bagasse samples were measured by ashing samples for at least 5 hours (not exceeding 16 hours) at 550°C in a muffle furnace, followed by extraction with 6M HCl and analysis using an Agilent 5110 inductively coupled plasma-optical emission spectrometer (ICP-OES, Santa Clara CA) (Xu et al. 2019). Bagasse contains similar or greater concentration of N, P, K, Si, Cu, Mn, and Zn than the mineral soils used in this assessment (Entisol from Clewiston, FL) (reported as dry basis shown in Table 1). Ca, Mg, and Fe concentrations were lower in bagasse compared to the mineral soil.

Table 1. Macro and micronutrient concentration in mineral soils, bagasse, and plant tissue (all values are reported on a dry-weight basis).

Various mixes and blends of granular fertilizer are typically used during planting. Some of the common fertilizers are diammonium phosphate, muriate of potash, and ammonium nitrate. Other compounds in the form of calcium silicate and slag can also be added as required. In addition, micronutrients can also be applied based on soil test recommendations for mineral soils. The exact mixes and rates are typically confidential information retained by individual growers shared at their discretion. Given that detailed access to fertilizer applications by growers is unavailable, our analysis utilized a reasonable estimate of a “typical” nutrient requirement delivered as fertilizer to sugarcane grown on the south Florida mineral soils over three sugarcane crop cycles (plant cane and two ratoons) (Table 2). We estimated that 194 lb/ac N, 48 lb/ac P, 208 lb/ac K, and 60 lb/ac Mg, in addition to other macro- and micronutrients, would be applied through typical fertilization practices.

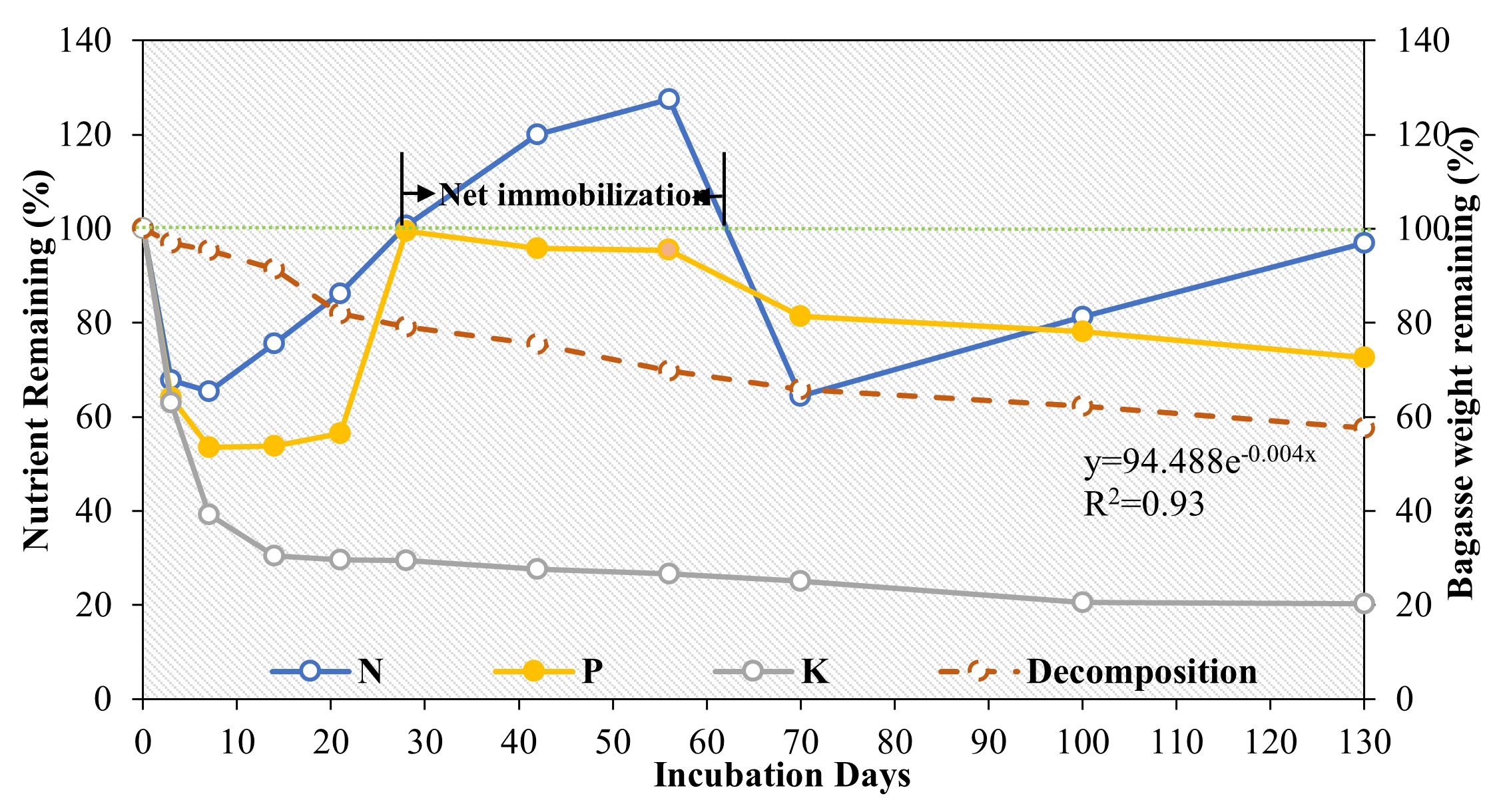

For this study, we estimated a one-time uniform application of bagasse (2-inch layer) corresponding to approximately 38 ton/ac across three sugarcane crop cycles. Generally, fresh bagasse moisture content can exceed 50%. For this assessment we used a 56.17% moisture content for bagasse from the estimates recorded by Xu et al. (2021). Based on the nutrient concentration of the bagasse (Table 1) and after correcting for moisture content, this bagasse application rate is expected to deliver 93 lb/ac of N, 9 lb/ac of P, 33 lb/ac of K, 70 lb/ac of Ca, and 0.54 lb/ac of Mg (Table 2), as well as varying quantities of micronutrients. In addition to losses via leaching, the process of mineralization may be slow, and all the nutrients are likely not to be available to the plant in the same growing season. A field incubation study conducted in a typical commercial sugarcane production system on mineral soils in south Florida estimated the decomposition rate of bagasse and mineralization rates of N, P, and K is shown in Figure 3. Approximately 40% of bagasse had been decomposed in 130 days, and approximately 30% of N was released from bagasse after 7 days of application. However, net N immobilization was observed afterwards due to its high C/N ratio (Xu et al. 2021). Much like N, approximately 50% of P was released from bagasse after 14 days of application, and P immobilization tended to have occurred afterwards. The potassium release pattern was different from N and P. There was a rapid release of K after about one week of bagasse application, and approximately 80% of K had been released in 130 days.

Although bagasse is not a fast-release type of nutrient source, it adds organic matter, which improves the water-holding capacity, reduces bulk density, and increases microbial population in the soil. Not all the nutrients listed will be released and made bioavailable at the same time. A portion of these nutrients get incorporated as recalcitrant organic matter in the soil; hence, only a percentage reduction in fertilizer savings can be expected.

Table 2. Approximate quantity of nutrients in the form of fertilizer applied compared to the quantity of nutrients that bagasse can potentially deliver to the soil when 38 tons/ac (2-inch layer) of bagasse is applied with a 56.17% moisture content.

The cost assessment estimations are based on the bagasse nutrient concentration (lb/ton) and the amount of bagasse added (lb/ac) when applying a 2 in. layer of bagasse corresponding to proposed 38 tons/ac, the application rate used in this assessment over three sugarcane crop cycles. Given the estimated bagasse N concentrationof 5.58 lb/ton, the bagasse application rate of 38 tons/ac, and adjusting for the 56.17% bagasse moisture content, the resulting N application rate (lb/ac) = 5.58 × 38 × (1-0.5617) = 93 lb/ac (Table 2).

Based on information provided by a local fertilizer vendor (April 2021), we were able to estimate the cost of individual nutrients applied on mineral soils on a $/lb basis over three sugarcane crop cycles (Table 3). Based on the bagasse nutrient concentration (Table 1), we estimated a potential nutrient cost savings of approximately $109/ac when 38 ton/ac of bagasse is applied to mineral soils over a period of three sugarcane crop cycles (Table 3). It is important to reiterate here that not all the nutrients are bioavailable at the same time. This estimate is simply based on the unit costs ($/lb) of inorganic nutrients present in fertilizer sources routinely used by sugarcane growers (Table 3). For example, with an expected N fertilizer application of 194 lb/ac (Table 2) that costs $0.68/lb (Table 3), the total cost of N would be $132 over three sugarcane crop cycles (plant cane plus two ratoons) (Table 3). As bagasse delivers 93 lb/ac N when applied at 38 ton/ac (Table 2), the cost saving from bagasse would be $63/ac, because 93 lb of N fewer would need to be applied per ac.

Table 3. Estimated cost ($/ac) of fertilizer for sugarcane over three sugarcane crop cycles (plant cane plus two ratoons) at the recommended rate on mineral soils compared to the estimated cost saving associated with the one-time application of 38 ton/ac bagasse, assuming that all nutrients are made bioavailable.*

Other Considerations

While only the nutrient costs are considered in this study, there are other application costs that need to be considered in the bagasse cost assessment as a potential soil amendment. Some of these include:

(a) Additional transport costs—The cost of transporting the bagasse and spreading it uniformly across a field may vary depending on the distance the material is hauled. It is more cost-effective to amend fields that are closer to the bagasse facility (sugar mill) than sites that are many miles away. Additionally, applying bagasse may imply additional labor and use of tractors equipped with bagasse-spreading applicators.

(b) Moisture content—Moisture can play a critical role in the cost of transporting bagasse. For example, for 1,000 lb of bagasse containing 30% moisture, a grower is effectively paying to move 700 lb of bagasse and 300 lb water, whereas a grower would incur the same transport expenses for only 300 lb of bagasse containing a 70% moisture content.

(c) Batch consistency—The nutrient content of bagasse can be variable. Certain batches contain variability in N, P, and K concentration. This difference will ultimately affect the amount of additional inorganic fertilizer that needs to be applied and cost associated with it, including the testing of each batch of bagasse to quantify nutrient content.

(d) Availability of nutrients—While bagasse can provide some labile (plant-available) nutrients as soon as it is applied, most of the bagasse needs to be mineralized for nutrients to be available for plant uptake. In addition to losses via leaching, the process of mineralization is slow, and all nutrients will not be available to the plant in the same growing season, as shown by the slow decomposition rate. However, bagasse adds organic matter, which improves the water-holding capacity, reduces bulk density, and increases microbial population in the soil. These factors are relevant when considering bagasse applications for nutrient delivery.

Conclusion

With recent global fertilizer shortages, and the resultant explosion in fertilizer prices and assessments indicating that this situation will not be resolved quickly, the issue of alternative fertilizer sources is of prime importance. Based solely on estimated nutrient costs, bagasse can be an economically feasible organic supplement that can be incorporated in the sugarcane production cycle. Incorporation of bagasse in soil could be a good option for sugarcane growers to improve their soil conditions while utilizing large tonnage of bagasse (by-product) produced each year in sugar production. Future research is recommended where the analysis includes the application of bagasse and the incorporation of it in the soil over time so that mineralization and stabilization can occur. This evaluation would need to be followed by subsequent soil analyses to verify actual bagasse contributions. Additional analysis is also necessary to fully understand the value of the environmental benefits (i.e., reduced water pollution and improved soil quality) and social benefits (i.e., higher-quality drinking water) from using bagasse, an organic fertilizer, instead of inorganic alternatives.

Acknowledgments

We wish to thank Chris Laborde and Rosa Muchovej (U.S. Sugar Corporation) for providing the bagasse, logistical assistance with experimental work, and communications related to cost assessment. We also wish to thank Jimmy Matthews (Wedgworth’s Inc.) for sharing information related to the current cost of fertilizers and other production inputs.

References

Baffes, J., and W. C. Koh. 2022. “Fertilizer Prices Expected to Remain Higher for Longer.” World Bank Blogs. https://blogs.worldbank.org/opendata/fertilizer-prices-expected-remain-higher-longer

Bhadha, J. H., N. Xu, R. Khatiwada, S. Swanson, and C. LaBorde. 2020. “Bagasse: A Potential Organic Soil Amendment Used in Sugarcane Production.” EDIS 2020 (5): 5. https://doi.org/10.32473/edis-ss690-2020

Hera, C. 1996. “The Role of Inorganic Fertilizers and Their Management Practices.” Fertilizer Research 43:63–81. https://doi.org/10.1007/BF00747684

Hergert, G., R. Nielsen, and J. Margheim. 2015. “A Historical Overview of Fertilizer Use: Almost 8,000 Years Ago Farmers Recognized Its Value.” Cropwatch, University of Nebraska, Lincoln. https://cropwatch.unl.edu/fertilizer-history-p1

Mahler, R. L. 2004. “Nutrients Plants Require for Growth.” University of Idaho Extension. https://www.extension.uidaho.edu/publishing/pdf/CIS/CIS1124.pdf

Merrigan, K. 2022. “Fertilizer Prices Are Soaring—and That’s an Opportunity to Promote More Sustainable Ways of Growing Crops.” The Conversation. https://theconversation.com/fertilizer-prices-are-soaring-and-thats-an-opportunity-to-promote-more-sustainable-ways-of-growing-crops-183418

Miura, T., A. Niswati, I. G. Swibawa, S. Haryani, H. Gunito, and N. Kaneko. 2013. “No Tillage and Bagasse Mulching Alter Fungal Biomass and Community Structure during Decomposition of Sugarcane Leaf Litter in Lampung Province, Sumatra, Indonesia. Soil Biology and Biochemistry” 58:27–35. https://doi.org/10.1016/j.soilbio.2012.10.042

Silvia, S., T. Miura, K. Nobuhiro, K. Fujie, U. Hasanuddin, A. Niswati, and S. Haryani. 2014. “Soil Microbial Biomass and Diversity Amended with Bagasse Mulch in Tillage and No-Tillage Practices in the Sugarcane Plantation.” Procedia Environmental Sciences 20:410–417. https://doi.org/10.1016/j.proenv.2014.03.052

USDA National Agriculture Statistics Service. 2021. https://quickstats.nass.usda.gov/

Vanlauwe, B., J. Kihara, P. Chivenge, P. Pypers, R. Coe, and J. Six. 2011. “Agronomic Use Efficiency of N Fertilizer in Maize-Based Systems in Sub-Saharan Africa within the Context of Integrated Soil Fertility Management.” Plant and Soil 339:35–50. https://doi.org/10.1007/s11104-010-0462-7

van Zwieten, L. 2018. “The Long-Term Role of Organic Amendments in Addressing Soil Constraints to Production.” Nutrient Cycling in Agroecosystems 111:99–102. https://doi.org/10.1007/s10705-018-9934-6

Xu, N., J. H. Bhadha, A. Rabbany, and S. Swanson. 2019. “Soil Health Assessment of Two Regenerative Farming Practices on Sandy Soils.” Sustainable Agriculture Research 8 (4): 61–71. https://doi.org/10.5539/sar.v8n4p61

Xu, N., J. H. Bhadha, A. Rabbany, S. Swanson, M. J. McCray, Y. C. Li, S. L. Strauss, and R. Mylavarapu. 2021. “Crop Nutrition and Yield Response of Bagasse Application of Sugarcane Grown on a Mineral Soil.” Agronomy 11:1526. http://doi.org/10.3390/agronomy11081526

Yusuf, M., Sarjiyah, and Mulyono. 2018. “Effects of Appropriate Composition of Sugarcane Bagasse Compost and Nitrogen Fertilizer on the Growth and Yield of Soybean (Glycine max L. Merill).” Advances in Engineering Research 172:126–132. https://doi.org/10.2991/fanres-18.2018.25