Backrubbers are a method of pesticide self-treatment for cattle. When bothered by insects or other pests, cattle tend to rub against objects. Backrubbers provide a rubbing surface that is treated with a pesticide. Cattle self-treat during rubbing, which reduces the number of flies, particularly horn flies and parasites such as lice, on the animal. Backrubbers may be purchased commercially or constructed from easily available materials. A properly designed backrubber that supplies pesticide reliably to the animal can be a valuable addition to an integrated pest management program.

The position of the backrubber is of highest importance. Positioning should "force" animals to use the devices frequently so that they will be effective. Backrubbers should be installed in high-traffic areas where animals travel through frequently, such as between mineral and salt stations, or feeding and watering areas and pastures (Figure 1). To ensure treatment of the head, the backrubber should be positioned low enough so that the animals are forced to drop their heads to pass under. Underbrush often will compete with backrubbers for scratching, so locations with shrubs should be avoided. Placement of devices between feed, water, or supplement improves fly control, but use should be monitored. Each animal must contact the backrubber every two to three days to be effective.

Credit: P. E. Kaufman (top two photos) and J. F. Butler (bottom left photo), University of Florida; C. Sheppard, University of Georgia, Bugwood.org (bottom right photo)

Materials Needed for a Cable-Type Backrubber

- Two four-inch eyelets or eyebolts

- Hog rings and pliers, as needed

- 15 to 20 ft of 9 gauge cable or chain

- 18 to 20 burlap bags (can be new or used)

- Two 8 ft by 6 inch diameter posts, pressure treated

- 30 to 40 strands binder twine (15 inch long)

- 20 to 25 strands baling wire (12 inch long)

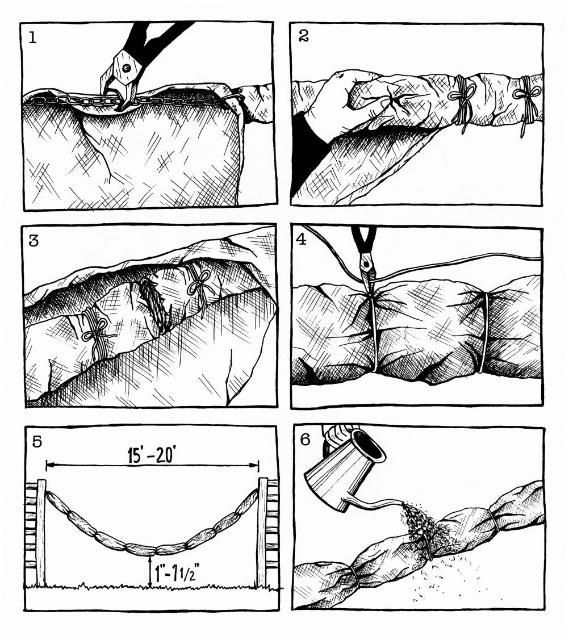

Construction of Cable-Type Backrubbers (see Figure 2)

- Attach bags lengthwise on the chain using hog rings at 10 inch intervals (Figure 2-1).

- Roll bags tightly and tie securely around the chain with binder twine (Figure 2-2).

- Wrap the rolled bags with a second layer of burlap, making sure to overlap the areas between bags (Figure 2-3).

- Twist baling wire every 8 inches along the backrubber. Clip the wires and push the cut ends into the burlap (Figure 2-4).

- Hang the backrubber between the posts so that it will sag to within 1–1½ ft off the ground (Figure 2-5).

- Pour one gallon of recommended pesticide on 15–20 ft of backrubber (Figure 2-6).

Credit: E. N. I. Weeks, University of Florida, and L. J. Weeks

Use of Cable-Type Backrubbers

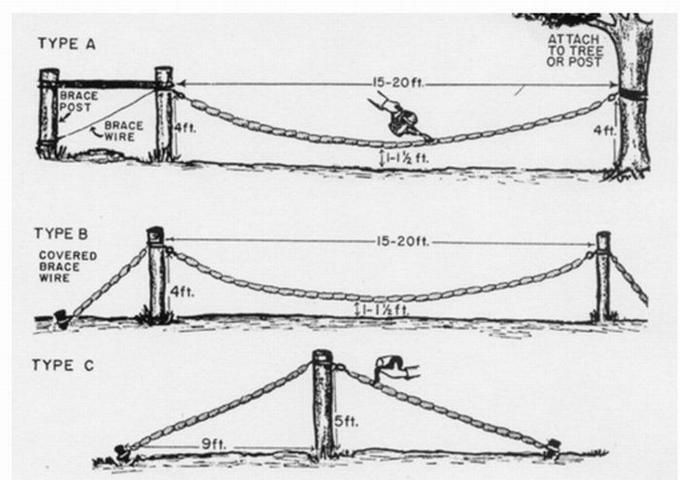

- Backrubbers may be modified to suit the management practices of any farm. The treated backrubber may be attached to trees or braced with wire and/or posts (Figure 3).

- Approximately one gallon of recommended pesticide should be used to treat a 15 to 20 ft backrubber.

- The backrubber should not be dripping; adjust volume added accordingly.

- One gallon oil cans work well for applying the pesticide oil suspension to the backrubber.

- Re-treat the backrubber every 2–3 weeks.

- One 15 to 20 ft backrubber should be available for every 50–75 animals.

- The addition of 18 inch strips of cloth at 4 to 6 inch intervals increases the area of contact and can increase insect control.

- Use livestock-grade mineral oil unless otherwise recommended on the pesticide label.

- Rotate pesticide classes between treatments.

- DO NOT use wettable powder formulations. They are unsuitable for backrubber use.

- DO NOT use diesel or kerosene because these oils evaporate quickly, which means that transfer of the pesticide will be low. These oils also may irritate the animals' skin.

- DO NOT use motor oil, transformer oil, or oil of unknown origin.

- DO NOT use vegetable oil because it encourages licking and accidental ingestion of the pesticide.

- DO NOT spray pesticide oil suspensions directly onto animals.

Credit: J. R. Strayer and J. F. Butler, University of Florida

Keys to Pesticide Safety

- Before using any pesticide, stop and read the precautions.

- Read the label on each pesticide container before each use. Heed all warnings and precautions.

- Store all pesticides in their original containers away from food or feed.

- Keep pesticides out of the reach of children, pets, and livestock.

- Apply pesticides only as directed.

- Dispose of empty containers promptly and safely.

Recommendations in this document are guidelines only. The user must insure that the pesticide is applied in strict compliance with label directions.

The Food and Drug Administration has established residue tolerances for certain pesticides in the meat of certain animals. When these and other approved pesticides are applied according to recommendations, the pests should be effectively controlled, and the animals' products will be safe for consumption.

The improper use of pesticides may result in residue in milk or meat. Such products must not be delivered to processing plants. To avoid excessive residues, use the pesticides recommended at the time suggested and in the advised amounts.

Locating an Approved Pesticide

In 2014, a group of livestock entomologists, as a part of Multistate Hatch Project S-1060, developed an online system for obtaining the names of registered pesticides appropriate for use with livestock and pets. This is a state-specific database (only certain states are represented, and Florida is one of these); if you are in another state, you must be certain that your state is represented in the dropdown list.

This database is easily searchable by the type of animal or site that you want to treat (such as a barn), as well as the targeted pest. From these two selections, you can then choose the "Method of Application" and the "Formulation Type." To use this system, please visit the following URL: https://www.veterinaryentomology.org/vetpestx.

Although the group continuously strives to keep this database current, it is ultimately your responsibility to ensure that the product that you choose is registered in the state that you plan to make the application and that you use the product in accordance with the label requirements and local laws and ordinances. Remember, "the label is the law" for pesticide use, and the uses indicated on the label, including the site of application and targeted pest(s) must be on the label.

If you have any challenges with this system, please contact your local UF/IFAS Extension Office (http://sfyl.ifas.ufl.edu/find-your-local-office/)

Selected References

Harvey, T. L., and J. R. Brethour. 1986. "Dust bag and backrubber applications of insecticides for control of pyrethroid resistant horn flies, Haematobia irritans (L)." Prev. Vet. Med. 3: 537–540.

Iowa State University. 2009. Fly control measures. https://www.cfsph.iastate.edu/Maddies_Textbook/Resources/InfectionControl/Fly%20Control%20Measures.pdf (18 November 2021).

Johnson, G. 2009. Horn flies on cattle: biology and management. https://cdn.website-editor.net/f53c587dba324ee79c03271fc5203548/files/uploaded/great%2520article%2520on%2520fighting%2520flies.pdf (18 November 2021).

Kessler, H., and W. L. Berndt. 1971. "Comparison of dust bags to backrubbers for control of horn flies and face flies Diptera-Muscidae on beef cattle in East-Central South Dakota." J. Econ. Entomol. 64: 1465–1466.

Mock, D. E. 1987. Managing insect problems on beef cattle. https://krex.k-state.edu/dspace/bitstream/handle/2097/21735/KSUL0009KSREODPUBSC671a.pdf?sequence=1&isAllowed=y (18 November 2021).

Palmer, W. A., and D. E. Bay. 1984. "A computer simulation model for describing the relative abundance of the horn fly, Haematobia irritans irrritans (L.), under various ecological and pest management regimes." Prot. Ecol. 7: 27–35.

Strayer, J. R. and J. F. Butler. 1972. External Parasite Control for Livestock. Gainesville: University of Florida Institute of Food and Agricultural Sciences.