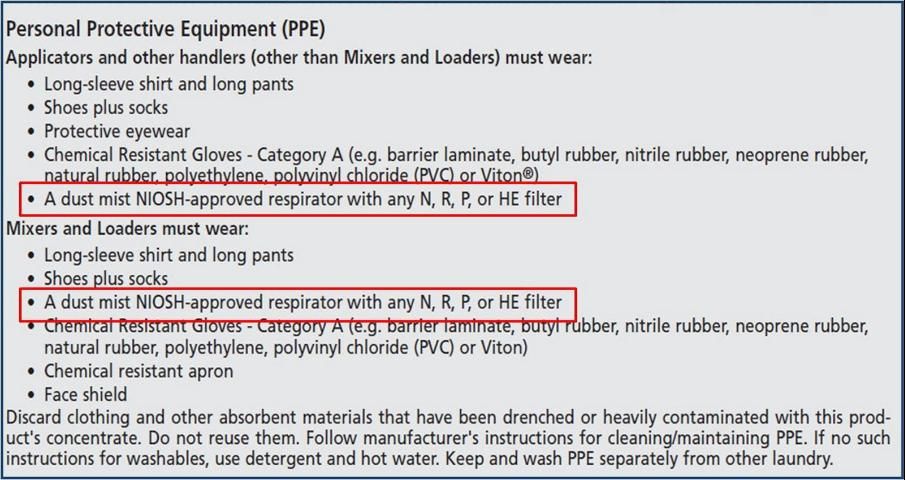

Respirators protect from breathing pesticide-contaminated air. Various pesticide formulations require different types of respirators. The label will provide specific instructions if required, as well as which type (Figure 1).

Credit: CDMS

Respirators are the most specialized piece of personal protective equipment (PPE) for working with pesticides, and proper selection is complicated. Specific information on choosing the appropriate respirator will be supplied by pesticide labels.

The National Institute of Occupational Safety and Health (NIOSH) is the federal agency responsible for testing and certifying respirators used in conjunction with pesticides (and other nonmining respiratory protection). Approval numbers beginning with the letter TC are assigned to all respirators reviewed by the agency and must be on the box containing the facepiece. Pesticide product labels often specify the type of respirator required by listing its TC number. In addition, filters are classified on the basis of oil degradation resistance and filter efficiency. The classification levels for oil degradation resistance are N (not oil resistant), R (oil resistant), and P (oil proof). The filter efficiency for each classification level may be 95, 99, or 100 percent. The following is a list showing several types of respirators and their TC code designations under the NIOSH classification system:

- TC-84A: nonpowered particulate respirators (N, P, and R filters)

- TC-21C: powered particulate respirators only (100 series filters)

- TC-23C: chemical cartridge respirators

- TC-14G: gas masks with canisters

- TC-19C: supplied-air respirators

- TC-13F: self-contained breathing apparatus

The product formulation, toxicity, and type of application influence the type of respirator needed. Manufacturers use criteria approved by the EPA to assign PPE respirator requirements on labels (Table 1).

Particulates are solid particles such as dusts and mists. Newer pesticide labels that specify organic vapor-removing cartridge respirators, once designated only as TC-23C, will also list which filters or pre-filters can be used with the respirator. The filters are identified by codes, such as HE, N, R, or P, which indicate the level of oil resistance offered by the filter. "N" filters are not resistant to oils but are excellent for use with dusts and granular formulations. "R" and "P" filters are either oil resistant (R) or oil proof (P). HE filters refer to "high efficiency" filters for powered-air purifying units, which can be used with oils. Manufacturers will designate a number that follows the HE, N, R, or P code on their products, and this number is an indication of the trapping efficiency. For example, a particulate respirator or filter with the N95 designation would be expected to have 95 percent efficiency in its trapping capacity. Pesticide label recommendations generally instruct the user to have a P100 filter with the chemical cartridge respirator when handling and applying oil-based pesticides.

One of the two common types of respirators is the air-purifying respirator. Some air-purifying respirators cover the entire face. There are also less expensive half-masks that cover the nose and mouth, and these respirators should be used only where there is sufficient oxygen. Air-purifying respirators have chemical cartridges or mechanical filters that remove airborne contaminants as air enters the respirator. The chemical cartridges are filled with activated carbon, which has a very high absorption capacity for gases and vapors. Each chemical cartridge is color-coded to indicate the use for which it was designed. A description of these codes is listed in Table 2. Mechanical filters provide protection by trapping particulate matter in the porous filter material.

Most air-purifying respirators (Figures 2–4) operate under negative pressure; that is, they rely on the power of the wearer's lungs to pull air through the filter elements. These include half-mask dust/mist respirators, half-mask dual-cartridge respirators, full-face dual-cartridge respirators, and canister-type gas masks. Dust/mist respirators (Figure 4) and some half-mask dual-cartridge respirators are disposable. The only air-purifying respirator that operates under positive pressure is the powered air-purifying respirator (PAPR). It has a fan that pulls air through the filters and circulates it over the wearer's face. Air-purifying respirators vary widely in price.

Credit: UF/IFAS Pesticide Information Office

Credit: UF/IFAS Pesticide Information Office

Credit: UF/IFAS Pesticide Information Office

The second basic type of respirator is the atmosphere-supplying respirator. This kind of respirator supplies an independent source of breathable air and is used in conditions where oxygen is deficient or the applicator is exposed to high concentrations of very toxic pesticides in enclosed areas. Breathable air is supplied to the wearer from an independent source through an air line, or the wearer carries oxygen in a tank. These respirators are relatively expensive and should be serviced and inspected by qualified personnel. One type is the supplied-air respirator (TC-19C) that uses long hoses to supply air to a full facemask. Some, but not all, supplied-air respirators have a blower or compressor. Another type is the self-contained breathing apparatus (TC-13F), also known as "SCBA" (Figure 5). This respirator uses a compressed air tank and provides complete respiratory protection against toxic gases in an oxygen-deficient environment.

Credit: FDACS

An applicator should perform a fit test to determine correct size of a respirator facepiece because a respirator that does not provide a proper seal is of little value. OSHA mandates that a fit test be performed every time a person puts on a respirator. Instructions for conducting fit tests generally accompany half-mask and full-face respirators.

Chemical cartridges should be replaced according to the manufacturer's recommendations or the pesticide label or when the wearer notices odor or experiences irritation. Prefilters will extend the life of chemical cartridges in dusty conditions. Mechanical filters should be replaced when breathing becomes difficult, the filter is damaged, or as specified by the manufacturer or the pesticide label. If no instructions are provided, replace cartridges and filters when the workday is over.

Use Respirators Properly

According to OSHA's respiratory protection standard (29 CFR 1910.1 34), employers must provide a medical evaluation to determine an employee's ability to use a respirator before the employee is fit tested or required to use the respirator in the workplace. Employees must also receive training on the proper use of the respirator for which they have been fit tested.

To work properly and provide the necessary protection, a respirator must fit tightly. The fit test is a method used to select the right size respirator for the user. OSHA's respiratory protection standard requires a fit test prior to initial use of a respirator, whenever a different respirator facepiece is used, and at least annually thereafter. An additional fit test is required whenever there are changes in the user's physical condition that could affect respirator fit, such as facial scarring, dental changes, cosmetic surgery, or an obvious change in body weight. All employees using either a negative or positive pressure, tight-fitting facepiece respirator must pass an appropriate fit test.

The fit test used depends on the type of respirator and the relative workplace exposure level. There are both qualitative and quantitative fits. In a qualitative fit test, a worker is exposed to an atmosphere containing an odorant, irritant, or taste agent and then asked to breathe normally, breathe deeply, move the head from side to side and up and down, grimace, bend at the waist, and talk. The wearer reports any noticeable odor or taste agent that leaks into the mask.

In a quantitative fit test, a particle-counting instrument is used to measure respirator fit by comparing the dust concentration in the surrounding air with the dust concentration inside the respirator. The ratio of these concentrations is called the fit factor. A modified filter cartridge (or a modified respirator facepiece) equipped with a sample port is used to collect air from inside the respirator. Having the sampler attached, the wearer is asked to make the same movements as described for the qualitative test. During these movements, the particle-counting device measures any leakages.

Every time a respirator is put on, a fit check should be conducted—also referred to as a user seal check—to be sure the respirator forms a complete seal around the face and air cannot leak in or out along the edges. To perform the fit check, the respirator must be put on properly. There should be a firm and comfortable fit against the face at all points.

There are two types of fit checks—the positive pressure check and the negative pressure check. "Positive pressure" refers to the user breathing out and exerting positive pressure on the respirator, and "negative pressure" refers to the user breathing in and exerting negative pressure on the respirator. The fit check must be performed before using a respirator in the field and may also be performed periodically while in the field.

- Positive pressure check—Cover the exhalation valve with your hand, and exhale gently into the facepiece (Figure 6). If a slight positive pressure is built up inside the facepiece without any evidence of leakage, the fit is satisfactory. This test method is the most widely used to check proper fit in the field.

- Negative pressure check—Close off the air inlet valves; that is, cover the cartridges with your hands, inhale gently to collapse the facepiece slightly, and hold your breath for 10 seconds (Figure 7). If the facepiece remains slightly collapsed and no leakage is detected, the respirator fits properly. It may be difficult to get a good seal when trying to cover the inlet valves (cartridges).

Credit: UF/IFAS Pesticide Information Office

Credit: UF/IFAS Pesticide Information Office

Most respirator styles will not provide protection if a beard or other facial hair is present because it does not allow the respirator to seal properly against the face. A person who has facial hair should use a loose-fitting hood or helmet-style respirator. Loose-fitting respirators include powered particulate respirators that constantly pump air through a cartridge or canister into a loose-fitting helmetlike or hoodlike head covering. The positive outward pressure caused by the steady outflow of air prevents contaminants from entering the headpiece. The purified air circulating over the user's head, face, and neck also provides some cooling. These loose-fitting respirators do not have to form a seal on the face, so they do not need a medical or a fit test, and people with facial hair can use them.

Not all loose-fitting respirators move the air at the same rate. Most pesticide handling tasks require a minimum airflow rate of 4 cubic feet per minute. With physically strenuous work, a respirator with an airflow rate of at least 6 cubic feet per minute should be used. Loose-fitting respirators are not nearly as tiring or as hot as face-sealing respirators.

If you are wearing a respirator that filters out dusts and mists, change the filter or respirator when you find it is getting hard to breathe through the respirator or if your filter gets torn, damaged, or wet. Do not use a filtering facepiece dust/mist mask if the pesticide soaks the mask. In this case, use a full-face respirator.

Additional Information

Fishel, F. M. (2012). Personal protective equipment for handling pesticides. PI-28. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/pi061 (Accessed March 2016).

Nesheim, O. N, F. M. Fishel, and M. A. Mossler. (2005). Toxicity of pesticides. PI-13. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/pi008 (Accessed March 2016).