Abstract

Greenhouses require energy to thrive. Most greenhouses require fans, water pumps, heating equipment for operation. A backup generator will keep a greenhouse operational with uninterruptible power supply. When selecting a generator, it is crucial to know how much power the backup generator needs to maintain the essential operations of the greenhouse. Besides, choosing a proper unit and installing and operating it correctly are critical for success. This article provides guidelines for generator selection and operation.

Introduction

An unpredictable power outage can lead to production losses and damage to valuable greenhouse plant material. Successful operation of a greenhouse water well requires the availability of electricity at all times. In the winter, electrical power is needed to run heater fans and controls; in the summer, electricity is needed to operate ventilation fans and to keep double-layered, film-covered houses inflated. An auxiliary power unit can provide insurance against losses or brown outs. A standby power system consists of a generator, an engine or tractor to power the generator, and a transfer switch.

Selection of Unit

It is not always necessary to provide standby power for all greenhouse electrical equipment. The largest users of power are often the water well pump and the ventilation fans. The generator power capacity should be about three times that of the wattage of the largest motor that is to be started, or at least two kilowatts of generator capacity for each brake horsepower as shown on the nameplate of the electrical motors.

When selecting a generator, determine the essential equipment that must be operated at the same time, and calculate the power needed to start and operate that equipment. If short stoppages of some equipment can be tolerated, a smaller generator can be used.

The current needed to run a motor is given on the nameplate attached to the motor, but the starting amperage will be from two to seven times this amount. More than one motor can be operated at once, but they should not all be started simultaneously. Start the largest or most heavily loaded one first.

Generators are rated in terms of kilowatts. You can get an estimate of the amperes that a generator will produce by dividing power in watts by voltage. At 230 volts, a generator of 5 kilowatts will produce 21.7 amperes. (See Equation 1).

The amps rating should also be given on the generator nameplate.

Table 1 gives the starting power requirements of single-phase electric motors. Three-phase motors have lower starting power requirements, so generators supplying power to three-phase motors can be sized to meet the running requirements alone. Follow manufacturers' recommendations to select the appropriate generator for your combination of voltages and single- and three-phase equipment.

Type of Units

The generator may be powered by a stationary engine or by the power take off (PTO) unit of a tractor. Automatic switching systems will require their own power unit. Manual switching systems can be PTO driven or use stationary power plants. If the generator is PTO driven, the tractor must produce two horsepower for each kilowatt of electric power produced by the generator. The use of PTO power reduces the amount of money invested in a system, and the tractor can be used for other greenhouse operations when not being used to drive the generator. Remember, it does take time to hook the tractor to the generator. However if a tractor is not running properly, it is often easier and faster to change tractors than it is to repair or replace a disabled stationary engine.

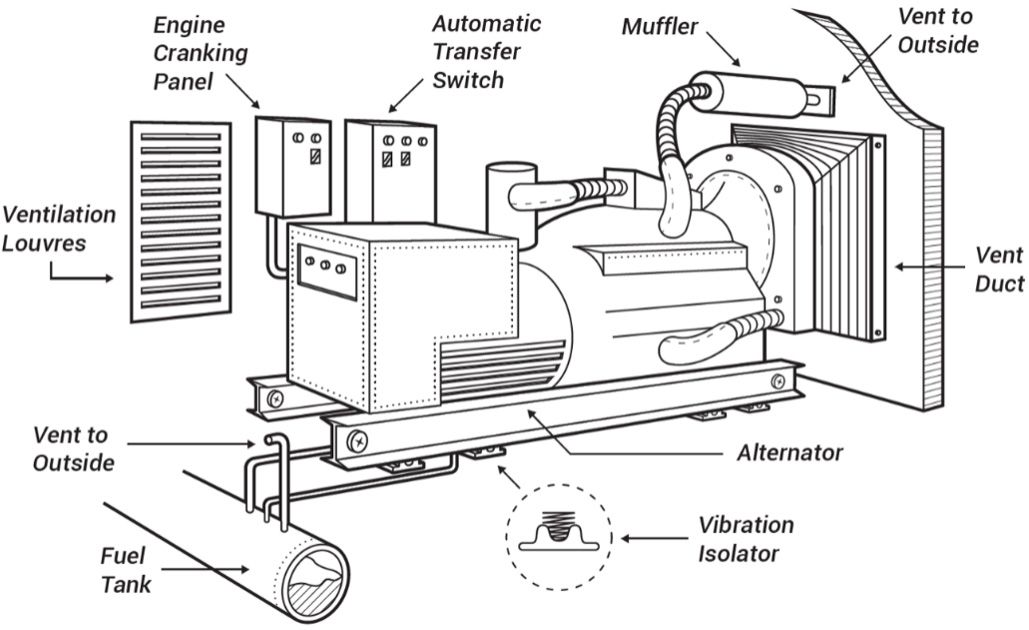

Gasoline, liquid propane (LP) gas, and diesel engines are available to power these units. LP fuels generally burn cleaner than gasoline. This promotes longer engine life and reduces frequency of service. Gasoline tends to form a varnish in the system during storage, which may make starting difficult. Except for very large engines, diesel units cost more initially than gasoline engines of comparable capacity. However, operating and maintenance costs are lower for diesel engines. A typical standby power unit is shown in Figure 1.

Credit: Jean Pompeo, UF/IFAS

The switching mechanism can be either manual or automatic. Automatic switches restore power in a minimum amount of time when power fails, but are expensive. If personnel are readily available to start the generator, a manually controlled system is more economical. Manual switching also makes it possible to use a smaller generator because the operation of equipment should be regulated so that only essential equipment is drawing power.

A standby power system should be completely automatic if critical operations cannot be without power for more than a short time. The generator must have the capacity to handle the starting current of all motors at once. This problem can be eliminated by controlling some motors with time delay relays. They can be set to turn on the motors in sequence to minimize the initial load starting requirements. The cost of this sequencing equipment should be compared to the savings resulting from the reduction in generator size.

Motor Protection

Protect all motors with thermally operated switches that break the circuit if the motor draws too much current. The same type of fuse should be built into the generator.

Installation

When selecting a location for the generator, several factors should be considered.

- Protection from the weather.

- Location near the main service entrance from the power line to minimize wire usage.

- Whether it is to be used on all circuits or only those that supply essential equipment.

Permanently installed, engine-driven electric generators should be mounted on a concrete base. Pads that damp vibrations should be placed between the engine mount and the concrete base to minimize the transfer of vibration to other equipment. If PTO power is used, a location must be selected where the tractor can easily be lined up. Size the wire based on the amount of current carried and the length of the wire. Follow National Electric Code (NEC) guidance when selecting wire sizes and transfer switches.

Use a double-pole/double-throw switch that is approved by NEC to transfer the load to the generator. This type of switch protects service men working on the line from shock, and protects against damage to the generator if the generator is connected to a power line. It is best to employ a professional electrician to wire an auxiliary power unit and transfer switches into your electrical system.

Venting Exhaust Fumes

Engines running on fossil fuels give off exhaust fumes that can damage plant materials and can be poisonous to personnel. If you use a tractor inside a building, use flexible tubing to vent the exhaust gases outside. The exhaust vent from either stationary engines or tractors must be located so that fumes cannot gain entry to the plant growing areas. Make sure that sparks from the exhaust cannot ignite flammable materials.

Operation of Manual Units

Follow manufacturers' recommendations when starting manually-operated standby units. When starting manual units, always turn off or disconnect all electrical loads before starting the unit.

Engage the transfer switch and gradually increase the load on the generator. Start large electric motors first because of their large starting requirements. When commercial power is restored, reduce the loads and return the transfer switch to the normal position. Do not stop the standby unit suddenly; allow the unit to stop freely, because sudden stops can damage the unit.

Care and Maintenance

Auxiliary generating equipment must be properly maintained for satisfactory operation. The generator should be started at least once a month to check for proper operation and recharge starting batteries. Operate the engine long enough to reach normal operating temperature. Oil should be changed and bearings lubricated on a regular basis.

The generator and power plant should be protected from the weather. Also protect equipment from mice and from birds building nests when the generator is idle; a 1/4-inch mesh over ventilating openings is recommended. Avoid lightning damage by grounding the frame of the generator. If the unit is belt driven, frequently check the belts for wear or rot, and use belt guards to prevent accidents. Check the condition of all electrical insulation and test automatic switching units once a week to make sure the unit will start when needed. Do not let fuel stand in unused storage tanks for long periods of times, because undesirable deposits may form.

Alarms

Provide alarms or devices that notify the greenhouse operator at home when power is interrupted. Check the operation of alarms frequently to make sure that personnel will be made aware that power has been lost during an outage. Make sure that alarms monitor all three phases of a three-phase system.

Conclusion

By selecting the proper auxiliary generator, insurance can be provided against loss and damage caused by power outages. This can be done by determining the critical equipment and the amount of power it takes to start the equipment. Install a double-pole/double-throw switch sized to handle the maximum current that will flow through the circuit when connected to the system. Install a generator that has a thermal overload device and has a power rating large enough to handle the critical items that must be used simultaneously. Make sure the system is large enough to provide power to equipment added in the future. Use proper venting techniques with exhaust fumes. Provide fail-safe alarm systems. Obtain the services of a professional electrician to wire your auxiliary power unit into your power system and make sure that your installation meets the requirements of the National Electric Code.