Introduction

Many commercial nurseries begin as small backyard operations, with little thought given to initial or future layout design. Nursery managers are often anxious to realize a rapid return on their investment and overlook the need for thorough nursery layout planning. Nursery managers may worry about nursery expansion or may not have a clear understanding of nursery crop production systems. An inefficient, haphazard layout design may result, requiring a costly change later.

The purpose of this publication is to provide nursery professionals considering expansions or those aspiring to start a nursery business with a framework for planning and implementing efficient nursery layouts. Visits to nurseries with similar production systems are valuable, and discussions with other managers about how they would change their production systems will usually give insight into an effective layout. A slight modification in the proposed design may increase flexibility for future expansion and increase time and motion efficiency.

Nursery Layout

A nursery operation encompasses many different phases and components of production. Proper timing of operations is essential, and efficient use of land and resources is important. Layout design must be efficient if the nursery is to be productive and competitive in today's market. Facilities or activity areas will vary with nursery type and the specific production model employed. For example, a nursery may produce small plants or liners that only require greenhouse space. Other nurseries may purchase liners, making propagation areas unnecessary.

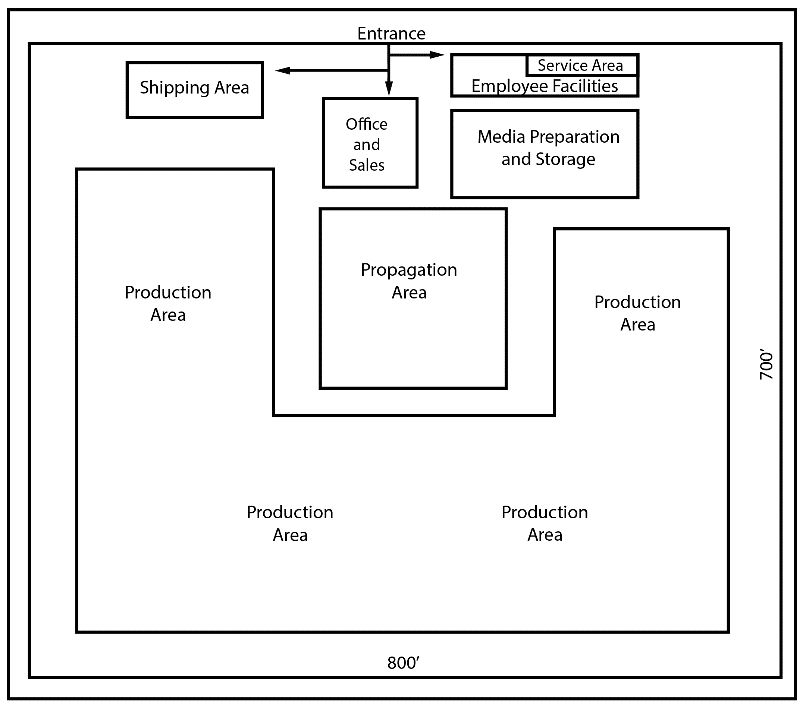

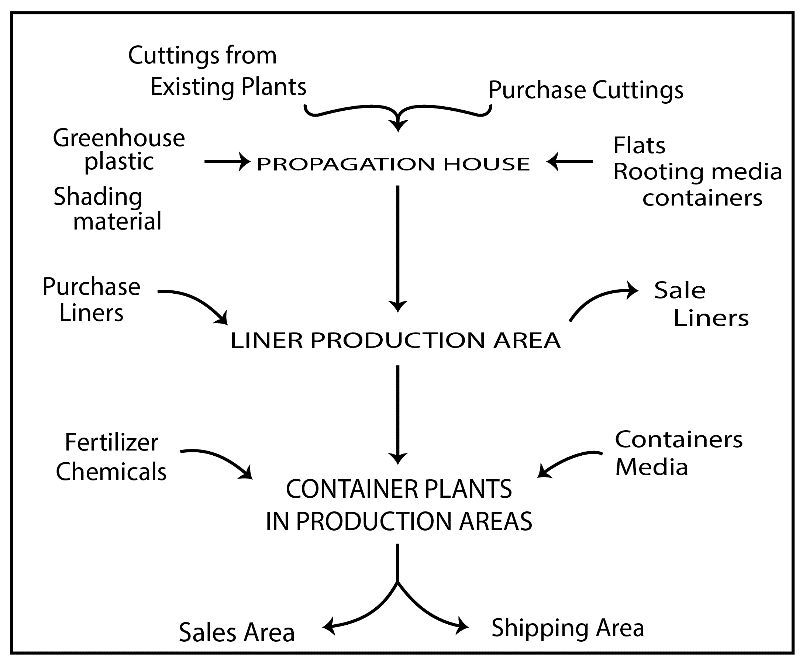

To begin, nursery activities and necessary space should be determined, taking into consideration room for expansion, and possible changes in products or sizes grown. A scaled drawing (Figure 1) of required areas or facilities will ensure nursery activities or operations progress efficiently (Figure 2). Appropriate judgment of distance and arrangement of areas can be achieved when every element is seen on the same scale. Scales where one inch equals 50 to 200 ft are common, but the dimensions of the property and the available drawing supplies and equipment may require other scales.

Credit: UF/IFAS

Credit: UF/IFAS

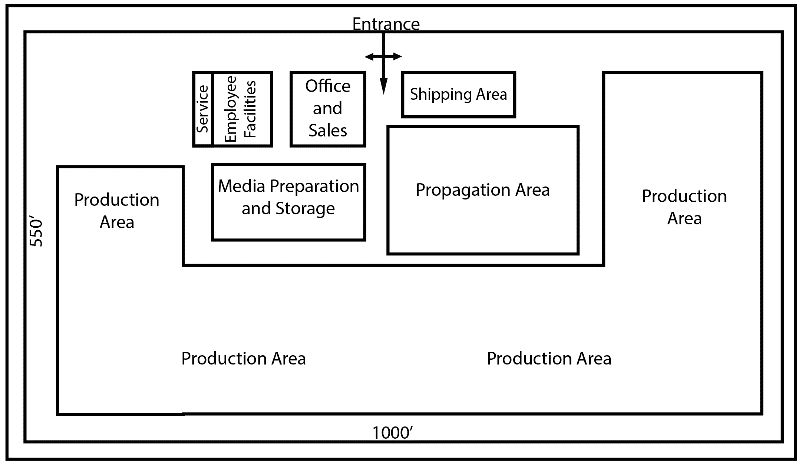

Figure 1 shows an efficient arrangement of the eight areas considered for a container nursery. The arrangement should account for landforms, slopes, natural barriers, and other constraints. The container nursery layout in Figure 1 is adaptable to most land shapes, except for very narrow tracts. The layout for narrow land tracts (Figure 3) requires more time to transport employees to work sites and plants to potting or shipping areas. Labor costs are 25% to 35% of total production costs for the average nursery (Hodges et al. 1997); a large portion of that labor is moving materials. Planning travel routes can improve efficiency. One way to evaluate equipment and personnel movement is to plot the routes on a scaled drawing of the nursery layout so that comparisons of alternative routes can be made. The cost of travel time is of more concern for nursery operations located on non-adjoining land. In this case, strategically locating shipping and potting areas near production areas can help to reduce travel time.

Credit: UF/IFAS

Nursery Entrance

The organization and appearance of a nursery gives visitors and customers an impression of the operation that directly influences sales. The nursery entrance provides the first and most important impression. The entrance should be accessible to the nursery office and shipping areas, and be landscaped with an attractive, uncluttered arrangement of plants. The entrance planting should display any special plant materials offered by the nursery, or plant materials that need to be introduced or emphasized.

Nursery Office and Sales Area

The nursery office should be clearly marked and located close to the nursery entrance (Figure 1). Customer vehicle parking must be available and signs should direct receiving trucks to the loading areas so drivers can proceed without delay. A sales area near the office with a representative display of salable plant materials allows customers to view salable plant material without traveling through the nursery. This saves time for customers and sales personnel.

Propagation Area

The propagation area is the heart of the nursery operation and must be accessible to the production and potting areas. Placing the propagation area close to the office can facilitate communication regarding long-term plant production decisions between office staff and propagation managers. Propagation area, size, and design are determined by irrigation and other infrastructure, the number of plants and species produced, and markets.

The propagation area may contain greenhouse structure designs from A-frame steel and fiberglass to Quonset PVC or galvanized pipe and polyethylene. Steel frame, gutter-connected, or ridge- and furrow-type greenhouses usually cover more than 1,000 sq. ft. conduit; PVC greenhouses usually cover less than 1,000 sq. ft. and cost considerably less than steel frame or ridge- and furrow-type houses. Plant species that require different rooting environments may be segregated using smaller greenhouses. However, several small greenhouses will require more land than one or two larger houses of equivalent square footage. This should be considered if land availability for the propagation area and facilities is limited.

Certain plant species, such as junipers, may be propagated outdoors in small containers or raised ground beds and will not require special propagation structures, but this method is not frequently used. Due to repeated mist cycles or frequent watering, this area must be located on well-drained soil to avoid ponding. Seeds may also be germinated in outdoor beds, although structures built to accommodate tiers or racks of seed-germinating flats will use space more efficiently. Outdoor propagation has the disadvantage of lacking water control. Abundant rain may occur and pack the rooting substrate, disrupting aeration and contributing to soil-borne diseases. Measures for weed-free zones around propagation areas and liner hardening areas should be taken to prevent weed seed dispersal in liner trays. Weed removal from liners or propagation trays is especially labor intensive.

Credit: UF/IFAS

The amount of land available for propagation may determine if plant stock blocks are maintained to supply cuttings. Stock blocks are generally 20% to 25% of the size of container production areas and should be close to the propagation area. Limited land availability requires taking cuttings from salable nursery plants and eliminating stock blocks. Cutting preparation areas may be included in the propagation area of the layout. A protective structure allows cutting preparation during inclement weather. This would be advantageous for a nursery producing large numbers of plants that propagate during the winter. A nursery producing primarily broadleaf evergreens that propagate during the summer may exclude a cutting preparation area from the layout and require cuttings to be prepared for propagation when cut from the plant.

Substrate Preparation and Storage

Substrate mixing and potting may be accomplished at one central location where the potting substrate or substrate components are stored in bulk quantities (Figure 4). The potting substrate or its components are stored either in loose piles or in open bins often made of concrete. Components are usually mixed by commercially available soil mixers, manure spreaders, or front-end loaders that scoop and dump the substrate several times on a concrete slab. A reinforced, raised slab (4 inches thick and 3 yd x 5 yd) will accommodate approximately 3 cubic yards of substrate. The raised concrete slab prevents incorporation of field soil into the substrate during mixing and eliminates contamination from diseases, weed seeds, and nematodes transported by runoff water.

Motorized mixing and transporting systems and potting machines should be protected by the structure that houses a permanent potting area and substrate storage area for the nursery (Figure 4). The permanent potting area may or may not be covered if commercial mixers and potting machines are not used. However, nurseries typically erect a permanent V-shaped hopper from which substrate falls onto a potting bench. The advantages and disadvantages of potting machines will depend on the operation, but many nursery operators agree that potting machines set a pace for employees. Placing the mixing and the potting areas next to each other minimizes substrate handling. A very large operation may have multiple mixing and potting areas throughout the nursery to reduce the distance traveled when placing newly potted plants in the field.

Production Areas

Production or plant growing areas will occupy the largest percentage of nursery land. They should be next to the potting area to facilitate the orderly movement and placement of plants in the field. A small part of the production area may be used for evaluating new plant materials with market potential.

Efficient transport of container plants to and from the field requires a well-designed road system. Roads should be crowned or sloped to one side and surfaced with gravel, shell, or other material to support equipment in wet conditions. Firm road surfaces also prevent traffic from splashing mud and debris on plants.

The number and size of production areas, roads, and walkways may vary depending on the equipment used and type of production. Road widths will depend on the equipment utilized, but when farm tractors and trailers are used, the perimeter roads should be about 30 ft (9.1 m) wide to allow turns from the narrower roads between plant beds.

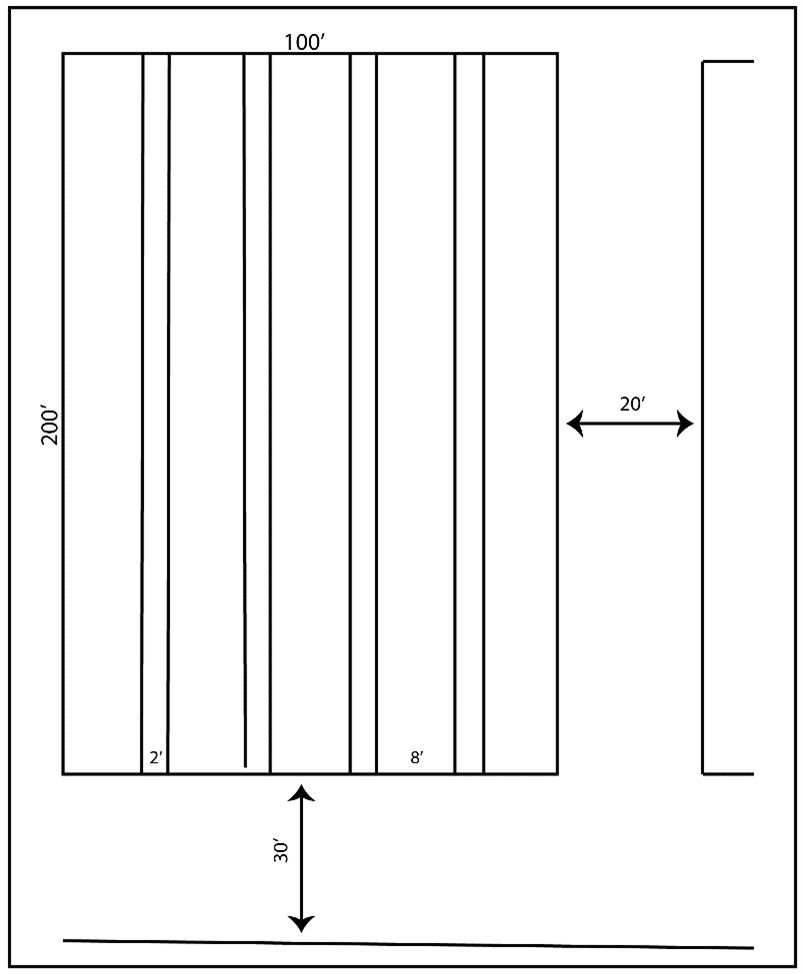

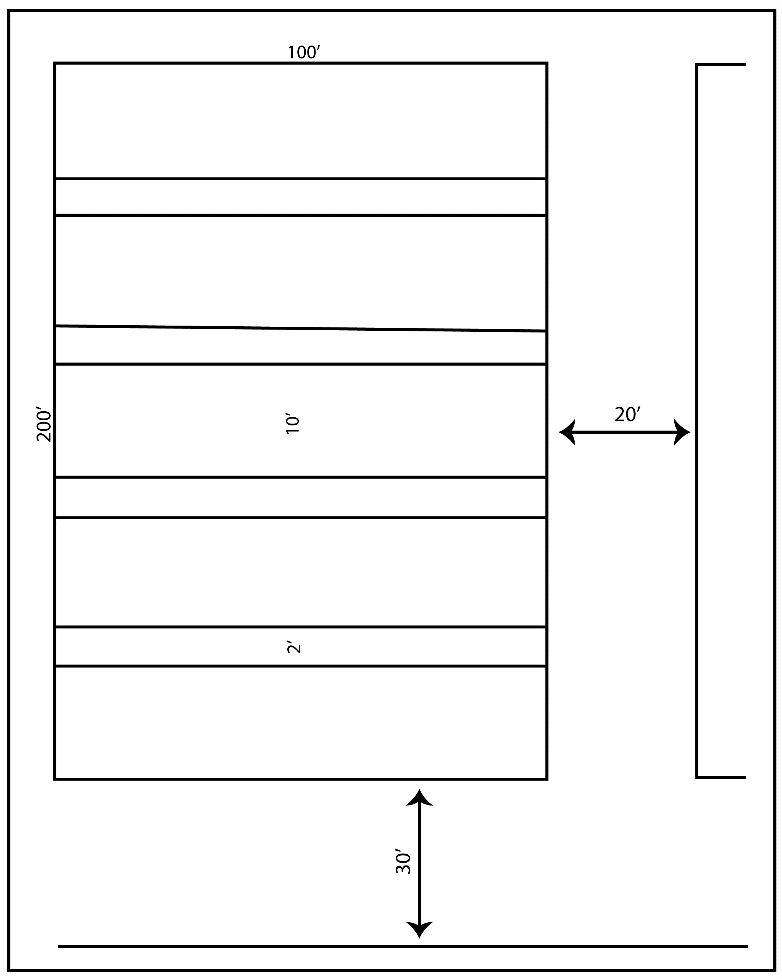

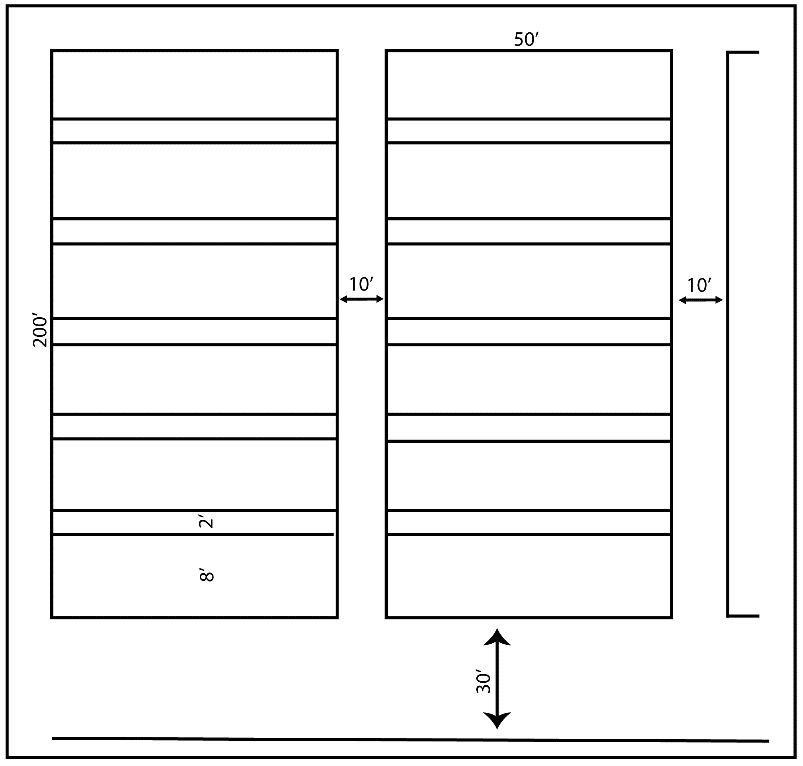

The production area designs in Figure 5, Figure 6, and Figure 7 have walkways that are 2 ft wide and plant beds that are 8 ft wide. Each of the designs has the same overall bed area; however, Figure 6 has half the number of walkways and bed length of Figure 5, and Figure 7 has half the number of walkways and bed length of Figure 6. The maximum distance a plant must be carried is 100 ft, 50 ft, and 25 ft for the designs in Figure 5, Figure 6, and Figure 7, respectively, with average walking distances of 50 ft, 25 ft, and 12.5 ft, respectively. Thus, moving plants in or out of the production beds can be done more efficiently with a design such as the one in Figure 7. Because labor is the most expensive recurring cost, design efficiency for plant transport can engineer savings into the production system over the long term.

Credit: UF/IFAS

Credit: UF/IFAS

Credit: UF/IFAS

Another advantage of the design in Figure 7 is that the perpendicular roads to walkways are not flanked by drainage ditches that must be crossed by personnel and graded periodically for rapid drainage of water. When growing plants in 5-gallon or larger containers, the design efficiency becomes more significant. Production beds in Figure 7 should slope approximately 3% to 4% from the edge of the 10-ft-wide road to the center of the 50-ft-wide production area that slopes toward one end. Runoff water flows on the surface material down the center of the 50-ft-wide production area into a drainage ditch located parallel and beside the 30-ft-wide road. This design may be modified by crowning or sloping to the center of the 50-ft-wide production area and placing a drainage ditch down the center of the 10-ft-wide road for runoff. Severe washing of the road may result if precautions are not taken. Allowing the water to flow across half the road at lined or reinforced intervals and lining the water ditch with concrete or ground cloth may prevent erosion from flowing water.

Production areas in Figure 5 and Figure 6 should be sloped or crowned 3% to 4% to the center along the 200-ft length so that runoff flows toward a 20-ft-wide road on either side of the production area. Ditches between the roads and production areas drain the runoff.

An alternative to crowning the production area (i.e., the center is the highest point or sloped to the center) is to slope the area to one side. The slope begins at the left side and progresses to the right, so the runoff flows into the ditch on the right side of the production area. The road on the right side of a production area slopes toward the ditch on the left side of the road. The ditch may slope to either end of the production area.

Another alternative is to gradually slope production areas from the side roads to the depressed center where water is conveyed either by the groundcover or by pipe to the ditch at the end of the production area. This method keeps roads at the highest point and water directed away with minimal ditches around the production areas. However, drainage pipes must be large enough to minimize clogging.

Production areas are commonly surfaced with gravel, shell, porous polypropylene, or black plastic. Gravel consisting of a particle mixture of 0.25 to 0.75 inches makes an excellent surface on which to place plants, but it is expensive as 100 tons of gravel will only cover about one half acre. Smaller gravel washes away easily, and one-gallon containers do not sit level on larger gravel. Polypropylene and black plastic must be secured around the edges to prevent wind displacement, and equipment driven on these materials may cause tears. Despite precautions, black plastic usually does not last more than two years. Polypropylene may last up to five years, but premature replacement may be necessary depending on the extent of weed intrusion. Natural shade areas on the nursery site may be used as production space. Shade may also be provided by shade structures. Roads and drainage ditches for production areas where shade houses are constructed are usually similar to those of non-shaded areas. Natural shade areas cannot be graded because of possible damage to existing tree roots, so care must be taken to select areas with a 1% to 2% slope. Avoid areas subject to flooding.

Shade structures should accommodate tall pieces of equipment and provide adequate turning space. This aspect is often overlooked. Limbs and/or trees may need to be removed in natural shade areas to aid accessibility.

The layout and dimensions of production areas must be known when designing the irrigation system. Production areas and roads may be modified to maximize irrigation efficiency. Most irrigation systems used in nurseries are permanent overhead delivery systems with impact or rotating nozzles that deliver water in a circular pattern. Irrigation pipes placed on the production area surface are occasionally used. These pipes should be placed parallel with roads for minimal interference with equipment.

Drip or micro-irrigation systems for container production may be used to minimize the total amount of water delivered to plant production areas. These systems efficiently deliver a specified amount of water to each container and must be properly designed to ensure adequate filtration and delivery rates. This may require a specific production area design. The irrigation design of the nursery should be filed for future reference in case irrigation system repairs are necessary.

Provisions for winter protection should be considered when designing container production areas. Winter protection may be provided by pushing containers together during cold periods and placing a protective wrap of paper, fabric, or polyethylene around the perimeter and over the top of the crowded containers. Plants from one or two beds are usually crowded together with the long axis of the group oriented in a north-south direction to minimize plant exposure to northerly winter winds. Placing groups north and south is simplified if plant beds are oriented in a north-south direction.

Quonset houses constructed for cold protection should be located within the production area based on the capacity and size of container plants. For example, approximately 400 one-gallon plants placed on an 8 ft x 50 ft production bed (spaced 1 ft on center) could be crowded together inside an 8 ft x 12.5 ft Quonset house. Therefore, an 8 ft x 25 ft Quonset frame would be erected for two 8 ft x 50 ft beds of plants. However, the use of wider, permanent Quonset structures could interfere with aisle traffic or equipment designed to pass over the tops of plants. Small, portable Quonset houses, usually 6 ft to 8 ft wide with variable lengths and constructed of lightweight materials, can aid in traffic flow.

Overhead irrigation for cold protection does not require a special production area size. However, many nurseries plan for only a portion of the production area to receive overhead irrigation for cold protection. The width and length of production areas may be adjusted to ensure proper irrigation delivery rates and adequate coverage when sprinkling.

Service Area

Equipment storage and repair facilities, along with pesticide, petroleum, and fertilizer storage facilities, comprise the nursery service area (Figure 1). They are usually close to the nursery office yet accessible to supply trucks servicing these facilities. The type of equipment and supplies needing shelter or storage determine the size and type of facilities. Enclosed metal buildings are excellent for repair and maintenance shops and may be used for storage of small pieces of equipment, such as hand sprayers, chain saws, and lawn mowers. Equipment repairs by commercial businesses may be less expensive; in this case, an equipment repair facility in the nursery would be unnecessary. Storage facilities for large pieces of equipment, such as tractors, forklifts, and sprayers, are often open-sided "pole barn"-type structures.

Pesticide storage and mixing facilities should be located in the service area but should be down gradient (around 100 ft) from any wellheads and have a water source that can deliver 20 to 50 gallons per minute to permit rapid filling of pesticide tanks. This capacity may not be available directly from a pressurized water source; however, a raised storage tank with a 2- to 3-inch opening will provide this fill rate for the spray tank. A pesticide storage building must be properly designed and identified as containing poisons.

Employee Facilities

Employee facilities are usually adjacent to the service area. They should be as far as possible from the pesticide storage area (Figure 1). Restrooms, showers, personal lockers, refrigerators, and dining tables are usually provided for employees. Employee parking between the service area and the employee facilities is a convenient arrangement.

Shipping Area

Some nurseries load plants directly from production areas, while other operations have designated loading areas within the nursery where plants are placed prior to shipment. Shipping areas within the nursery require access roads 20 to 25 ft wide with firm surface material and turning space to accommodate 30-ft-long trucks. Placing plants in this area before customer arrival reduces loading time, but irrigation and shade must be provided. Another loading alternative is to build a loading dock. A covered loading dock is preferable because it would permit loading trucks during inclement weather. Most loading docks are 4 ft high and constructed of concrete. The docks should be large enough to accommodate tractors, conveyors, plant racks, and other equipment used in the loading process. Loading docks should be accessible from the public highway and adjacent to the office due to the interaction between the shipping foreman and sales personnel (Figure 1).

Even after the nursery layout design has been implemented, adjustments that would expedite certain production processes are not uncommon. Changes should only be made after careful examination of the available options because corrections to the existing layout design are often difficult to make without interrupting existing production practices. Examine the cost-benefit relationship of the change before acting. If adjustments are not feasible at the time, make notes of the suggested changes and incorporate them later in the existing operation or in the next phase of nursery expansion.

Reference

Hodges, A., L. Satterthwaite, and J. Haydu. 1997. Business Analysis of Ornamental Plant Nurseries in Florida, 1995. Economic Information Report EI 97-3. Gainesville: University of Florida Institute of Food and Agricultural Sciences.