Introduction

Fresh horticultural goods often require drying post-harvest to preserve quality and allow for successful long-term storage of plant material. The Food and Agricultural Organization of the United Nations states that "... freshly harvested agricultural produce is a living thing that breathes and undergoes changes during post-harvest handling," and that post-harvest food losses are classified as a "... modification or decrease of food quantity or quality which makes it unfit for human consumption," (FAO Chapter 2 n.d.). Given the influx of hops (Humulus lupulus) cultivation in the state of Florida, the focus of this publication will be on helping Florida hop growers and hobby brewers efficiently dry hops prior to storage, but these principles can be applied to any high-value horticultural crops that require a post-harvest drying period, such as teas, herbs, and other medicinal or aromatic species.

Shortly after harvest, hops must be used or dried to prevent incidence of mildew and mold growth. Large-scale hop producers purchase or construct large drying facilities, called oasts, to dry their hops. Although effective, oasts are often impractical and unnecessary for small- to medium-size hop producers, to whom few commercial drying apparatuses are available. Recognizing this need, a low-cost drying rig was developed and designed at the UF/IFAS Mid-Florida Research and Education Center (UF/IFAS MREC) to provide effective drying of hops and other horticultural plant material. This drying apparatus can be easily assembled without tools and is ideal for small-scale plant drying needs.

Credit: Sean M. Campbell, UF/IFAS

Moisture Content (MC)

Freshly harvested plant material contains large amounts (greater than 75%) of moisture within the leaves, flowers, and fruit. Referred to as the moisture content of the plant material, it is primarily expressed as a percentage or decimal. Although beneficial and critical to plant functioning, high moisture content present within harvested plant material can lead to development of mildew and mold when stored post-harvest, and can render stored plant material unfit for consumption or use. To reduce potential of mold and mildew, moisture content of plant material must be reduced to within an acceptable level prior to storage.

The FAO recommends a maximum of 13% moisture content in cereal grains to ensure preservation, but values vary dependent upon crop type (FAO Chapter 2 n.d.). For example, hop cones should be dried to a final moisture content of between 8% and 10% for optimal preservation (Brown 2013). To achieve this, one may use heat, forced air, or a combination of both.

Credit: Sean M. Campbell, UF/IFAS

Drying Environment

Harvested plant material quality is influenced by various environmental factors during the drying process, such as heat, air, and light. The drying environment should be carefully designed and controlled, as the post-harvest environment can significantly influence the quality of dried horticultural goods. To help understand the influence of each, descriptions of how heat, air, and light impact dried plant material are presented in the following text.

Heat

Moisture present in harvested plant material can be removed through exposure to high temperatures, often in the 120°F‒130°F range. While effective at removing moisture content, heat can negatively affect compounds important to flavor and aroma characteristics. Like other aromatic plant products, hops are prized for their volatile compounds. If compounds responsible for these attributes are removed or altered during the drying process, they will be less valuable, or unusable, to brewers. The result is dried plant material with little to no aroma or off-flavors that may be described as "grassy" or "muted". To avoid this, moderate temperatures (120°F‒130°F) must be maintained throughout the drying process. Although popular for drying an array of different food products, food dehydrators are often operated at temperatures greater than 135°F.

Ovens and microwaves are a popular low-cost alternative to food dehydrators; however, they often fail to maintain low enough heat levels to prevent degradation of harvested plant material. If heat is utilized in the drying of hops, temperatures must be kept low (less than 130°F) to avoid loss of volatile compounds.

Air

Essential for reducing moisture content from harvested plant material; once an ideal moisture content is obtained for harvested plant material, additional exposure to air should be avoided. Excess or continued exposure to air allows oxygen and moisture to interact and degrade volatile compounds, primarily through oxidation. This reaction can lead to stale or musty aromas. To avoid oxidation, plant material should be placed in airtight packaging and stored in a cool, dry place after being dried to a proper moisture content. Hops should be packaged and stored in multi-layer plastic or mylar vacuum sealed bags as close to drying as possible to prevent excess exposure to air.

Light

Light is often present during the drying process and may be difficult to avoid. Although light can negatively impact quality of harvested material, mainly from exposure to natural ultra-violet (UV) light sources, it often requires long durations of exposure before degradation significantly impacts quality. The most common result of excessive light exposure with hops, or products produced with hops, is the production of unpleasant aromas and flavors. These are often described as skunky, stale, or lightstruck (Beer Sensory Science 2011).

Once proper moisture content is obtained through drying, hops should be packaged and stored in a dark environment to avoid UV light exposure. This is most easily done through storing hops in opaque or non-transparent packaging materials. For this reason, bottled beer is stored, shipped, and sold in dark-colored bottles to avoid or minimize negative impacts of UV light exposure (Beer Sensory Science 2011).

Drying Rig

Given the need for small-scale drying, scientists at the UF/IFAS MREC designed and developed a low-cost drying rig that can quickly and effectively dry plant material to a proper moisture content for storage without the use of heat. By drying plant material quickly and effectively without heat, volatilization reactions are minimized, and aromatic properties of harvested plant material are preserved. The primary use of the drying rig has been to dry hop cones; however, it may be used for an array of plant material where a low-temperature drying environment is required or preferred.

Components

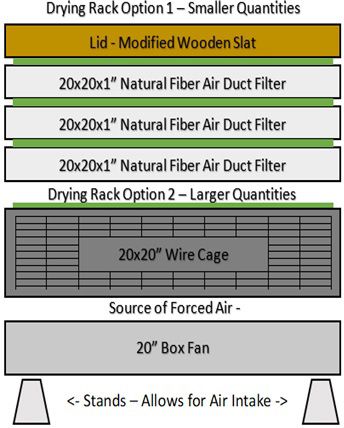

Modifiable depending upon size, shape and quantity of plant material being processed, an effective drying system can be made using a few essential components: a source of forced air, drying racks, and a lid to hold it all down (Figure 1).

Source of Forced Air

The source of forced air can vary based on the application, but most commonly can be a simple and low-cost household fan. The source should be placed either underneath or behind the drying racks, dependent upon design, and should be positioned to allow for maximum air flow. The drying rig illustrated in Figure 1 and 3 is comprised of a 20" box fan (Lasko Power Plus) as its source of airflow. As illustrated, the rig is arranged to discharge airflow upward, allowing ample room for air intake. In the system shown, four stands are placed underneath the fan to allow sufficient air intake. Stands can be any material capable of supporting the weight of the fan while allowing enough clearance. Stands pictured in Figure 1 are comprised of hard plastic measurement cups purchased at a hardware store.

Drying Racks

Selection of drying rack material and its construction is influenced by physical characteristics of the horticultural good being dried. For example, small plant material, such as the leaves of tea or aromatic herbs, requires fine mesh racks to prevent loss of material during drying. Medium-sized plant material, such as hops, can utilize a larger screen mesh size than what is required to dry small crops. Conversely, fine screen size required to dry small crops may impede optimal airflow for larger material. Drying racks illustrated in this guide utilize 20×20×1" natural fiber household air duct filters. Cellulose fiber filters allow for high airflow, no loss of plant material, and are food safe. For larger material, such as whole plants or large plant leaves, a higher airflow should be used along with a low-restriction wire cage constructed from food safe material (Figure 3). While the height of the drying racks can vary, it's important to not exceed the airflow capability of the air source and create excessive restriction within racks. To assess adequate airflow is present, check to ensure air is flowing through the rack furthest from the air source.

Credit: Sean M. Campbell, UF/IFAS

Lid

Force is created by the upwards airflow; thus, a lid is required to hold drying material in place whenever forced air is applied. The lid may be constructed of various materials. A cellulose household air filter may be used as a simple and cost-effective lid. To utilize this lid type, place one 20×20×1" filter on top of the stacked racks and secure it to the air source with cords, string, or a weight. For the rig illustrated, a small 20×20" non-pressure treated wooden pallet was made as the weight. In the case of the wire cage, a lid of the same material should be made. It is important to note that all components, including the weight, must be constructed from food safe material.

Operation

Air Flow

Once constructed, operation of the drying rig is simple and effortless. To prepare the rig for operation, first spread freshly harvested plant material in layers onto racks, ensuring material is not stacked to a depth beyond two or three units high. Layering material beyond this depth within racks will significantly restrict airflow and result in uneven drying. A proper depth for hops is approximately 2‒3 layers of cones. In the system shown in Figures 1 and 3, drying racks are placed on top of the fan, and then held into place by a lid. Most commercially available fans come with a control for fan speed. The drying rig may be operated at any speed, with medium airflow rates recommended, as high air flow rates can dry the plant material too rapidly.

Drying Time

Drying time depends on various factors, including airflow rate, depth and moisture content of harvested plant material, rack design, and ambient air temperature and humidity. Estimated drying time of three to four 20×20×1" cellulose racks with freshly harvested hops arranged to a depth similar to that illustrated in Figure 3, is approximately 24 hours. Drying should continue until harvested plant material reaches target moisture content as determined through sample measurements, which is explained next.

Percentage Moisture Content (% MC)

Moisture content of harvested plant material must be reduced to prevent formation of mildew and mold during storage. Dried % MC target values vary by crop, with hops requiring a % MC of between 8% and 10% by weight. To determine when sufficient drying has been achieved, a few simple calculations can be used. To accomplish this, you will need a scale that ideally is capable of measuring hundredths of a gram (0.01g) and a method to dry plant material. Steps necessary to calculate % MC of plant material are listed below:

Step 1. Dry a Representative Sample of Harvested Plant Material: Moisture content is expressed as the percent of water within plant material. In order to dry plant material to a specific % MC, you will first need to dry a small representative sample of your harvested plant material to calculate initial % MC. As this sample will be destroyed in the process, it is recommended to use roughly 10‒20 cones to accomplish this. Take your small representative sample of undried, freshly harvested plant material, place it on a scale, and record its weight. This weight will be recognized as the initial harvested weight. Next, place the material within a food dehydrator or oven at low temperature (120°F‒140°F) and let it dry at one-hour intervals, stopping each hour to inspect the material to ensure it does not burn or brown. As a faster alternative to this method, a microwave oven may be used. If using a microwave, it is important that the material be heated in short intervals (30 sec to 1 min) and allowed to cool between intervals to avoid burning of plant material. Between intervals, reweigh plant material and record its weight. Repeat this several times until the mass does not decrease between drying intervals. Once you have reached a consistent weight (additional drying time does not result in a decrease in plant material weight) across three consecutive weighings, the plant material has no moisture present and has reached 0% MC (FAO Chapter 16 n.d.).

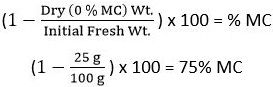

Step 2. Calculate Moisture Content in Freshly Harvested Material: To determine % MC of freshly harvested material, we will use the previously collected weight data to perform a simple calculation. Begin by dividing final dry weight (weight at 0% MC) by recorded initial weight (weight before drying). For example, if the dry weight of hops is 25 g and the initial weight was 100 g, we should calculate a value of 0.25. Subtract this value from 1 and multiply the difference by 100 to determine % MC of the initial, freshly harvested material. To continue with our example, subtract 0.25 from 1, which equals 0.75, and then multiply this by 100. If done correctly, we should arrive at a value of 75% MC as illustrated in the mathematical calculation below:

Results of this calculation inform us that our initial % MC was equal to 75%. For hops, % MC must be between 8% and 10% before packing to eliminate concern of mildew and mold during storage.

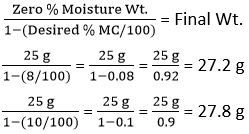

Step 3. Calculate Target Weight for Desired % Moisture Content: Having determined the initial % MC of the harvested material, we can now calculate the range of target weights needed before plant material can be packaged and stored. To determine this, we need to identify the range of desired % MC for the dried material. For example, with hops, the range of final target % MC is between 8% and 10%. Using this information, we can calculate the range of target weights using previously collected data. To accomplish this, start by dividing the lower range of desired % MC (8% in our example) by 100. Then, subtract this value from 1. Next, divide the previously calculated dry weight of material (25 g in our example) by this value to determine the expected weight of our sample when it reaches 8% MC. Repeat these steps using the upper range of the desired % MC (10% in our example). If calculated correctly, our initial mass of 100 g of hops should weigh between 27.2 and 27.8 g when moisture content is between 8% and 10% as illustrated by the mathematical calculation below:

In this example, if we start with 100 g of freshly harvested hops and dry them in preparation for packaging and storage, we would want to stop drying once our original 100 g sample weighs between 27.2 and 27.8 g to achieve between 8% and 10% MC (Brown 2013).

Credit: Sean M. Campbell, UF/IFAS

Credit: Sean M. Campbell, UF/IFAS

Storage

Once the plant material has reached the target % MC, the dried materials should be placed in an airtight container or package, then stored in a cool, dark, dry place until ready for use. This procedure is outlined in the EDIS publication Packaging and Storage of Hops (Humulus lupulus) (https://edis.ifas.ufl.edu/publication/ep561).

References

Beer Sensory Science. 2011. "Lightstruck." https://beersensoryscience.wordpress.com/2011/03/17/lightstruck/

Brown, Diane. 2013. Drying Hops on a Small Scale. Michigan State University Extension. pp. 1‒4. https://www.canr.msu.edu/news/drying_hops_on_a_small_scale

FAO. "Chapter 2 - Post-Harvest System and Food Losses." https://www.fao.org/3/ac301e/ac301e03.htm

FAO. "Chapter 16 - Grain crop drying, handling and storage." http://www.fao.org/docrep/015/i2433e/i2433e10.pdf

Acknowledgements

Alton Brown. The MREC drying rig is based off a design featured on season 9, episode 1 of his show "Good Eats", entitled "Urban Preservation II: The Jerky".