Introduction

Weed management in container plant production is a serious problem and remains one of the most expensive and time-consuming aspects of the plant nursery industry. Due to the confined growing environment within containers, weeds have the potential to decrease the growth of ornamental crops by over 60%, subsequently extending the production time (Fretz 1973). Weeds compete for light, water, nutrients, and space, which ultimately results in decreased crop growth and yield. Even when weed competition is not a primary concern, consumers still expect containers to be free of weeds.

Weed management in container nurseries is primarily based on the use of timely preemergence (PRE) herbicides and supplemental hand weeding. While the use of herbicides is an effective method for weed control, there can be downsides such as the ongoing cost of chemicals and applications, potential concerns regarding recycled irrigation water (Poudyal and Cregg 2019) and adequate labor available to apply the herbicides on time, among other site-specific issues that may arise. However, the most challenging issue with PRE herbicides is often crop safety, especially when considering tropical plants, ferns, succulents, and many other herbicide-sensitive crops commonly produced by Florida growers. Additionally, for growers who produce fruit trees, blueberries, or other fruits for the retail market, herbicide labels typically preclude application on bearing plants or for up to 12 months before fruit can be harvested. Due to these concerns, nursery growers are gradually implementing more non-chemical methods for weed management. Among the most commonly adopted non-chemical approaches in recent times is the utilization of mulch.

This publication serves as a guide for nursery growers, covering the best practices on mulching, and discusses mulch types, application techniques, cost, and management practices in container plant production. For more information, visit EDIS publication #ENH1361, “Mulching Herbs, Vegetables and Fruit Trees in the Florida-Friendly Edible Landscape” (https://edis.ifas.ufl.edu/publication/EP625).

Mulch and Its Benefits

Mulch is defined as any material placed or applied in a layer onto the soil's surface (Crutchfield, Wicks, and Burnside 1986). Mulching provides many benefits in the landscape including minimizing soil erosion, improving soil moisture retention, regulating soil temperature, increasing soil organic matter, promoting plant establishment and growth, supporting root development, providing food and shelter for earthworms, and stimulating microbial activity in the soil (Chalker-Scott 2007; Cregg and Schutzki 2009; Foshee et al. 1996; Maggard et al. 2012). While these benefits are noteworthy, the primary use of mulch in container plant production is for weed control.

The precise mechanism through which different types of mulch control weeds varies depending on the specific mulch material and target weed species (Chalker-Scott 2007). In general, research has shown the main factors contributing to weed control include light exclusion (Teasdale and Mohler 2000), decreasing available air and water for germinating weed seeds (Richardson et al. 2008), and creating a physical barrier (Chalker-Scott 2007). Many different types of mulch are currently available that offer one or more of these characteristics and can be successfully implemented into an integrated weed management program.

Mulch Types

Mulch is categorized into organic and inorganic materials. Organic mulch may consist of rice hulls, pine bark, wood chips, wood shavings, coconut coir, nut (peanut, pecan) shells, oyster shells, cacao bean hulls, pelletized newspaper, recycled wastepaper, pine straw, and others. Inorganic mulching materials include rocks, gravel, shredded rubber, recycled tires, and other possible waste byproducts. Based on available research, it is recommended to avoid using inorganic mulches in container plant production. Rubber mulches have been linked to the leaching of heavy metals such as zinc, selenium, lead, and cadmium, which have caused reduced growth in some ornamental plants (Kanematsu et al. 2009). Additionally, rocks, gravel, and stones would make the containers heavy and impractical or cost-prohibitive for transportation.

The optimal mulch materials for container production should possess several key characteristics: minimally available nutrients, the ability to dry rapidly despite frequent irrigation, ease of application, slow decomposition rates, non-toxicity to both humans and crops, and aesthetic appeal for customers. There exists a wide range of organic mulch materials. The choice of mulch materials depends on their availability, their cost based upon the region, how consistently they can be obtained, and whether they meet desired quality standards.

Credit: Yuvraj Khamare, UF/IFAS

The commonly used mulch materials in container plant production include pine bark (or other types of bark), rice hulls, and wood chips (Figure 1). Pine bark and other tree-derived mulch materials often have comparatively large particle sizes, low levels of available nutrients, and somewhat hydrophobic properties, all of which create an environment that is not favorable for weed germination and growth (Richardson et al. 2008). Similarly, rice hulls are known to be hydrophobic, and their inability to retain water is a primary mechanism by which they suppress weeds (Altland, Boldt, and Krause 2016). Rice hulls are also very lightweight, can be shipped fairly economically, and can be applied using several different types of equipment specifically designed for rice hull application.

Wood chips are typically inexpensive, renewable, convenient, and locally available. Generally, larger particle sizes offer enhanced weed control by significantly reducing light penetration and facilitating faster drying, as opposed to smaller particle-sized material (≤ 0.5 inch) or “shredded” wood products. On the other hand, fine-textured materials are unsuitable for weed control and may even serve as a source of weed seeds, leading to increased weed germination (Chalker-Scott 2007). Fine-textured materials have the capacity to retain larger amounts of water, as reducing particle size leads to smaller but more numerous pores. Nutrient-dense materials, like compost, are also unsuitable for weed control since they can increase weed germination and benefit weed growth in some instances. Several studies have indicated that many weed species are more responsive than crops to soil with higher nutrient levels (Blackshaw, Molnar, and Larney 2005).

In addition to the previously discussed materials, there are various less commonly used mulch materials in container production, including utility mulch, fallen leaves, pine straw, grass clippings, recycled paper, and sawdust (Figure 2). Utility mulch is often obtained for free or at a low cost through utility companies or tree services involved in clearing branches for utility lines or development purposes. However, utility mulch may not be suitable for containers as it may contain weed seeds, leaves, and dirt. Similarly, pine needles are a popular choice for landscaping, but they are not ideal for container production as they settle and decompose quickly (Rainey et al. 2022).

Credit: Chris Marble, UF/IFAS

An alternative approach to traditional mulching involves using weed discs made from materials such as paper, jute, black polyethylene, fiberglass, wool, coco coir, various fabrics, or biodegradable plastic (Figure 3). These circular container discs match the diameter of the container surface, blocking light and serving as a physical barrier. The disc features a single cut to allow insertion around the stem of the container-grown crop. Weed discs, however, are not widely adopted due to factors such as high cost, application difficulty (especially for multi-stem plants or when using multiple liners in one pot), and limited availability (Chong 2003).

Credit: Yuvraj Khamare, UF/IFAS

There are no mulch types that are 100% effective against all weed species, so some growers might combine preemergence herbicides and mulch in order to increase control or provide more flexibility when scheduling herbicide applications. This approach combines the physical barrier properties of mulch with the chemical control of herbicides to reduce the amount of herbicide required, decrease herbicide-leaching, and provide a slow-release carrier for the herbicides (Derr 1994; Samtani et al. 2007).

When combining herbicides and mulch together, preemergence herbicides can be applied either before or after mulch is applied. When targeting seeds already in the container substrate, greater control may be achieved by applying herbicides prior to mulch application. However, in most cases, the container potting soil will be relatively free of weed seeds at potting. Moreover, applying herbicide after the mulch application is more likely to be effective on weed seeds that are blown into the pots over time. Increased control over the use of herbicides or mulch alone has been observed regardless of herbicide timing (Saha et al. 2019).

Researchers have also investigated the use of herbicide-treated mulches in containers. In this scenario, the mulch is pre-treated with an herbicide, and then the mulch is applied to container-grown plants. This practice can be effective, but the mulch must be handled as if it were a pesticide (e.g., proper personal protective equipment must be worn), and it is usually not feasible to pre-treat mulch at a commercial scale.

Mulch Application

Research has shown that the depth of mulch in a container can significantly influence the success of weed control. It is recommended to apply mulch at a depth ranging from 1 to 2 inches, as this has been shown to achieve effective weed control while also minimizing costs. For example, Bartley et al. (2017) found that applying pine bark nuggets at a 2-inch depth led to 99.5% control of spotted spurge and eclipta. Similarly, rice hulls applied at a depth of either 1 or 2 inches resulted in a nearly 100% control of flexuous bittercress (Cardamine flexuosa) and liverwort (Marchantia polymorpha) (Altland and Krause 2014). However, the depth of mulch should vary depending on the size of the container. Applying a 2-inch layer of mulch in a 1-gallon container would lead to a significant 27% reduction in substrate volume, which could reduce the growth of some plants and limit their potential for root growth. For this reason, depths of 0.5 to 1 inch are typically used in smaller pots.

While the majority of container plant production relies on liners propagated through cuttings, mulching can enhance seed germination and seedling survival when starting plants from seeds, but it is highly specific to mulch and plant species. When starting plants from seed, it is advisable to use a thinner layer of mulch, preferably after seeding. Deeper mulches are great for weed control but not a great choice for propagating plants by seed. Once seedlings have emerged, mulching has been shown to enhance both their growth and survival rates (Chalker-Scott 2007).

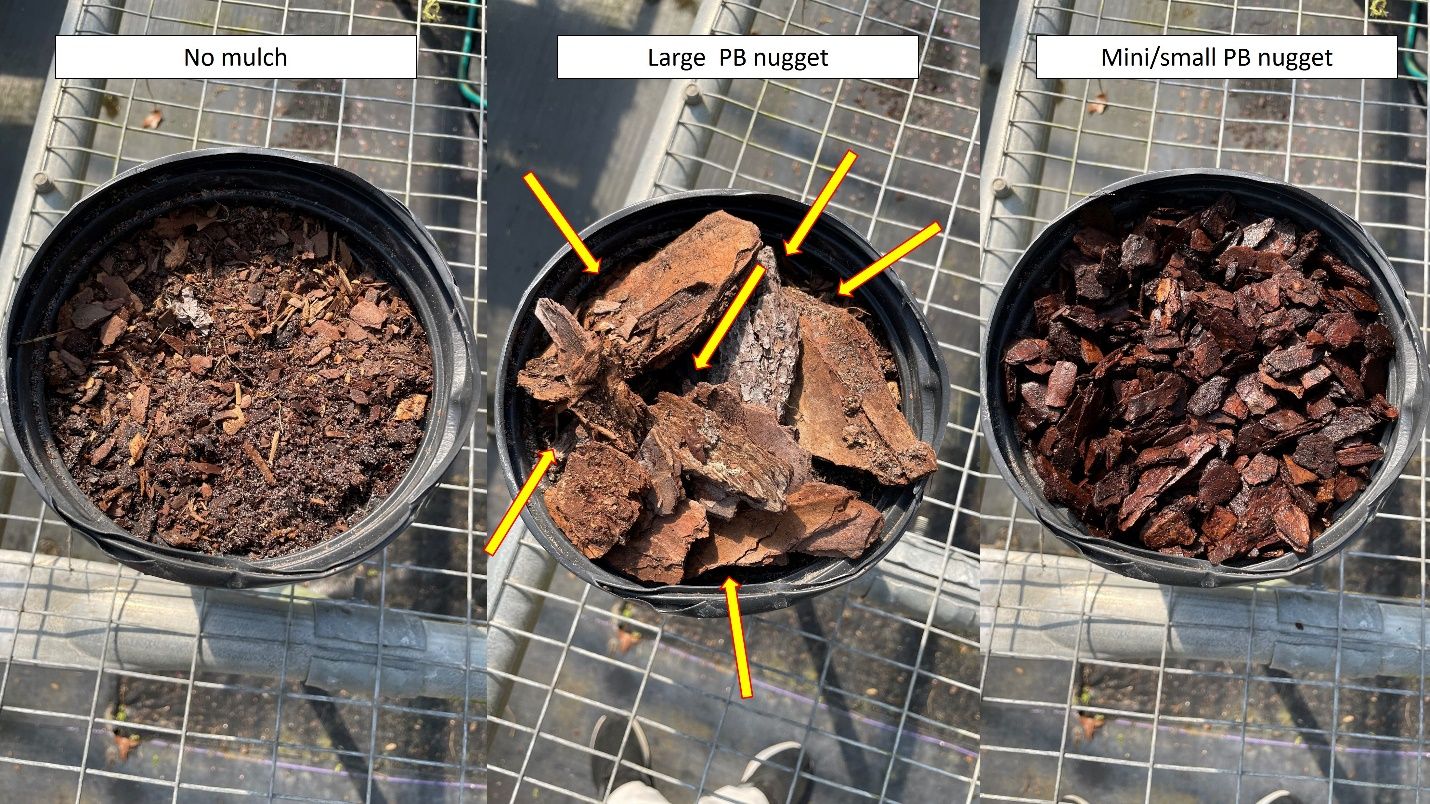

Generally, employing coarse mulches with larger particle sizes that are placed at a depth adequate to cover the container media surface would achieve optimal weed control. These larger particles block more light and facilitate quicker drying compared to smaller particles. However, this is largely dependent on the type of mulch material. For example, rice hulls can adequately cover the container surface with just a 0.5-inch application, while larger pine bark nuggets require a 2-to-3-inch depth to achieve complete coverage. It is crucial to note that large pine bark nuggets or wood products with large particle material may not be suitable for smaller containers (e.g., 1 gallon) as they leave gaps between the nuggets, allowing weed seeds to germinate (see Figure 4). Additionally, choosing a reputable and certified source of mulch can reduce the risk of weed contamination.

Credit: Chris Marble, UF/IFAS

Homeowners can usually buy mulch in bags, typically containing 2 or 3 cubic feet of mulch per bag. In the case of container nurseries or larger projects, opting for bulk mulch sold by the cubic yard is a more cost-effective choice. Determining the amount of mulch needed to cover a container at a 2-inch depth involves calculating the area of the container's surface.

To find the area, measure the pot’s diameter, and then divide that number in half to determine the radius, which is the distance from the center to the edge of the container. You then square the radius and multiply by 3.14. For instance, if the radius of a 1-gallon container’s surface is 3.3 inches, the required mulch would be calculated as follows: 3.3 inches × 3.3 inches × 3.14 = 34.2 square inches or 0.23 square feet. (Square feet is calculated by dividing square inches by 144.)

Once the area of the pot is determined, multiply it by the depth of mulch desired (in this case, 2 inches) to get cubic inches, a volume calculation: 34.2 square inches (area of the pot) × 2 inches (desired mulch depth) = 68.4 cubic inches or 0.04 cubic feet. (Cubic feet is determined by dividing cubic inches by 1,728.)

The next step would be determining how many pots you need to mulch. For this example, we will say 1,000. In this case, you would need 0.04 cubic feet of mulch × 1,000 pots = 40 cubic feet of mulch. Since you will most likely be purchasing mulch in cubic yards, convert to cubic yards by dividing cubic feet by 27: 40 cubic feet ÷ 27 = 1.48 cubic yards of mulch that is needed to mulch 1,000 1-gallon pots at a 2-inch depth. While the cost of mulch may seem high compared to herbicides, it can become economical in the long run by minimizing expenses associated with hand weeding, reducing the required amount of herbicide in a season, and lowering labor costs for herbicide application. As an illustration, the retail price of mini pine bark nuggets, ranging from 1.5 to 3 inches in particle size, is $4.25 for a 3-cubic-foot bag. In contrast, the bulk price for the same mulch by the cubic yard is $35. See Tables 1, 2, and 3 for estimates of pine bark, hardwood mulch, and parboiled rice hulls from current retail pricing, which can vary significantly depending on the location and quantity.

Table 1. Mini pine bark nuggets (1-to-3-inch particle size) cost estimate applied at either 1- or 2-inch depth in four different container sizes.

Table 2. Hardwood chips blend cost estimate applied at either 1- or 2-inch depth in four different container sizes.

Table 3. Parboiled rice hulls cost estimate applied at either 1- or 2-inch depth in four different container sizes.

For comparison, a standard preemergence herbicide application can cost less than $0.01 per container for each application (in chemical cost), but as preemergence herbicides are typically broadcast, over 50% of what is applied may fall outside of the container, unavailable for weed control, which can increase costs significantly (Gilliam, Fare, and Beasley 1992). Mulch becomes more economical when 1) herbicides cannot be used due to crop safety issues and hand weeding becomes the only recourse; 2) longer-term plants are being grown (one or more years in production), so there is more time to recoup the cost of mulch, and more herbicide applications can be eliminated; and 3) herbicide applications are often missed due to labor shortages or inclement weather resulting in weed control failures.

Drawbacks of Mulching

Organic mulch materials may come with potential drawbacks, such as their rapid degradation and requiring reapplication for longer-term nursery crops. This can lead to higher material costs and increased labor demands during the mulching process. Placing mulch against the trunks of container-grown plants may pose another concern, as it could elevate the risk of pest pressure, particularly pathogens, if irrigation is not managed properly. Applying mulch at a depth of 4 inches or more can negatively impact plant growth due to reduced soil aeration and slower soil warming (Greenly and Rakow 1995). Additionally, there's a disadvantage associated with the potential loss of material, whether through container blow-over or the susceptibility of lighter materials like rice hulls or sawdust to be carried away by strong winds or heavy rain. When mulch is lost due to wind or pot blow-over, it must be reapplied, which is much more costly than reapplying a preemergence herbicide.

Summary

There are many benefits to using mulch as part of a weed control program in container nursery production. While expensive, mulch can serve as an effective substitute for preemergence herbicides in container plant production in many different scenarios. Like other weed control methods, mulch may not provide 100% weed control. Although, it does provide major benefits when herbicides cannot be used and can enhance the sustainability of container plant production.

References

Altland, J. E., J. K. Boldt, and C. C. Krause. 2016. “Rice hull mulch affects germination of bittercress and creeping woodsorrel in container plant culture.” American Journal of Plant Sciences 7 (16): 2359–2375. https://doi.org/10.4236/ajps.2016.716207

Altland, J., and C. Krause. 2014. “Parboiled rice hull mulch in containers reduces liverwort and flexuous bittercress growth.” Journal of Environmental Horticulture 32 (2): 59–63. https://doi.org/10.24266/0738-2898.32.2.59

Bartley, P. C., G. R. Wehtje, A. M. Murphy, W. G. Foshee, and C. H. Gilliam. 2017. “Mulch type and depth influences control of three major weed species in nursery container production.” HortTechnology 27 (4): 465–471. https://doi.org/10.21273/HORTTECH03511-16

Blackshaw, R. E., L. J. Molnar, and F. J. Larney. 2005. “Fertilizer, Manure and Compost Effects on Weed Growth and Competition with Winter Wheat in Western Canada.” Crop Protection 24 (11): 971–980. https://doi.org/10.1016/j.cropro.2005.01.021

Chalker-Scott, L. 2007. “Impact of Mulches on Landscape Plants and the Environment—A Review.” Journal of Environmental Horticulture 25 (4): 239–249. https://doi.org/10.24266/0738-2898-25.4.239

Chong, C. 2003. “Experiences with Weed Discs and Other Nonchemical Alternatives for Container Weed Control.” HortTechnology 13 (1): 23–27. https://doi.org/10.21273/HORTTECH.13.1.0023

Cregg, B. M., and R. Schutzki. 2009. “Weed control and organic mulches affect physiology and growth of landscape shrubs.” HortScience 44 (5): 1419–1424. https://doi.org/10.21273/HORTSCI.44.5.1419

Crutchfield, D. A, G. A. Wicks, O. C. Burnside. 1986. “Effect of Winter Wheat (Titicum aestivum) Straw Mulch Level on Weed Control.” Weed Science 34 (1): 110–114. https://doi.org/10.1017/S0043174500026564

Derr, J. F. 1994. “Innovative Herbicide Application Methods and Their Potential for Use in the Nursery and Landscape Industries.” HortTechnology 4 (4): 345–350. https://doi.org/10.21273/HORTTECH.4.4.345

Foshee, W. G., W. D. Goff, K. M. Tilt, J. D. Williams, J. S. Bannon, and J. B. Witt. 1996. “Organic mulches increase growth of young pecan trees.” HortScience 31 (5): 811–812. https://doi.org/10.21273/HORTSCI.31.5.811

Fretz, T. A. 1973. “Herbicide-Impregnated Mulches for Weed Control in Container Nursery Stock.” Scientia Horticulturae 1 (2): 165–170. https://doi.org/10.1016/0304-4238(73)90027-7

Gilliam, C. H., D. C. Fare, and A. Beasley. 1992. “Nontarget Herbicide Losses from Application of Granular Ronstar to Container Nurseries.” Journal of Environmental Horticulture 10 (3): 175–176. https://doi.org/10.24266/0738-2898-10.3.175

Greenly, K. M., and D. A. Rakow. 1995. “The Effect of Wood Mulch Type and Depth on Weed and Tree Growth and Certain Soil Parameters.” Journal of Arboriculture 21 (5): 225–225. https://doi.org/10.48044/jauf.1995.036

Kanematsu, M., A. Hayashi, M. S. Denison, and T. M. Young. 2009. “Characterization and Potential Environmental Risks of Leachate from Shredded Rubber Mulches.” Chemosphere 76 (7): 952–958. https://doi.org/10.1016/j.chemosphere.2009.04.026

Maggard, A. O., R. E. Will, T. C. Hennessey, C. R. McKinley, and J. C. Cole. 2012. “Tree-based mulches influence soil properties and plant growth.” HortTechnology 22 (3): 353–361. https://doi.org/10.21273/HORTTECH.22.3.353

Poudyal, S. and B. M. Cregg. 2019. “Irrigating Nursery Crops with Recycled Run-off: A Review of the Potential Impact of Pesticides on Plant Growth and Physiology.” HortTechnology 29 (6): 716–729. https://doi.org.10.21273/HORTTECH04302-19

Rainey, D., E. Momol, J. Marvin, T. Wichman, C. Marble, L. Barber, and S. Haddock. 2022. “Florida-Friendly Mulches and Their Uses: EP626/ENH1362, 12/2022.” EDIS 2022 (6). https://doi.org/10.32473/edis-EP626-2022

Richardson, B., C. H. Gilliam, G. Fain, and G. Wehtje. 2008. “Nursery Container Weed Control with Pinebark Mininuggets.” Journal of Environmental Horticulture 26 (3): 144–148. https://doi.org/10.24266/0738-2898-26.3.144

Saha, D., S. C. Marble, B. J. Pearson, H. E. Perez, G. E. MacDonald, and D. C. Odero. 2019. “Mulch Type, Depth, Herbicide Formulation, and Postapplication Irrigation Volume Influence on Control of Common Landscape Weed Species.” HortTechnology 29: 65–77. https://doi.org/10.21273/HORTTECH04208-18

Samtani, J. B., G. J. Kling, H. M. Mathers, and L. Case. 2007. “Rice Hulls, Leaf-Waste Pellets, and Pine Bark as Herbicide Carriers for Container-Grown Woody Ornamentals.” HortTechnology 17 (3): 289–295. https://doi.org/10.21273/HORTTECH.17.3.289

Teasdale, J. R., and C. L. Mohler. 2000. “The Quantitative Relationship Between Weed Emergence and the Physical Properties of Mulches.” Weed Science 48 (3): 385–392. https://doi.org/10.1614/0043-1745(2000)048[0385:TQRBWE]2.0.CO;2