Introduction

During and after harvest, ornamental fish are visually inspected for quality (see UF/IFAS Fact Sheet FA-117, Harvesting Ornamental Fish Ponds, https://edis.ifas.ufl.edu/FA117). Quality is determined by a number of desirable characteristics. These characteristics include size, color, fin development, and sex, as well as indicators of health such as scale loss, torn fin rays, eye damage, and parasite load. This time-consuming selection process is known as grading.

During grading, the farmer must keep in mind the quality requirements set by each buyer. Size is the main characteristic considered when grading for a marketable fish (e.g., small, medium, or large). A farmer can grade fish for size visually by hand or with a mechanical grader. Grading fish mechanically allows the farmer to select marketable fish by the net-full as opposed to one at a time by hand. After grading fish for size, color is the next important consideration. A commonly used procedure is to grade mechanically for size first, and next to grade by hand for color and other characteristics. Grading can occur on the pond bank or inside a holding facility. Careful handling during grading is important for minimizing stress (see UF/IFAS Circular 919, Stress-Its Role in Fish Disease, https://edis.ifas.ufl.edu/FA005) and maximizing the quality of harvested fish.

After a partial harvest, the producer should carefully consider the genetics of the remaining fish. During production of live-bearing species such as the swordtail, a population of fish may be kept in a pond for two or more years resulting in a group of fish sizes ranging from fry to older adults. Many live-bearers are sexually mature in only a few months and inbreeding often occurs. Consequently, culling (removing undesirable fish from a population) helps maintain favorable traits in the population and prevents low fecundity, stunted growth, and poor quality.

The amount of time spent grading fish is dependent on available manpower (number and skill) and equipment as well as the specific characteristics that are being considered.

Methods

Mechanical Grading

Mechanical graders are used to separate large numbers of fish quickly into desired size categories. This technique minimizes the time required for size grading. A mechanical grader is a box with a grate(s) that has floats built into its sides allowing the grader to float near the surface of the water. As harvested fish are placed into the grader, small fish swim through the grates and larger fish are retained. The grader can also be moved gently up and down or side to side in the water to facilitate this process.

Mechanical graders are made of metal (i.e., aluminum, stainless steel, galvanized steel, or zinc-coated steel). The space between the bars in the grate determines the size of fish retained in the grader. This gap or space is usually expressed in millimeters.

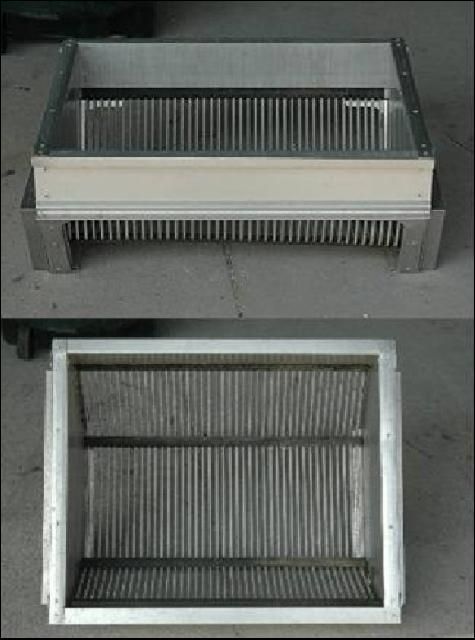

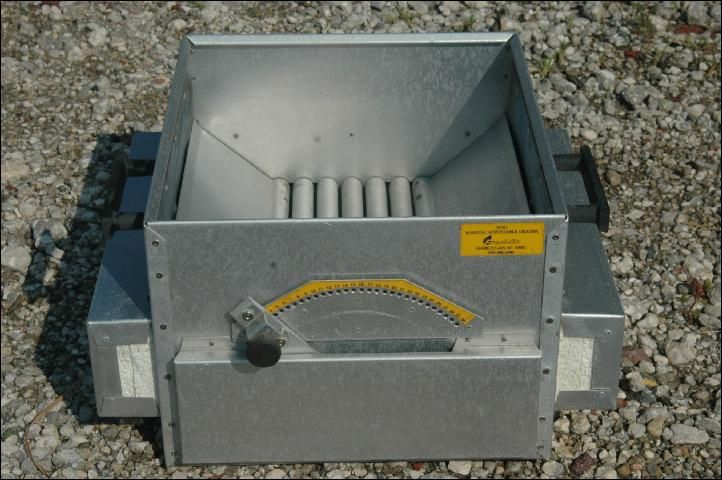

In Florida ornamental fish production, the two most commonly used mechanical graders are the insertable box grader and the adjustable one-piece grader. An insertable box grader is a small box (e.g., 19 inches wide x 23 inches long x 10 inches deep) (Figures 1 and 2) that accepts inserts with grates of varying size. The removable grates or inserts range in grate size (space between each grate) from 3 to 38 mm (1/8 to 1-1/2 inches). The inserts are available in increments of 0.76 mm (0.03 inch). The box and grates (inserts) are sold separately, allowing the farmer to purchase specific inserts as needed. It should be noted that the grading process is based on the width of the fish and, with experience, the farmer should be able to correlate the spacing of the inserts with the desired length of marketable fish. An adjustable one-piece grader (Figure 3) can be adjusted to produce spacing sizes of 6.4 to 29 mm (1/4 to 1-1/8 inch) by moving the adjustment knob to the desired setting.

Credit: Tina Crosby (2004)

Credit: Tina Crosby (2004)

Credit: Tina Crosby (2004)

Crowding fish in the grader can cause physical damage and make grading more difficult because smaller fish cannot easily swim out of a crowded grader. Fish that are retained in the grader are generally dumped directly into a transport box. However, if working with a sensitive fish species (i.e., moonlight gouramis, rainbow fish, scissortail rasboras), a net may be used to dip the fish out of the grader. The time required to grade fish depends on the number of fish needed.

Graders vary in cost. An adjustable one-piece grader may be up to five times as expensive as a small floating box grader without inserts. However, in addition to the box grader, farmers should take into account the number of inserts that must be purchased to effectively grade their product. In 2014, an adjustable one-piece grader cost $545–$1,000, a small box grader cost $220–$230, and each individual insert for a small box grader cost $145–$190. The cost of the small box grader should be compared to that of the adjustable one-piece grader, which essentially has 30 built-in inserts. See the appendix for a list of vendors.

Hand Grading

Hand grading allows the farmer to inspect each fish visually for specific characteristics. As the number of characteristics selected increases, so too does the time required to hand grade. To save time and increase the efficiency of hand grading, some farmers use grading tables made of smooth plastic framed in wood. The grading table (Figure 4) must first be wet down. Some producers use an additive (e.g., Stress Coat, Novaqua) to protect the mucus layer (slime coat) of the fish which may further protect them from possible skin damage and scale loss during handling; however, this benefit has not been proven. The fish are placed on the center of the table and then quickly slipped into one of the available holes (Figure 4, see arrows). Each hole has a bucket beneath it with holding water. Different buckets hold fish that are sellable, keepers, or culls. The sellable fish are transported to the holding facility. Live-bearing fish that are keepers, but too small for immediate sale, are returned to a pond or held inside for future sales. The culls are usually deformed or do not exhibit the proper physical characteristics and are discarded. With experience, a farmer can evaluate a single fish within seconds.

Credit: Tina Crosby (2004)

Various species of fish will react better to certain methods of grading. Sensitive fish species, such as rainbow fish, pearl gouramis, moonlight gouramis, and scissortail rasboras, should be graded by hand to avoid high mortalities.

Advantages and Disadvantages

There are advantages and disadvantages to mechanical grading with an adjustable one-piece grader, mechanical grading with the insertable box grader, and hand grading. Table 1 summarizes the major advantages and disadvantages for each method.

Summary

Producers should become technically efficient to reduce stress placed on fish during the grading process and to insure the highest-quality product available. When the farmer is selecting fish for sale, the specific characteristics required by each buyer and the sensitivity of the fish species to handling should be considered and may determine which method of grading is best. Because size is usually the first grading consideration, farmers often use a mechanical grader to select a larger number of fish of a specific size category. These fish can then be hand graded for other quality requirements if necessary. If fish are particularly sensitive and will not tolerate mechanical grading well, they should only be hand graded. Mechanical graders are available in a variety of types, sizes, and price ranges. With experience and the proper equipment, producers can grade fish efficiently and sell a higher quality product.

Recommended Reading

UF/IFAS Circular 919 Stress - Its Role in Fish Disease. https://edis.ifas.ufl.edu/FA005

UF/IFAS Fact Sheet FA-7 Fish Fingerlings: Purchasing, Transporting, and Stocking. https://edis.ifas.ufl.edu/FA013

UF/IFAS Fact Sheet FA-16 Ammonia in Aquatic Systems. https://edis.ifas.ufl.edu/FA031

UF/IFAS Fact Sheet FA-27 Dissolved Oxygen for Fish Production. https://edis.ifas.ufl.edu/FA002

UF/IFAS Fact Sheet FA-117 Harvesting Ornamental Fish From Ponds. https://edis.ifas.ufl.edu/FA117

UF/IFAS Fact Sheet FA-119 On Farm Transport of Ornamental Fish. https://edis.ifas.ufl.edu/FA119

UF/IFAS Fact Sheet FA-120 Preparation of Ornamental Fish for Shipping. https://edis.ifas.ufl.edu/FA120

SRAC Publication No. 474 The Role of Stress in Fish Disease. https://fisheries.tamu.edu/files/2019/01/SRAC_0474.pdf

Appendix

The use of trade names in this publication is solely for the purpose of providing specific information. UF/IFAS does not guarantee or warranty the products named, and references to them in this publication does not signify our approval to the exclusion of other products of suitable composition. This may not be a complete list of box grader and adjustable one-piece grader providers.

PentairAquatic-Eco Systems

2395 Apopka Blvd

Apopka, FL 32703

877-347-4788

The Florida Tropical Fish Farms

Association, Inc. (FTFFA) Association Co-op Store

5129 State Road 674

Wimauma, FL 33598

813-938-1162

Memphis Net and Twine

P.O.Box 80331

Memphis,TN 38108

1-888-674-7638

Fresh-Flo, Corporation

3037 Weedon Creek Rd.

Sheboygan, WI 53981

920-208-1500