Credit: UF/IFAS file photo

Introduction

This publication estimates the costs and returns for an established hibiscus nursery in south Florida. The information presented in it was collected through field interviews with growers and industry specialists. It is based on a variety of production practices by multiple nurseries of different scales. The data is intended only as a guide for estimating the financial requirements of running an established hibiscus operation. This publication will be useful to current and future hibiscus growers, wholesalers, and processors, especially those exploring the economic viability of producing hibiscus plants.

Tropical hibiscus (Hibiscus rosa-sinensis) is a bushy evergreen shrub or small tree that is native to the temperate regions of Asia. For many tropical countries, hibiscus is culturally significant, and its imagery is synonymous with the aesthetic of tropical life. Tropical hibiscus has become a prominent commercially cultivated species of hibiscus due to a variety of benefits, including its ability to produce large, vibrant flowers in many colors that bloom continuously over the summer months. Tropical hibiscus requires very high amounts of sunlight and is intolerant to temperatures below 50°F, which is why Florida provides an ideal environment for its cultivation. Florida is now the largest producer of floriculture crops in the United States, with commercial operations totaling $1.13 billion. Florida accounts for 78% of the wholesale value of cut cultivated greens, 69% of foliage plants, and 29% of potted flowering plants (USDA 2021).

The production of hibiscus is severely threatened by several invasive pest species, including weevils, thrips, aphids, spider mites, mealy bugs, and caterpillars (Revynthi et al. 2021). The most concerning pest for hibiscus currently is the invasive hibiscus bud weevil (HBW) (Anthonomus testaceosquamosus) (Revynthi et al. 2021). Multiple nursery owners indicated that pests were one of the largest impediments to optimal production. Given the importance of aesthetics when producing ornamental plants, the cosmetic damage that many of these pests cause can significantly lower nursery production.

There is also rising demand for the cultivation of plants with minimal pesticides due to concerns about the potential negative environmental and health effects. Large retailers, such as Walmart and Home Depot, have announced that they will require ornamental suppliers to not apply neonicotinoid insecticides (4A), which impact pollinators, and instead utilize integrated pest management, as verified by a third party, by 2025. (Walmart Policy and Guidelines: Walmart U.S. Pollinator Health Position; Home Depot: Commitment Policy, Achieved Goals.) Integrated pest management (IPM) is an alternative production strategy to conventional pesticide application that uses a broad-based approach that integrates both chemical and non-chemical practices for sustainable control of pests. This could have significant implications for nursery operators, as respondents from our survey indicated that large retailers accounted for on average 80% of their nursery production.

Tropical hibiscus is an economically significant crop. Demands for hibiscus are changing, particularly around pesticide use, and current growers and those considering beginning a tropical hibiscus operation should be aware of trends so that they can adjust production practices. This publication estimates the cost and returns of producing outdoor-grown tropical hibiscus, using both traditional methods and IPM, to better inform growers and other stakeholders about its economic feasibility.

Main Assumptions

Production costs and revenues were based on an approximate annual budget for a one-acre operation outdoors. All estimates were based on previous literature and survey responses from a small sample of hibiscus growers in south Florida from May 2023. This survey was approved for distribution by the Human Subjects Institutional Review Board at the University of Florida (IRB202300437). Growers may employ a variety of cultural practices when growing hibiscus, and production costs will therefore vary depending on the nursery. For this analysis, we also assume the production of larger 3-gallon tropical hibiscus plants, typically grown as outdoor decoration. Additionally, considering that growers in south Florida generally own the land where their nurseries are, we consider an approximate rental cost of $1,000/acre for the opportunity cost of the land.

Production Timeline—The production cycle for hibiscus can be divided into five phases, using the timeline in Table 1.

Table 1. Production timeline.

Plant hibiscus in August and September; prune plants October–February; tend to flowering plants and sell/ship them March–June; and clean production facilities in July.

Nursery Layout—Production is typically organized into bays of 5,000 plants in pots arranged in rows in 6–12” spacings. Each bay would be approximately 20,000 sq ft, so our representative nursery with only one acre would have the production space for two bays. Therefore, there is a planting density of approximately 10,000 plants/acre.

Yield—Based on the information provided by growers, the average production loss or shrinkage rate ranged from 5%–15%. For our analysis, we consider a shrinkage rate of 10%, resulting in an average plant yield of 9,000 plants/acre/year.

Hibiscus Prices—The price estimate for a 3-gallon hibiscus was based on information provided by growers. However, many growers reported having production contracts for large quantities or bulk orders, and therefore the price provided for a single plant was an approximation. A single 3-gallon hibiscus plant is estimated to cost $12.

Seeds/Cuttings—Hibiscus is generally propagated by rooted cuttings (called liners). The cuttings are taken during previous years’ pruning seasons or are externally sourced from other nurseries. These cuttings are treated with root hormones and grown in mist beds until they develop strong roots and are large enough to be transplanted into the 3-gallon pots. The degree to which each nursery handles its propagation production can vary significantly. Seedling/cutting material costs are estimated at $1,000/acre/year.

Growth Media—The soil and growing media comprise a significant portion of the input costs for producing outdoor tropical hibiscus. Tropical hibiscus plants require a high amount of water and nutrient-rich soil that still allows for adequate drainage. To produce 10,000 3-gallon outdoor tropical hibiscus plants, we estimate the use of approximately 4,600 cubic feet of growing media at $2/ft3, resulting in a total cost of $9,200/acre/year.

Fertilization—Fertilization treatments represent the second largest category of direct costs. Fertilization treatments for hibiscus include biweekly applications of N-P-K fertilizer. Based on grower responses, the most common type of fertilizer used is Nutracoat, 18-6-8. The estimated cost of fertilization is $7,324/acre/year.

Pest Control—The following is an estimate of the costs of traditional pest management. Insecticide applications typically occur once or twice a week, depending on precipitation, at an estimated cost of $512/acre/year. Similarly, fungicide and bactericide applications occur once or twice a week, with an estimated cost of $500/acre/year.

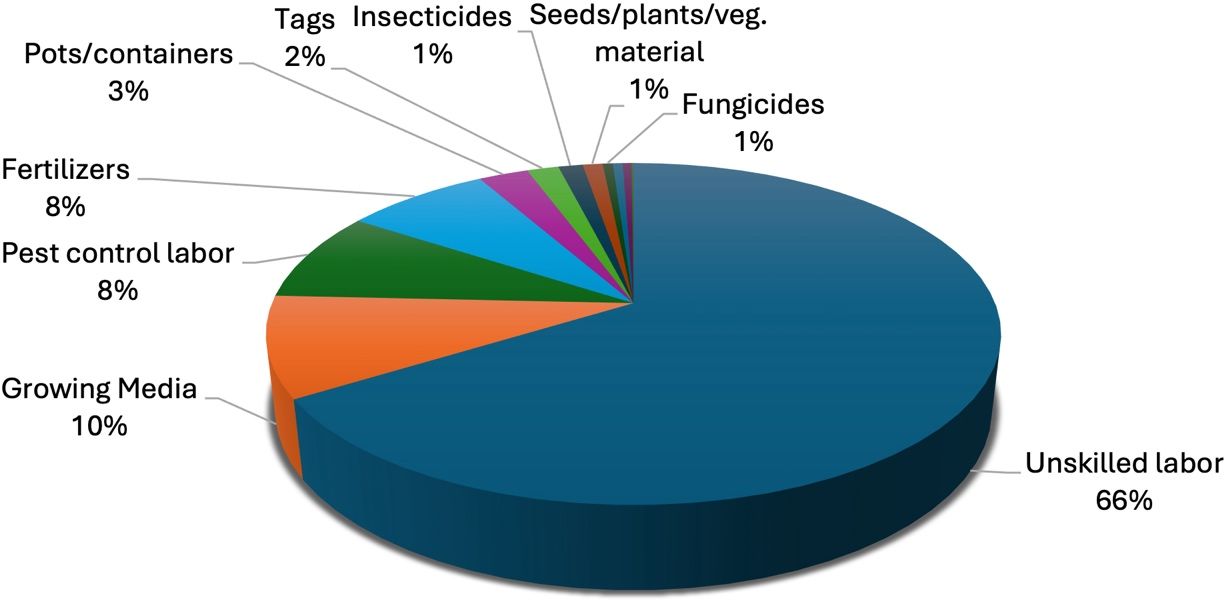

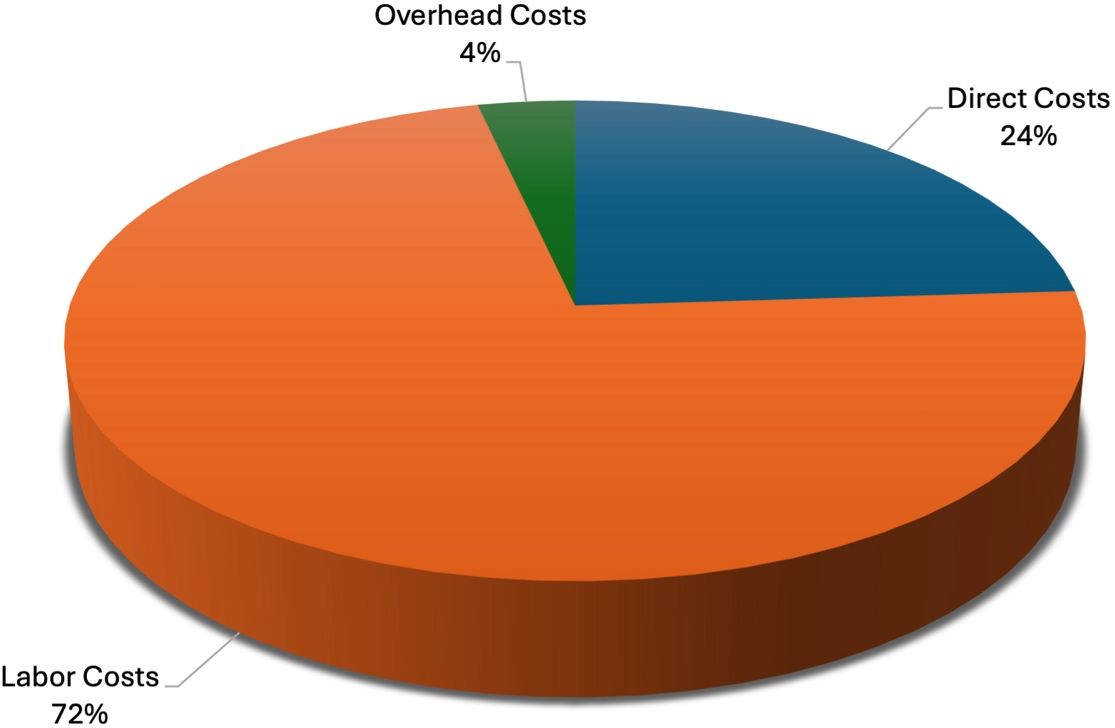

Labor Costs—Like production for other specialty crops, hibiscus production is labor-intensive. Labor costs comprise over 66% of the total variable costs. Hibiscus production requires regular pruning, removal of fallen buds, fertilizer application, and other forms of crop management. As did previous analysts of this sector (Khachatryan and Wei 2023), we further separate labor costs into three categories: unskilled, pest control, and skilled labor at corresponding wages of $15, $17, and $20 per hour. These wages were estimated based on the average wages from job postings for each of these job types on Indeed in Miami-Dade County for May 2023.

Variable Costs—Total variable costs amount to $96,291/acre/year, which is approximately 96% of the total production costs. As shown in Table 2, the largest components of variable costs are unskilled labor (66%), growing media (9.6%), and pest control labor (8.5%).

Credit: UF/IFAS

Interest on capital—This is the cost of borrowing money or the opportunity cost for using equity. A rate of 5% was considered in the given analysis. Interest on operating capital is estimated at $123/acre/year.

Irrigation—As mentioned previously, hibiscus requires a high amount of water to grow adequately. Costs are estimated based on reported water utility rates from Miami-Dade County for the growing period of 32 weeks. Average irrigation costs are estimated to be $1,312/acre/year.

Fixed Costs—This constitutes the costs that are incurred regardless of the level of production. It includes cash overhead costs (e.g., insurance and taxes), non-cash overhead costs (e.g., land rent), and other overhead costs (e.g., machinery use, electricity, telephone, computer, and other miscellaneous office expenses). Total fixed costs are estimated to be $1,723/acre/year.

Credit: UF/IFAS

Integrated Pest Management

Recommendations for IPM strategies were based on experimental results from the Ornamental Entomology lab at the UF/IFAS Tropical Research and Education Center. Here are the currently recommended IPM strategies for hibiscus:

- Sanitation: Throughout the season, it is recommended that the hibiscus plants be checked weekly for pests. Fallen flower buds should be removed either by hand or using equipment. Sanitation has been recommended for management of HBW and to reduce populations of other hibiscus pests in nurseries (Bográn, Helnz, and Ludwlg 2003; Revynthi et al. 2021).

- Systemic Insecticide Application: Application of systemic pesticides is recommended. Make applications in February to prepare each plant for increased pest populations in the warmer spring and summer months when pests proliferate. Prophylactic applications with systemic insecticides have been shown to protect hibiscus plants from a potential HBW infestation (Vargas et al. 2023).

- Biological Control: When HBW populations are low, entomopathogenic nematodes and fungi treatments are recommended to replace some contact insecticide treatments. These biological control agents are recommended because they are compatible with commonly used pesticides and have shown efficacy against the HBW (Vargas et al. 2024). Begin nematode and fungi treatments after systemic applications near the end of February, and alternate weekly among entomopathogenic fungi, nematodes, and contact insecticides until the start of the shipping season. Two applications of entomopathogenic nematodes, such as BioSC, are estimated to cost $936/acre/year. Two applications of entomopathogenic fungi, such as Bioceres or BotaniGard, are estimated to cost $238/acre/year.

- Contact Pesticides: Non-neonicotinoid contact insecticide and fungicide applications can occur throughout the harvesting season, from February to May. Several contact insecticides (conventional and biorational) are efficacious against the HBW (Greene et al. 2023).

For this analysis, we assume that these integrated pest management strategies would result in additional hours of pest control and sanitation labor, reduced use of insecticide usage, and an additional biological control cost of $1,174/acre/year. Recommendations for biological control practices do not affect pathogen infections. Therefore, fungicide and bactericide applications remained unchanged.

Return and Profitability Analysis

Based on a shrinkage rate of 10% and an average yield of 10,000 plants/acre, the estimated total cost to produce hibiscus is $99,826/acre/year (Table 2). Based on this yield and estimated cost, the per-acre net income for producing hibiscus using traditional pest management is approximately $8,174. Net income is a good indication of the long-term feasibility of a crop because it includes fixed costs in its estimate. However, many growers are more concerned about the gross margin because it can show whether a crop meets the minimum requirements for short-term profitability. The gross margin is the total revenue minus just the total variable costs. The gross margin for producing hibiscus is $11,709/acre/year. Both estimates imply that hibiscus can be very economically competitive. The per-acre net income for producing tropical hibiscus using integrated pest management is $876 lower (Table 3). However, it’s important to note that that is without assuming any increases in yield due to better pest management.

Table 2. 1-Acre Hibiscus Production Budget.

Table 3. 1-Acre Hibiscus Production Budget with IPM.

Table 4. Variable Cost Breakdown Table.

Table 5. Total Cost Breakdown.

Sensitivity Analysis

Table 6 presents a sensitivity analysis of the net returns. Under the best-case scenario, where both price and yield are assumed to increase by 8%, the net return would increase from $8,174/acre to $9,534/acre. Under the worst-case scenario, where both price and yield decrease by 8%, the net return would decrease from $8,174/acre to $6,918/acre. Table 7 presents a sensitivity analysis of the gross margin. Under the best-case scenario, where both price and yield are assumed to increase by 8%, the gross margin would increase from $11,709/acre to $13,657/acre. Under the worst-case scenario, where both price and yield decrease by 8%, the gross margin would decrease from $11,709/acre to $9,910/acre. Price changes (keeping the production constant) have the same level of impact on net returns as do quantity changes (keeping the price constant). An 8% increase in the base price (base yield of 10,000 plants.) has the same impact on net returns as an 8% increase in yield (base price, $12/plant).

Table 6. Sensitivity Analysis Net Return Per Acre.

Table 7. Sensitivity Analysis Gross Return Per Acre.

Conclusion

The estimated net income for operating an outdoor one-acre nursery producing 3-gallon tropical hibiscus plants is $8,174. This is an excellent return and indicates that hibiscus is a financially lucrative crop option for specialty crop growers in south Florida. This conclusion is further supported by the fact that many hibiscus nurseries already have production efficiencies that may lower their variable costs. Owning the land, having existing propagation systems, preparing soil mixes, and utilizing labor across multiple crops are a few production strategies that contribute to lower variable costs.

Our analysis also showed that incorporating IPM strategies will moderately increase costs. However, while costs do increase moderately with IPM, the potential benefits are high. Using IPM increases yields thanks to decreased pest damage, increases the number of potential retailers, avoids pesticide resistance build-up, and presents no potential harmful health effects to agricultural workers. In fact, if IPM is used to replace some traditional pesticide treatments, it may reduce worker’s exposure to pesticides. Incorporating IPM strategies will also benefit the surrounding pollinator ecology, which is critical for the longevity of the ornamental industry. The viability of IPM depends on the availability of labor that can be directed toward pest management and sanitation and on familiarity with the use of biological controls, both of which will vary depending on the nursery and its resources.

In this analysis, we do not consider the costs associated with establishing a new nursery, such as land development, building irrigation systems, or developing market connections. However, our results do indicate that there is significant potential to make an economic profit operating a hibiscus nursery, and that profit could be used to amortize many of the financial barriers to entry. Also, considering that hibiscus production is already well established in south Florida, it is unlikely that an increase in production will result in significant market saturation and reduced prices.

References

Bográn, Carlos E., Kevin M. Helnz, and Scott Ludwig. 2003. “The Bud Weevil Anthonomus testaceosquamosus, a Pest of Tropical Hibiscus.” In Proceedings of the SNA Research Conference Entomology, Atlanta, GA, USA, 48:147–49. Accessed August 12. 2024. https://irp.cdn-website.com/5d757b5b/files/uploaded/section03.pdf

Greene, A. Daniel, Xiangbing Yang, Yisell Velazquez-Hernandez, German Vargas, Paul E. Kendra, Catharine Mannion, and Alexandra M. Revynthi. 2023. “Lethal and Sublethal Effects of Contact Insecticides and Horticultural Oils on the Hibiscus Bud Weevil, Anthonomus testaceosquamosus Linell (Coleoptera: Curculionidae).” Insects 14 (6): 544. https://doi.org/10.3390/insects14060544

Khachatryan, Hayk, and Xuan Wei. 2023. “FE1105/FE1105: Production Costs and Profitability for Select Greenhouse Grown Annual Bedding Plants: Partial Enterprise Budgeting and Sensitivity Analysis: FE1119/FE1119, 7/2022.” EDIS 2022 (4). Gainesville, Florida. https://doi.org/10.32473/edis-fe1119-2022

Revynthi, Alexandra M., Yisell Velazquez Hernandez, Juleysy Rodriguez, Paul E. Kendra, Daniel Carrillo, and Catharine M. Mannion. 2021. “ENY-2069/IN1328: The Hibiscus Bud Weevil (Anthonomus testaceosquamosus Linell, Coleoptera: Curculionidae) ENY2069/IN1328, 9/2021.” EDIS 2021 (5). Gainesville, Florida. https://doi.org/10.32473/edis-in1328-2021

Vargas, German, A. Daniel Greene, Yisell Velazquez-Hernandez, Xiangbing Yang, Paul E. Kendra, and Alexandra M. Revynthi. 2023. “A Prophylactic Application of Systemic Insecticides Contributes to the Management of the Hibiscus Bud Weevil Anthonomus testaceosquamosus Linell (Coleoptera: Curculionidae).” Agriculture 13 (10): 1879. https://doi.org/10.3390/agriculture13101879

Vargas, German, Yisell Velazquez-Hernandez, A. Daniel Greene, Xiangbing Yang, and Alexandra M. Revynthi. 2024. “Entomopathogenic Nematodes to Control the Hibiscus Bud Weevil Anthonomus testaceosquamosus (Coleoptera: Curculionidae), above Ground and on Soil Surface.” BioControl 69 (1): 91–101. https://doi.org/10.1007/s10526-024-10242-9