Introduction

Between 2003 and 2012, global production of avocados increased at an annual average growth rate of 3.2 percent, from 3.17 million tonnes in 2003 to 4.35 million tonnes in 2012. The United States was the fourth largest global avocado producer in 2012, with 245,000 tonnes, following Mexico, Indonesia, and the Dominican Republic (FAOSTAT 2013). Production of avocados in the United States occurs mainly in the states of California, Florida, and Hawaii. California produces about 86 percent of the US-grown avocados, primarily the Hass variety. Florida produces approximately 13 percent and Hawaii produces less than one percent of the US-grown avocados, primarily the green-skinned variety (USDA/ERS 2013a).

Consumption of avocados is on the increase worldwide, and avocados are no longer regarded as an exotic fruit. Although the United States is one of the largest avocado-producing countries, its consumption greatly exceeds its domestic production. Since 2003, US avocado consumption has increased from approximately 308,099 tonnes to 727,897 tonnes in 2012. As a consequence, per-capita consumption has increased by about 8.1 percent, from 1.06 kilograms (kg) in 2003 to 2.32 kg in 2012 (USDA/ERS 2013b). The increase in US consumption of avocados has positioned the United States as the number one avocado importer in the world.

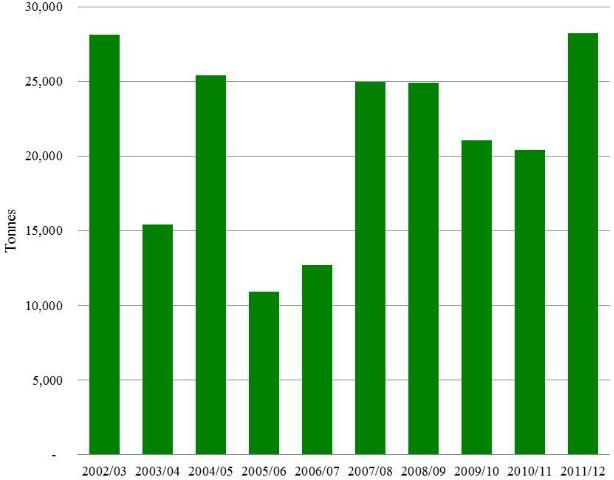

Florida's commercial production of avocados occurs on approximately 7,400 acres, mainly in Miami-Dade County. Most of the production is by small-scale growers, with farm size averaging less than 15 acres (Evans and Nalampang 2010). Because of inclement weather (e.g., hurricanes and droughts) and the unavailability of large tracts of lands to increase plantings (Figure 1), avocado output in Florida has not increased noticeably since 2003. The 2012 output level of 28,213 tonnes, which represented an increase of 38 percent over the previous season, was in line with the 2003 season, which recorded an output level of 28,123 tonnes.

Credit: USDA/FAS (2013)

Despite its relatively small contribution (<15%) to both total US domestic production and consumption of avocados, the avocado industry is extremely important to the state of Florida and to the more than 350 growers and handlers who depend on it to supplement their revenue. In the 2012 season, the Florida avocado industry was valued at $23.5 million (USDA/ERS 2013a) at the farm gate and about $35 million dollars at the wholesale level, with an economic impact of more than $55 million (Evans et al. 2011). Moreover, the Florida avocado industry employs more than 1,000 full-time/part-time farmworkers (Edward Evans, personal communications 2014).

A major concern for the future of the Florida avocado industry is laurel wilt disease (LW), which was first detected in Florida orchards in 2012. Laurel wilt is caused by fungus transmitted by the ambrosia beetle. Cost-effective management of LW relies heavily on the early detection and destruction of affected trees (sanitation). While not an official recommendation, some suggest that since the beetles are less attracted to younger trees, growers might consider leaving the young orchards in production while replanting only older and less productive orchards. Since the long-term survival of the Florida avocado industry may ultimately depend on a combination of eradication, prophylactic treatment, and replanting the trees, the purpose of this article is to provide an updated guidance on the costs of establishing an avocado orchard. Information presented in this study is based on interviews with growers, orchard service companies, extension agents, and other industry personnel. It is intended as a guide only to make production decisions, prepare budgets, and investigate insurance options. A follow-up document to this one will focus on the cost and return of maintaining an orchard after it has been established.

Assumptions

Orchard Specifications

Cost data were gathered from several south Florida orchards of varying sizes. Since the majority of orchards are small (<15 acres), the information presented represents the per-acre cost to establish a hypothetical five-acre orchard in south Florida. Establishment of an avocado orchard requires six years from planting to full production.

Establishment and Production Practices

Land preparation for orchard establishment

In south Florida, new avocado orchards usually are planted on existing agricultural land that was previously used for agricultural production. As a result, roads and drainage systems have already been installed and are not considered part of the establishment cost.

The sandy and limestone soils of Florida, if not subjected to flooding, can produce satisfactory avocado yields, ranging between 11,000 and 19,500 pounds per acre, depending on the variety, and assuming about 100 trees per acre (Crane 2013). Avocado land operation includes rock plowing, land clearing and disking, and building mounds. Most of the growers interviewed indicated that these are customized operations that are performed by various orchard service companies because the purchase of machinery and equipment needed is particularly expensive.

Planting

In Florida, the avocado market is dominated by several green-skinned varieties, such as Monroes, Simmonds, Pollock, Choquete, and Lula. Measured in feet, different planting spaces between trees are used, ranging from 18 feet (100 trees per acre) to 20 feet (87 trees per acre). The common practice is to plant 87 trees per acre, but many of the newer orchards are increasing tree density to 100 trees per acre. For the calculations done in this study, we used the planting density of 100 trees per acre and a replanting percentage of two percent (2%) for the second year.

As mentioned earlier, when establishing a new orchard, most avocado growers hire an orchard service company to complete all the operations needed to plant new trees. Orchard service operations include digging, planting, staking, wrapping, and mulching. The growers are responsible for buying the young trees, which are usually sold in three-gallon pots.

Pruning

Avocado trees do not require extensive pruning, especially in the early years. Most of the pruning comes later in the life of the crop and involves biennial clearing of the top of the canopy, eliminating dead branches, and maintaining the desired crown height and width of each tree. Some growers prune with the only goal being removing excessive flowers throughout the spring.

Growers should keep the trees at or below 20 feet high so that they don't topple over from heavy winds and hurricanes. For early varieties, prune each year between May and September, depending on the variety planted. In contrast, mid and late varieties should be pruned right after harvesting the crop every other year (biennial). For our calculations, we assumed hand pruning once a year after the third year of establishment, with the idea to remove excess flowers and promote vegetative growth.

Irrigation

Irrigation systems are installed during the first year of establishment, right before planting. The most common irrigation system used is high-volume irrigation because it serves as under-tree freeze protection. In most cases, when a new orchard is being established, a high-volume system has already being installed. In such cases, most growers install micro-sprinklers as a support for the high-volume irrigation system.

The frequency of irrigation depends on several factors, such as weather, rainfall, variety planted, type of soil, and season of the year. Concentrate irrigation during the dry season and phenological events (from-flowering-to-harvest). A general recommendation is to irrigate one inch of water per week. Our calculations are based on an irrigation frequency of once a week. Since growers in Florida are not required to pay for irrigation water, we focused our calculation on the cost to run the irrigation pumps and the labor needed to maintain and monitor the irrigation system.

Pest management

Avocados are attacked by a variety of insects throughout the year. The majority of these insects do not cause significant damage to the orchard, nor do they limit production. Most growers apply pesticides only when pest infestation is rampant. The most common insects attacking Florida avocado orchards are the avocado looper (Epimecis detexta), pyriform scale (Protopulvinaria pyriformis), dictyospermun sScale (Chrysomphalus dictyospermi), avocado red mites (Oligonychus yothersi), borers (e.g., ambrosia beetles, Xylosandrus sp.), avocado lace bugs (Acysta perseae), and red-banded thrips (Selenothrips rubrocinctus) (Mossler and Crane 2001).

Ambrosia beetles were not of significant concern to US avocado orchards until 2002, when the exotic species, red bay ambrosia beetle, Xyleborus glabratus and its nutritional symbiont Raffaelea luricula began attacking and destroying trees belonging to the lauraceae family, which includes avocado in the United States (Mayfield III, Crane, and Smith 2008). The Ambrosia beetle carries the Raffaelea sp. fungus, which, once inside the tree, interferes with the tree's mechanism for conducting water to tissues and causes the tree to wilt and ultimately to die. While LW is known to be devastating to mature trees, and research on developing an effective prophylactic treatment is nearing completion, the establishment costs outlined in this study do not take into consideration the costs of prevention and management of LW because the information is not yet available.

Pesticides and fungicides that are effective against other pests are applied annually to recently planted avocado orchards on an as-needed basis. Such chemicals are copper, permethrin, tilt, emmametin, larvacide, and sulfur. For our calculations, we included the cost of larvicide and sulfur, which are applied at least once a year, starting during the first year of establishment.

Weed management

The main weed management methods used in Florida are hand weeding, spraying, and mowing. During the first two years of establishment, growers hand weed and spray herbicide five to eight times a year (five applications were used for our calculations). However, after the second year of establishment, avocados are usually sprayed five times a year, along with mowing between rows.

Fertilization

The type and amount of fertilizer applied depends mainly on the type of soil and age of the tree. A 6-6-6 formulation is applied six times a year during the first two years of establishment at a rate of one pound per tree. An 8-3-9 formulation is applied six times a year during the third to sixth years at a rate of two to three pounds per tree. As to be expected, the amount of fertilizer applied increases with the age of the trees.

Soils in south Florida are very alkaline (pH above 6.5), disabling the absorption of micronutrients. The most common micro-nutrient applied every year in most avocado orchards is iron, which is applied once or twice a year in a chelated form. A multi-nutrient, micro-nutrient blend, such as Keyplex, is also applied as part of the annual fertilization plan (Olszack 2014).

Harvest, Marketing, and Inspection Risk

Although it takes about six years for an avocado orchard to reach its full potential (considered mature), fruit starts to emerge during the third year of establishment. The Florida Avocado Administrative Committee (FAAC) is a Federal Marketing Order with the general responsibility to oversee the grade, size, quality, maturity, container, and pack requirements for Florida-grown and imported avocados. It also authorizes regulations on the size, capacity, and weight of the containers used to ship avocados to market. The same minimum grade, size, and maturity requirements are applied to both domestic and imported avocados.

Harvesting costs for picking and hauling to packinghouses are calculated by pound of avocado harvested. We used an average price of $0.05 per pound based on the information obtained from growers. We did not include the assessment of $0.30 per bushel that goes toward funding the activities of the FAAC, nor the inspection fee of $0.40 per bushel because these costs are usually paid by the handlers and deducted before final payment is made to the growers.

Yield and Prices

Yield

Avocado trees start bearing during the third year of establishment, with yields increasing year after year. Trees are not consistered mature until the seventh year. Table 1 identifies the yields used in our calculations.

Prices

For revenue, we used $0.32 per pound, which reflects the three-year average price paid to the growers by the packinghouses. These prices were sourced from the USDA/NASS (2013) database. This price was used to estimate the gross returns for the third to sixth years. Since prices tend to vary considerably throughout the season and by varieties, the prices in our study reflect the industry average. For example, during the past ten-year period, average prices ranged from a low of $0.22 per pound to a high of $0.47 per pound.

Interest on Operating Capital

Interest on operating capital is calculated at a rate of five percent. This represents borrowing or the opportunity cost of capital, and reflects the credit rate charged by local banks.

Labor

The wages used in this study represent the average obtained from growers and include benefits. For skilled labor (e.g., machine operator), a wage rate of $18 per hour was assumed, and for unskilled labor, a rate of $12 per hour was used. Skilled laborers include pickup truck and ATV drivers. These rates were based on interviews conducted with growers and include payments of fringe benefits.

Cash Overhead

The main cash overhead costs included in the study were property taxes and property insurance.

Property taxes

In Miami-Dade County, agricultural producers are taxed at the income-earning potential of the land in agricultural production, rather than at what a willing buyer would pay for the land. Hence growers who receive an agricultural classification pay a much lower rate than the market rate, which also depends on the type of agricultural operation. For orchard crops, we used a rate of $100 per acre. This rate only applies to that portion of the land used for actual agricultural production and not the homestead (Evans et al. 2011).

Property insurance

Liability insurance depends on the particular type of coverage. We used an annual average of $100 per acre, which includes property and crop protection.

Investment repairs

Repairs and maintenance are calculated at two percent of the investment value. Based on the information obtained from the growers, the repair cost for irrigation systems was calculated at five percent of the investment value.

Other expenses

Other expenses include interest on operating capital, which is calculated at a five percent rate (average rate on a short-term bank loan), and on leaf analysis, which is done twice a year prior to fertilizing.

Non-cash Overhead

Land rent

In Florida, most avocado growers already own the land for establishing an orchard. Very few new avocado orchards in Florida are being established on new land. However, we included an opportunity cost for the land used with the idea to reflect the amount of money that could have been earned if some other productive alternative had taken place. To reflect the opportunity cost of land, we used the current rental rate of approximately $500 per acre.

Ownership cost of investment

For our analysis, we took into account the basic machinery needed in an avocado orchard, such as tractors, ATVs, sprayers, trimmers, and tools. Using the capital recovery method, we calculated an annual amount of money to be charged to the orchard in a set period of time that would allow the value of the asset to be recovered. This amount is calculated using a designated interest rate, which in our case was five percent.

Summary of Establishment Costs

Table 2 illustrates the layout of the annual per-acre costs incurred when establishing an avocado orchard in south Florida. By the seventh year, the avocado orchard is considered to be mature; therefore, the first six years of the orchard are considered the establishment years. Based on the calculations in Table 2, at the end of the sixth year, it will cost approximately $9,300 per acre to establish an avocado orchard.

This $9,300 comprises a cash contribution of $3,638 and a non-cash cost (contribution from ownership of machinery, equipment, and other investments used in the establishment of the orchard) of $5,670. Of course, if the grower does not own most of the necessary machinery and equipment, the cash component of the establishment cost would increase. For example, if the owner were in fact leasing the land for $500 per annum, the cash component would increase from $3,638 to $4,138, while the non-cash component would be reduced to $5,170. Although the cash contribution in the sixth year is only $3,638, it should be noted that sufficient provision would have to be made to cover the peak demand for funds. This occurs around the fourth year when the accumulated net cash cost is at its highest, which is $7,997. In other words, the owner would have to have access to this amount of capital per-acre while waiting for the orchard to become established.

To determine the amount to charge the business each year after the orchard has been established, the total establishment cost of $9,300 is amortized at a five percent real rate of interest for 40 years (this is the estimated economic life of the orchard without taking into account the establishment years). This works out to be about $542 per acre, representing the annual cost for capital recovery (interest and depreciation). This amount will be added to the non-cash overhead charges every year, starting with the seventh year (once the orchard has been established). Put another way, if a grower were purchasing an acre of avocado trees that had been established for six years, that grower should be willing to pay about $9,300 for the acre plus the cost of the land. To recoup the $9,300 over the next 40 years, $542 should be aside each year so that at the end of the 40 years, the grower would have sufficient money to establish a new orchard.

Concluding Remarks

Florida's avocado industry represents an important part of the Florida agricultural economy—with estimated output (revenue) impacts of more than $55 million annually and supporting in excess of 1,000 full-time and part-time jobs. Since 2012, the Florida avocado industry has come under tremendous pressure with the discovery of the LW disease. Between 2012 and 2014, more than 5,000 trees have been eradicated, representing close to one percent of the total commercial avocado trees in the production area. Although most of the eradicated trees were non-productive, the long-term profitability and survivability of the industry will depend on the discovery of cost-effective LW treatment. Unitl a cost-effective treatment is found, growers might consider combining sanitation efforts with replanting aged and non-productive trees, since younger trees stand a better chance of not being infected. Consequently, the purpose of this publication was to provide guidance on the per-acre cost of establishing an avocado orchard in south Florida.

Our calculations suggest a cost of $9,300 per acre to establish an avocado orchard in south Florida. This amount is the total accumulated cost from the first year to the sixth year of establishment and includes both cash and the non-cash cost (cost imputed for ownership of land, equipment, and machinery used in the production process). Starting in the seventh year, the orchard is considered to be mature. The production and maintenance costs and returns of a mature orchard are provided in a separate document.

Acknowledgements

The authors are indebted to growers, orchard service development companies, and agricultural researchers, who graciously contributed to the development of this study. We want to especially thank Mr. Walter Olszack, Mr. Wayne Worthley, Dr. Wanda Montas, Dr. Carlos Balerdi, and Mr. Louis Trapp from Irritech international.

References

Crane, J. 2013. Interview with Braulia De Oleo on the details on avocado establishment (December 6).

Evans, E., and S. Nalampang. 2010. Sample avocado production costs and profitability analysis for Florida. FE837. UF/IFAS Extension. https://edis.ifas.ufl.edu/fe837. Accessed October 7, 2014.

Evans, E.A., J. Crane, A. Hodges, and J. Osborne. 2010. Potential economic impact of Laurel Wilt Disease on the Florida avocado industry. HortTechnology 20(1):234-238.

Evans, E., M. Mosquera, R.L. Clouser, and J. Crane. 2011. Florida's use-value assessment law: Questions and answers for Miami-Dade County Agricultural Classification. FE890. UF/IFAS Extension. https://edis.ifas.ufl.edu/fe890

FAOSTAT. 2013. FAOSTAT website. Food and Agriculture Organization Statistics, Rome, Italy. Mayfield III, A., J. Crane, and J. Smith. 2008. Laurel Wilt: A threat to redbay, avocado, and related trees in urban and rural landscapes. HS391. UF/IFAS Extension. http://ufdc.ufl.edu//IR00004233/00001.

Mossler, M., and J. Crane. 2001. Florida crop/pest management profile: Avocado. PI048. UF/IFAS Extension. https://edis.ifas.ufl.edu/pi048.

Olszack, W.R. 2014. personnal communication.

USDA/ERS. 2013a. Avocados: Production, season-average grower price, and value, by state, 1980/81 to date. United States Department of Agriculture, Economic Research Service, Washington, D.C.

USDA/ERS 2013b. Fruit and tree nut data yearbook: Tables. United States Department of Agriculture, Economic Research Service, Washington, D.C. http://www.ers.usda.gov/data-products/fruit-and-tree-nut-data/yearbook-tables.aspx#40875.

USDA/FAS. 2013. USDA/FAS Website. United States Department of Agriculture-Foreign Agricultural Service, Washington, D.C. http://apps.fas.usda.gov/gats/ExpressQuery1.aspx.

USDA/NASS. 2013. Avocados: Production, season-average grower price, and value, by state, 1980/81 to date. United States Department of Agriculture, National Agricultural Statistical Service, Washington, D.C. (November).