Introduction

All beverages, regardless of the product, share the need for packaging. There are many types of packaging, each with advantages and disadvantages that must be assessed for containment. The purpose of this publication is to discuss several alternative packaging options and quantify the pros and cons of each. As beverage industries adopt alternative packaging options, it is crucial to recognize the potential that product packaging can have on the consumer experience. This EDIS publication will focus on packaging alternatives for wine; however, these alternative packaging options are applicable for more than just wine.

Packaging Type

The most important function of beverage packaging is to protect and preserve the quality of the beverage it contains (Sajilata et al. 2007). This primarily involves preventing oxidation from light and air, which can cause degradation of the flavor and aroma compounds within the beverage. Another important requirement of the packaging is that it should be unreactive. It should not absorb flavors from the beverage or pollute the beverage with undesirable flavors (i.e., flavor scalping). Also, it should not leech packaging chemicals into the beverage (i.e., flavor tainting) (Sajilata et al. 2007; Revi et al. 2014). The current wine market has wine packaged in a wide range of materials, including glass, a variety of plastics, aluminum, and plastic-covered paper (Tetra Pak®)(Table 1). The perception that premium wine can only come in glass with natural cork closures has slowly been changing over the years (Revi et al. 2014; Robinson 2019). Despite glass being an inert material, most consumers do not age wine longer than a few months. Furthermore, a reliance on glass has stalled the ability of the wine industry to investigate alternative packaging (Roux and Gérand 2014).

Table 1. A summary table for each of the packaging types discussed. This includes a short description of the key advantages and disadvantages of each packaging type, as well as the common size and recyclability.

Bottles

Glass bottles are still the most popular and preferred way to package all different types of wine because of their superior gas and vapor barrier protection, stability over time, transparency, and ability to be recycled (Athens 2009; Colman and Päster 2009). Glass is made by combining relatively inexpensive quartz sand (silicon dioxide) with soda ash (sodium oxide), dolomite (calcium oxide and magnesium oxide), and feldspar (aluminum oxide). Other packaging types often weigh less and are more economical; however, glass still shows a superior capability to preserve the quality of the wine. For example, wines packaged in PET and other packaging types tend to have shorter lifespans (Fradique et al. 2011; Ferrara and De Feo 2018; Duncan and Webster 2009; Hopfer et al. 2013). Unfortunately, for several decades, glass bottles have slowly been gaining weight because people often associate heavier bottles with higher-quality wine. Journalists who write about wine have nicknamed these bottles “bodybuilders” for how thick and heavy the glass bottles have become. However, there is no connection between the thickness or weight of the bottle to the quality of the wine. What is true is that using glass bottles results in heavy packages that are inefficient to ship and shatter easily when dropped.

PET (Polyethylene Terephthalate)

PET is the common name for polyethylene terephthalate, which is part of the polyester family (Shirakura et al. 2006). PET bottles have been widely used for foods and beverages, including soda, juice, and water, for decades (Dombre, Rigou, and Chalier 2015; Shirakura et al. 2006). PET bottles can effectively trap or exclude carbon dioxide (CO2) but also protect sensitive products against sensory and nutritional deterioration caused by exposure to air. The barrier properties of the PET can be improved with the addition of oxygen scavengers within the bottle. Round, lightweight PET bottles have been used to package wine for the past 20 years and have recently been transformed to become flat. Recycled flat PET (rPET) bottles are 87% lighter at approximately 0.14 lb (60 g) compared to the approximately 1 lb (460 g) of traditional glass bottles, while remaining 100% recyclable (Thompson-Witrick et al. 2021). The decrease in weight has been estimated to reduce the shipping cost by up to 30% (ESKO 2016). Of course, there are cons to each different beverage packaging type, and PET bottles are no different. If glass wine bottles are considered high-end luxury products, then PET bottles are considered cheap and of low quality. PET does not perfectly protect the wine from oxygen. To counteract this, manufacturers of PET bottles have started combining barrier technology with oxygen scavengers. An oxygen scavenger is either a substance or product that will react with and remove oxygen from the system. Despite these efforts, PET bottles still allow more oxygen to transmit into the package than glass. This increase in oxygen transmission into the PET bottle ultimately shortens the shelf life of wine (ESKO 2016).

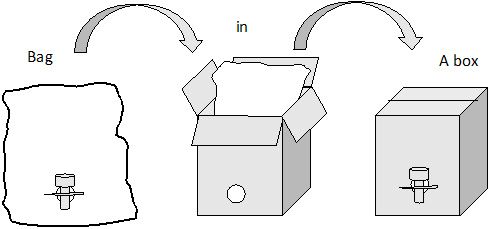

Bag-in-Box

The bag-in-box package (see Figure 1) is a flexible, collapsible, welded double bag made of synthetic films with a polypropylene (PP) valve, placed inside a rigid outer box or container with a spout attached for dispensing the contents. The wine pouches are filled under vacuum and back-filled with nitrogen to remove the remaining oxygen from the bag. As wine is removed from the container through the valve, the pouch collapses, protecting the wine from oxygen (Revi et al. 2014). This type of packaging is commonly used for medium-quality table wine. The most common sizes available on the market are 3L and 5 L (Kalkowski 2014).

Credit: Used with permission from Drew Budner, Coastal Carolina University, in Thompson-Witrick et al. (2022).

As with PET, the major issue associated with packaging wine in bag-in-box is the decrease in shelf life compared to traditional glass bottles (Fradique et al. 2011). In the 1970s, Australians noticed that their bag-in-box wine started to taste oxidized and have lower free SO2 values only three months after packaging. Improving from previous designs, today’s bag-in-box is made with an O2-barrier for the bag, spout, and closure. It also consists of a single flexible valve piece, which opens and closes when the lever is activated (Robertson 2006). These newer designs keep the wine fresh for two to three weeks after it has been opened (Weed 2019). Bag-in-box is a popular non-glass packaging type for wine, holding about 5% of the market share.

Aluminum cans

Within the last two decades, wine has become available in aluminum cans (Williams 2019). Cans are made from three different materials: (1) aluminum, (2) tin-coated steel (tinplate), and (3) electrolytic chromium coated steel (ECCS) (Geueke 2016). Unfortunately, bare aluminum metal is highly reactive and has the ability to form an incredibly thin (nanometer) passive layer of aluminum oxide when exposed to air or water (Vargel 2004). To combat this reactivity, aluminum cans are lined with a thin (1–10 µm) polymer coating on the interior of the can to protect the bare aluminum. Without the protective interior polymer layer, wine’s acidic pH could cause the interior of the can to slowly corrode. Due to its interactions with wine, the interior liner is considered a food contact substance by the FDA and must meet their strict safety standards. In the United States, can liners were made of bisphenol A (BPA) based epoxy resins until May 2015, when the state of California passed Prop 65, requiring manufacturers to label their BPA-based packaging materials. BPA-based products are suspected of being endocrine disruptors, which can disturb immune and nervous system functions. Thus, current manufacturers are now using BPA-alternative can liners such as acrylic (Bomgardner 2019).

Under the current standards updated at the end of 2020, canned wine can be manufactured and sold in various sizes including 500, 375, 200, and 100 mL. Can sizes are also available in 355, 250, and 187 mL, which represent about one-half, one-third, and one-fourth the size of a standard wine bottle, respectively. Since changing these standards, wineries are allowed to package wine in smaller sizes, opening up new markets for the industry (Weed 2020; McIntyre 2019). It is beneficial for canned wine to be served in smaller containers because of its higher alcohol content compared to beer (Williams 2019).

Tetra Pak®

Tetra Brik® or Tetra Prisma ® (Tetra Pak, Lund, Sweden) are aseptic cartons made using a type of multilayered packaging composed of three main, separate materials: paperboard, polyethylene polymers, and aluminum (Tetra Pak 2018b). Paperboard is the primary material within the packaging. The paperboard provides stability, strength, a smooth texture, and ink-receptive surfaces necessary for printing labels. The polyethylene polymers protect the product and the packaging against both exterior moisture from the environment and interior moisture from the product. This layer also forms a food-safe layer between the product and packaging materials, as well as allows the paperboard to stick to an aluminum foil layer. The presence of the aluminum foil layer protects the product against oxygen and light, preventing any photooxidative reactions (Tetra Pak 2018a).

Tetra Pak products enable wine producers to ship greater numbers of cartons compared to traditional wine packaging options like glass bottles. These products also come in 200 and 500 mL sizes, expanding the package size options and providing a single-serving option for the product (Tetra Pak n.d.). Costing only $0.10 to $0.25 to fill and produce, Tetra Pak packaging provides wine producers with an inexpensive alternative to glass (Gannon 2009). Since Tetra Pak packaging is lighter than glass, the cost to ship the product is also reduced. Moreover, the packaging is flexible, so breakage is less likely to occur, reducing product loss.

References

Athens, K. 2009. "Bottler Caters to Regional Wineries." Sustainable Industries, January.

Bomgardner, M. M. 2019. "How a New Epoxy Could Boot BPA from Cans." Chemical and Engineering News, March 5. https://cen.acs.org/business/consumer-products/new-epoxy-boot-BPA-cans/97/i10

Colman, T., and P. Päster. 2009. "Red, White, and ‘Green’: The Cost of Greenhouse Gas Emissions in the Global Wine Trade." Journal of Wine Research 20 (1): 15–26. https://doi.org/10.1080/09571260902978493

Dombre, C., S. Marais, C. Chappey, C. Lixon-Buquet, and P. Chalier. 2014. "The Behaviour of Wine Aroma Compounds Related to Structure and Barrier Properties of Virgin, Recycled and Active PET Membranes." Journal of Membrane Science 463: 215–225. https://doi.org/10.1016/j.memsci.2014.03.066

Dombre, C., P. Rigou, and P. Chalier. 2015. "The use of active PET to package rosé wine: Changes of aromatic profile by chemical evolution and by transfers." Food Research International 74: 63–71. https://doi.org/10.1016/j.foodres.2015.04.026

Dombre, C., P. Rigou, J. Wirth, and P. Chalier. 2015. "Aromatic Evolution of Wine Packed in Virgin and Recycled PET Bottles." Food Chemistry 176: 376–387. https://doi.org/10.1016/j.foodchem.2014.12.074

Duncan, S. E., and J. B. Webster. 2009. "Chapter 2 Sensory Impacts of Food–Packaging Interactions." In Vol. 56, Advances in Food and Nutrition Research, edited by S. L. Taylor. Academic Press. https://doi.org/10.1016/S1043-4526(08)00602-5

Eilert, S. J. 2005. "New Packaging Technologies for the 21st Century." Meat Science 71 (1): 122–127. https://doi.org/10.1016/j.meatsci.2005.04.003

ESKO. 2016. "Wine Packaging: The Pros and Cons of PET Bottles." Packaging Innovations, February 22. Archived March 4, 2016. https://www.packaginginnovation.com/packaging-materials/wine-packaging-the-pros-cons-of-pet-bottles/

Ferrara, C., and G. De Feo. 2018. "Life Cycle Assessment Application to the Wine Sector: A Critical Review." Sustainability 10 (2): 395. https://doi.org/10.3390/su10020395

Ferrara, C., V. Zigarelli, and G. De Feo. 2020. "Attitudes of a Sample of Consumers Towards More Sustainable Wine Packaging Alternatives." Journal of Cleaner Production 271: 122581. https://doi.org/10.1016/j.jclepro.2020.122581

Fradique, S., T. Hogg, J. Pereira, and M. F. F. Pocas. 2011. "Performance of Wine Bag-in-Box During Storage: Loss of Oxygen Barrier." Italian Journal of Food Science 23: 11–16.

Gannon, S. 2009. "Pushing the Packaging Envelope—Alternative Formats and Closures Growing Fast in Volume Sales." Wines & Vines, November. https://winebusinessanalytics.com/features/article/68765/Pushing-the-Packaging-Envelope

Geueke, B. 2016. "Dossier: Can Coatings." Food Packaging Forum. Zenodo. https://doi.org/10.5281/zenodo.200633

Hopfer, H., P. A. Buffon, S. E. Ebeler, and H. Heymann. 2013. "The Combined Effects of Storage Temperature and Packaging on the Sensory, Chemical, and Physical Properties of a Cabernet Sauvignon Wine." Journal of Agricultural and Food Chemistry 61 (13): 3320–3334. https://doi.org/10.1021/jf3051736

Kalkowski, J. 2014. "Bringing Innovation to Bag-in-box." Packaging Digest, January 29. https://www.packagingdigest.com/smart-packaging/bringing-innovation-to-bag-in-box

McIntyre, D. 2019. "Once a niche product, canned wine enters the mainstream." The Washington Post, June 21. https://www.washingtonpost.com/lifestyle/food/once-a-niche-canned-wine-enters-the-mainstream/2019/06/21/acc49556-9202-11e9-b570-6416efdc0803_story.html

Revi, M., A. Badeka, S. Kontakos, and M. G. Kontominas. 2014. "Effect of Packaging Material on Enological Parameters and Volatile Compounds of Dry White Wine." Food Chemistry 152: 331–339. https://doi.org/10.1016/j.foodchem.2013.11.136

Robertson, G. L. 2006. Food Packaging: Principles and Practice. 2nd ed. CRC Press. https://doi.org/10.1201/9781420056150

Robinson, J. 2009. "Lighter Bottles, Tougher Cardboard." JancisRobinson.com, May 14. https://www.jancisrobinson.com/articles/lighter-bottles-tougher-cardboard

Robinson, J. 2019. "Carbon Footprints, Wine and the Consumer." JancisRobinson.com, December 12. https://www.jancisrobinson.com/articles/carbon-footprints-wine-and-consumer

Roux, P., and Y. Gérand. 2014. Comparative Life Cycle Assessment of the NOVINPAK® PET/RPET Bottle and Traditional Glass Bottle including Vine Growing and Vine Making.

Sajilata, M. G., K. Savitha, R. S. Singhal, and V. R. Kanetkar. 2007. "Scalping of Flavors in Packaged Foods." Comprehensive Reviews in Food Science and Food Safety 6 (1): 17–35. https://doi.org/10.1111/j.1541-4337.2007.00014.x

Shirakura, A., M. Nakaya, Y. Koga, H. Kodama, T. Hasebe, and T. Suzuki. 2006. "Diamond-like Carbon Films for PET Bottles and Medical Applications." Thin Solid Films 494 (1–2): 84–91. https://doi.org/10.1016/j.tsf.2005.08.366

Steckenborn, E. 2020. "Why the Future of Wine Packaging Is Recycled PET." Beverage Daily, March 6. https://www.beveragedaily.com/Article/2020/03/06/Why-the-future-of-wine-packaging-is-recycled-PET#

Tetra Pak. n.d. "Tetra Prisma Aseptic." Assessed April 15, 2021. https://www.tetrapak.com/en-us/solutions/packaging/packages/tetra-prisma-aseptic

Tetra Pak. 2018a. "Materials." https://www.tetrapak.com/packaging/materials

Tetra Pak. 2018b. "Tetra Pak Packaging Material - Packed with Innovation." YouTube, 0:03:02. Posted February 27, 2018. https://youtu.be/fR-esiS1Pn0

Thompson-Witrick, K. A., E. R. Pitts, J. L. Nemenyi, and D. Budner. 2021. "The Impact Packaging Type Has on the Flavor of Wine." Beverages 7 (2): 36. https://doi.org/10.3390/beverages7020036

Vargel, C. 2004. Corrosion of Aluminium. Science-Direct Online Ed. https://doi.org/10.1016/B978-0-08-044495-6.X5000-9

Weed, A. 2019. "Canned wine comes of age." Wine Spectator, May 22. https://www.winespectator.com/articles/canned-wine-comes-of-age

Weed, A. 2020. "Canned wine sales are bursting at the seams." Wine Spectator, August 3. https://www.winespectator.com/articles/canned-wine-sales-are-bursting-at-the-seams

Williams, M. 2019. "Is the future of wine in the can?" Forbes, October 26. https://www.forbes.com/sites/michellewilliams/2019/08/28/is-the-future-of-wine-in-the-can/#3d8590b76cc3