This is the fourth publication in the cellular agriculture series that provides information for seafood industry producers on production strategies for developing novel cultivated seafood products.

Introduction

The transition from a linear to a circular bioeconomy represents a pivotal shift in how we approach resource utilization and waste management. In a linear bioeconomy, resources are extracted, used, and disposed of, leading to significant waste and environmental impact. Conversely, a circular bioeconomy emphasizes the reuse, recycling, and repurposing of materials, thereby minimizing waste and fostering sustainability.

Fish waste, including fish skin, is a significant byproduct of the seafood industry that is often discarded. However, these materials hold untapped potential within the circular bioeconomy. Cellular agriculture offers a groundbreaking approach to seafood production, where fish cells are cultivated to produce fish meat without the need for traditional fishing or aquaculture. This method not only promises to meet the growing demand for seafood but also addresses critical issues such as overfishing and habitat destruction. In this context, using fish waste as a resource for cell-based seafood production emerges as a compelling solution. By integrating fish waste into the production process, we can enhance the sustainability and efficiency of cellular agriculture. This approach aligns with the principles of the circular bioeconomy, transforming waste into valuable inputs and closing the loop in seafood production. This EDIS publication provides information on the potential of fish skin and other fish waste materials to be used as natural sources in cell-cultivated seafood (i.e., seafood products manufactured by culturing fish muscle and fat production cells) production and its scaffolding.

What is a scaffold in cell-cultivated seafood?

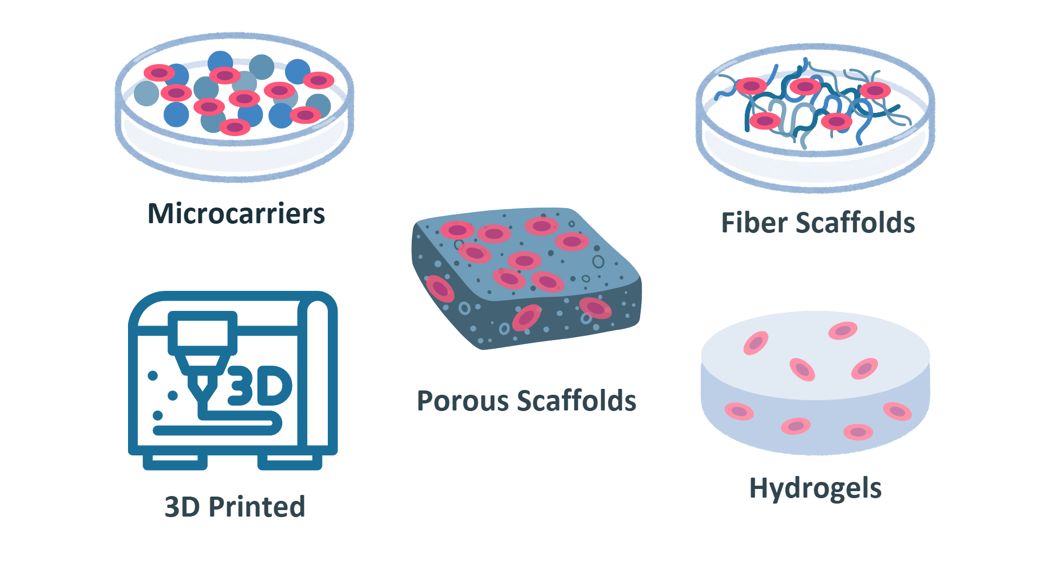

In cell-cultivated seafood, scaffolds provide structural support to growing cells. A scaffold can help the cells grow in a specific cell type (e.g., myocytes, adipocytes, and epithelial cells) and can also deliver growth factors or nutrients (Good Food Institute n.d.). A scaffold is typically a porous material that facilitates cell growth. The scaffold contains several components that encourage cell growth and determine the tissue's texture (Kamalvand et al. 2021). Scaffold materials are also responsible for the cell signaling that initiates cell differentiation, the process in which stem cells become specialized cells like muscle (myocytes) and skin (epithelial) cells (Ahmed et al. 2021). Through structural support and cell signaling, the scaffold plays a critical role in promoting the growth and development of cell cultures.

Although academic and industry research has shown that scaffold-free growth is possible, using scaffolds aids the development of more desirable textures in cell-cultivated seafood. Both natural and synthetic materials can be used as scaffolds (Good Food Institute n.d.). Natural materials include derivatives of animals, plants, and fungi. Extensive research on these types of scaffolds in tissue engineering aims to regrow and repair organs. However, there is a significant knowledge gap about the use of various scaffolds and scaffolding techniques for cell-cultivated seafood production. Some companies have explored using a plant-based material for cell-cultivated seafood production. A few companies have reported using plant-based scaffolds in the form of porous scaffolding material and microcarriers inside bioreactors (Waltz 2021; Poinski 2021). Since plant-based scaffolds lack flavor, one cell-based seafood company has researched adding flavoring to the scaffold to enhance the final product (Poinski 2021). However, plant-based scaffolds have drawbacks, such as the land and resources needed to produce them. Therefore, it is important to consider multiple options for scaffolding materials.

Credit: Julia Tvedt and Razieh Farzad, UF/IFAS

Fish Skin as a Natural Scaffolding Material

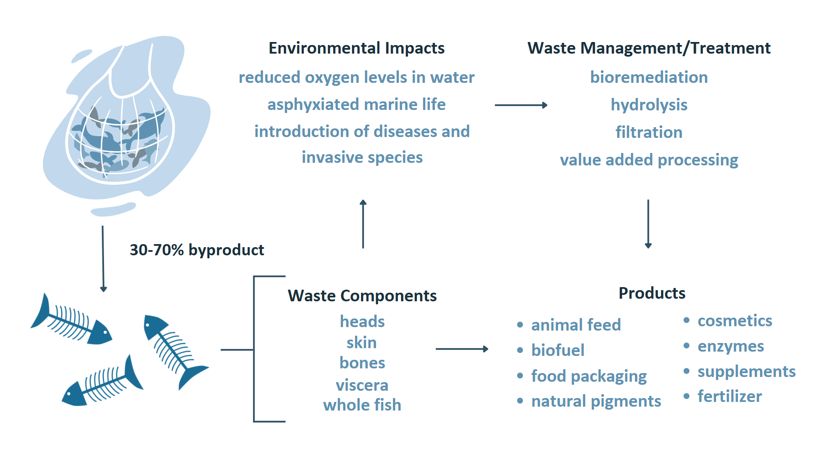

A large portion of fish goes unused for human consumption in seafood processing. According to the Food and Agriculture Organization (FAO), between 30% and 70% of whole fish become byproducts. For example, only 30% of tilapia is consumed as fillets, while 70% is not used for human consumption. It is also estimated that 50%–70% of tuna is discarded in canning (FAO 2024). These byproducts can go through further processing or be disposed of as waste. Biowaste from fishing and improper waste disposal can cause several environmental issues, such as a lack of oxygen in the water or the introduction of diseases and invasive species on the seafloor (Nelluri et al. 2024). To reduce the environmental impact, fish waste is recycled into new products in several industries. Fish waste is already used as a source of animal feed, biofuels, natural pigments, enzymes, gelatin, and proteins in the food and cosmetic industries (Arvanitoyannis and Kassaveti 2008). Fish byproducts are rich in nutrients like high-quality proteins; lipids with long-chain omega-3 fatty acids; vitamins A, D, and B12; and minerals like iron, zinc, selenium, and iodine (FAO 2024). These nutrients make fish waste a good starting point for several value-added products.

Credit: Julia Tvedt and Razieh Farzad, UF/IFAS

In addition to the several aforementioned uses, waste from fish processing, such as fish skin, could be used as a natural scaffold for cell-cultivated seafood production. There is limited data on the use of fish skin for cell-cultivated seafood. However, cell-cultivated meat has already been grown on scaffolds from animal and fish skin (Lee and Choi 2024). Due to substantial differences in sensory properties between meat and seafood, it is uncertain if fish cells will also have favorable results with similar methods. However, fish skin has promising potential as a scaffolding material for seafood due to its natural similarity to fish muscular tissue. Additionally, fish skin has shown promise in promoting cell growth, such as wound healing and tissue regeneration in biomedical engineering. Medical applications of tissue engineering with fish skin include treatments like regrowing skin in burn victims (Esmaeili et al. 2023). By drawing upon existing knowledge of tissue engineering and cell-cultivated meat, it is possible that fish skins could be a new source of scaffolding for cell-based seafood. This use of fish skins as a scaffold for cell-cultivated seafood has the potential to increase sustainability in the fishing industry and promote a circular bioeconomy.

Conclusion

The environmental impact of the fishing industry is well documented, and the need for more sustainable food systems is growing. Millions of metric tons of fish waste still go back into the ocean and cause harm to the environment. However, in an effort to be more sustainable and economically efficient, fish waste is processed and reused in several industries. Fish skin, in particular, has shown promise in tissue engineering and cellular agriculture. It also shows promise as a potential scaffold material for cell-cultivated seafood. Reusing fish skins from fish waste in this way would help improve overall sustainability by reducing environmental impact and upcycling an otherwise discarded ingredient.

References

Ahmad, K., J. -H. Lim, E. -J. Lee, H. -J. Chun, S. Ali, S. S. Ahmad, S. Shaikh, and I. Choi. 2021. “Extracellular Matrix and the Production of Cultured Meat.” Foods 10 (12): 3116. https://doi.org/10.3390/foods10123116

Arvanitoyannis, I. S., and A. Kassaveti. 2008. “Fish Industry Waste: Treatments, Environmental Impacts, Current and Potential Uses.” International Journal of Food Science & Technology 43 (4): 726–745. https://doi.org/10.1111/j.1365-2621.2006.01513.x

Esmaeili, A., E. Biazar, M. Ebrahimi, S. Heidari Keshel, B. Kheilnezhad, and F. Saeedi Landi. 2023. “Acellular Fish Skin for Wound Healing.” International Wound Journal 20 (7): 2924–2941. https://doi.org/10.1111/iwj.14158

Food and Agriculture Organization of the United Nations (FAO). 2024. The State of World Fisheries and Aquaculture 2024 – Blue Transformation in Action. https://doi.org/10.4060/cd0683en

Good Food Institute. n.d. “Scaffolds for Seafood.” Dive Deep: Cultivated Meat Scaffolding. Accessed April 10, 2023. https://gfi.org/science/the-science-of-cultivated-meat/deep-dive-cultivated-meat-scaffolding/#scaffolds-for-seafood

Kamalvand, M., E. Biazar, M. Daliri-Joupari, F. Montazer, M. Rezaei-Tavirani, and S. Heidari-Keshel. 2021. “Design of a Decellularized Fish Skin as a Biological Scaffold for Skin Tissue Regeneration.” Tissue and Cell 71: 101509. https://doi.org/10.1016/j.tice.2021.101509

Lee, S.-H., and J. Choi. 2024. “Three-Dimensional Scaffolds, Materials, and Fabrication for Cultured Meat Applications: A Scoping Review and Future Direction.” Food Hydrocolloids 152: 109881. https://doi.org/10.1016/j.foodhyd.2024.109881

Nelluri, P., R. Kumar Rout, D. Kumar Tammineni, T. J. Joshi, and S. Sivaranjani. 2024. “Technologies for Management of Fish Waste & Value Addition.” Food and Humanity 2: 100228. https://doi.org/10.1016/j.foohum.2024.100228

Poinski, M. 2021. “Why Finless Foods is taking the plunge into plant-based fish.” Food Dive, August 9. https://www.fooddive.com/news/why-finless-foods-is-taking-the-plunge-into-plant-based-fish/604051/

Waltz, E. 2021. “No Bones, No Scales, No Eyeballs: Appetite grows for cell-based seafood.” Nature Biotechnology, November 15. https://www.nature.com/articles/d41587-021-00022-6