Introduction

This publication focuses on the nitrogen (N) fertilizer best management practices (BMP) for green fresh-market and processing cabbage head (Brassica oleracea Capitata) production in Florida. This publication aims to provide management strategies that comply with statewide BMP guidelines to optimize economic yield while minimizing nitrogen (N) losses to the environment. The guidelines presented in this document are supported by field-based research conducted by UF/IFAS and lay out the foundation for precision agriculture efforts for fresh cabbage production in Florida. This document does not include N-fertilizer guidelines for Chinese cabbage or napa cabbage types. This document is divided into three main sections. The first section describes the cabbage production practices and nutrient demand for different plant development stages. The second section summarizes the research findings for N-fertilizer rate application and timing. The third section provides a practical guide for N-fertilizer management for cabbage in Florida.

In summary, the application of an N-fertilizer rate of 175 lb/acre may not supply sufficient N for a cabbage crop when produced on bare ground in sandy soils, primarily due to the excessive N losses. The information and data presented in this document support adjusting the current UF/IFAS N-fertilizer rate of 175 lb/acre N for cabbage production to 225 lb/acre with the adjustment by the plant population for bare-ground and plasticulture systems. These revisions will allow cabbage producers to maintain economically viable yields and sustainable operations across production systems common to the Florida vegetable industry while mitigating water quality impacts associated with overfertilization, improper timing of fertilizer application, and high rainfall events. This publication's target audience is cabbage growers, Extension agents, crop consultants, representatives of the fertilizer industry, state and local agencies, students, instructors, researchers, and interested Florida citizens.

Florida Cabbage Production

Cabbage is an important vegetable commodity in Florida, planted on approximately 9,000 acres with a value of production of almost $50 million (USDA-NASS 2023). Nationally, Florida cabbage ranks 3rd in value of production. Cabbage is produced in several counties across the state, from south Florida (e.g., Palm Beach County) to the Tri-County Agricultural Area (i.e., St. Johns, Flagler, and Putnam Counties). Cabbage is a cool-season crop, and weather during the growing season is a major driver of yield. Thus, differences in yield are expected between years and even planting dates within the same year. For example, the first planting dates around October are characterized by fast initial plant growth, shorter seasons, and higher yield. Planting dates during November coincide with lower air temperature and reduced solar radiation, resulting in a longer season (>100 days) between planting and harvest and relatively lower yield potential.

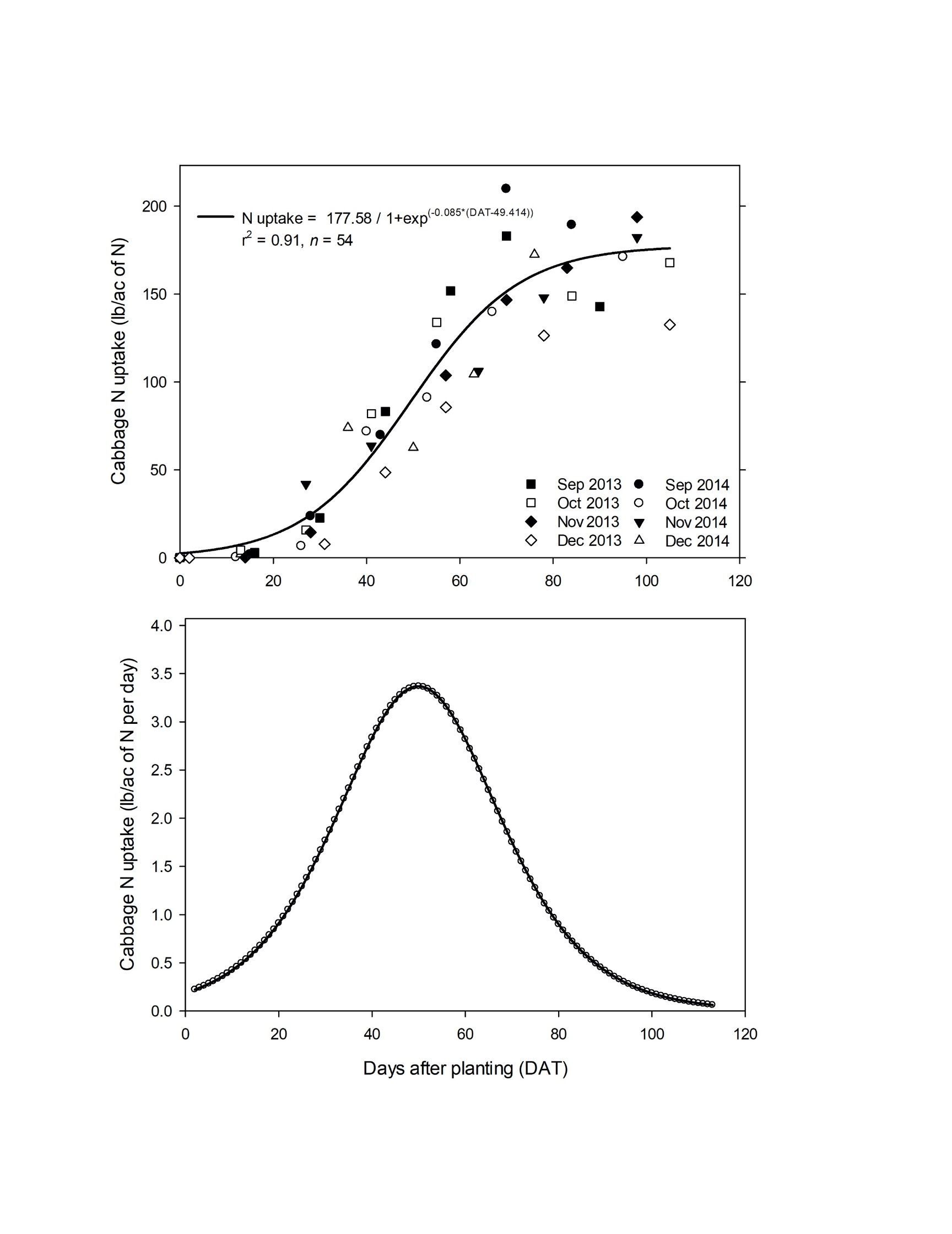

The majority of the cabbage fields rely on seepage irrigation due to the predominance of production on Spodosols with a shallow water table. There are also cabbage production areas in Florida where the dominant soil types are Entisols with a well-drained soil profile, where sprinkler/overhead irrigation is the predominant irrigation method. For both soil types, cabbage can be produced either on bare ground or plastic mulch with drip irrigation. The commercial production of cabbage under seepage generally uses bare-ground hills spaced 40 inches apart with an in-row plant spacing of 8 inches, which results in approximately 19,600 plants/acre. On well-drained soils, row spacing is generally 36 inches with 8 inches of in-row plant spacing (21,780 plants/acre). In the plasticulture system, cabbage is generally grown on 4-foot-wide raised beds spaced 6.67 feet center to center, with black plastic mulch and two drip-irrigation tapes. The increased surface area covered by the plastic mulch allows for different plant spacing arrangements (i.e., 3 or 4 planted rows with in-row planting spacing ranging from 10 to 14 inches and a plant population of 16,800 to 26,130 plants/acre) leading to an increase in cabbage plant population per area (Barrett et al. 2015). Despite the 36% higher cost of plastic mulch and drip systems compared to bare-ground systems, the higher plant population on plasticulture makes the system economically viable, resulting in up to 57% higher profit than the bare-ground system (Barrett et al. 2018a; Paranhos et al. 2016). During periods of freezing temperatures, there was far less damage on plasticulture cabbage vs. conventional observed in a demonstration trial in Hastings in the 2018–19 season (Mussoline et al. 2019). The use of plastic mulch and drip tape also includes some benefits regarding N-fertilizer management. With drip irrigation, fertilizer management is facilitated by fertigation, where a nutrient solution, in conjunction with irrigation water, is directly applied to the root zone. Fertilizer applications can be split with ease during the season to match the cabbage nutrient uptake curve (Figure 1). Plastic mulch improves soil water conservation and minimizes the risk of nitrate leaching from the root zone.

The distinctions in plant population between bare-ground and plasticulture systems are very important due to differences in fertilizer amounts per cultivated area; however, we used the amount of fertilizer per plant to compare N-fertilizer rate recommendations between both systems and to perform further adjustments accounting for variations of plant population within each production system.

Summary of N-Fertilizer Research on Cabbage

N-Fertilizer Management in Bare-Ground Cabbage Production

A study was conducted by UF/IFAS to evaluate the cabbage yield and quality in response to N-fertilizer rates in the Hastings, FL area. More details about this study can be found at da Silva et al. (2020). The study was conducted in the winter of 2016 and 2017. The plant population in the study was 19,600 plants/acre, with a plant row spacing of 40 inches center to center and a plant in-row spacing of 8 inches. All fertilizer N rate treatments received 45 lb/acre of N, 20 lb/ac of P2O5, and 37 lb/acre of K2O at preplant of fertilizer blend NPK, and 42, 60, and 78 lb/acre of N (15.5% N as calcium nitrate in three subsequent applications for a total of 170, 225, and 280 lb/acre of N [equivalent to rate of 0.009, 0.011, and 0.014 lb of N per plant, respectively]), applied at 14, 28 and 42 days after transplanting (DAT). Posttransplant fertilizer was banded near the planted row, followed by midrow disking. Cabbage cultivars tested were ‘Bravo’, ‘Cheers’, ‘Capture’, ‘Bronco’, ‘Ramada’, and ‘Bruno’. Two contrasting patterns of rainfall occurred. In 2016, the cumulative rainfall from transplant to harvest was 10.5 inches, with two major rain events of 2.3 and 2.4 inches at 9 and 89 DAT. The 2017 crop season was much drier, with only 2.1 inches and only two occasions with minimum air temperature in the 40s°F. The average air temperature was similar between both growing seasons, with minimum and maximum average air temperature ranging from 52°F to 77°F. Between 70 and 90 DAT in the 2016 season was also cooler than in 2017, with minimum air temperatures reaching the low 30s°F on four occasions.

The lack of interaction between N-fertilizer rates and cabbage cultivars indicated that a similar response of cabbage yield to N-fertilizer rate is expected regardless of cabbage cultivar(s). Cabbage yield response to N-fertilizer was directly related to the precipitation pattern within each season. In 2016, increasing N-fertilizer application rates did not increase total (45,391 lb/acre) or marketable (38,618 lb/acre) cabbage yield (Table 1). In the same year, about 14%–16% of the plants were classified as culls (<2 lb heads) with no differences between N-fertilizer treatments. The lack of yield response to N-fertilizer rates is an indication that N-fertilizer was not the limiting factor for cabbage yield in 2016. On the contrary, the main reason for reduced yield may be attributed to reduced solar radiation available to the crop in 2016 due to the several days with overcast sky and the low air temperatures during crop maturation.

Table 1. Cabbage total and marketable yield (head size >2 lb) response to N-fertilizer rates under bare-ground production system with 19,600 plants/acre in Florida. Adapted from da Silva et al. (2020).

The growing conditions were more favorable for cabbage production in 2017. Therefore, cabbage yield response to N-fertilizer rates were captured. In 2017, there was an increase in total yield with increasing N-fertilizer rate (Table 1). The N-fertilizer rate of 280 lb/acre yielded more than 170 lb/acre; however, the 225 lb/acre rate yielded similarly to the 280 and 170 lb/acre rates. Marketable yield was significantly higher in the 225 and 280 lb/acre fertilizer N rates compared to the 170 lb/acre N-fertilizer rate. The proportion of culls were 9%, 5%, and 4% for the N-rates 170, 225, and 280 lb/acre of N-fertilizer, respectively. There was no difference in marketable yield for 170 lb/acre of N-fertilizer between 2016 and 2017, confirming that even when growing conditions are favorable as observed in 2017, 170 lb/acre of N-fertilizer rate was not enough to support the potential yield. These results indicates that cabbage yield may be limited with 170 lb/acre of N but not with 225 lb/acre of N-fertilizer, which was the fertilizer N rate required to sustain maximum marketable yields in sandy soils.

N-Fertilizer Management in Plastic Mulch Cabbage Production

UF/IFAS conducted a series of studies in the Hastings area between 2010 and 2015 to develop crop management practices for cabbage on plastic mulch to optimize cabbage plant population, N-fertilizer rates, and irrigation management (Barrett et al. 2018a, 2018b; Barrett et al. 2015; Paranhos et al. 2016).

A field study conducted in 2013 and 2014 using plastic mulch evaluated cabbage yield and N uptake of cultivar ‘Bronco’ for planting dates from September, October, November, and December. The study used a plant population of 26,136 plant/acre (4 rows with plant in-row spacing of 12 inches) and a single N-fertilizer rate of 238 lb/acre of N (equivalent to 0.009 lb of N per plant). Preplant granular fertilizer blend was incorporated into the beds using a 10-15-10 (NPK) at a rate of 100, 150, and 100 lb/acre of N, P2O5, and K2O, respectively, prior to fumigation and plastic mulch installation. The preplant fertilizer application supplied 42%, 100%, and 42% of the total N, P2O5, and K2O, respectively. The remaining N and K fertilizers were applied by fertigation for a total injected rate of 140 lb/acre of N as calcium nitrate (15.5% of N) and 140 lb/acre of K2O as muriate potash (61% of K2O). Fertigation events were divided into four applications at 14, 28, 42, and 56 DAT. The proportion of N and K2O applied in each fertigation event was equivalent to 8%, 15%, 20%, and 15% of the total N and K2O. The strategy of splitting fertilizer matched with the cabbage N-uptake curve, and the last application of N occurred at 56 DAP, which coincided with the peak cabbage N-uptake about 49 DAP (Figure 1).

Credit: Adapted from Paranhos (2015)

Similarly to other cole crops, cabbage growth is generally slow in the first 20 DAT, corresponding to the seedling developmental stage of up to 9–12 true leaves. In this early stage, plant N uptake rate increases from 0.25 to 1.0 lb/acre of N (Figure 1). Cabbage growth progresses from precupping, head formation, and initial head-filling stages within the period of 30–70 DAT. This period is characterized by a very rapid growth of the aboveground plant tissues and great demand for N uptake. The measured plant N uptake rate increased from 1.0 lb/acre of N/day, peaking around 50 DAT with a rate of N uptake at 3.5 lb/acre of N/day (Figure 1, bottom). For cabbage production using fertigation, fertilizer injections should occur between transplant and 70 DAT. The head fill and maturing stages occur after 70–80 DAT, coinciding with a decrease in the rate of N uptake up until the time of harvest.

In this study, marketable cabbage yield ranged from 41,853 to 62,809 lb/acre and was mostly impacted by climatic conditions and planting dates. The total N uptake in the aboveground plant tissues (i.e., cabbage head and wrapper leaves) ranged from approximately 145 to 218 lb/acre of N across planting dates, which when divided by the plant population in this study is equivalent to 0.006 to 0.008 lb of N per plant (Table 2). The N use efficiency (NUE), which is an indicator of capability of the plant to use the soil-available N, ranged from 27%–55%, with an average of 40%.

Table 2. Marketable yield (lb/acre), aboveground N accumulation (lb/acre), and nitrogen use efficiency (NUE) for cabbage cultivar ‘Bronco’ fertilized with 238 lb/acre of N (i.e., equivalent to 0.009 lb of N per plant) and a plant population of 26,136 plant/acre cultivated on plastic mulch in the 2013 and 2014 seasons in Hastings, FL. Adapted from Paranhos (2015).

A N-fertilizer rate study was also conducted using plastic mulch for two consecutive seasons in 2013 and 2014. In the 2013 season, the N-fertilizer rates tested were 80, 176, 261, 350, and 525 lb/acre of N at a plant population of 31,363 plant/acre (16% higher population than the previous study). The range of N applied in the first year was 0.003 to 0.017 lb of N/plant. In the 2014 season, the same plant population was tested and N-fertilizer rates were adjusted to 200, 300, 400, 500, and 600 lb/acre of N, representing a range of 0.006 to 0.019 lb of N/plant. Preplant granular fertilizer blend was incorporated into the beds using 80 lb/acre of N, 36 lb/acre of P2O5, and 66 lb/acre of K2O the 2013 season, and 200 lb/acre of N rate for the 2014 season. In both seasons, additional P was supplied preplant using a triple superphosphate 0-20-0 phosphorus fertilizer for a total of 100 lb/acre of P2O5 for all treatments. Calcium nitrate (15.5-0-0) and potassium chloride (0-0-50) were used to supply the remaining N and K2O via fertigation, keeping K balanced with N. The fertigation schedule supplied fertilizer at increasing concentrations during the exponential crop growth phase and then at reduced concentrations as crop growth slowed near maturity. During the 2014 season, there were 12 weekly fertigation events in which fertilizer was distributed at 2%, 4%, 4%, 8%, 8%, 10%, 10%, 12%, 12%, 12%, 10%, and 10% of the injected total, respectively. During the 2014 season, the number of fertigation events was reduced to 7, in which fertilizer was distributed at 5%, 5%, 10%, 20%, 25%, 25%, and 10% of the injected total, respectively.

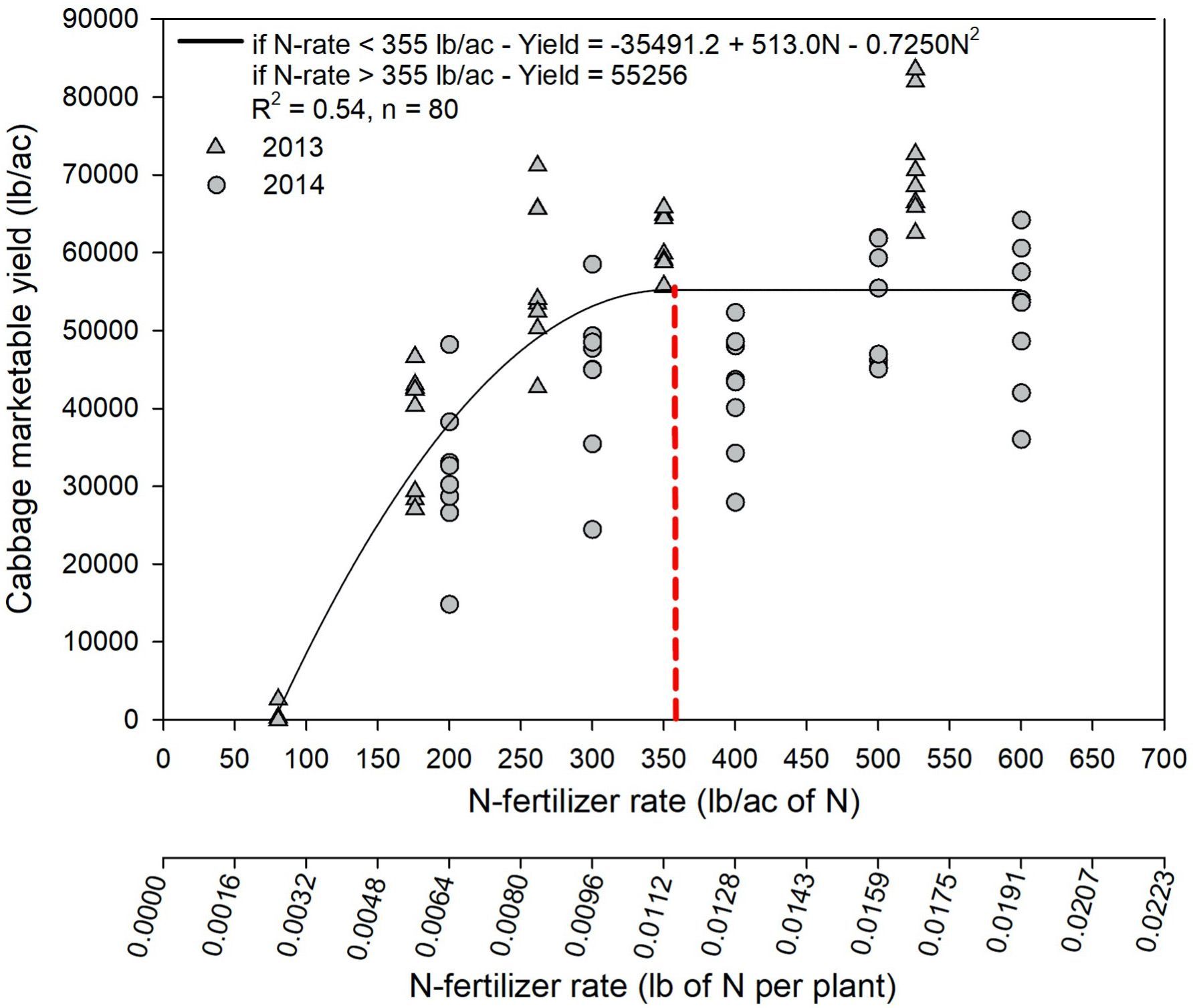

Figure 2 shows the cabbage marketable yield response to increasing N-fertilizer rates for the two years of study combined. The 2013 season was much cooler and drier, resulting in higher marketable yield than 2014. Different weather conditions for these cropping seasons allowed for examining cabbage yield in response to N-fertilizer rates and a determination of an optimum N application rate range regardless of the weather conditions. Maximum cabbage marketable yield as indicated by the response of a quadratic-plateau model was reached with N-fertilizer rates of 355 lb/acre (equivalent to 0.0113 lb of N/plant) and no additional increase in yield with N-fertilizer rates above 355 lb/ac.

Credit: Data source: Barrett et al. (2018b)

The results from the plastic mulch trials are comparable to the bare-ground trials when the rates are expressed on a plant population basis, indicating that a minimum N-fertilizer rate of 0.0115 lb of N/plant is required, and the per-plant rate can be adjusted to a rate per acre using the actual plant population. For example, bare-ground cabbage production with 19,600 plants/acre would require a N-fertilizer rate of 225 lb/acre of N, while cabbage cultivated on plastic mulch with a plant population of 26,136 plant/acre would require a N-fertilizer rate of 300 lb/acre of N to achieve maximum yield. It is noteworthy that the bare-ground system is a less efficient system with regard to use of space, irrigation water use, and susceptibility to nutrient loss via leaching than the plastic mulch system. In bare ground, supplemental N-fertilizer rate may be required if excessive rainfall occurs after the last fertilizer application. In this case, guidelines for supplemental application can be found in EDIS article HS711, “Soil and Fertilizer Management for Vegetable Production in Florida” (https://edis.ifas.ufl.edu/cv101). Application of supplemental N-fertilizer using plasticulture and fertigation should be carefully evaluated because the susceptibility of leaching is much reduced compared to the bare-ground system.

N-Fertilizer Best Management Practices for Cabbage

Best management practices are defined as a practice or combination of practices based on research, field-testing, and expert review to the most effective and practical on-location means, including economic and technological considerations for improving water quality in agricultural discharges (FDACS 2015). Many factors that should be considered to design an N-fertilizer program for cabbage are based on the “Four Rs Principles,” which include the right rate, right timing of application, right placement, and right source of fertilizer and in-season diagnostic of nutrient status. More information on the general concepts of 4Rs can be found at EDIS article SL411, “The Four Rs of Fertilizer Management” (https://edis.ifas.ufl.edu/ss624). The principles of plant nutrition presented in the BMP manual (FDACS 2015) are discussed below, emphasizing cabbage.

Principle 1—Supplying the Right Amount of Nutrients Based on Plant Population, Cultivation Method, and Planting Date

The selection of a realistic N-fertilizer rate for cabbage is an important decision that will directly impact yield, economic return, and potential N leaching. It is noteworthy that the N-fertilizer rate is not the only factor that can limit cabbage yield. Other factors impacting cabbage yield potential include, but are not limited to, planting date, cultivars, soil type, weather conditions, disease and pest management, and adequate irrigation. A commercial cabbage head size ranges between 2–4 lb; oversized heads >4 lb are not desirable and frequently refused by fresh produce buyers. Cabbage yield is limited to one head per plant, so increasing the plant population per acre is one way to increase the yield per area, and excessive N-fertilizer applications will not increase yield. Because there is a limit on commercial cabbage head size, assuring that the required amount of N is available for plant uptake when needed is critical for a successful nutrient management plan. UF/IFAS has determined that a cabbage plant will require about 0.0115 lb of N-fertilizer/plant. This value was determined using two independent methods:

(1) By determining the total amount of N in the aboveground plant tissues, which ranged from 145 to 218 lb/acre, then dividing by the number of plants in the study, which resulted in 0.006 to 0.008 lb of N per plant. The average NUE was 40%, meaning 40% of the N-fertilizer applied was used by the cabbage plant. Using these N-per-plant and NUE values, the N-fertilizer rate required ranges from 0.096 to 0.0128 lb of N-fertilizer per plant.

(2) By using the N-fertilizer rate curve (Figure 2), from which a maximum yield of 55,256 lb/acre was obtained when N-fertilizer rate reached 355 lb/acre (or 0.0113 lb of N/plant) for a population of 31,363 plant/ac. From the bare-ground study, it was concluded that the minimum N-fertilizer rate of 225 lb/acre (0.0114 lb of N/plant) was necessary to reach the average cabbage yield 55,777 lb/ac.

In practice, the N-fertilizer for cabbage can be determined as follows:

Example 1: Cabbage grown on bare ground with a row spacing of 36 inches with in-row plant spacing of 8 inches has a population of 21,780 plants/acre × 0.0115 lb of N/plant = 250 lb/acre of N-fertilizer.

Example 2: Cabbage grown on plastic mulch 4-foot-wide raised beds spaced 6.6 feet center to center with black plastic mulch and two drip-irrigation tapes. Plant arrangement is 3 planted rows with in-row spacing of 10 inches, with a total plant population of 23,522 plants/acre. Plant population of 23,522 plants/acre × 0.0115 lb of N/plant = 271 lb/acre of N-fertilizer.

Table 3 and 4 present equivalent N-fertilizer rate recommendation according to variations of plant population based on row spacing and in-row plant spacing for bare-ground and plastic mulch cabbage production in Florida.

Table 3. Cabbage plant population (plants per acre) as function of row spacing and in-row plant spacing and respective N-fertilizer rate recommendations for cabbage grown on bare ground in Florida.

Table 4. Cabbage plant population (plants per acre) as function of bed spacing, number of cultivated rows per bed, and in-row plant spacing and respective N-fertilizer rate recommendations for cabbage grown on plastic mulch in Florida.

Principle 2—Diminishing Returns

Increasing N-fertilizer rates showed a positive response to marketable cabbage yield up to a N-fertilizer rate of 225 lb/acre of N (0.0115 lb/plant) on bare ground and 335 lb/acre (0.0113 lb/plant) on high-population plastic mulch. At N-fertilizer rates above that point, marketable yield stops responding to increasing N-fertilizer applications; reductions in net return may occur with the increase cost of N-fertilizer.

Principle 3—Fertilizer Timing

N-fertilizer application timing can effectively reduce N-fertilizer leaching in cabbage production because of the improved synchronization with crop demand. The optimum application timing of N-fertilizer for cabbage should match the nutrient uptake curve (Figure 1). In practice, three to four split applications should be considered. For bare ground, application of 20%–30% of the N can be incorporated in the row or bed at planting, followed by two additional applications (e.g., at 6–8 inch tall plants and the initial head formation stage) as top-dress, banded, or knifed-in on the side of rows with liquid fertilizer. Additional N-fertilizer applications can occur after leaching rain events. Guidelines for supplemental application can be found at EDIS article HS711, “Soil and Fertilizer Management for Vegetable Production in Florida” (https://edis.ifas.ufl.edu/cv101).

Credit: L. Zotarelli, UF/IFAS

For the drip-irrigated, plastic mulch systems, apply 30% of N-fertilizer in the bed at planting. The remaining N-fertilizer can be injected up to 4 times during the season every two weeks (e.g., 14, 28, 42, and 56 DAT) at equivalent rates of 10%, 15%, 25%, and 20% of the total N.

In-season adjustment of N-fertilizer can be made by evaluating the plant tissue N concentration (i.e., dry samples sent to the lab for total N content analysis; results are generally expressed as percentages). In this case, the most recently mature leaf can be sampled 8 weeks after planting. The adequate level of N% concentration is between 3%–6%; N% concentration below and above these values indicates high and deficient levels of N% concentration, respectively.

Principle 4—Fertilizer Sources

N-fertilizer sources can be found in ammoniacal and nitrate forms. In the soil, nitrate forms are preferred by plants for uptake, but they are also more susceptible to leaching than ammonium. Thus, in selecting N-fertilizer sources, it is recommended that 25%–50% of the N-fertilizer be supplied from nitrate sources (Liu et al. 2018). Also, the application of N-fertilizers in liquid or dry form has not shown differences in yield response. Guidelines on the conversion from liquid to dry and vice-versa can be found in EDIS article HS1200, “How to Convert Liquid Fertilizer into Dry Fertilizer in Fertigation for Commercial Vegetable and Fruit Crop Production” (https://edis.ifas.ufl.edu/hs1200).

A successful N-fertilization program can be achieved using water-soluble N-fertilizer sources when the proper timing and rate of N-fertilizer are chosen. The use of controlled-release N-fertilizers (CRF) or slow-release fertilizer (SLF) is not widely adopted by cabbage growers, mainly because of the higher relative cost compared to the water-soluble sources and the uncertainties in synchronization of nutrient release and plant uptake. More research is needed to match the synchronization of CRF N-fertilizer sources for short-season vegetable crops like cabbage. More information on the use of CRF can be found in EDIS article HS1255 “Controlled-Release and Slow-Release Fertilizers as Nutrient Management Tools” (https://edis.ifas.ufl.edu/hs1255).

References

Barrett, C. E., L. Zotarelli, L. G. Paranhos, P. Dittmar, C. W. Fraisse, and J. VanSickle. 2018a. “Economic Feasibility of Converting from a Bare Ground System with Seepage Irrigation to Plasticulture for Cabbage Production: Where Is the Risk?” HortScience 53 (6): 875–881. https://doi.org/10.21273/HORTSCI12966-18

Barrett, C. E., L. Zotarelli, L. G. Paranhos, P. Dittmar, C. W. Fraisse, and J. VanSickle. 2018b. “Optimization of Irrigation and N-Fertilizer Strategies for Cabbage Plasticulture System.” Scientia Horticulturae 234:323–334. https://doi.org/10.1016/j.scienta.2018.02.063

Barrett, C. E., L. Zotarelli, L. G. Paranhos, B. S. Taylor, P. Dittmar, C. W. Fraisse, and J. VanSickle. 2015. “Optimum Planting Configuration for High Population Plasticulture Grown Cabbage.” HortScience 50 (10): 1472–1478. https://doi.org/10.21273/HORTSCI.50.10.1472

da Silva, A. L. B. R., J. S. Candian, L. Zotarelli, T. Coolong, and C. T. Christensen. 2020. “Nitrogen Fertilizer Management and Cultivar Selection for Cabbage Production in the Southeastern United States.” HortTechnology 30 (6): 685–691. https://doi.org/10.21273/HORTTECH04690-20

Mussoline, W., B. Wells, G. K. England, and L. Zotarelli. 2019. “Improved Productivity and Economic Advantages of Advanced Cabbage Production on Plasticulture.” Proc. of Fla. State Hort. 132:108–110. https://journals.flvc.org/fshs/article/view/132381/136086

Paranhos, L. G. 2015. “High Density Cabbage Production under Plasticulture: Yield, Nitrogen Uptake, Irrigation Demand and Economics.” Horticultural Sciences. University of Florida, Gainesville, FL, p. 115.

Paranhos, L. G., C. E. Barrett, L. Zotarelli, T. Borisova, R. Darnell, and K. Migliaccio. 2016. “Cost-Benefit Analysis of Cabbage Grown Using a Plasticulture and seepage bare ground Production System in Florida.” HortTechnology 26 (6): 699–706. https://doi.org/10.21273/HORTTECH03444-16

USDA-NASS. 2023. “2023 State Agriculture Overview — Florida.” Accessed 20 August 2024. https://www.nass.usda.gov/Quick_Stats/Ag_Overview/stateOverview.php?state=FLORIDA