This document was developed subsequent to completion of the National Mango Board–sponsored research projects “Fresh-Cut Mangos as a Value-Added Product” and “Overcoming Limitations for Processing Riper Mango Fruit for Fresh-Cut Mango,” and we thank the following project participants for their experience and expertise that helped to inform the contents of this handbook:

Jinhe Bai, Elizabeth A. Baldwin, Elena Branca, Christopher Ference, Sierra Jamir, Xiuxiu Sun, and David Wood, US Horticultural Research Laboratory, USDA, ARS, Fort Pierce, FL

Carlos H. Crisosto, Gayle M. Ulrich Crisosto, and Ana Ibanez, Plant Science Department, University of California, Davis, CA

Carolina Abrahan, Kim Cordasco, Sonya Stahl, and Yurui Xie, Horticultural Sciences Department, University of Florida, Gainesville, FL

Dennis Kihlstadius of Produce Technical Services and Timothy Beerup of Beerup, Inc.

Disclaimer

The National Mango Board (NMB), an instrumentality of the US Department of Agriculture, commissioned this work to assist the mango industry. Every effort has been made to ensure the accuracy and completeness of the information. However, NMB makes no warranties, expressed or implied, regarding errors or omissions and assumes no legal liability or responsibility for loss or damage resulting from the use of information contained in this document. Mention of a trademark or proprietary product is for identification only and does not imply a guarantee or warranty of the product by the US Department of Agriculture. The US Department of Agriculture prohibits discrimination in all its programs and activities on the basis of race, color, national origin, gender, religion, age, disability, political beliefs, sexual orientation, and marital or family status.

Table of Contents

Background and Purpose

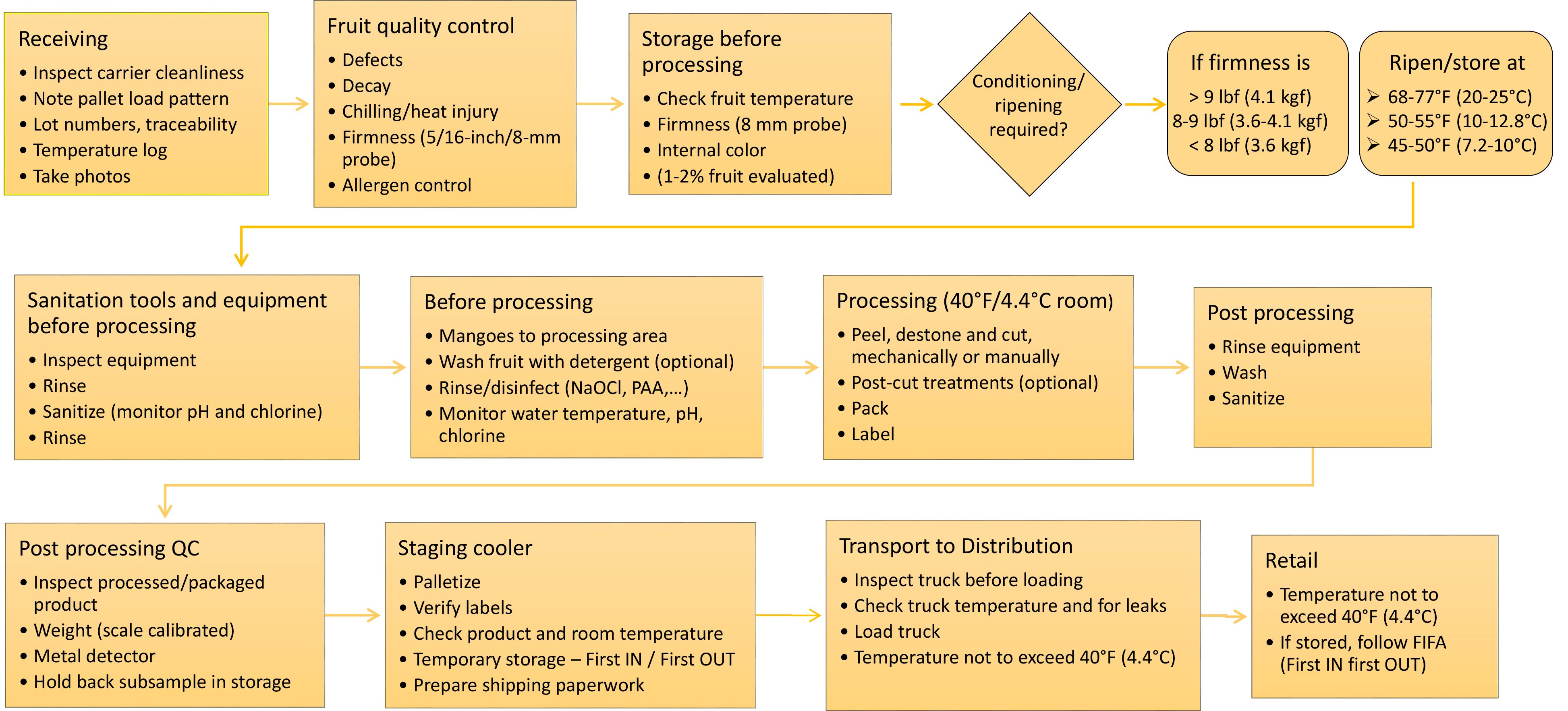

Process Map for Fresh-Cut Mangos

Sanitation and Other Food Safety Practices

Worker sanitation practices

Sanitation of facilities and processing equipment

Fruit washing prior to and during processing

Safe handling practices during and after processing

Food safety testing

Mango Procurement

Mango varieties for fresh-cut

Optimum maturity/ripeness for processing

Packaging for whole fruit

Transport temperature

Receiving Mangos at the Processing Facility

Temperature and condition of fruit and transport equipment on arrival

Initial fruit quality control inspection

Storing Mangos Prior to Processing

Ripening Mangos Prior to Processing

Temperature Management after Ripening

Processing Operations and Considerations

Fruit handling prior to processing

Fruit temperature prior to and during processing

Peeling, pitting and cutting

Supplemental treatments to reduce deterioration

Anti-browning treatments

Firming treatments

Edible coatings

Package filling, closing, and sealing

Packaging for Fresh-Cut Mango

Package design and labeling criteria and recommendations

Modified atmosphere packaging (MAP)

Storage and Shipping of the Processed Product

Receiving Fresh-Cut Mangos at the Retail or Food Service Distribution Center

Staging for Loading at the Retail or Food Service Distribution Center and Transport to Stores

Fresh-Cut Mangos at Retail Stores and Food Service Establishments

Unloading and holding on docks at stores

Temporary holding in walk-in coolers at retail stores and food service establishments

Display conditions and product rotation

Fresh-Cut Mangos in the Home

Refrigerator temperature

Appearance and odor when opening

Best-by dates versus temperature

After the package is opened

Appendix

Recordkeeping

Quality control procedures

Initial fruit inspection

Measuring fruit maturity and ripeness

Measuring fruit quality

Background and Purpose

Ensuring that the quality and consistency of the fresh-cut mangos that are available to consumers in the United States are as good as they can possibly be is an important goal of the National Mango Board (NMB). The NMB-funded projects “Fresh-Cut Mangos as a Value-Added Product” and “Overcoming limitations for Processing Riper Mango Fruit for Fresh-Cut Mango” were conducted to identify impediments to successfully meeting that goal. The final deliverable of those projects is this best management practices manual for producing fresh-cut mangos marketed in the United States. The manual includes quality-control procedures to use when managing fresh-cut mango commercial operations.

Every step in the preparation of fresh-cut mangos contributes to delivery of good quality and shelf life to customers. Therefore, attention to detail is required at each step, from acquiring and selecting the whole fruit to processing and distribution of the fresh-cut product. This manual outlines the major steps involved in fresh-cut mango processing and distribution and addresses the common problems and recommended best practices that will ensure delivery of the best possible quality fresh-cut mango products to your customers.

Process Map for Fresh-Cut Mangos

Credit: UF/IFAS

Sanitation and Other Food Safety Practices

Worker Sanitation Practices

Workers should wash their hands immediately when they enter the facility from outside.

Workers showing signs of illness or open lesions that could contaminate a food or food-contact surface should be excluded from the processing facility.

Workers should have a dedicated room to change their clothes and put on clean boots, coats, gloves, hats, hair nets, before entering the processing room. All jewelry should be removed. Workers should wear clothes that do not have buttons, only zips. Gloves should be of impermeable materials. Upon entering the processing room, workers must wash their hands again and put on aprons, gloves, and masks.

Any time a surface other than a sanitized food surface must be touched, such as a doorknob, handle, or cart, gloves should be changed or gloved hands dipped in a bucket with bleach at 200 ppm or other sanitizer.

Credit: K. Brecht, UF/IFAS

Workers should have a dedicated break room and follow cleaning and sanitation practices when leaving and upon re-entering the processing facility. Educational signs and posters should be placed in the break room and/or the changing room.

Workers should be regularly trained, including supervisors.

For more information: CFR21-Subpart A, §117.10 - Personnel: CFR - Code of Federal Regulations Title 21 (fda.gov)

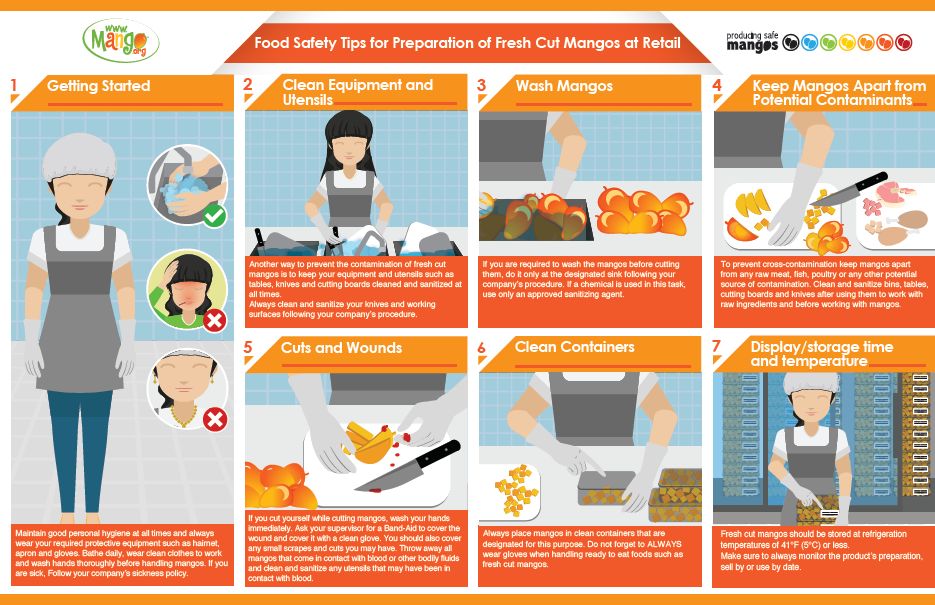

Credit: National Mango Board, www.mangofoodsafety.org/english/Fresh_Cut_Retail/Mango-Tips-Preparation3.pdf

Sanitation of Facilities and Processing Equipment

Facilities should be maintained clean and in proper repair to avoid any possible food contamination. This includes walls, ceilings (no peeling paint), lights (no loose-hanging fixtures, no accumulated dust), drains (no accumulated food residues), heating and/or air conditioning systems in good function, with air intake such as to prevent contaminated air in the facility. Positive air pressure in the processing area should help airborne contaminants on the food. Adding dehumidifiers in cold rooms would reduce moisture favorable for development of listeria (Suslow and Harris 2000). Pests (insects, spiders, and rodents) must be excluded using methods that do not contaminate foods. Recommended practices include spraying cracks and crevices at regular time intervals (weekly or monthly) and checking rodent and insect traps daily.

Equipment and utensils should be kept clean and sanitized before and after processing.

Pest control and sanitizing chemicals should be stored in a separate locked storage room, where no other food ingredients or food containers are stored.

Waste and disposal of mango peels and seeds as well as runoff of cleaning water need to be done following local environmental laws.

For more information:

- CFR21- Subpart B – Building and Facilities. §117.35 – Sanitary operations.

- Trevor Suslow and Linda Harris. 2000. “Guidelines for Controlling Listeria monocytogenes in Small- to Medium-Scale Packing and Fresh-Cut Operations.” https://ucfoodsafety.ucdavis.edu/sites/g/files/dgvnsk7366/files/inline-files/8015.pdf (These are specific recommendations to control Listeria monocytogenes in the processing plant, but they apply to all bacteria.)

All processing equipment should be manufactured in accordance with food safety rules, using noncorrosive surfaces, with no possible contaminations from fuel, oil, metal fragments, unsafe water, or any contaminant.

There should be enough space between walls and processing equipment to allow for proper cleaning and sanitation.

Refrigerated storage for foods should have a recording thermometer and, if possible, should be fitted with automatic control to regulate temperature or send an alarm when the temperature is out of range. Also avoid condensate areas in the refrigerated zone. Allow good air circulations.

For more information:

- FS15/FS076: Basic Elements of a Sanitation Program for Food Processing and Food Handling (ufl.edu)

- CFR21- Subpart B – Building and Facilities. §117.40 – Equipment and utensils

After processing, equipment should be thoroughly inspected for particle residues from the cut fruit. Cleaning of food processing surfaces should consist in the following sequence: RINSE – CLEAN – RINSE – SANITIZE. Clean and sanitize equipment first, then walls and floors.

The quality of water to carry out these procedures is of primary importance: highly alkaline (pH > 8.5) or acidic (pH < 5.0) water may affect the efficiency of cleaning and sanitation and enhance deposits and metal corrosion. Impurities in water, hard water, food residues and/or residues from cleaning materials can enhance formation of microbial biofilms. Biofilms are generally formed by some microorganisms under favoring conditions and are difficult to remove. Cleaners or sanitizers with strong oxidizing properties are required to remove biofilms from food surfaces. Water must be potable and pathogen-free.

Fresh-cut mango processing results in residue rich in soluble sugars, which easily dissolve in warm or hot water. A mild detergent can be used in combination with hot-water washes, followed by an appropriate sanitizer. Sanitizers include chlorine in various forms (e.g., sodium hypochlorite—bleach and chlorine dioxide), iodophors, quaternary ammonia, peroxyacetic acid, and others. Chlorine-based sanitizers are almost ineffective in high-alkaline water. Therefore, it is recommended to reduce water pH below 7.5 (but not less than 6.5) using mild acids. Food-grade acids such as acetic acid (vinegar) or citric acid are acceptable. A list of approved no-rinse food contact sanitizers can be found in the Code of Federal Regulations: 21 CFR 178.1010.

It is recommended to verify the cleanliness of equipment with the use of swabs after each sanitation event.

For more information:

- FS14/FS077: Basic Elements of Equipment Cleaning and Sanitizing in Food Processing and Handling Operations (ufl.edu)

- Guidance for Industry: Guide to Minimize Microbial Food Safety Hazards of Fresh-cut Fruits and Vegetables | FDA

Fruit Washing Prior to and during Processing

Before processing, fruit should be washed, perhaps multiple times, to minimize potential contamination from the fruit peel. Fruit should go through a cleaning line using brushes to wash any soil from the fruit surface. A fruit cleaner is recommended in the first wash, followed by one or multiple rinse steps containing antimicrobial chemicals. Washing and rinsing the fruit should be done in a room separated from the processing room. Mangos used for fresh-cut processing are usually washed at the packinghouse, but they should be washed again and rinsed with water containing antimicrobials immediately prior to processing. The microbial load on the fruit surface can be considerably reduced with a final rinse of water containing chlorine (100 ppm, not to exceed 200 ppm; pH adjusted to 6.5 to 7.0), peroxyacetic acid (80–100 ppm; pH 3.2), or acidified sodium chlorite (200 ppm; pH 2.5 to 2.9). Sodium hypochlorite (NaOCl—bleach) or calcium hypochlorite (CaCl2O2) are the common forms of chlorine solutions.

Use chlorine and other antimicrobial solutions labelled for use as food processing aids. Commercial household bleach cannot be used because it often contains fragrances and surfactants not allowed for use in foods.

Credit: J. K. Brecht, UF/IFAS

Other, gaseous sanitizers include chlorine dioxide and ozone, but they require special equipment and may be difficult to implement in a fruit processing facility.

Once sanitized, fruit should only be handled with clean gloves and carried from one room to another (if applicable) in sanitized containers.

Bins and other containers should never be cleaned on the floor or direct soil, where splashes could recontaminate the container.

Safe Handling Practices during and after Processing

Once processing is initiated, all cutting operations should be done in the most sanitary manner with no interruption until packaging. Processing should be carried on at 40°F (4.4°C).

Any injury of a worker occurring during processing should result in immediate removal of the worker from the line, removal and discard of contaminated fruit, and the area contaminated with blood or bodily fluid washed and sanitized.

After cutting and packaging, cut fruit should be stored at a temperature not to exceed 40°F (4.4°C). Fresh-cut mango is a Time/Temperature Control for Food Safety (TCS) food according to FDA guidelines (US FDA 2017). If fresh-cut mango is allowed to be exposed to a temperature above 41°F (5°C) at any time after cutting, it would be considered to have been adulterated and must be discarded (3-501.17 and 3-501.18).

Traffic flow between receiving, packing, and shipping should be monitored and controlled (Suslow and Harris 2000). See Figure 3. Food Safety Tips for Preparation of Fresh Cut Mangos at Retail: Mango-Tips-Preparation.

For more information:

- US FDA. 2017. 2017 Food Code. https://www.fda.gov/food/fda-food-code/food-code-2017

Food Safety Testing

At every point in the delivery of raw products, storage, washing, sanitation, processing, packaging, storage of finished product and transport to retailer, critical control points should be identified. As per the US Food and Drug Administration (FDA) definition, “HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.”

Labels on the finished product should identify processing date, lot number and other identifiers that should be included in a product recall program in the event of a product recall.

Credit: J. K. Brecht, UF/IFAS

Mango Procurement

Mangos should be sourced from a farm certified with best agricultural and handling practices, including traceability to be verified upon receiving.

Mango Varieties for Fresh-Cut

All the major mango varieties (Kent, Keitt, Haden, Tommy Atkins, and Honey) are used for fresh-cut processing, but when available Kent is preferred due to its low fiber content and high yield of useable fruit tissue. Conversely, Honey (Ataulfo) is less preferred due to its low yield for processing. Larger size fruit of a given variety are usually preferred for fresh-cut processing, also due to greater flesh yield.

Optimum Maturity/Ripeness for Processing

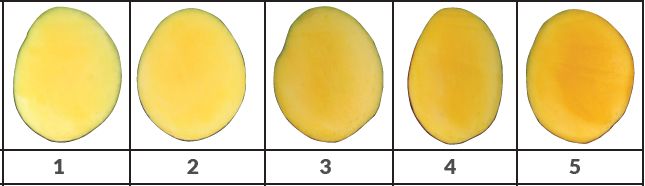

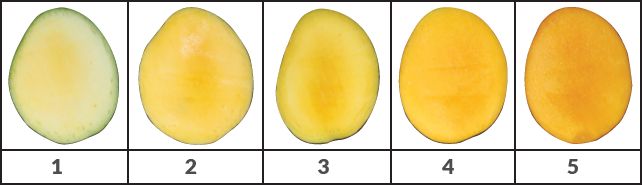

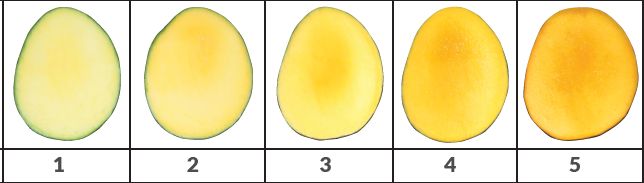

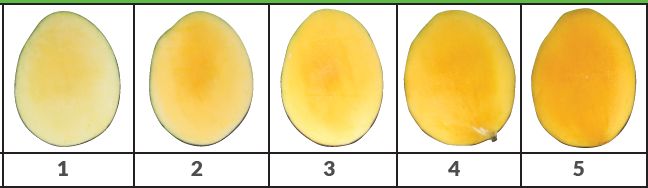

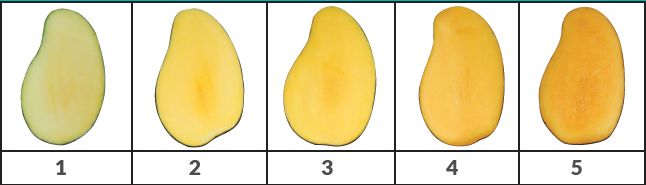

Fresh-cut mango products ideally should be ready to eat by the consumer right out of the package. However, when processed into a fresh-cut product, fully ripe (Stage 5) mango has insufficient shelf life to provide the minimum 10-day shelf life typically required by retailers. So, almost fully ripe (Stage 4) fruit should be chosen for fresh-cuts. See Appendix, Figure 32, for the commonly used 1 to 5 scale of mango maturity/ripeness.

Partially ripe mangos at 2.7 to 3.6 kg-force (6 to 8 lbs-force) flesh firmness as measured using a penetrometer with an 5/16-inch (8-mm) diameter Magness-Taylor type convex-tip probe have been found to be at the best stage to provide an optimum combination of sensory quality and shelf life. This firmness corresponds to Stage 4 internal color development and indicates complete conversion of starch to sugar and a good balance of sweet and acid taste and good mango aroma.

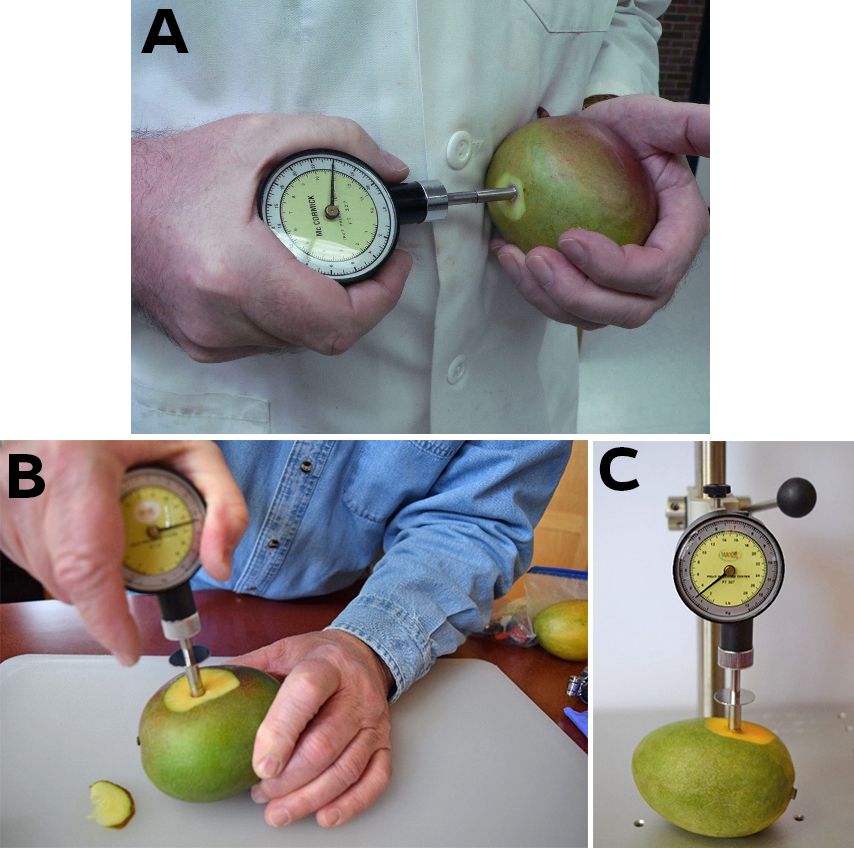

A penetrometer is highly recommended for the best accuracy and repeatability when measuring fruit firmness. Only a very few experienced persons may be able to approximate the proper fruit firmness for processing by squeezing a fruit with their entire hand, but not as reliably as when using a penetrometer. See “16. Appendix. b. Quality Control Procedures. iii. Measuring Fruit Quality” for the proper procedures to follow for measuring mango firmness, soluble solids (sugar), and acidity.

Packaging for Whole Fruit

Whole mangos are mostly handled in single-layer cartons with or without lids and with base dimensions that result in 100% coverage of the surface area on the standard 100 × 120 cm (40 × 48 inch) Grocery Manufacturers Association (GMA) pallets currently used in the United States. Traditionally, these packages have been 12-down or 14-down (number of packages in one layer on a standard pallet), containing 4.5 kg (10 lbs) of fruit. Larger, 5-down and 10-down mango packages have been designed and are recommended by the National Mango Board (https://www.mango.org/professionals/industry/mango-packaging-palletization/). All mango packages should be ventilated in both the horizontal and vertical directions for proper air movement, which is critical for proper temperature management during transport, storage, and conditioning (ripening). Package strength must also be sufficient to retain sufficient stacking strength to avoid pallet shifting or collapse in typically high-humidity storage and transport environments.

Credit: Leo Ortega, National Mango Board

Transport Temperature

Mangos may be transported from the various growing regions at temperatures from 50°F to 55°F (10°C to 12.8°C) depending on the ripeness stage of the fruit. Fruit at Stage 1 (physiologically mature, but prior to the beginning of ripening) and Stage 2 (ripening initiated) should be shipped at no less than 55°F (12.8°C) to avoid chilling injury, while riper fruit (Stages 3 to 4, one-half to three-quarters ripe) can be shipped at progressively lower temperatures as ripening advances (Table 1). Note that every mango in a given load will not be at the exact same maturity/ripeness stage. Therefore, these temperature recommendations should be followed so that the least advanced fruit in a given load are protected from chilling injury.

Ripened mangos in the U.S. that are ready to be processed may be shipped locally, for short distances, from importers or ripeners to the fresh-cut processors, at temperatures from 40°F to 50°F (4.4°C to 10°C), depending on the exact ripeness stage of the fruit. As previously stated, fresh-cut processing of mango, a Time/Temperature Control for Food Safety (TCS) food according to FDA guidelines (US FDA 2017), must be conducted at temperatures that do not exceed 40°F (4.4°C). The reason that ripe mango fruit can withstand a brief exposure (up to 2 days) to such cold temperatures is because mangos become less sensitive to chilling injury as they ripen.

Table 1. These are the lowest safe temperatures at which mangos at different maturity/ripeness stages can be stored for any duration while avoiding chilling injury. Ripe mango fruit may be stored briefly (up to 2 days) as low as 40°F (4.4°C) prior to fresh-cut processing. (Brecht et al., 2012; Osuna Garcia, 2015; Báez et al., 2018).

Receiving Mangos at the Processing Facility

Temperature and Condition of Fruit and Transport Equipment on Arrival

Mangos shipped from an importer or other domestic handler to a U.S. processing facility should be at the expected temperature that corresponds to their ripeness. The mango cartons should be palletized and may be delivered as straight loads (i.e., a full reefer truck trailer or marine container) or as part of a mixed truck load depending on the size of the order. The truck thermostat and fruit pulp temperature of mangos that will require further conditioning (ripening) before they can be processed may be anywhere from 46°F to 55°F (7.8°C to 12.8°C) depending on the ripeness stage of the fruit (Table 1). Fruit that are ripe and ready to be processed may be transported short distances to the processing facility at even lower temperatures, down to 40°F (4.4°C), so as to be ready for immediate processing. It is also possible for mangos to be conditioned at ripening conducive temperatures in the range of 68°F to 72°F (20°C to 22.2°C) during transport for short duration shipments to the fresh-cut processorin order to promote further ripening if needed.

The area in which mangos are received should be refrigerated, ideally also in the 46°F to 55°F (7.8°C to 12.8°C) range, depending on the ripeness stage of the fruit. Dock doors should remain closed until a reefer trailer or container has been backed up against the door. The dock doors should be equipped with cold tunnels (gaskets) to make a tight seal between the climate-controlled dock and the rear (door end) of the reefer trailer or container. The cold tunnels prevent outside ambient air from entering the refrigerated dock and the interior of the trailers or containers. Once the trailer or container is in place, the dock and unit doors may be opened, and the reefer unit can be turned off. Although not a recommended practice, if the unloading takes place on a nonrefrigerated or open dock, turning off the reefer is critical because it will prevent the unit’s fan from sucking warm, moist air into the trailer where the moisture will condense, potentially weakening fiberboard cartons.

Credit: J. K. Brecht, UF/IFAS

Before accepting and unloading the mangos, perform a quality control (QC) check of the condition of the mangos, including pulp temperature and firmness measurements (see “Initial Fruit Quality Control Inspection”). If the fruit pass the QC inspection, inspect the trailer or container to determine that it has been properly maintained and is clean, without residue from previous loads evident:

- The unit should have an intact air delivery chute.

- The pallets should have been loaded using a centerline-loading pattern so that they are not contacting the trailer sidewalls to prevent outside heat from being conducted through the trailer walls and into the product.

- Spacers or air bags should have been placed between the pallets and the trailer walls to prevent the load from shifting during transport.

- The floor ducts should be free of any material that may block airflow.

- The tops of the pallets should come no closer than 7.5 cm (3 inches) from the bottom of the air chute.

- For truck trailers, there should be a space between the last pallets and the door to permit return air to flow horizontally from the rear to the front of the load through the carton vent holes.

- Load locks should have been placed after the last pallets to prevent load shifting.

- The trailer or container should be clean, with no odor or visual evidence of previous loads.

- Document the inspection. An inspection sheet should include product type, source, date shipped, package code, quantity of boxes, and truck cleanliness. Always retrieve the temperature log and take photos.

Credit: J. K. Brecht, UF/IFAS

Collect the portable temperature recorder(s) and download the data. Document the specific location of each recorder in the load. The recorder should have been placed on the outside rear face of the last pallet at eye level to record air temperature at the farthest point from the reefer unit. In some cases, recorders may have also been placed (1) inside a pallet near the center of the load where product heating is most likely to occur; and (2) inside the first pallet near the front bulkhead of the reefer unit to detect any occurrences of short cycling of refrigerated air. Temperature recorders should not have been placed directly on the trailer walls because this may result in elevated readings that do not accurately reflect the air temperature in the load space. Retain and copy the entire label and strip chart or recorder download, judiciously review the temperature records, and send the recorders to the manufacturer for post-trip calibration if temperature management problems are suspected. Determine if the record indicates that the product was maintained at the desired shipping temperature before accepting the shipment.

Credit: J. K. Brecht, UF/IFAS

Initial Fruit Quality Control Inspection

Quality-control personnel should sample mangos from each load to assess fruit maturity and defects prior to acceptance. The inspection should include evaluation for the presence of any defects or decay, firmness measurement using a penetrometer with an 8 mm diameter Magness-Taylor type convex-tip probe, evaluation of flesh color development, and measurement of flesh soluble solids content (°Brix) with a refractometer. Special attention should be paid to the presence of any symptoms of chilling injury or heat injury (see “16. Appendix. b. Quality Control Procedures. iii. Measuring Fruit Quality”) because those disorders compromise ripe fruit quality.

The fruit firmness and flesh color development can be used to determine the need for further conditioning or ripening prior to processing into fresh-cuts. Internal flesh color development is scored using a 1 to 5 scale as shown in Figure 32 in the Appendix, with a score of 1 corresponding to no initiation of ripening-related yellow or orange color and scores of 2, 3, 4, and 5 corresponding to 25%, 50%, 75%, and 100% yellow to orange flesh color development, respectively. Peel color is not a reliable indicator of ripeness, because some mango varieties may retain green peel color when fully ripe.

- The extent of yellow or orange color development in the flesh of mango fruit is the most reliable ripeness indicator in all cultivars.

For lots of mangos that are determined to need conditioning (ripening) before they can be processed, 1%–2% percent of fruit should be evaluated for firmness and flesh color development when the shipment is received. Additional cartons of fruit should be set aside for monitoring their ripening progress until the lot is determined to be at the proper ripeness stage for processing. Firmness measurements should be made using a penetrometer. Determining the flesh color development from the stone toward the outermost flesh requires cutting the fruit, but it is the best way to judge mango ripeness (see Appendix).

Credit: J. K. Brecht, UF/IFAS

It is strongly recommended that quality-control data from each load be used as a guide to adjust processing facility practices (extent of required sorting by maturity and defects) in order to assure optimum fresh-cut product quality.

Recommendations

- Assign no more than one or two people to conduct QC inspections for uniform and repeatable results. If additional inspectors are required due to the volume of mangos being inspected, these inspectors must be adequately trained and certified to assure uniform and repeatable results.

- Take single-carton samples in a standard pattern from the front, middle, and rear (door) areas of the load, sampling the top, center, and bottom of the pallets on both the left and the right at each of those three areas, for a total of 18 sample cartons.

- Immediately measure the flesh temperature as the pallets are being unloaded and the samples are being collected.

- Take mango flesh temperature readings from three basic areas within the trailer or container (i.e., the front, the middle, and the rear door areas). Ideally, the temperature at the upper left, upper right, center, lower left, and lower right should be measured in all three areas during an inspection (for a total of 15 readings).

- Document the visual appearance of the fruit, cartons, and pallets with a standard battery of digital photographs.

- Evaluate the fruit for (1) overall condition and ripeness; (2) flesh color development, firmness, and soluble solids (°Brix); and (3) incidence and severity of defects, damage, disorders, and decay, both externally and internally.

- Verify absence of allergens (mixed loads).

Storing Mangos Prior to Processing

Mangos should be stored in a clean, well-ventilated area. Mangos that are at the proper ripeness stage for processing may be held temporarily at 40°F (4.4°C) (usually overnight is sufficient) to bring the fruit down to the proper temperature for processing in compliance with the FDA rule regarding Time/Temperature Control for Food Safety (TCS) food (US FDA 2017). Mangos that are unripe (Stage 1) or partially ripe (Stages 2 to 4) and being stored temporarily prior to conditioning to ready them for processing (see “Ripening Mangos Prior to Processing” section) should be held at 45°F to 55°F (7.2°C to 12.8°C) depending on the ripeness stage of the fruit to avoid chilling injury (see Table 1). The relative humidity in all rooms containing mangos should be maintained at 90% to 95%. If inhibition of ripening is desired, ethylene gas may be scrubbed from the cold room air with an absorbent or oxidizer system (ozone or hydrogen peroxide). Alternatively, one full fresh air exchange each day will minimize accumulation of ethylene in the room. For mangos that are to be conditioned to reach the proper ripeness stage for processing, see “Ripening Mangos Prior to Processing,” below.

- Mango fruits are living organisms that respire and produce respiratory heat and therefore must be refrigerated to be maintained at a constant temperature. Refrigeration capacity in mango storage rooms should be sufficient to remove the fruit respiratory heat and maintain uniform product temperature (within at least 1.8°F [1°C]) throughout the load. This requires both sufficient cooling capacity and adequate air circulation.

- A rule of thumb for airflow in cold-storage rooms used for room cooling is 0.052 to 0.104 cubic meters per second (cms) per 1,000 kilograms of produce capacity [100 to 200 cubic feet per minute (cfm) per ton].

- To maintain produce temperature, a lower airflow of 0.0104 to 0.0208 cms per 1,000 kilograms of produce capacity (20 to 40 cfm per ton) is all that is required.

- The room should be loaded in such a way that air is free to flow uniformly past all the pallets.

Ripening Mangos Prior to Processing

Different aspects of mango ripening are able to proceed over a wide temperature range from 60°F to 86°F (15.6°C to 30°C), but only a narrow temperature range of 68°F to 72°F (20°C and 22.2°C) results in optimum quality because that is where the best combination of color, texture, and flavor can develop. Mangos should be ripened to color stage 3 or 4 (see Appendix, Fig. 32), but no less than 8 lbf (3.6 kgf) for Kent and Tommy Atkins, and 9 lbf (4.0 kgf) for Keitt (compression test) for processing. These firmness values are only indications, and processors should determine a target firmness for their operation by testing a few fruit before processing, considering a target storage duration before the fruit will be processed.

- The extent of yellow or orange color development in the flesh of mango fruit is the most reliable ripeness indicator in all cultivars.

Mangos ripened constantly at lower temperatures are more acid and may require extra time at a higher temperature to achieve a good sugar:acid balance. Higher temperatures used throughout ripening can cause development of unpleasant odors and blotchy peel color. Recent research at the University of Florida, funded by the National Mango Board, has shown that the ripening temperature during the first 4 days (i.e., in ripening rooms) affected overall mango ripening time. Initiating mango ripening at 60°F or 65°F (15.6°C or 18.3°C) using banana ripening schedules extended the total ripening time at 70°F (21.1°C) by 3 or 4 days compared with initiating the ripening at 70°F or 75°F (21.1°C or 23.9°C), but the final quality of the ripe mangos was not affected.

Credit: J.K. Brecht, UF/IFAS

Mangos can be conditioned (ripened) simply by maintaining the fruit at a ripening conducive temperature. However, application of ethylene (100 ppm) for 24 hours, especially in a pressure-ripening room like those used to ripen bananas over a 4-day to 5-day ripening program schedule, results in greatly improved ripening speed and especially uniformity. Ethylene is a plant hormone that exists as a gas and naturally controls the ripening process of fruits like apple, avocado, banana, kiwifruit, honeydew and muskmelons, papaya, peach, pear, and tomato, as well as mango. Applying ethylene initiates fruit ethylene production if it is not already underway and coordinates the ripening of all the fruit in a lot of mixed maturities so that the fruit ripen together. This improves the uniformity of a lot of fruit, which improves processing efficiency.

Pressure ripening systems force the conditioned air in a ripening room through the pallets of fruit to achieve almost perfect temperature uniformity, which also promotes uniform ripening. After the 24-hour ethylene treatment, the fruit should be maintained at the preferred ripening temperature with periodic checks of flesh firmness until the fruit are at the desired stage for processing. This additional time can be in the ripening room or in a storage room, depending on operational logistics.

Many mangos in the United States have their ripening initiated in the same ripening rooms that are used for banana ripening, utilizing banana ripening schedules of 4 to 5 days and temperatures of 60°F to 65°F (15.6°C to 18.3°C). The previously mentioned research at the University of Florida, funded by the National Mango Board, suggests that this practice results in good-quality mangos when the ripening is allowed to continue to completion at 68°F to 72°F (20°C to 22.2°C).

Temperature Management after Ripening

Ripened mangos that are ready for processing need to be quickly cooled to the recommended processing temperature of at least as low as 40°F (4.4°C) just before processing. This can be effectively accomplished using forced-air cooling or hydrocooling, with the latter being the more rapid method. Simply transferring the warm fruit to a 40°F (4.4°C) storage room is not a preferred method because the cooling will be significantly slower and nonuniform, counteracting the benefits achieved by ethylene treatment and pressure ripening. The fruit to be processed should have all reached 40°F (4.4°C) before they are processed to conform to the FDA rule regarding Time/Temperature Control for Food Safety (TCS) food (US FDA 2017).

Processing Operations and Considerations

Processors should determine the amount of fruit that can be processed in one day according to their facility and available labor. The amount of fruit required for daily production is determined by the expected yield of fresh-cut product, which varies by mango cultivar and fruit size category (larger fruit of a given cultivar have higher yield). The yield should only need to be determined once for a given cultivar and fruit size category, by weighing a sample of whole fruit before processing and weighing the resulting processed product. Once a processing date is scheduled for a batch of fruit, the sanitation protocol should be implemented.

All instruments and surfaces that will come in contact with mangos during processing will be sanitized before processing. Fruit must be cut using well-maintained, sharp cutting tools, knives, or automated peelers. Cutting boards and all surfaces must be sanitized. Employees will wear hairnets, new or just-washed lab coats and aprons, and gloves. A bucket with bleach at 200 ppm should be available to employees to dip their hands frequently to keep the gloves sanitized, or they should change gloves frequently.

Credit: S. A. Sargent, UF/IFAS

Fruit Handling Prior to Processing

Fruit should be washed with brushes and fruit cleaner, rinsed with potable water1 then go through a final rinse with a sanitizer (e.g., 100 ppm NaOCl). Whole fruit should only be washed in dedicated areas and only approved sanitizers or antimicrobial agents used. The water temperature should not exceed 40°F (4.4°C).

Available sanitizing agents include, but are not limited to, NaOCl (bleach) at 200 ppm (pH needs to be adjusted to pH = 6.5 with an acid), peroxyacetic acid at 100 pm (pH = 3.2), and acidified sodium chlorite (NaClO2) at 200 ppm (pH = 2.5 to 2.9).

1 Information on safe drinking water:

Fruit Temperature Prior to and during Processing

Once the fruit are washed and sanitized, they should be processed immediately. If immediate processing is not possible, storage temperature should be 40°F (4.4°C) and not exceed 24 hours to avoid physiological chilling damage to the fruit and to avoid recontamination.

Processing will be performed at 40°F (4.4°C) or lower, and once cut and packed, processed fruit should be kept at no greater than 40°F (4.4°C) during storage and transport. As with all fresh-cut produce, it is imperative to maintain the cold chain, avoiding temperatures greater than 40°F (4.4°C) (US FDA 2017).

Peeling, Pitting and Cutting

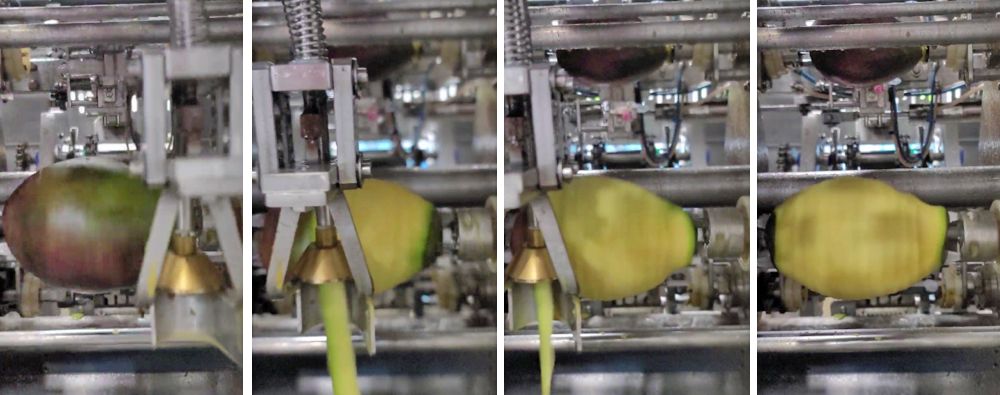

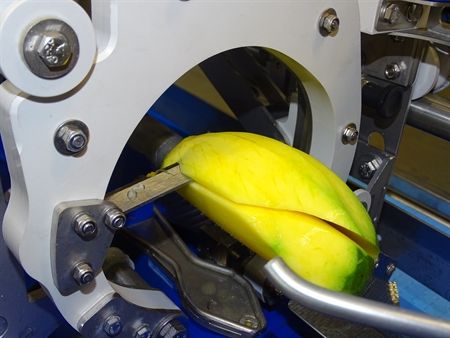

Machines to peel, pit, and slice mangos are available commercially. Machines are usually modular, with washing, sanitizing, peeling, coring, and slicing subunits. Because mangos have a prolate (elongated) and oblate (flattened on the narrow side) spherical shape, they usually need to be placed manually on a holder. Then each fruit is rotated against a sharp blade. The blade typically goes against the shape of the fruit via sensors, and the peeling depth can be adjusted, depending on manufacturers [approximately 2 mm (5/64-inch) depth should be sufficient. If the peel depth is not sufficient, the tissue underneath is prone to browning.

Then the pit is removed with two parallel blades. Some manufacturer systems remove the pit before peeling, others after peeling.

Mango ripeness must be such that it can sustain peeling and pitting forces without disintegrating. Several manufacturers of fresh-cut fruit processing machinery claim to have machines that are capable of processing fairly ripe mangos. All manufacturers claim their machines process from 20 to 40 fruit per minute, depending on the machine capacity. Mango peeling, pitting and cutting machinery must be regularly adjusted and maintained according to the manufacturer’s guidelines to operate optimally.

Credit: Fresh Del Monte Produce, Inc.

Credit: ZTI Smart Machines

In spite of improving processing speed, machines still require a certain amount of labor. Some plants prefer processing mangos manually. In this case, the processing line has workstations where the same person peels, splits the fruit along both sides of thepit, cuts and packs, or lines have workstations with specialized tasks—peeling, cutting, packing.

Most fresh-cut processors peel and de-pit the mangos manually, using knives to peel the fruit and either a knife or a de-pitting instrument with two, parallel blades to remove the pit. Complete removal of the peel tissue is critical because any remaining subepidermal tissue is prone to browning during fresh-cut mango shelf life.

Credit: Elena Branca, USDA/ARS

Credit: Fresh Del Monte Produce, Inc.

Supplemental Treatments to Reduce Deterioration

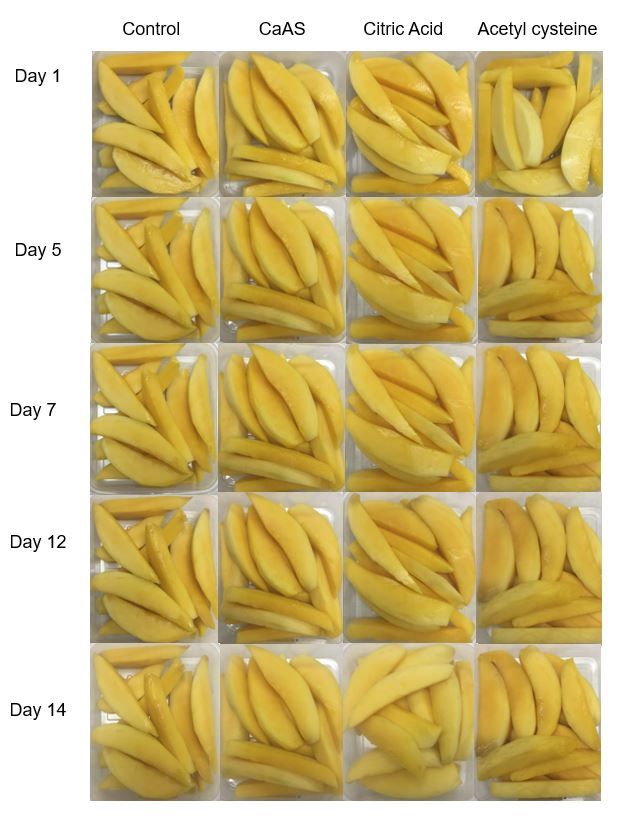

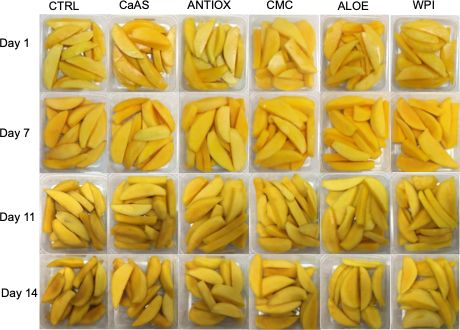

Some fruit require post-cutting treatments to slow down aging processes. Even though it is not as susceptible to browning as other fruit, mango can benefit from compounds that reduce the rate of browning and softening. The most common procedure to apply antibrowning and firming compounds is by dipping the fruit slices in aqueous solutions that contain the active compound for a short amount of time (for example, 30 seconds). Afterwards, the liquid is left to drain, and the fruit are ready to be packaged.

Alternatively, the cut mango fruit could be sprayed with antibrowning and firming compounds and coatings, which is already used in some other commercial packing and processing applications. However, to date, there is no commercial equipment to do this on fresh-cut fruit. In research conducted at the USDA ARS U.S. Horticultural Research Lab in Fort Pierce, Florida, an airbrush was used to demonstrate that applying coatings by spraying can be effective on various small fruits. Figure 17 shows an airbrush being used to apply a coating in the research funded by the National Mango Board (Marin et al. 2021), which showed that this application technique was effective for applying antibrowning and firming compounds to extend the shelf life of fresh-cut ripe mango slices. This technique could be scaled up for commercial fresh-cut processing facilities.

Credit: David Wood, USDA/ARS

Antibrowning Treatments

Any compound that prevents or delays oxidative reactions in fruit tissue can prevent browning.

Browning can be delayed by acidification, because low pH inhibits oxidative reactions. Acidification is achieved with food-grade acids such as acetic, ascorbic, citric, fumaric, malic, oxalic, phosphoric and tartaric acids. However, some acids may impart off-flavors and should be used in concentrations that do not affect mango’s natural taste and flavor.

Citric acid is one of the most used antibrowning ingredients in fresh-cut industry because it is the most prevalent acid in fruit. It has been proven particularly efficient in mango and, due to its low price, is an excellent candidate as an antibrowning ingredient. It is typically applied in concentrations ranging from 0.5% to 2%. For instance, a citric acid solution prepared at 0.8% (w/v) could efficiently delay tissue browning of fresh-cut mango without providing any strange flavor.

Credit: Plotto et al., unpublished

The use of reducing agents or antioxidants is another effective tool to prevent the browning of fresh-cut produce. Ascorbic acid, cysteine and glutathione are examples of these type of compounds. In fact, a salt derived from ascorbic acid, calcium ascorbate, is widely commercially used by the fresh-cut fruit industry. In general, ascorbic acid and its derivatives are applied in concentrations ranging from 0.5% to 4%. For their part, cysteine and glutathione may have negative effects on flavor when used at concentrations needed to achieve acceptable levels of browning inhibition. For that reason, it is recommended to apply these compounds in low concentrations and in combination with other ingredients.

Firming Treatments

Calcium can strengthen fruit tissues by rearranging polysaccharides in the cell wall, especially pectin. Hence, compounds containing calcium are effective in slowing down softening of fresh-cut mango. Calcium ascorbate and calcium lactate are examples of firming agents employed for these purposes. Calcium chloride can be used too but can confer bitterness to the product. Depending on the compound, calcium salts are usually applied in concentrations ranging from 0.1% to 2%.

Although some of the antibrowning and firming agents can be used individually, in practice, it is usual to apply combinations of several antibrowning agents and firming agents which, in general, include an acidulant and one or more reducing agents. For instance, some typical post-cutting applications could be 2% ascorbic acid, 1% calcium lactate and 0.5% cysteine or 2% calcium ascorbate, 0.8% citric acid and 0.4% cysteine. These ingredients are usually soluble in water, making them easily applicable.

Credit: J. K. Brecht, UF/IFAS

Edible Coatings

Edible coatings can reduce deterioration of fresh-cut mango by providing a thin layer of semipermeable materials onto the fruit surface. Edible coatings have multiple functions, but mostly, they are used to prevent fruit surface dehydration. They can also slow down metabolic processes that lead to tissue senescence by limiting gas exchange, thus decreasing respiration. Edible coatings also act as vehicles for the antibrowning and firming agents as a means of improving their distribution on the fruit surface. In this case, the coating agent is first dissolved in water and the active compounds are then incorporated and mixed.

Ingredients for edible coatings are widely available and possible combinations are immense. Coatings based on polysaccharides have frequently been used in research and development, although proteins can also be applied. In the case of mango there are reports showing the good performance of coatings based on alginate, carrageenan, cellulose derivatives (carboxymethylcellulose), gellan and pectin, among others. Combined with antibrowning and firming compounds, they can effectively improve fresh-cut mango quality and shelf life.

Credit: Marin et al. 2021. HortTechnology 31:27–35; with permission

The concentrations of dry materials in the edible coatings can range from 1% up to 4% depending on their nature and particular characteristics. The material concentration has a direct influence on the coating final thickness, ease of application and functionality: the higher the concentration, the thicker the coating layer and more impermeable is the coating to water and gases. It is important to make sure the coating has enough thickness to effectively carry out its function without affecting the fruit metabolism by creating an impermeable barrier that would block gas exchanges.

Some coatings can impart undesirable taste and flavor and even modify the mangos’ natural color. Furthermore, some coating ingredients could be contaminated with yeast or undesirable microorganisms. It is important to verify microbial status of an ingredient before use, and once cleared, use filtered or sterile water to dissolve them.

Various chemicals that are useful as antibrowning, antioxidant, firming or edible coating ingredients for fresh-cut mango are widely available from chemical manufacturers. However, it is important to be sure that only food-grade quality chemicals are applied to food products, including fresh-cut mangos. Some ingredients are more difficult to obtain as food grade, and processors should perform due diligence to source a pure and approved ingredient as an additive to fresh-cut mangos. Finally, any post-cutting treatment, including ingredients in the coating, must be disclosed on the label under the ingredient list of the final product.

Package Filling, Closing, and Sealing

Fresh-cut mango is usually marketed in rigid plastic packages with snap-top lids that are filled and closed by hand, with spot checks to assure proper net weight. Shrink-wrap plastic may be applied to the seal as a tamper-evident feature. Such seals can make the rigid package airtight, which although ok for short durations at 40°F (4.4°C) or lower, can eventually lead to the development of extremely low O2 and high CO2 concentrations that can result in off-odors and off-flavors. Flexible packaging may also be used, and the bags are typically filled/weighed and sealed by machine.

Automated packaging machinery should be inspected on a regular schedule for cleaning and sanitizing.

Credit: J. K. Brecht, UF/IFAS

Packaging for Fresh-Cut Mango

Package Design and Labeling Criteria and Recommendations

Packaging material must be food grade and maintained in clean condition and appropriate for their intended purpose. The package size and shape should accommodate the fresh-cut mango pieces so as to maximize the use of internal package volume without causing physical damage due to compression. Fresh-cut mango should be packaged in breathable packaging; otherwise, the living, respiring tissue will consume all of the oxygen in the package and begin to ferment and eventually die. See the section “Modified Atmosphere Packaging (MAP)” below for a description of a properly designed breathable package.

Credit: Fresh Del Monte Produce, Inc.

All packaged fresh-cut produce must be in compliance with applicable state food code requirements and contain label information pursuant to the requirements of 21 CFR 101. Label information should include the following:

- Product type.

- Mango variety and country of origin (optional).

- Product ingredients listed in order of their predominance in the food.

- Net weight.

- Product inventory and identity code.

- Lot and/or date code of the product.

- Recommended handling statement for retailer and consumer handling and storage, especially the proper temperature for the product.

- Company name and address, including zip code.

- Production code to facilitate tracking, tracing and recall.

Credit: Fresh Del Monte Produce, Inc.

Master cartons to contain fresh-cut mango consumer packages should be designed to tightly contain the packages so as to minimize movement during transport. The carton dimensions should result in 100% coverage of the surface area on the standard 40 × 48 inch (100 × 120 cm) GMA pallet. Carton stacking strength should be sufficient so that the bottom layer of cartons in a pallet can withstand the weight of the upper layers without failure, even in environments with high humidity, which weakens fiberboard.

Credit: Fresh Del Monte Produce, Inc.

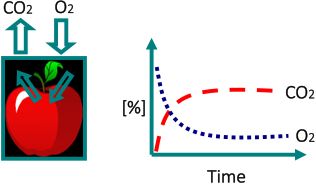

Modified Atmosphere Packaging (MAP)

Modified atmosphere packaging (MAP) is packaging that is designed to establish an atmosphere with reduced oxygen and that often also includes elevated carbon dioxide compared to normal air. This is achieved by balancing the product respiration rate at a selected temperature with the permeability or diffusion properties of the package so that an equilibrium is established that maintains the desired combination of oxygen and carbon dioxide concentrations. The process of respiration consumes oxygen and generates carbon dioxide. The optimum atmosphere will reduce the product metabolic rate to the greatest extent possible without significantly triggering fermentative metabolism, which is damaging to plant tissue.

Credit: J. K. Brecht, UF/IFAS

There are several ways in which MAP may be designed to achieve a desired modified atmosphere. Rigid packages may be designed to allow gas to move through the snap lid seal or through a hole in the package covered by a semipermeable or microporous patch. Flexible packages are either made with semipermeable films or with a hole in the film that is covered by a semipermeable or microporous patch, or a combination of both approaches.

The atmosphere in MAP may be allowed to establish itself passively over time as the product respires, but shelf life will be lost during the lag time before establishment of the optimum atmosphere. For highly perishable fresh-cut products, this loss of shelf life is usually unacceptable, so commonly the MAP is flushed with nitrogen or a gas mixture during the package sealing process so that the optimum atmosphere is immediately established—so-called active MAP.

The modified atmosphere chosen for MAP slows the metabolic reactions of the fruit tissue that otherwise lead to deterioration and quality loss. Thus, MAP is a supplement to proper temperature management that further controls product deterioration and extends shelf life. MAP is commonly used for fresh-cut fruits and vegetables because the peeling, slicing, and cutting to which they are subjected greatly accelerate the tissue metabolism, leading to faster quality deterioration that cannot be sufficiently controlled by low temperatures. However, products in MAP must be maintained within a very narrow designed temperature range—exceeding the designed temperature will cause elevated respiration rates, resulting in development of too low oxygen and too high carbon dioxide concentrations, and tissue fermentation.

A modified atmosphere package for fresh-cut mango should be designed by a person with the requisite knowledge and experience to design a practical, effective package and who can recommend best handling practices for using MAP. The MAP should be designed for the optimum temperature of 40°F (4.4°C).

Storage and Shipping of the Processed Products

Fresh-cut mango should always be handled in master cartons on pallets. Storage of fresh-cut mango should always be for the shortest time possible to accommodate marketing and at the optimum temperature range of 40°F (4.4°C) or lower. As mentioned in section 6, “Storing Mangos Prior to Processing,” refrigeration capacity and airflow in storage rooms should be sufficient to maintain uniform product temperature (within 1.8°F [1°C]) throughout each pallet, and the room should be loaded so that refrigerated air flows uniformly past all of the pallets. Handling on pallets promotes proper air circulation around the product. This is necessary and critical because fresh-cut mango respires and produces respiratory heat at even higher rates than the whole fruit.

Credit: Fresh Del Monte Produce, Inc.

For quality control (QC), it is recommended that a representative sample of each lot of fresh-cut product be retained in a storage room maintained at 40°F (4.4°C) or lower until the rest of the lot has been delivered to buyers. At that time, the QC fresh-cut fruit sample that was held under ideal storage conditions will be available to be compared to the reported quality of the shipped product, if necessary, to provide evidence as to whether any discrepancies that might be noticed by receivers are due to the different conditions to which the fresh-cut product was exposed during distribution as opposed to problems with its initial condition.

When available, packaged fresh-cut mangos should go through a metal detector.

Credit: Anna Marin-Gozalbo, USDA/ARS

Likewise, fresh-cut mango should always be shipped at 40°F (4.4°C) or lower. The area in which fresh-cut mangos are staged for loading onto truck trailers should be refrigerated, ideally at 40°F (4.4°C) or lower. Dock doors should remain closed until a trailer has been backed up against the door.

- Fresh-cut mango should be stowed quickly in precooled trailers from a staging area that is properly refrigerated (i.e., cooler than 40°F [4.4°C]). Cold tunnels should be situated tightly between the climate-controlled loading dock door and the rear (door end) of the reefer trailer. The cold tunnels prevent outside ambient air from entering the refrigerated dock and the interior of precooled trailers.

- The trailer should be precooled to the desired temperature before loading. This is done by setting the desired temperature, closing the rear doors, and waiting for the trailer to reach the desired temperature. Allow sufficient time for precooling trailers as part of the loading operation. Microprocessors on newer trailers have an automatic precooling function.

- Once the trailer has been cooled, the reefer unit can be turned off during loading. If the loading takes place on a nonrefrigerated or open dock, turning off the reefer is critical because it will prevent the unit’s fan from sucking warm, moist air into the trailer where the moisture will condense, potentially weakening fiberboard cartons.

- It is critical for proper temperature management within trailers that the unit has an intact air delivery chute.

- Use a centerline-loading pattern so that pallets do not contact the trailer sidewalls. This prevents outside heat from being conducted through the trailer walls and into the product. Pallets and floor ducts provide for air circulation under pallets. Tops of pallets should come no closer than 3 inches (7.5 cm) from the bottom of the air chute.

- Use spacers or air bags between the pallets and the trailer walls to prevent the load from shifting during transport.

- Leave a space between the last pallets and the door of the trailer to permit return air to flow horizontally from the rear to the front of the load through the carton vent holes.

- Use load locks after the last pallets to prevent load shifting.

Use of portable temperature recorders is recommended during shipping of fresh-cut mango so as to have records that the product was maintained at the desired shipping temperature. Place the recorder on the outside rear face of the last pallet at eye level to record air temperature at the farthest point from the reefer unit. If desired, recorders can also be placed (1) inside a pallet near the center of the load where product heating is most likely to occur; and (2) inside the first pallet near the front bulkhead of the reefer unit to detect any occurrences of short cycling of refrigerated air.

- Never place temperature recorders directly on the trailer walls. This may result in elevated readings that do not accurately reflect the air temperature in the load space.

Receiving Fresh-Cut Mangos at the Retail or Food Service Distribution Center

A procedure similar to that described in the section “Receiving Mangos at the Processing Facility” for temperature measurements and initial fruit quality control inspections should be followed when receiving a shipment of fresh-cut mango. Immediately upon arrival and prior to unloading the pallets from the trailer, the temperature of the fresh-cut mangos should be measured to ensure that the product temperature is 40°F (4.4°C) or lower. Fresh-cut mangos should be unloaded directly from the reefer trailer onto a refrigerated receiving dock at the distribution center (DC) that is maintained at 40°F (4.4°C) or lower in order to maintain the integrity of the cold chain. Holding time on the receiving dock should be limited to that required for identifying and recording the load and retrieving temperature recorders.

Recommendations

- Truck trailer reefer units should be turned off while they are being unloaded. Running reefer units while unloading the cargo can cause the transfer of unwanted hot or cold ambient air and exhaust fumes into the cargo space.

- Pallets of fresh-cut mangos should be moved from the trailer directly to the cold-storage area; do not hold pallets on the receiving dock.

- There should be space available immediately inside the cold-storage area to hold fresh-cut mangos for inspection prior to stowing the pallets in the cold room and/or on pallet racks.

- Receivers should retrieve every temperature recorder from the shipment, document the specific location of each recorder in the load, retain and copy the entire label and strip chart or recorder download, judiciously review the temperature records, and send the recorders to the manufacturer for post-trip calibration if temperature management problems are suspected.

- Pallets of fresh-cut mangos should be stored on racks in a cold room that is set to a temperature of 40°F (4.4°C) or lower until the product is sent to the retail outlets.

- Due to the extreme perishability of fresh-cut mango, the product should be moved through the DC as quickly as possible.

- The schedule of product rotation should be “first in, first out.”

Staging for Loading at the Retail or Food Service Distribution Center and Transport to Stores

- The area in which fresh-cut mangos are staged for loading onto truck trailers for delivery to retail outlets should be refrigerated at 40°F (4.4°C) or lower. Dock doors should remain closed until a trailer has been backed up against the door.

- If the dock area cannot be properly refrigerated, stage loads that include fresh-cut mangos in the cold-storage area instead. Load the pallets directly from the cold room into the precooled trailer to avoid warming.

Problems occurring during transport to retail stores:

- Hasty loading operations at the DC can cause damage to pallets, which creates unstable conditions for the fresh-cut mango cartons, leading to potential for further damage.

- Normally, trailers used to deliver fresh-cut mangos do not use air bags to protect pallets from movement (leaning) during delivery.

- Reefer units can exhibit serious variations in temperature that can result in suboptimum conditions for fresh-cut mangos.

- Mangos are typically delivered to retail stores in truck trailers containing a wide variety of produce and other food items. The carrying temperature chosen is always a compromise among the products being carried and may not be best for fresh-cut mangos.

- Older trailers used for delivering to retail stores may not maintain temperature well due to air leaks and may have dripping condensation that can damage fiberboard cartons.

Recommendations to avoid common problems during transport to retail stores:

- Train DC personnel in general handling practices, including how to identify quality problems with fresh-cut mangos.

- Set up pallets and secure them so as to avoid any mechanical damage.

- Inspect trailers to ensure cleanliness; clean and sanitize if necessary before loading any product.

- Set up a regular schedule to inspect trailers for damage, leaking water, and reefer unit operation.

- Develop a delivery plan that ensures fresh-cut mangos are loaded into trailers in the most conducive location for maintaining their optimum temperature of 40°F (4.4°C) or lower when multiple products are being delivered in mixed loads and supervise the operation.

- Use air bags or other bracing materials in between the pallets and between pallets and trailer walls.

- Avoid exposure of fresh-cut mangos to extreme outside temperatures during loading and unloading.

Fresh-Cut Mangos at Retail Stores and Food Service Establishments

Deliveries from DCs to stores are typically done 4 to 7 days per week. Therefore, the best practice is for managers to order only enough fresh-cut mango for 1–2 days’ sales. During the day, fresh-cut mango that will be rotated onto the refrigerated display cases should be kept in the walk-in cooler at no higher than 40°F (4.4°C).

Unloading and Holding on Docks

Unload the order promptly upon arrival and have a plan for moving the most perishable items (like fresh-cut mango) quickly to their optimum holding area. If the trailer with the order remains open awaiting the personnel responsible for the reception process, the temperature inside the trailer can warm (or chill) significantly during such delays. Like receiving fresh-cut mangos at the DC, the receiving party should record temperature in the truck before unloading, which should not exceed 40°F (4.4°C).

Credit: J. K. Brecht, UF/IFAS

An inspection sheet should include product description, source (processor’s name), processing date (if available), expiration date (as described on package), and package description (type). Any problems in package integrity (open lid, smashed clamshell) and fruit quality must be recorded.

Recommendations to avoid common problems during unloading/holding on dock:

- Minimize the time that trailer doors are open at the dock. Trucks deliver products to more than one location, and the drop-off time at each place cumulatively exposes fresh-cut mangos to damaging outside temperature extremes (hot or cold).

- Train personnel in produce temperature sensitivity, including that of fresh-cut mangos. Make sure that workers understand that exposure of fresh-cut mango to temperatures of 5°C (41°F) or above may render the product unsalable according to the FDA Food Code.

- Designate personnel to help in product unloading to minimize product exposure to damaging outside temperatures.

- Perform a QC inspection upon delivery and provide prompt feedback to the DC regarding the results of the inspection. Use the information to make improvements to fresh-cut mango handling practices at the DC and during delivery.

Temporary Holding in Walk-in Coolers at Retail Stores and Food Service Establishments

Product should be stored at no more than 40°F (4.4°C) to conform to the FDA rule regarding Time/Temperature Control for Food Safety (TCS) food (US FDA 2017). A storage map should indicate product location and date in. Product movement from the back room to the store shelves should follow the “first in, first out” rule. The cooler should be well ventilated with no external odor that might contaminate the product. Personnel should verify there is no condensation point in the storage room, and condensate from drip pans should be regularly inspected and cleaned. Any source of contamination, from the cold room or cross contamination between products, should be monitored daily and immediately addressed should a problem arise.

Any packages that have passed the “sell by” date must be removed from the cold room and disposed immediately. Personnel should be trained to identify spoiled fresh-cut mangos (browning, translucency/watersoaking, bacterial or fungal growth, slimy slices) and bloating of the container and immediately remove them from the cold room.

Credit: Megan Kinsman, UF/IFAS

Recommendations to avoid common problems during storage in the back room or walk-in cooler at stores and food service establishments:

- The manager should regularly inspect the back room and cooler area. The following points should be emphasized:

- Walk-in cooler doors should be kept open only for the time necessary to enter or exit.

- Strip curtains should be used on the walk-in cooler doors and must be kept in good repair.

- Calibrated thermometers should be placed in the back room and cooler and positioned away from doors or radiant heat sources (motors or lights) in order to indicate representative temperatures.

- Placement of produce in the cooler room should take into account product temperature requirements.

- Fresh-cut mangos for sale at retail stores and food service establishments should not be placed in a cooler that is above 40°F (4.4°C).

Display Conditions and Product Rotation in Retail Stores

Product display at the retail store is the last step in a cool chain for fresh-cut mangos that extends all their way back to the country of origin for the whole fruit. Fresh-cut mangos in retail stores must be displayed in refrigerated display cases, preferably with closed doors, which are able to maintain lower and more uniform temperatures than open display cases. Personnel should regularly inspect the display to assure that the temperature remains constant and does not reach 5°C (41°F) or above to conform to the FDA rule regarding Time/Temperature Control for Food Safety (TCS) food (US FDA 2017). This includes measuring temperatures in different locations to “map” the temperature distribution within the display, adjusting the display to avoid blockage of proper airflow that can lead to product warming and accelerated loss of quality. Maintaining good temperature control right up to and while the fresh-cut mangos are displayed for sale has a positive effect on the product appearance, flavor, and shelf life, so that retail stores realize maximum sales.

Any packages that have passed the “sell by” date must be removed from the display immediately. Personnel should be trained to identify spoiled fresh-cut mangos (browning, translucency/watersoaking, bacterial or fungal growth, slimy slices) and bloating of the container and immediately remove them from the shelves. Product rotation on the store shelves should follow the “first in, first out” rule.

Credit: J. K. Brecht, UF/IFAS

A program of regular cleaning and sanitation of the fresh-cut mango display case is key to keeping the display pleasing and attractive. Rotate the fresh-cut mango display frequently to remove unattractive and especially expired packages. When rotating the display, move older packages from the bottom to the top or front of the display to encourage greater overall fresh-cut mango sales.

Recommendations to avoid common stocking and display preparation and rotation problems:

- Place fresh-cut mangos on display as soon as they are delivered to the retail store; order more frequently to avoid storing fresh-cut mangos at the store.

- In line with the extreme perishability of fresh-cut mango, orders of additional product should be placed at the shortest frequency possible.

- Display fresh-cut mangos only in refrigerated displays, preferably with doors.

- Inspect the fresh-cut mango display frequently during the day and immediately remove unattractive or expired packages.

- Maintain a good cleaning and sanitation program for fresh-cut mango displays so that they always show their best quality appearance to customers.

Fresh-Cut Mangos in the Home

Refrigerator Temperature

Fresh-cut mangos should be brought home from the retail store promptly and placed directly into a refrigerator that has its thermostat set no higher than 40°F (4.4°C).

Appearance and Odor When Opening

Always closely inspect fresh-cut mango when you remove it from the refrigerator. Indications of spoilage include brown and translucent (water-soaked) tissue, bloated packages, and off-odors including fermented, sour milk, sulfurous or moldy. If you have any doubts, discard the product.

Best-by Dates versus Temperature

Follow the best-by dates on packages of fresh-cut mango regardless of your refrigerator temperature—you cannot assume that proper temperatures were maintained throughout the time before you purchased the product.

After the Package is Opened

It is best to only remove the amount of fresh-cut mango that you intend to consume, immediately returning the remainder of the product to the refrigerator. If any fresh-cut mango that was removed from the refrigerator is left uneaten, it should also be discarded.

Appendix

Recordkeeping

Keeping records is an important part of a quality control (QC) program at any stage of mango handling and processing, along with handling the fresh-cut products. If whatever is done is not recorded, it is as if it was never done when the time comes to show an inspector that best practices were followed.

Each operation should assign an employee to be responsible for the QC program. The QC manager should bring together the most knowledgeable people in the operation to prepare a list of all the operations and procedures conducted in the facility, such as those described in this manual. The QC manager should then develop a form for recording that all those operations and procedures are being done—and done correctly and on a regular basis.

Quality Control Procedures

Initial Fruit Inspection

When mangos are received at a fresh-cut processing facility, a sample of the fruit should be sampled and evaluated for quality and condition, particularly for the stage of ripeness. Sufficient number of fruit need to be sampled to determine the distribution of ripeness stages in the shipment. According to the Shipping Point and Market Inspection Instructions for Mangos (USDA AMS 2006), which is used by licensed inspectors who enforce the US Standards for Grades of Mangos, “As a general rule a minimum of 1.5 to 2% of the lot must be examined,” ensuring that the sample is representative of the entire lot and including inspection of all the fruit in each carton. However, for the purposes of an arrival QC inspection, it is permissible to inspect fewer fruit if no evidence of quality issues are encountered among the first few cartons inspected.

Credit: Fresh Del Monte Produce, Inc.

Measuring Fruit Maturity and Ripeness

Many ripeness indices have been tested for mango fruit, including specific gravity, skin color, flesh color, starch content, total solids (dry matter content), soluble solids content, and titratable acidity. The fruit shape (fullness of the shoulders; shoulders rising above the stem attachment point) is an indicator that the fruit were harvested at a fully developed stage. Skin color changes from dark green to light green to yellow in some but not all cultivars as the fruit ripen. Red blush forms on the skin of some mango cultivars while on the tree in response to sunlight exposure, but the blush is not an indicator of ripeness. Fruit firmness judged by hand compression is often used as a nondestructive indicator of mango ripeness but is not recommended due to its subjective and imprecise nature. Similarly, development of ripe mango aroma indicates that a mango is ripe but is also subjective and imprecise.

- The extent of yellow or orange color development in the flesh of mango fruit is the most reliable ripeness indicator in all cultivars.

Degree of ripeness according to flesh color is determined by the development of yellow or orange color from the seed surface outwards toward the peel using a 5-point scale as shown in Figure 32.

Credit: J. K. Brecht, UF/IFAS

Measuring Fruit Maturity and Quality

Soluble solids content (SSC; °Brix). Sugars are the major soluble solid in fruit juice; therefore, SSC can be used as an estimate of sugar content and is an excellent indicator of ripe mango quality. However, the SSC is only an estimate of sugar content since organic acids, amino acids, phenolic compounds, and soluble pectin also contribute to SSC. Starch suspended in the juice of immature or unripe mangos can also interfere with the SSC measurement and result in erroneously high readings. Best fresh-cut mango quality is associated with SSC of 14% or higher, and low SSC may be a rejectable attribute.

Credit: J. K. Brecht, UF/IFAS

The SSC can be determined in a small sample of fruit juice using a refractometer that measures the refractive index, which indicates how much a light beam is slowed down when it passes through the fruit juice. The refractometer has a scale for refractive index and another for equivalent °Brix or percent SSC, which can be read directly. Digital refractometers remove potential operator error in reading values.

The SSC levels in mature green mangos (minimum of 7% to 9% at harvest) increase with ripening to ideally reach 14% to 20% in ripe fruit. Minimum acceptable SSC levels in unripe fruit may be lower for mangos intended for export, depending on the shipping distance. Thus, the minimum SSC for mangos exported to the United States from South America may be lower than for fruit exported from Central America and Mexico, but the total solids (dry matter) content should be similar.

Credit: J. K. Brecht, UF/IFAS

Juice is most commonly extracted by squeezing half of a fruit directly onto the prism of a handheld refractometer. However, hand squeezing firm fruit at harvest can vary from person to person and give variable results. Hand squeezing can result in an overestimation of SSC content because juice drips out of the ripest portion of the fruit first.

Another method used to obtain juice from very firm fruit is to slice off the cheek portion of the fruit and then scrape the edge of a knife along the exposed flesh, collecting a small amount of juice on the knife blade, which is then dripped onto the refractometer prism.

To make things easy and quick, part of the flesh tissue from both cheeks can be used to measure SSC content. Take out flesh tissue from the equatorial region (2 to 3 plugs) of each side of a mango using a potato peeler and juice it with a lemon squeezer; use the resulting juice to determine the SSC content with a digital refractometer.

Titratable acidity. The percent titratable acidity (TA) is complementary to the soluble solids content (SSC; °Brix) because the balance of sugars and acids is very important for ripe mango taste. However, the TA is not as commonly measured as the SSC because it is a slower process that requires the use of some laboratory equipment. To measure the TA, first collect juice from one or more mangos until you have 6 grams of juice. To each juice sample add 50 milliliters of water. Titrate each juice-water sample with 0.1 Normal sodium hydroxide solution to an end point of pH 8.2; determining when the solution has reached pH 8.2 can be accomplished by using a pH meter or by the appearance of a pale rose-pink color when phenolphthalein indicator dye is added. Record the number of milliliters of NaOH solution that was added and calculate the % TA as follows:

% acid = [ml NaOH used] x [0.1 N NaOH] x [0.064*] x [100]/grams of juice

*The milliequivalent factor for citric acid, the predominate organic acid in mango fruit.

Credit: J. K. Brecht, UF/IFAS

Recently, handheld combined refractometer-acidity meters have been developed (Figure 36). For measuring total acids, juice still needs to be filtered and weighed, but the overall procedure is much faster than titration using a pH-meter or phenolphthalein indicator.

Credit: Sandra Matlack, USDA, ARS, Fort Pierce

Flesh color. Maturity and ripeness can be indicated by flesh color (e.g., about 75% of the area showing yellow color equals stage 4 on the 5-point scale shown in the accompanying photographs; Figs. 37-41). Skin ground color (change from dark green to light green to yellowish green) is less reliable as an indicator of ripeness than flesh color.

Credit: National Mango Board

Credit: National Mango Board

Credit: National Mango Board

Credit: National Mango Board

Credit: National Mango Board

Fruit firmness. Firmness of mango fruit decreases with ripening. Minimum flesh firmness for mangos to be processed into fresh-cut product differs for different cultivars, but for reasonable shelf life it should generally not be below 6 to 8 lbs-force as measured using a penetrometer with an 5/16-inch (8 mm) diameter Magness-Taylor type convex-tip probe. For determining when mangos are ready to be processed into fresh-cuts, flesh firmness has been found to be a more reliable indicator than flesh color.

Many destructive and nondestructive methods have been used to measure mango fruit firmness. The most common method for measuring firmness is based on flesh penetration force on both cheeks (with skin removed) using a penetrometer with a 5/16-inch (8 mm) tip. Because mangos ripen (and the flesh softens) from the inside out, the depth at which the skin is removed prior to measurement should be consistent from fruit to fruit for accurate measurements (about 1/16 inch or 1.5 mm). The probe is inserted to the 5/16-inch (8 mm) depth that is shown by a scribed line on the tip (Figure 42). A slower but better method is to slice the fruit in half lengthways and take the measurements on either side of the seed, midway between the seed surface and the skin.

Credit: J. K. Brecht, UF/IFAS