This document details all steps needed to estimate accurately in gallons-per-acre (GPA) how much a properly calibrated boom sprayer will apply.

Introduction

One of the most important tasks for a pesticide applicator is making sure the correct amount of pesticide is applied to the target site. Calibration is the process by which the amount of pesticide being applied per a unit of area is determined. Problems in calibration can lead to the application of too little or too much pesticide. Studies have shown that pesticides are often applied at rates the pesticide applicator does not intend. If, however, too little pesticide is applied, the pest may not be controlled as intended. Sometimes it's possible to repeat the application. In other cases, a repeat application may cause an overdose. Using more product than label directions recommend is illegal, costly, and will not control pests more effectively, but it will potentially leave harmful residues.

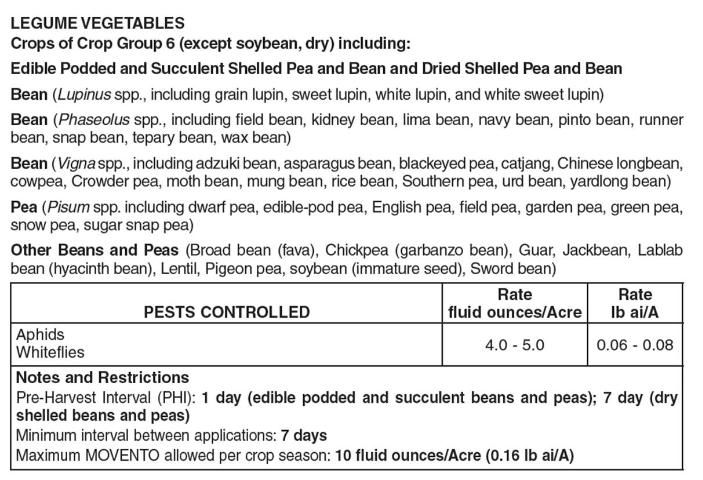

The section of the label "Directions for Use" will list the rate of application effective for control of the target pest(s). Often the effective level of application will be listed as a range of rates, depending upon various conditions, such as environmental factors and the target pest's stage of growth (Figure 1).

Credit: Crop Data Management Systems

Getting Started

Because not all nozzles output the same amounts, EDIS Publication PI23 Boom Sprayer Nozzle Performance Test (https://edis.ifas.ufl.edu/PI015) explains how to correct sprayers for variations in nozzle output. Before calibrating your broadcast boom sprayer, perform a nozzle uniformity check (Figure 2).

Credit: UF/IFAS Pesticide Information Office

Basic Calibration Principles

Output of a broadcast boom sprayer is based on several variables:

-

Pressure that forces liquid through the nozzle tip;

-

Nozzle orifice (tip opening) size;

-

Ground speed; and/or

-

Spacing of nozzles on the boom or width of spray pattern.

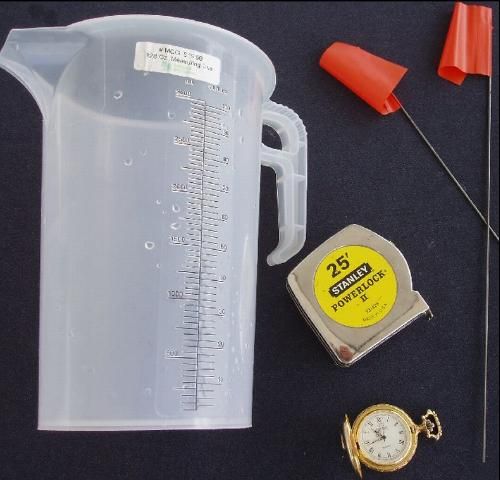

Basic tools needed to calibrate a broadcast boom sprayer are the following: graduated measuring bucket or cylinder, stopwatch or watch with a second hand, two flags or stakes to mark a premeasured distance, and a tape measure or measuring wheel (Figure 3).

Credit: UF/IFAS Pesticide Information Office

Calibration Step-by-Step

Sprayer output is most commonly referred to in terms of gallons-per-acre (GPA). Determining GPA consists of two basic principles—amount of area covered by the sprayer in a given amount of time and amount of output from an average nozzle on the sprayer's boom. The following steps describe how a broadcast boom sprayer can be calibrated by collecting the liquid delivered from the average nozzle that is applying to 1/128th of an acre. Using this method, the number of ounces of liquid collected from the average nozzle will be equal to the number of gallons the sprayer's boom will apply to one acre, since there are 128 fluid ounces in one gallon. The steps in this process follow below.

Step 1. Determine swath-width-per-nozzle (in feet) as follows:

Nozzle spacing in inches = swath width in feet

12

Step 2. Since 1/128th of an acre = 340 ft2, calculate the distance needed by your boom's nozzle spacing to make a test run that will treat 1/128th of an acre.

____340 ft2_______ = test-run distance (in feet)

Swath-width-per-nozzle (in feet)

Step 3. Select a place with enough space for your equipment to make a "rolling-start" approach at operating speed. Based on the calculation in Step 2, measure the test-run distance needed. Use flags, stakes, or some markers to clearly mark the beginning and end of the test-run area.

Step 4. Choose a gear setting, engine speed, and pump pressure. Record these values for future reference.

Step 5. Fill the sprayer's tank with clean water, then approach the test-run area at operating speed with the boom shut-off valve open (sprayer applying clean water).

Step 6. Using a stopwatch or a watch with a second hand, begin timing the moment the sprayer enters the test-run area. As precisely as possible, stop timing when the sprayer passes the end flag of the test-run area. For added precision, repeat the test and average the times. It's easier to have a second person conduct the timing (Figure 4).

Credit: UF/IFAS Pesticide Information Office

Step 7. Record the number of seconds elapsed during the test run. If there is any doubt about the time, repeat Step 6 until you are confident of an accurate time.

Step 8. Park the sprayer and set the brake, but keep the engine rpm at the same setting used on the test course. Continue to run the pump and keep the boom shut-off valve open, so the sprayer is still applying clean water.

Step 9. From the nozzle-uniformity check, select a nozzle whose output closely represents the average calculated for all nozzles on the boom. This calibration nozzle will serve as a good indicator of overall boom performance.

Step 10. Obtain a clean, graduated container marked in fluid ounces and a stopwatch or a watch with a second hand.

Step 11. For the same amount of time as it took to drive the test course, collect the spray output (water) from the calibration nozzle. Record the number of fluid ounces collected from the calibration nozzle during the test time.

Step 12. Interpret the results of your calibration nozzle's output based on the number of fluid ounces of water collected from the calibration nozzle during the test time. This number indicates the GPA being applied by the boom sprayer (Figure 5). For example, if you caught 20 fluid ounces, then operating the sprayer at the selected settings will apply 20 GPA. Likewise, collecting 47.2 ounces would mean an equivalent GPA of 47.2.

Credit: UF/IFAS Pesticide Information Office

Additional Information

Fishel, F.M. 2005. Boom Sprayer Nozzle Performance Test. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/PI015

Ferrell, J. A., Sellers, B. A., and Leon, R. 2005. Calibration of Herbicide Applicators. Gainesville: University of Florida Institute of Food and Agricultural Sciences. https://edis.ifas.ufl.edu/WG013