Peanut, a nitrogen-fixing legume, is a popular crop in the Southeast region of the United States. Florida, Georgia, and Alabama are among the top peanut-producing states in the U.S. In Florida, peanuts primarily thrive in the Panhandle and north central regions due to the sandy, well-drained soils and subtropical climate. One of the most important nutrients for growth is calcium. Because calcium contributes to seed development, it is vital to determine the need for calcium fertilization and the appropriate application timing, and to understand different calcium sources. This article examines the sources of calcium, application rate and timings of these sources, and their effect on peanut growth. The purpose of this article is to share knowledge about calcium fertilization in peanuts among crop advisors, Extension agents, and farmers.

Importance of Calcium for Peanut Production

Calcium is an essential mineral element present in the soil, and it contributes to the metabolic and biochemical processes of plants. It is required for the development of cell walls and membranes in plants. Calcium is particularly critical for peanut seed development, and optimum levels of calcium in the soil can improve the formation of pods and seed germination. Insufficient calcium availability or absorption of calcium by peanut seed leads to calcium deficiency, which in its most extreme cases results in empty pod formation, called “pops.” Peanut seeds may still form in calcium-deficient situations, but the germination of the seeds is reduced. Past studies showed that optimum application of calcium in the pegging zone resulted in higher yield, better seed germination, higher protein content, higher oil content, less aflatoxin contamination, and decreased decayed and cracked pods (Ursal et al. 1994; Habib 2014). Hence, calcium is one of the most important nutrients in peanut production.

In addition to calcium availability, peanut plant absorption of calcium is important. The amount absorbed depends on the concentration of calcium in the soil solution and the amount of water absorbed by the plant. Therefore, soil moisture plays an essential role in facilitating the absorption of calcium by plants. Studies have found that absorption of calcium in peanut pods can be increased by irrigation because it increases moisture levels in soil (Cox et al. 1976). However, since calcium is highly mobile in soil, it can leach out of the pegging zone under irrigated conditions, especially in sandy soils (Gascho 1993). Further details regarding soil moisture with different calcium sources are discussed in the following sections.

Determining Need for Calcium Fertilization

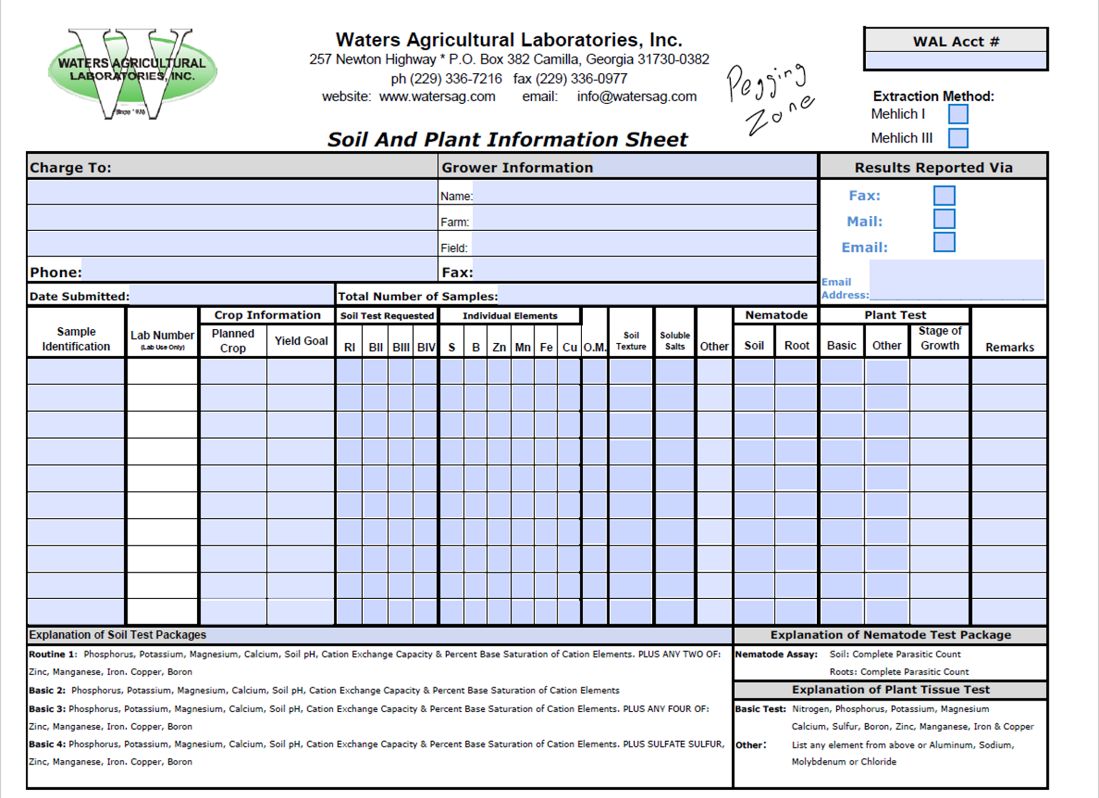

To determine calcium fertilization requirements, first conduct pegging zone soil sampling (3 inches deep, next to the row, after emergence) to determine the existing calcium levels in the soil (Figure 1). Determining calcium needs based on soil samples collected in January or February at 6 inches or deeper is not as reliable as pegging zone soil sampling after emergence. In addition, based on strong interaction between soil moisture and calcium availability, Howe et al. (2012) suggested the use of two critical pegging zone soil calcium values based on irrigation status (i.e., 150 ppm for irrigated peanuts and 250 ppm for non-irrigated peanuts).

There is no need to apply gypsum if the pegging zone soil samples show 500 lb/acre (or 250 ppm) of soil test calcium and the calcium to potassium ratio is 3:1 (University of Georgia Extension 2024). However, if one or both requirements are not met, supplemental calcium will be needed for optimal production. Large-seeded peanut types such as Virginia’s require more calcium than runner types. Tillman et al. (2010) also reported that large-seeded cultivars like C-99R may have higher calcium requirements. Among runner type cultivars, ‘Southern Runner’ had higher absorption compared to three other runner-type cultivars with same-sized seed. Soil test levels of about 500 lb/acre of calcium result in maximum yields of runner-type peanuts while almost double soil test levels are necessary for maximum yield of Virginia type peanuts. In general, runner and Spanish peanuts require around 200 lb/acre of elemental calcium while large-seeded Virginia type peanuts require around 400 lb/acre of elemental calcium (University of Georgia Extension 2024). For peanuts grown for seed, regardless of the soil test calcium levels in the pegging zone, application of gypsum at the rate of 1000 lb/acre is essential for good germination of peanut seeds. Therefore, while soil test calcium levels may show sufficiency for normal growth, peanuts grown for seed production need this additional gypsum application to support optimal germination. This extra gypsum is important to ensure good seed germination, address the specific needs of peanuts, and enhance overall crop health and yield.

Credit: Akash Shah, UF/IFAS

Points to Consider

- Maintain soil moisture at 50% to 75% of the soil’s field capacity to ensure optimal calcium uptake by plants. If irrigation is not available, higher calcium fertilization rates may be beneficial.

- Minimize competition from other nutrients, particularly K and Mg, as they can inhibit calcium uptake. The ratio of Ca:K should be at least 3:1.

- If sending soil samples to Waters Agricultural Laboratories in Georgia: Make sure to mention pegging zone sample (Figure 2).

Credit: Hardeep Singh, UF/IFAS

With a cotton-peanut rotation, another thing to consider is the possibility of excessive potassium application to cotton and the antagonistic effect that it can have on calcium and magnesium uptake during the peanut growing season. When more potassium is applied to the soil than the crop (cotton) can absorb, the leftover potassium accumulates in the soil. This potassium surplus in the soil can obstruct calcium uptake by peanut plants. If the ratio of potassium to calcium in the soil extract (1 part soil to 2 parts water) is higher than 10, potassium shows an antagonistic effect on calcium by obstructing the plant’s ability to uptake calcium (Jakobsen 2009).

Calcium Sources and Considerations

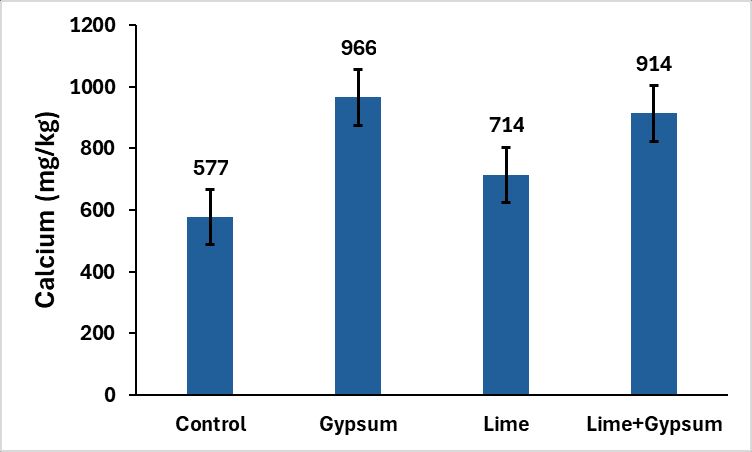

Because calcium is absorbed by the peanut pod and seed directly from the soil, it is important to fertilize the soil with the most available sources of calcium. While discussing various calcium sources, we will focus on the application rate, application timing, preferred soil type, and effects of overapplying vs. underapplying. Figure 3 illustrates the soil-extractable calcium from research plots treated with different calcium fertilizers during a field experiment conducted at the UF/IFAS West Florida Research and Education Center (UF/IFAS WFREC).

Credit: Hardeep Singh, UF/IFAS

Gypsum

Gypsum (calcium sulfate) is a commonly recommended source of calcium used in peanut production. Gypsum does not affect soil pH, but it can improve soil structure and helps decrease sodium in sodic soils. Application of gypsum at the right time is very important due to its fast mineralization rate. The critical calcium absorption period begins about 20 days after the entrance of the peg into the soil and lasts for the following 6–8 weeks. Around 92% of calcium is absorbed by the pods within 20 to 80 days after peg penetration into the soil, out of which 69% of calcium is absorbed within the first 20–30 days (Mizuno 1960). Therefore, gypsum should typically be applied at early bloom so pods can absorb calcium from soil. The timing of application is impacted by the soil type. Well-drained, sandy soils are ideal for peanuts, but they can be more prone to calcium leaching than loamy soils. Both pod formation and soil type explain why gypsum is typically applied at bloom rather than at planting: if applied too early, it can leach faster than lime because of its water-soluble properties. Moreover, because developing pods are absorbing calcium dissolved in the soil solution through the hull during the 60- to 90-day “peak pod fill” period, applying gypsum after 100 days of planting is too late.

The response of gypsum application can vary between non-irrigated and irrigated peanut production. Gypsum applications have been shown to increase yields in non-irrigated fields, but not in irrigated fields (Howe et al. 2012). The lack of a yield response to additional calcium in irrigated fields is likely because adequate soil moisture results in a higher diffusion gradient and calcium uptake even at lower pegging zone soil calcium levels. Conversely, the availability of soil calcium is typically lower in soils with limited moisture; applications of additional calcium (gypsum in this particular case) typically result in a yield increase.

Lime

Calcitic and Dolomitic Lime

Lime is a reliable source of calcium and is especially useful if the soil pH is too acidic (below 5.8, with the target soil pH for peanut being 6.2–6.5). Several types of lime can be used for calcium fertilization (Figure 4), including dolomitic lime, calcitic lime, or lime mud/papermill lime. If soil samples show only Ca to be low, then calcitic lime would be satisfactory. However, if both Ca and Mg are low, then dolomitic limestone should be used. It is not recommended to deep turn your soil after lime application as this results in deeper deposition of calcium, which is not available where peanut requires it (i.e., in the pegging zone) (Capasso 2020).

Credit: Satinderpal Singh, UF/IFAS

The application rate for lime differs between fields based on the soil pH. Applying lime 3 to 6 months before planting peanuts is recommended to allow time for the lime to break down and calcium to be available at the time of pegging. Due to the lower solubility of lime, it is less susceptible to leaching than gypsum. It is essential to apply lime at the right time, because if lime is applied too late (at planting or sometime later), there might not be enough time to mineralize and get calcium to the pegging zone when the pods need it most. In contrast, if the lime is applied earlier than 6 months prior to planting, it may break down, and the calcium may have leached and become unavailable to the peanut crop.

Lime Mud (Papermill Lime)

Lime mud/papermill lime is a by-product produced in converting wood chips into pulp for making paper. In addition to the main ingredient, calcium carbonate, lime mud also contains trace amounts of magnesium carbonate and other minerals. It can be spread with typical fertilizer spreading equipment and raises soil pH like dolomitic or calcitic lime sources. Lime mud has a calcium carbon equivalent near 100%, and application rates should be determined using soil test recommendations and the moisture content of the lime mud. The average moisture content of lime mud is around 30%. Lime mud with a moisture content near 50% is difficult to spread, and it is required to apply more per acre to correct for water weight (Gaskin et al. 2017). In addition to the calcium carbon equivalency of approximately 100%, lime mud/papermill lime also has a finer texture than dolomitic and calcitic lime sources. Since the reactivity of liming materials also depends on particle size, lime mud/papermill lime is just as effective in raising soil pH as traditional lime sources (Gaskin et al. 2017).

Caution should be taken when storing lime mud/papermill lime. Make sure that it is stored in a way that reduces or eliminates the risk of runoff from stored piles. Runoff can create large areas with extremely high soil pH and affect potential water sources, including nearby ponds. It is also important to consider the presence of heavy metals because lime mud is part of the papermill industry. Not all lime mud may contain contaminants (Morris et al. 2000; McBride and Spiers 2001) (Table 1), and frequently lime mud may contain metals comparable to agricultural lime. However, as manufacturing processes of different papermill industries vary, it is important to test it for the presence of heavy metals.

Table 1. Trace metal concentrations in lime mud/papermill lime and agricultural lime (Gaskin et al. 2017).

Calcium Chloride/Calcium Thiosulfate (Through Irrigation)

Highly soluble forms of calcium, such as calcium chloride and calcium thiosulfate, are usually applied as liquid products instead of spreading dry gypsum or lime. Applying calcium chloride and calcium thiosulfate through center pivot at the rate of 25 lb/acre during bloom has been shown to enhance yield and seed germination of peanuts (Harris and Beasley 2012). In fact, application of liquid calcium products like calcium thiosulfate are effective in supplying calcium to the pegging zone, especially when soil calcium levels are near or below the optimum levels or during crucial growth phases. Applying 10 gallons/acre of calcium chloride or 20 gallons/acre of calcium thiosulfate through a pivot during the peak pod fill period (approximately 75 days after planting) can provide advantages, particularly when additional calcium is needed during crucial growth stages or when soil tests show calcium deficiency (Harris and Beasley 2012; University of Georgia Extension 2024). Moreover, in situations where leaching rainfall occurs within three weeks after gypsum application, supplementing 10 gallons/acre of calcium chloride through irrigation systems can be considered beneficial. However, these treatments do not increase the calcium levels in soil tests after harvest compared to gypsum applications. Thus, it fails to take the place of gypsum when managing long-term calcium availability.

Supplying calcium using calcium chloride/calcium thiosulfate through irrigation is not the same as foliar calcium application. When applying through irrigation systems, the water runs off the leaves and goes onto the soil, allowing the calcium to enter the soil and reach the pegging zone. In a foliar application, the spray volume is just enough to cover the plant canopy. For comparison, applying one inch of water through the center-pivot system releases about 27,000 gallons of water per acre, while a foliar-fed system applies 10 gallons per acre. Calcium does not translocate through the plant from the leaves to the developing pods; therefore, foliar feeding is not recommended because it fails to provide sufficient calcium levels in the pegging zone (Harris 2021).

Take-Home Messages

- Calcium is an essential nutrient, required for good seed germination, viability, and pod formation of peanuts.

- Calcium deficiency can cause malformed seeds, pod rot, and “pops” (pods with no seeds).

- Gypsum and lime are two reliable calcium sources for soil application.

- Application of gypsum should be done at early bloom or approximately 30 to 45 days after planting.

- For peanuts grown for seeds, 1000 lb/acre of gypsum should be applied to ensure good germination of seeds regardless of soil test calcium levels in the pegging zone.

- Lime should be applied 2 to 3 months prior to planting.

- Lime mud can be a cost-effective alternative to agricultural lime but requires moisture and heavy metal testing to determine its application rate.

- Calcium chloride fertigation can provide benefits in some conditions such as a leaching due to rainfall (4 to 6 inches) within three weeks after gypsum application; however, it fails to increase soil test calcium levels after harvest.

- Foliar application of calcium is not effective and is not a reliable option to provide calcium to peanut plants.

References

Adams, J. F., D. L. Hartzog, and D. B. Nelson. 1993. “Supplemental Calcium Application on Yield, Grade, and Seed Quality of Runner Peanut.” Agronomy Journal 85 (1): 86–93. https://doi.org/10.2134/agronj1993.00021962008500010018x

Cox, F. R., G. A. Sullivan, and C. K. Martin. 1976. “Effect of Calcium and Irrigation Treatments on Peanut Yield, Grade and Seed Quality.” Peanut Science 3 (2): 81–85. https://doi.org/10.3146/i0095-3679-3-2-8

Gascho, G. J., S. C. Hodges, A. K. Alva, A. S. Csinos, and B. G. Mullinix. 1993. “Calcium Source and Time of Application for Runner and Virginia Peanuts.” Peanut Sci. 20:31–35. https://doi.org/10.3146/i0095-3679-20-1-9

Gaskin, J., W. Miller, and L. Morris. 2017. “Land Application of Pulp Mill Lime Mud.” Accessed on March 15, 2024. https://extension.uga.edu/publications/detail.html?number=B1249

Habib, M. A. 2014. Calcium Management Towards Peg and Pod Development of Groundnut. Doctoral dissertation. Department of Agronomy, Sher-e-Bangla Agricultural University Dhaka. Accessed on March 11, 2024. https://scholar.google.com/scholar_lookup?title=Calcium%20Management%20towards%20Peg%20and%20Pod%20Development%20of%20Groundnut&publication_year=2014&author=M.A.%20Habib

Harris, G. 2021. “Calcium Q & A.” The Peanut Grower, June 1. Accessed on February 29, 2024. https://peanutgrower.com/feature/calcium-q-a/

Harris, G., and J. Beasley. 2012. “Lime, Gypsum or Calcium Chloride Through the Pivot?” The Peanut Grower, June 1. Accessed on February 28, 2024. https://peanutgrower.com/feature/lime-gypsum-or-calcium-chloride-through-the-pivot/

Howe, J. A., R. J. Florence, G. Harris, E. van Santen, J. P. Beasley, J. P. Bostick, and K. B. Balkcom. 2012. “Effect of Cultivar, Irrigation, and Soil Calcium on Runner Peanut Response to Gypsum.” Agronomy Journal 104 (5): 1312–1320. https://doi.org/10.2134/agronj2012.0115

Jakobsen, S. T. 2009. “Interaction between Plant Nutrients: III. Antagonism between Potassium, Magnesium and Calcium.” Acta Agriculturae Scandinavica, Section B — Soil & Plant Science 43 (1): 1–5. https://doi.org/10.1080/09064719309410223

McBride, M. B., and G. Spiers. 2001. “Trace Element Content of Selected Fertilizers and Dairy Manures as Determined by ICP-MS.” Commun. Soil Sci. Plant Analysis 32 (1&2): 139–156. https://doi.org/10.1081/CSS-100102999

Mizuno, S. 1959. “Physiological Studies on the Fructification of Peanut: 1. Distribution of Radioactive Calcium Administered to the Fruiting Zone in the Fruiting Organ.” Japanese Journal of Crop Science 28 (1): 83–85. https://doi.org/10.1626/jcs.28.83

Morris, L. A., W. L. Nutter, W. P. Miller, and M. Overcash. 2000. “Treatment and Use of Pulp and Paper and Textile Industry Residues in Southern U.S. Forests.” In The Forest Alternative Principles and Practice of Residuals Reuse, edited by C. L. Henry, R. B. Harrison, and R. K. Bastian. University of Washington. https://www.researchgate.net/publication/284290788_Treatment_and_use_of_pulp_and_paper_and_textile_industry_residues_in_southern_US_forests

Tillman, B. L., M. W. Gomillion, G. Person, and C. L. Mackowiak. 2010. “Variation in Response to Calcium Fertilization among Four Runner-Type Peanut Cultivars.” Agronomy Journal 102 (2): 469–474. https://doi.org/10.2134/agronj2009.0306

University of Georgia Extension. 2024. UGA Peanut Production: The 2024 Agronomic Quick Reference Guide. Accessed on March 12, 2024. https://peanuts.caes.uga.edu/content/dam/caes-subsite/peanuts/docs/2024/UGA-Peanut-Agronomic-2024.pdf

Ursal, G. R., A. S. Jadhav, and S. M. Bachchhav. 1994. “Effects of Calcium Fertilization on Yield, Quality and Nutrient Uptake by Ground Nuts.” Journal of Maharashtra Agricultural Universities 19 (3): 404–407. https://www.cabidigitallibrary.org/doi/full/10.5555/19960704243