Credit: Fine Agrochemicals Limited (2020)

Peanut (Arachis hypogaea) is a legume and, therefore, a nitrogen-fixing species. It is also one of the most profitable row crops in the southeastern United States, with average gross returns (not accounting for production costs) of approximately $900 per acre over the past five years (2020–2024) in Florida. Growers in the state have averaged 155,200 harvested acres of peanuts annually, yielding 3,602 pounds per acre and generating about $139.7 million in production value each year (USDA NASS 2025). These production levels are driven by the Panhandle and north central regions of Florida, where well-drained, sandy soils and favorable climate conditions support consistent yields.

Plant growth regulators (PGRs) are commonly used in cotton and fruit trees. Peanut growers have not traditionally used them, mainly because the effectiveness and economic benefits of PGRs did not outweigh the costs. However, in certain situations of excessive vine growth, PGRs can improve harvest efficiency and yield potential. The most common PGRs in peanut production, such as Kudos® 27.5 WDG (Figure 1), use the active ingredient prohexadione calcium. All PGR information in this article has been based on the use of prohexadione calcium products. This publication outlines the benefits of PGRs and discusses when they can be a practical tool for peanut farmers, Extension agents, and agricultural workers.

Importance of PGRs in Peanut Production

Peanut vine growth depends heavily on variety, soil fertility, and weather conditions (Monfort 2018). Certain varieties, such as FloRun™ ‘331’, Georgia-12Y, and Georgia-16HO, often produce excessive vine growth under high rainfall or irrigated conditions with fertile soils (Monfort 2018; Wright et al. 2020). Managing vegetative growth in these high-vigor varieties is now a key part of peanut production. Unchecked vine growth reduces airflow in the canopy, increases disease risk, limits fungicide coverage, and makes harvest more difficult. Excessive vine growth can cause lateral branches to sprawl over and obscure the original planting lines, making it difficult for diggers to stay aligned. This misalignment increases the likelihood of missed pods and harvest losses (Jordan et al. 2001).

PGRs help growers manage excessive growth by shortening internode length and keeping vines more compact (Treadway 2020). This regulation improves row visibility and supports more efficient digging (Singh et al. 2024). Research shows that prohexadione calcium can shorten vine length by 1.5–2 inches without reducing leaf count, thus improving row structure while maintaining yield (Monfort et al. 2021). This also helps improve row visibility, which assists in aligning the digger on the rows. Remember that misalignment of the digger during peanut harvest can lead to significant digging losses, especially if a GPS is not used. To get the most benefit, growers must apply PGRs at the right growth stage and under the right field conditions (Tillman 2021).

Credit: Barry Tillman, UF/IFAS

Evaluation of PGRs in Peanut Production

Research studies conducted throughout the southeastern region of the U.S. have evaluated the response of peanuts to PGR applications. According to research conducted in Georgia, applying a PGR at only 75% of the label’s maximum seasonal rate (or 10.87 oz/ac in total) increased yield by about 700 lb/ac compared to untreated plots, and resulted in $85 per acre net return (Studstill et al. 2020). A study in North Carolina found that PGRs improve digging efficiency and reduce vine-related yield losses, particularly in high-vigor varieties and irrigated fields (Beam et al. 2002). In these cases, a faster harvest and reduced pod losses from inefficient digging may make up for the cost of the PGR. However, the results were variable as demonstrated in on-farm trials in Mississippi. They found that in fields with only moderate growth, PGRs may not be worth the investment (Treadway 2020). Therefore, growers should consider the following in their decision to apply PGRs.

- Field history: If past seasons have shown excessive vine growth, delayed digging, uneven crop patterns, or harvesting issues, the field may benefit from PGR use. Look for patterns of high biomass or digging losses.

- Cultivar selection: Certain varieties (such as newer, high-vigor lines) naturally produce more vines. These types are the most likely to benefit from PGR applications.

- Expected rainfall: Wet seasons or irrigated fields promote vine growth. If forecasts predict abundant rainfall, a PGR can help manage the expected growth.

- Soil fertility: Nitrogen fertilization or overall soil fertility can encourage lush vine development. Preplanting and in-season soil testing can help evaluate any levels of high nutrient availability. Specifically, chicken litter applications have been noted to increase vine growth (Wright et al. 2020).

Rainfed vs. Irrigated Fields

Rainfed fields often have variable growth due to changing soil moisture, making it important to monitor conditions before applying PGRs (Singh et al. 2024). In these cases, vine growth may be inconsistent, so regulation is not always necessary (Huber 2018). In contrast, irrigated fields tend to have more uniform and vigorous growth, making PGRs more useful (Huber 2018; Johnson 2020). Previous research performed at the UF/IFAS West Florida Research and Education Center (UF/IFAS WFREC) in Jay, FL, found that excessive vine growth can slow harvest and lead to greater digging losses in well-fertilized, irrigated conditions, making PGRs a valuable tool (Singh et al. 2024). However, it is important to note that higher PGR application rates in rainfed fields or those with sandy soils can stunt growth and potentially result in yield loss (Tillman 2021).

Choosing the Right Timing and Rate for Application

Timing plays a critical role in the effectiveness of PGRs. The first spray is typically targeted for the time during which vines are approximately 50% from complete row closure, when approximately half of the lateral vines meet in the row middle — generally around 55–65 days after planting. This will vary depending on the cultivar’s growth and growing conditions. In practice, some growers apply earlier, especially in situations with rapid vine growth or when rain and field conditions threaten to delay application. A second spray, when used, is typically applied 14 days after the first, ideally just after full row closure. This aligns with both the product label, which recommends a second application at 100% row closure, and research findings that support a two-week interval as effective timing (Tillman 2021). Field conditions such as irrigation access, soil moisture, or equipment availability often influence the timing between applications.

To ensure effective uptake, avoid applications when plants show signs of drought stress, nutrient deficiency, or disease, because these conditions reduce PGR performance. Additionally, prohexadione calcium requires a minimum of 8 hours without rain after spraying to allow proper absorption into plant tissues (Atucha 2024).

In addition to timing, the total seasonal rate of PGRs also influences performance and return on investment. According to the Kudos® 27.5 WDG label, the maximum seasonal rate is 21.75 oz/ac. Most growers generally perform two applications of up to 7.25 oz/ac each, resulting in a typical seasonal maximum of 14.5 oz/ac; this standard will act as 100% of the label’s total seasonal rate for the purposes of this article. Research from UF/IFAS WFREC as well as other regional studies have shown that growers can achieve similar vine control and yield performance using reduced seasonal rates.

For example, lower rates, especially the 10.87 oz/ac total seasonal rate (approximately 75% of the typical 14.5 oz/ac program), have delivered similar or better vine control and yield performance (Johnson 2020; Studstill et al. 2020; Monfort et al. 2021; Treadway 2020). In a two-year trial (2021–2022) at UF/IFAS WFREC, a total seasonal rate of 10.87 oz/ac split in two applications achieved the highest average pod yield among other treatments (Table 1). Compared to the untreated control, this PGR rate increased yield by 715 lb/ac. The 10.87 oz/ac seasonal rate was applied in a split application of 5.44 oz/ac per spray. Other treatments in the trial included total seasonal rates of 7.25 oz/ac, 14.5 oz/ac, and 18.12 oz/ac. Each of the total season rates was split in half over two applications.

Table 1. Effect of different application rates of PGRs (prohexadione calcium) on peanut pod yields from trials conducted at UF/IFAS WFREC in Jay, FL, in 2021–2022.

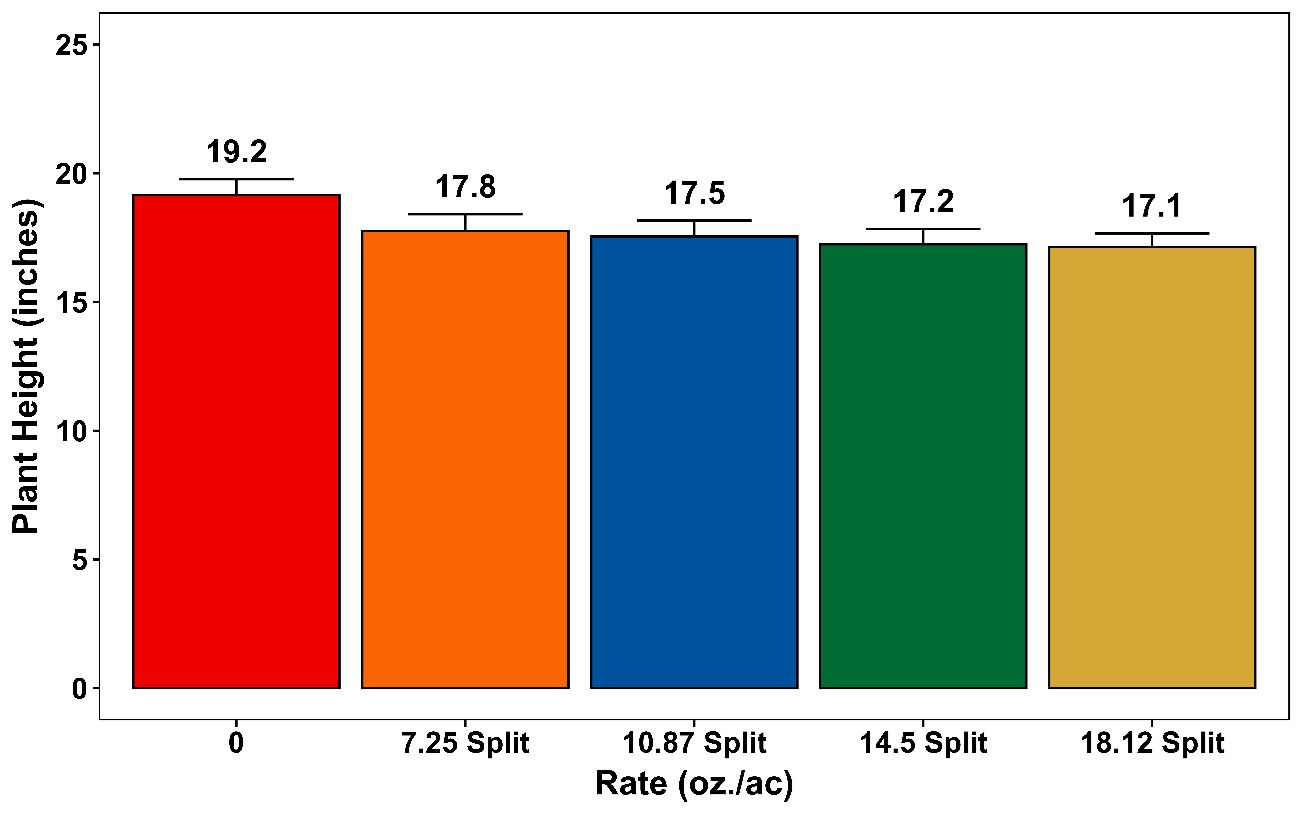

Along with yield, plant height was measured as an indicator of vine control. All PGR treatments reduced plant height compared to the untreated control. While plants in the control plots reached a height of 19.2 inches, PGR-treated plants were up to 2 inches shorter, a reduction of roughly 5%–10%, depending on the rate. The most noticeable suppression occurred at the 14.5 oz/ac and 18.12 oz/ac total seasonal rates, each treatment averaging about 17 inches. Even the 50% of the total season rate (7.25 oz/ac) reduced height by 1.4 inches, showing that reduced rates can still effectively manage vegetative growth (Figure 3).

Credit: Satinder Singh, UF/IFAS

To further evaluate how timing and rate interact under field conditions and to compare different rates and timings, additional trials were conducted at UF/IFAS WFREC in 2023 and 2024 (Table 2). The top-performing treatment was the label-recommended rate of 14.5 oz/ac per season with two split applications of 7.25 oz/ac.

Although the 75% rate also performed better than the untreated control, it did not outperform the full standard-practice label rate. In relatively low-stress conditions, such as irrigated fields with consistent rainfall and good nutrient availability, vigorous vine growth may require the full rate to achieve optimal pod retention and digging efficiency. In contrast, reduced rates may be more appropriate in rainfed fields where drought stress is more likely, or in situations where growers seek to manage input costs. Either way, yield increased by a range of 51 lb/ac to 319 lb/ac in response to PGRs, underscoring the importance of making rate decisions based on field conditions.

Table 2. Effect of different application rates of PGRs (prohexadione calcium) on peanut pod yields from trials conducted at UF/IFAS WFREC in Jay, FL, in 2023–2024.

Improving Peg Strength to Boost Yield

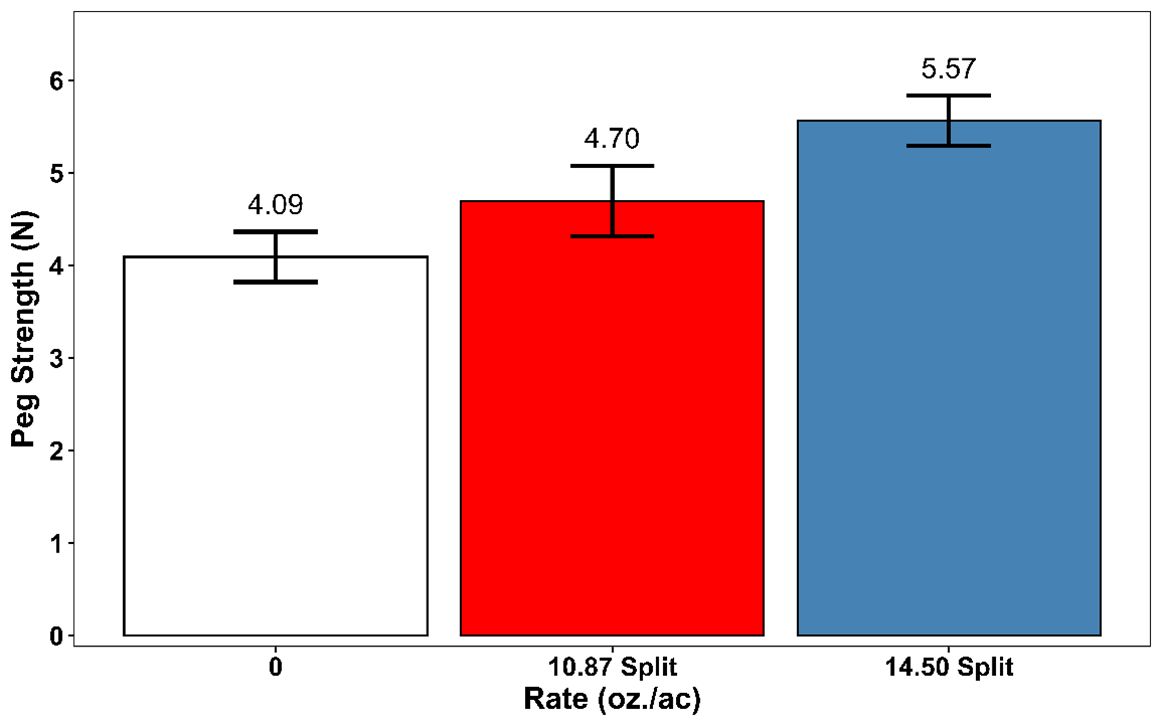

Peg strength plays a critical role in peanut harvesting. Stronger pegs help pods stay attached to the plant while digging. When pegs are weak, more pods detach and remain in the soil, thus decreasing overall yield potential (Studstill et al. 2020). In this study, peg strength was measured using a force gauge to find the amount of force (in newtons) required to detach a pod from the plant.

Additional research has shown that using a reduced rate of prohexadione calcium can still reduce vine biomass, improve pod retention, and increase yield potential by improving digging efficiency (Studstill et al. 2020; Treadway 2020). The UF/IFAS WFREC 2023–2024 trial also demonstrated that peg strength improved with PGR application, with the highest strength observed at the full 14.5 oz/ac total seasonal rate, and with a noticeable increase at the 10.87 oz/ac total seasonal rate compared to the untreated control (Figure 4). This highlights the value of using PGRs to manage vine growth and reduce pod losses, especially when aiming to improve harvest efficiency by reducing unharvested pod losses.

Credit: Satinder Singh, UF/IFAS

Product Evaluation and Tank Mixing

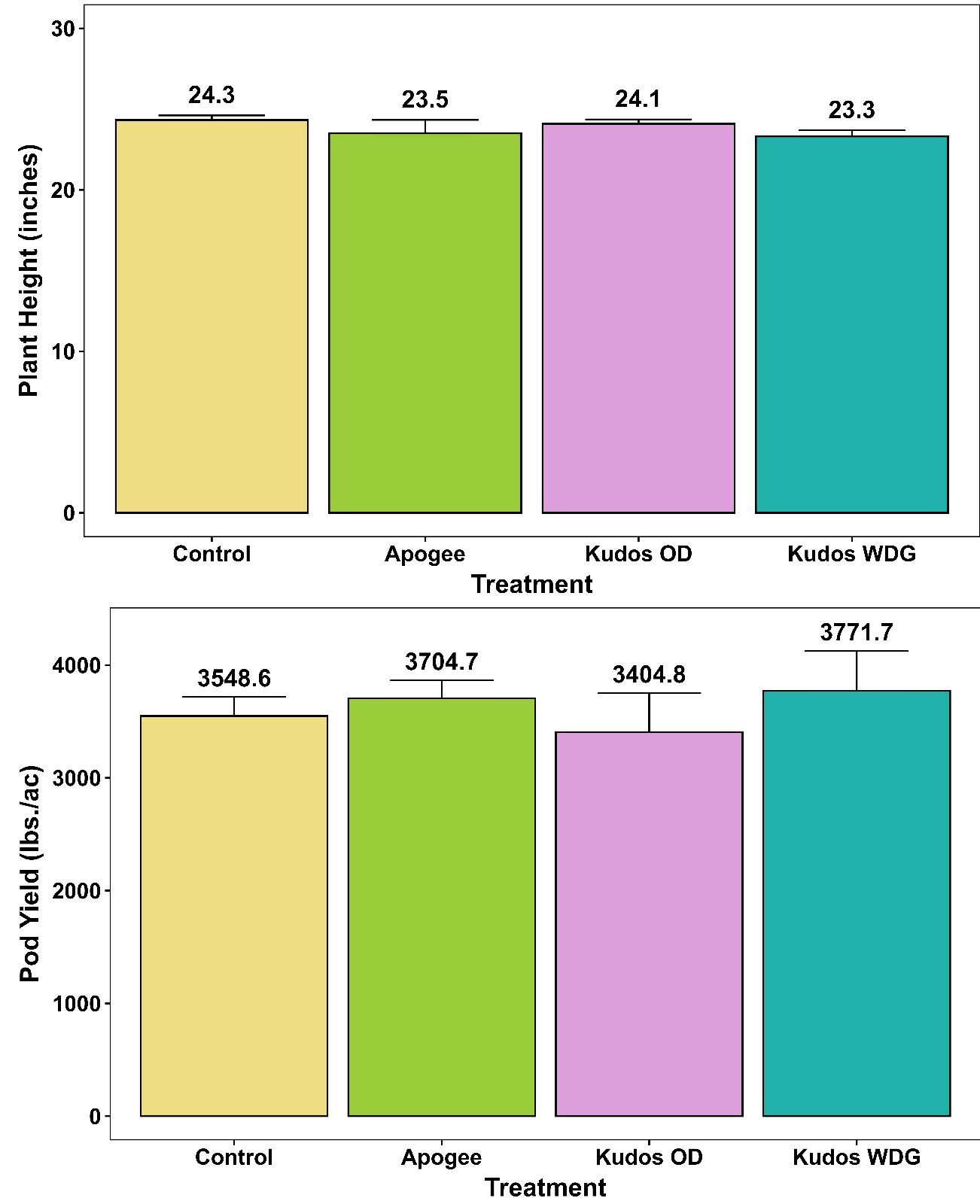

Two widely known commercial prohexadione calcium products are Apogee® and Kudos®. While Apogee® is no longer available, Kudos® is currently offered in two formulations: a liquid (OD) and a granular (WDG). These formulations may differ in ease of mixing, uptake, and field performance.

A separate trial at UF/IFAS WFREC compared the performance of three prohexadione calcium products: Apogee®, Kudos® OD, and Kudos® WDG, each applied at 75% of the label’s standard seasonal rate (10.87 oz/ac). All treatments reduced plant height compared to the untreated control, and both Apogee® and Kudos® WDG appeared to increase pod yield (Figure 5). Kudos® WDG showed the highest yield and one of the greatest reductions in plant height, suggesting strong overall performance under these conditions. Apogee® had similar results in both vine control and yield. Kudos® OD reduced plant height but yielded less than the other PGR treatments. These observations suggest that product formulation may influence field results.

Credit: Satinder Singh, UF/IFAS

To improve prohexadione calcium uptake, a nitrogen source such as ammonium sulfate (AMS) or urea ammonium nitrate (UAN) should be added in the spray tank. The UF/IFAS WFREC’s findings support the industry-recommended additive rates that improve absorption and make PGR applications more effective (BASF Corporation 2020; Singh et al. 2024). Without a nitrogen source, PGR effectiveness can drop significantly (Huber 2018; Singh et al. 2024).

Recommended tank mix additives (BASF Corporation 2020):

- 1 pint of UAN (28%–32% nitrogen) per acre OR

- 1 lb of spray-grade AMS (21% nitrogen) per acre

Take-Home Messages

- PGRs can help control excessive vine growth, especially in high-vigor cultivars and rainy conditions.

- For best results, apply PGRs around the time of 50% row closure, followed by a second application 14 days later if vine growth remains aggressive.

- Using seasonal rates of 10.87 oz/ac can result in yields similar to the full seasonal label rate of 14.5 oz/ac, which provides an alternative to reduce costs.

- Adding AMS or UAN to the spray mixture improves PGR uptake and effectiveness.

- PGRs do not always increase profits. Farmers should take costs and yield potential into consideration. While PGRs can improve yield and reduce harvest losses in some cases, results vary based on many agronomic factors.

References

Atucha, A. 2024. “Prohexadione Calcium (Apogee, Kudos) at Pink for Bitter Pit Control.” UW Fruit Program. https://fruit.wisc.edu/2024/04/18/prohexadione-calcium-apogee-kudos-at-pink-for-bitter-pit-control/

BASF Corporation. 2020. “Apogee® Plant Growth Regulator — Label (EPA Reg. No. 7969-188).” Label accepted by U.S. EPA, Office of Pesticide Programs, December 18. https://www3.epa.gov/pesticides/chem_search/ppls/007969-00188-20201218.pdf

Beam, J. B., D. L. Jordan, A. C. York, T. G. Isleib, J. E. Bailey, T. E. McKemie, J. F. Spears, and P. D. Johnson. 2002. “Influence of Prohexadione Calcium on Pod Yield and Pod Loss of Peanut.” Agronomy Journal 94: 331–336. https://doi.org/10.2134/agronj2002.3310

Fine Agrochemicals Limited. 2020, February 7. “Master Label: Kudos® 27.5 WDG.” EPA Reg. No. 62097-41. U.S. Environmental Protection Agency. https://www3.epa.gov/pesticides/chem_search/ppls/062097-00041-20200207.pdf

Huber, A. 2018, April 24. “Using a Plant Growth Regulator.” Peanut Grower. https://peanutgrower.com/feature/using-a-plant-growth-regulator/

Johnson, L. 2020, October 30. “Testing Apogee Plant Growth Regulator in Dryland Peanut Fields.” Panhandle Ag e-News. https://nwdistrict.ifas.ufl.edu/phag/2020/10/30/testing-apogee-plant-growth-regulator-in-dryland-peanut-fields/

Jordan, D. L., J. B. Beam, P. D. Johnson, and J. F. Spears. 2001. “Peanut Response to Prohexadione Calcium in Three Seeding Rate–Row Pattern Planting Systems.” Agronomy Journal 93(1): 232–236. https://doi.org/10.2134/agronj2001.931232x

Monfort, W. S. 2018. “Re-examination of Growth Regulators for Managing Vine Growth in Newly Released Runner Peanut Cultivars.” University of Georgia Extension. https://extension.uga.edu/about/our-impact/impact-stories/impact-statement/8812/re-examination-of-growth-regulators-for-managing-vine-growth-in-newly-released-runner-peanut-cultivars.html

Monfort, W. S., R. S. Tubbs, B. L. Cresswell, E. L. Jordan, N. B. Smith, and X. Luo. 2021. “Yield and Economic Response of Peanut (Arachis hypogaea L.) Cultivars to Prohexadione Calcium in Large-plot Trials in Georgia.” Peanut Science 48(1): 15–21. https://doi.org/10.3146/PS20-29.1

Singh, H., M. J. Mulvaney, M. Bashyal, and K. Singh. 2024. “Prohexadione calcium applications increase peanut peg strength.” Agronomy Journal 116: 3108–3116. https://doi.org/10.1002/agj2.21682

Studstill, S. P., W. S. Monfort, R. S. Tubbs, D. L. Jordan, A. T. Hare, D. J. Anco, and W. G. Tyson. 2020. “Influence of Prohexadione Calcium Rate on Growth and Yield of Peanut (Arachis hypogaea).” Peanut Science 47(3): 163–172. https://doi.org/10.3146/PS20-11.1

Tillman, B. 2021, July 16. “Can growth regulators boost peanut yields?” Panhandle Ag e-News. https://nwdistrict.ifas.ufl.edu/phag/2021/07/16/can-growth-regulators-boost-peanut-yields/

Treadway, Z. R. 2020. “Determining the Effect of Prohexadione Calcium Growth Regulator on Growth and Yield of Peanut [Arachis hypogaea (L.)] in Mississippi.” Master’s thesis. Mississippi State University. https://search.proquest.com/openview/27277815716b8b8a50171547d1ace2ca/

United States Department of Agriculture, National Agricultural Statistics Service (USDA NASS). 2025. Quick Stats. https://quickstats.nass.usda.gov/

Wright, D. L., B. L. Tillman, I. M. Small, P. Devkota, Z. Grabau, S. Paula-Moraes, and N. Dufault. 2020. “Peanut Production Guide 2020: Management and Cultural Practices for Peanuts.” EDIS. https://doi.org/10.32473/edis-aa258-2006