Introduction

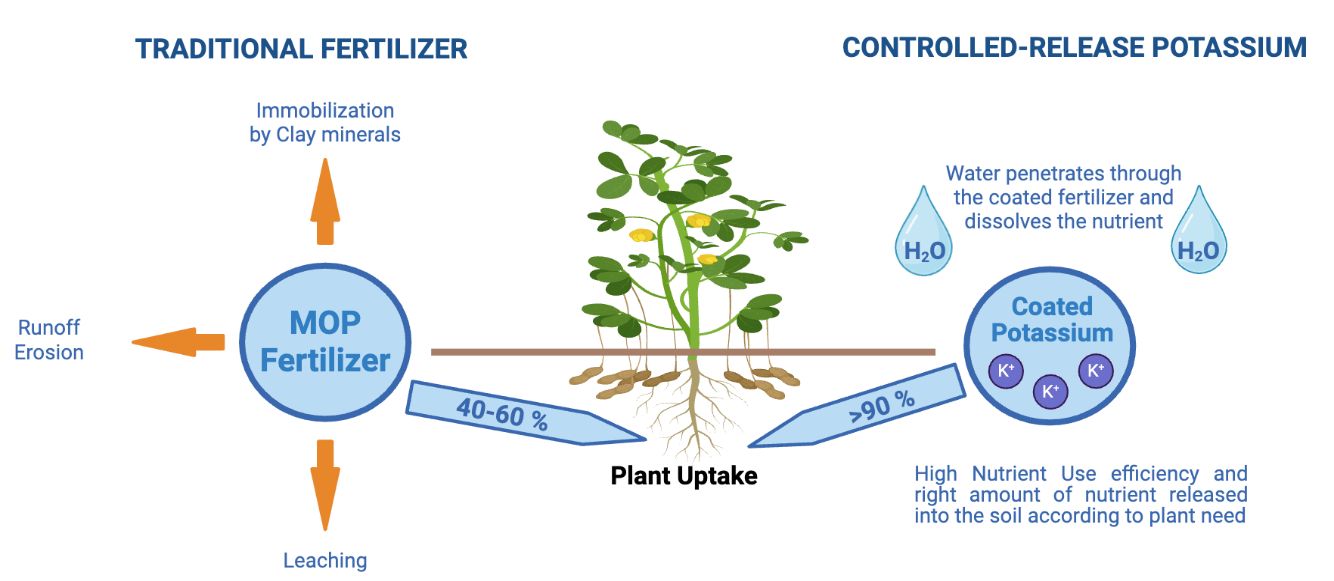

Most peanuts in the United States are produced in the Southeastern Coastal Plain. In Florida, peanut production occurs primarily in Suwannee Valley (north central Florida) and the Florida Panhandle, which represent sandy and/or deep sandy soils. The second most essential nutrient absorbed by the peanut crop is potassium (K); efficient K management is critical for plant growth, productivity, and yield benefits, along with maintenance of soil fertility. However, current conventional K fertilizer application methods often lead to environmental issues such as nutrient depletion through leaching and surface runoff. These concerns are particularly prevalent in Florida’s peanut fields due to the poor nutrient-holding capacity of sandy soils and frequent rainfall events. To optimize potassium use efficiency for peanut production, controlled-release fertilizers (CRFs) offer a solution by extending nutrient availability in the soil and reducing nutrient losses. Slow-release fertilizers and controlled-release fertilizers are different technologies, and details are provided in Ask IFAS publication HS1255 (Liu et al. 2023). CRFs are polymer-coated fertilizers, an advanced fertilizer technology that releases nutrients gradually over time to meet crop needs. The release of nutrients in the CRFs is regulated by environmental conditions such as temperature. This publication focuses on the use of controlled-release potassium (CRK) fertilizer in sandy soils for peanut production. It will provide an overview of the mechanisms and benefits of using this new technology in peanuts. This article highlights valuable insights for producers, crop advisors, Extension agents, and farmers about the use of CRK fertilization for peanut production in Florida.

Potassium’s Importance in Peanut Production

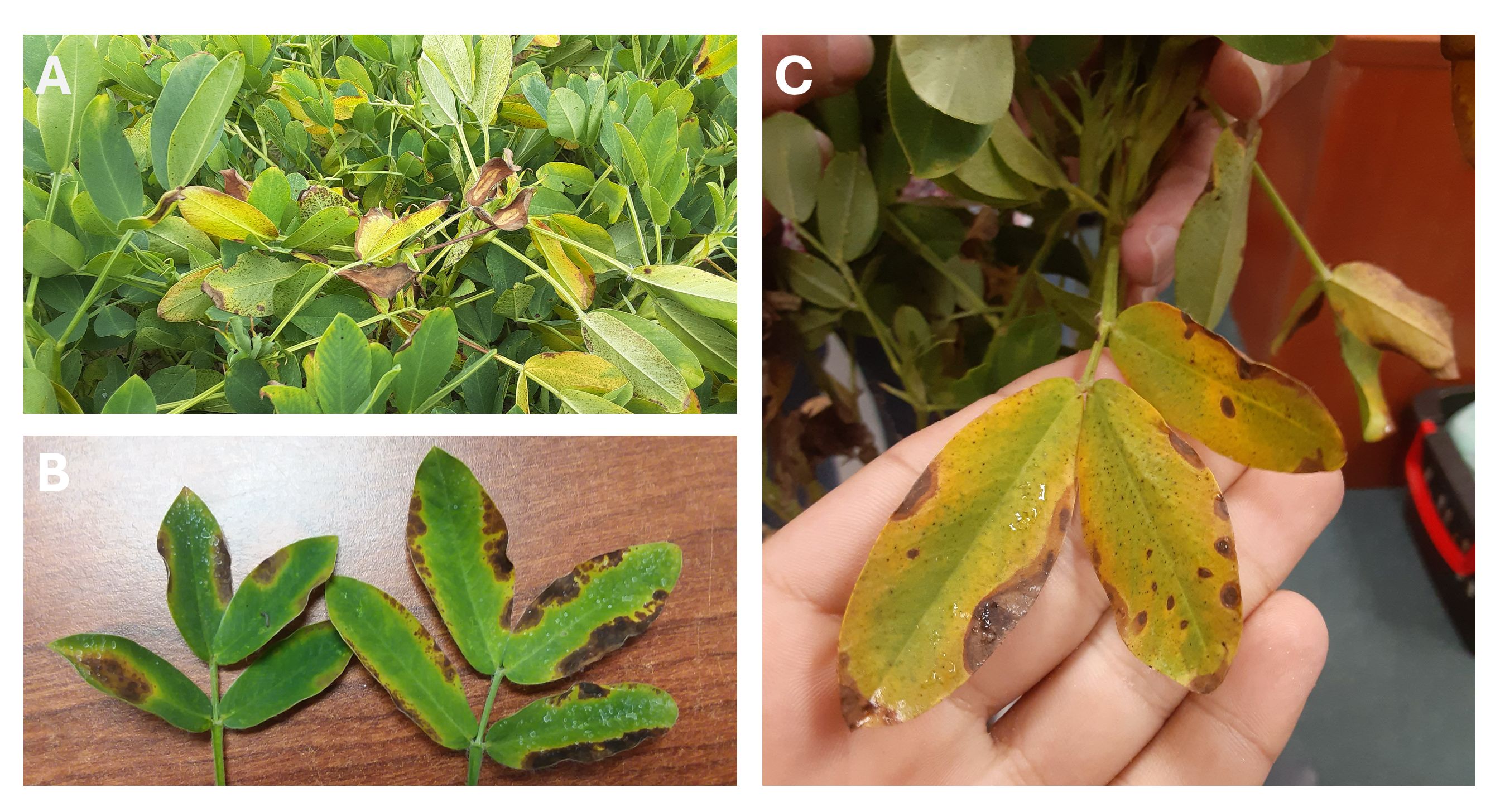

Potassium is an essential nutrient for peanut growth, yield, and physiological and biochemical processes, including photosynthesis, enzyme activation, carbon fixation, water regulation, protein synthesis, and nutrient uptake (Khan et al. 2023). As a leguminous crop, peanut fixes most of its required nitrogen (N) from the atmosphere. Adequate K helps root development, enhances drought and stress tolerance, and promotes proper growth and pod formation. Potassium deficiency in peanut fields leads to poor yield and reduced marketability. Potassium deficiency symptoms appear as chlorosis of older leaves and lead to poor pod filling, reduced kernel size, and decreased resistance to diseases and environmental stress such as pests and drought, which in turn cause yield reduction and economic losses for growers (Kvien and Bergmark 1987). Potassium deficiency symptoms cause yellowing of margins (chlorosis) that may progress to scorched brown edges (necrosis). Refer to Figure 1 for potassium deficiency symptoms on peanut crop.

Credit: Ethan Carter, UF/IFAS

Need for Potassium Fertilization in Florida Soils

In sandy soils with low organic matter and poor nutrient and water holding capacity, most of the K applied is leached through the soil with rainfall or irrigation events. In peanut production with low-K sandy soils, 50%–70% of applied K leaches away, leaving crops deficient. Effective K management strategies are crucial to obtain optimal peanut production in such conditions. According to UF/IFAS recommendations, K should be applied based on the soil test potassium (STK) levels using the Mehlich-3 extractant. For soil testing low in K, 100 lb K2O/acre are needed. For soil testing medium in K, 40 lb K2O/acre are needed. For soil testing high in K, no K2O application is needed. For details, refer to Ask IFAS publication SL129 (Mylavarapu et al. 2021). Currently, farmers use conventional K fertilizer sources such as potassium sulfate (K2SO4; sulfate of potash) and potassium chloride (KCL; muriate of potash). Potassium chloride is the cheapest source and is commonly used, but its use should be avoided if there are field salinity issues. Potassium sulfate has a lower salt index and includes sulfur, which helps in protein synthesis and improves peanut yield quality.

Mechanism of CRK

Credit: Dr. Sudeep Sidhu’s Agronomy Lab, UF/IFAS

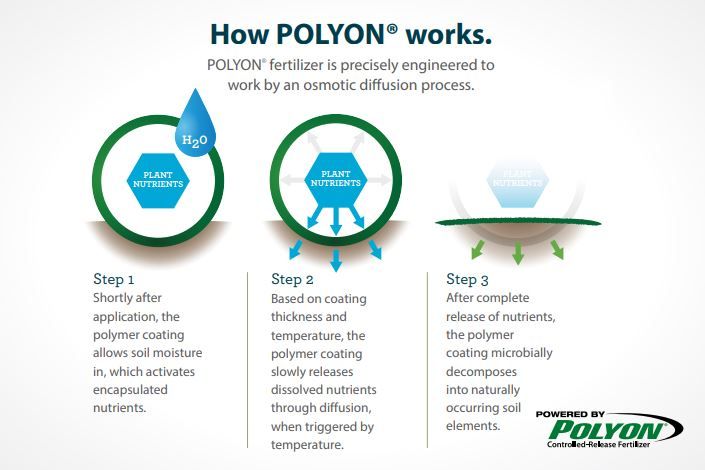

Controlled-release potassium (CRK) consists of polymer-coated fertilizer granules formulated to release K gradually over time into the soil. For visual differences in CRK and conventional MOP, see Figure 2. For the release of potassium from CRK fertilizer, a minimum soil moisture content of 6% to 8% is required to activate the polymer. The rate of nutrient release depends on the thickness and consistency of the coating material, soil temperature, fertilizer placement (surface or below ground), and granule formulation used for making CRK. Unlike conventional K sources such as MOP, which dissolve rapidly in water and are more prone to leaching, especially in sandy soils and high-rainfall regions, CRK helps retain nutrients in the root zone throughout the season. Nutrient release from CRK takes place in three phases: (1) lag phase, (2) constant release, and (3) decay period (Shaviv 2001; Trenkel 2010). CRK products contain soluble K fertilizers such as potassium chloride (KCl) encapsulated in a polymer coating. This polymer layer permits water to penetrate the granules and dissolve the nutrients, then releases them through the coating at a controlled rate. The rate of release is influenced by soil temperature rather than the instant dissolving of the fertilizer. Refer to Figure 3 for visuals of the controlled-release fertilizer mechanism. After application of CRK, soil moisture penetrates the polymer coating and activates the encapsulated nutrients, which are released from the coating material slowly based on the coating thickness and temperature. The release rate of CRK is designed in a synchronized pattern to meet changing crop nutrient requirements. In Florida, several controlled-release fertilizer products for different nutrients are available from different brands with proprietary coating technologies. The nutrient release for these products varies with the thickness of the coating and with the coating technology used by these brands. For example, the release of two polymer-coated MOP products from Harrell’s is listed in Table 1.

Credit: Dr. Tom Reed, Harrell’s LLC

Table 1. Nutrient release duration of POLYON® coated MOP products at 86°F.

How to Apply Controlled-Release Potassium Fertilizer for Peanut

In peanut production, CRK can be effectively applied either in a band or swath around the row using a first product rig. Fertilizer can be banded 2 inches deep along the peanut row, ensuring accessibility to the root zone for optimum nutrient uptake. CRK and conventional MOP fertilizers can be applied in combination in different ratios to meet the initial K requirement of the peanut crop during the early growth stages. In our studies, potassium was applied at two different rates: 100 lb/acre and 150 lb/acre applied individually and in ratios of 80:20 or 20:80. Refer to Table 2 for treatment details. Fertilizer was applied in a band of 1.25 feet on both sides of the peanut row and then rototilled in the soil at a depth of 3 to 4 inches. Based on multi-year studies using CRK, it was observed that potassium applied at lower rates using a CRF provided similar yield and quality when compared to MOP or CRF and MOP mixtures. Different treatments did not impact total sound mature kernels (TSMK) percentage in our trials. In our current studies, we are testing surface banding of CRF at 2 inches from the peanut row without rototilling it in the soil.

Table 2. Potassium fertilizer treatment details using conventional fertilizer (MOP) and CRF.

Advantages of Using CRK in Peanut Production

- CRK fertilizers provide consistent and gradual release of nutrients throughout the growing season. The steady supply ensures K availability to plants during critical growth stages such as pod filling (Figure 4).

Credit: Vikash Verma, UF/IFAS

2. Polymer-coated CRK products release nutrients dependent on soil temperature, not moisture levels. Therefore, during leaching rainfall events, CRK provides steady K release into the soil, fulfilling crop requirements.

3. Based on recent field trials, K uptake in peanut peaks from flowering to the early pod filling stage. CRK provides adequate K during the pegging and pod filling stages, which contributes to improved pod set, seed development, and overall crop quality. Refer to Figure 5 for visuals of tissue K concentration during the field trials from the 2024 growing season.

4. CRK fertilization reduces the risk of K leaching by releasing nutrients in the root zone. CRK fertilization helps in achieving higher K use efficiency than conventional K sources.

Credit: Dr. Sudeep Sidhu’s Agronomy Lab, UF/IFAS (unpublished data).

Challenges of Using Controlled-Release Fertilizers

The current price of CRF technology is higher compared to conventional fertilization methods, which may discourage adoption by some growers. However, CRFs can reduce the need for multiple split applications, as well as labor requirements, machinery usage, fuel, and operational costs. CRF has a lower specific gravity, which may result in it being easily washed away by heavy rainfall if left on the soil surface. To tackle these challenges, soil incorporation of CRF is strongly recommended.

Take-Home Messages

- CRK fertilizer releases nutrients gradually into the soil over time, aligning with the crop demand during critical growth stages such as pegging and pod filling.

- CRK fertilizers reduce the nutrient loss from leaching, especially in sandy soils, which are common across peanut-growing regions in Florida.

- Use of CRK fertilization increases nutrient use efficiency, helping growers to reduce the costs of split application and labor, and enhances crop quality.

- Trials in north central Florida demonstrate that CRK use helps in maintaining consistent yield performance and desirable crop quality.

- Implementing CRK fertilization in peanut production follows UF/IFAS best management practices (BMPs) by improving nutrient use efficiency and reducing environmental risks.

References

Guodong, L., L. Zotarelli, Y. Li, D. Dinkins, Q. Wang, and M. Ozores-Hampton. 2014. "Controlled-Release and Slow-Release Fertilizers as Nutrient Management Tools: HS1255/HS1255, 10/2014." EDIS 2014(8). https://doi.org/10.32473/edis-hs1255-2014

Harrell’s LLC. n.d. POLYON® Product Information. Harrell’s LLC. https://www.harrells.com

Khan, C., N. U. N. Memon, N. A. Wahocho, N. Akhtar, M. I. Majeedano, N. Sharif, M. F. Jamali, and Q. Khan. 2023. “Effect of Potash Fertilizer on Vegetative Growth and Pod Yield of Groundnut (Arachis hypogaea L.) in Semiarid Region.” Journal of Applied Research in Plant Sciences 4(02): 647–652. https://doi.org/10.38211/joarps.2023.04.02.190

Kvien, C. S., and C. L. Bergmark. 1987. “Growth and Development of the Florunner Peanut Cultivar as Influenced by Population, Planting Date and Water Availability.” Peanut Science 14(1): 11–16. https://doi.org/10.3146/i0095-3679-14-1-4

Mylavarapu, R., D. Wright, and G. Kidder. 2021. "UF/IFAS Standardized Fertilization Recommendations for Agronomic Crops: SS163/SL129, rev. 10/2021." EDIS 2021(5). https://doi.org/10.32473/edis-ss163-2021

Shaviv, A. 2001. “Advances in Controlled-Release Fertilizers.” In Advances in Agronomy (Vol. 71). 1–49. Elsevier. https://doi.org/10.1016/S0065-2113(01)71011-5

Trenkel, M. E. 2010. Slow- and Controlled-Release and Stabilized Fertilizers: An Option for Enhancing Nutrient Use Efficiency in Agriculture (2nd edition). IFA, International Fertilizer Industry Association.